Aluminum alloy superstructure block hoisting method

A technology of superstructure and hoisting method, which is applied in ship construction, transportation and packaging, ship parts, etc., can solve the problems of restricted area shipbuilding technology application, easy deformation of general section hoisting, affecting the loading accuracy of the slipway, etc., so as to improve the hoisting efficiency. , Improve the overall rigidity, the effect of convenient installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

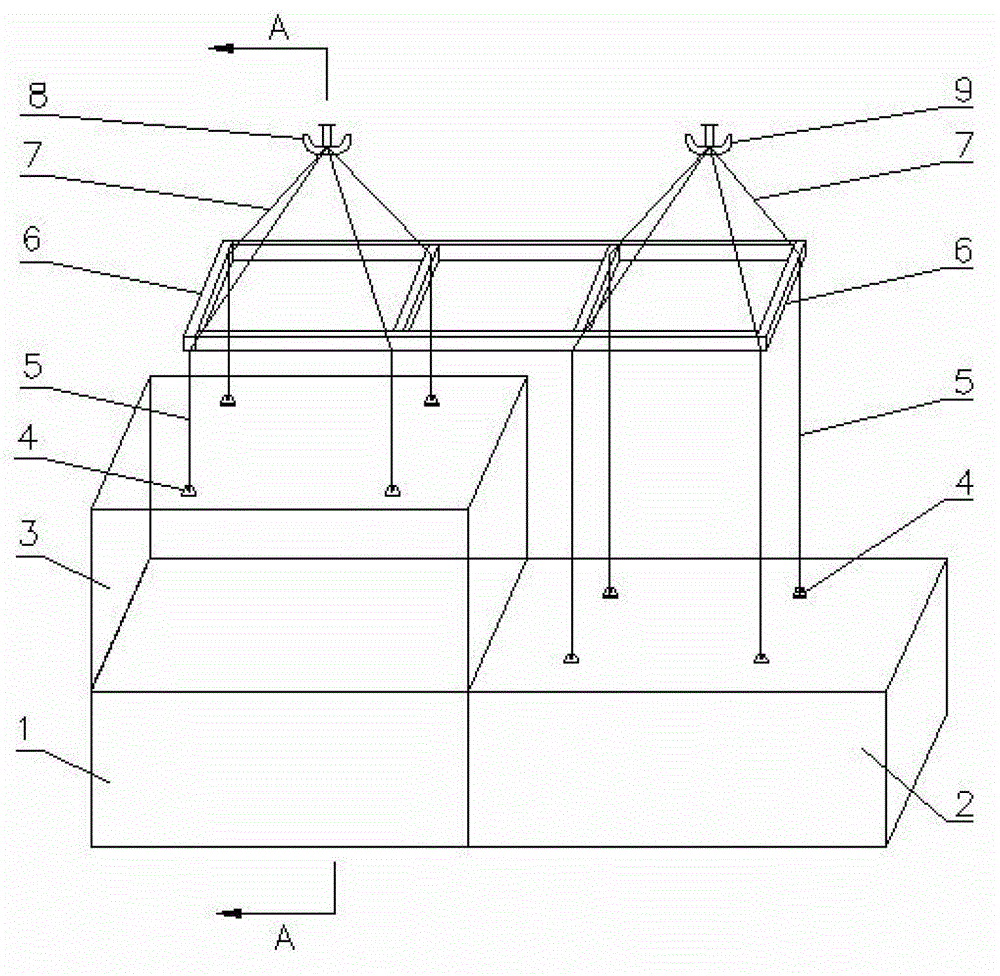

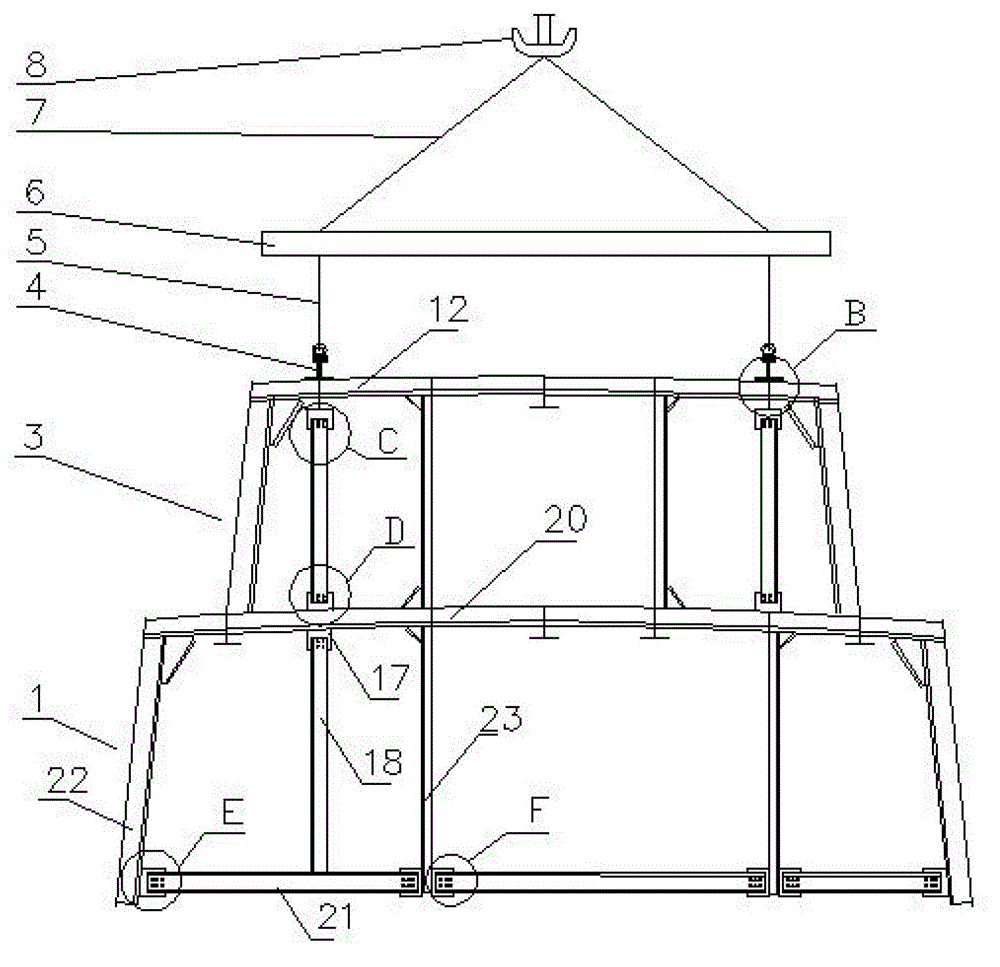

[0030] figure 1 Shown is a schematic diagram of the general section of the aluminum alloy superstructure hoisting, the hoisting process is as follows:

[0031] Firstly, according to the weight, structural form and center of gravity of the aluminum alloy superstructure total section, determine the number of multiple lifting points, multiple lifting point positions and the overall hoisting method of the aluminum alloy superstructure total section; Two cranes 8, 9 carry out joint hoisting.

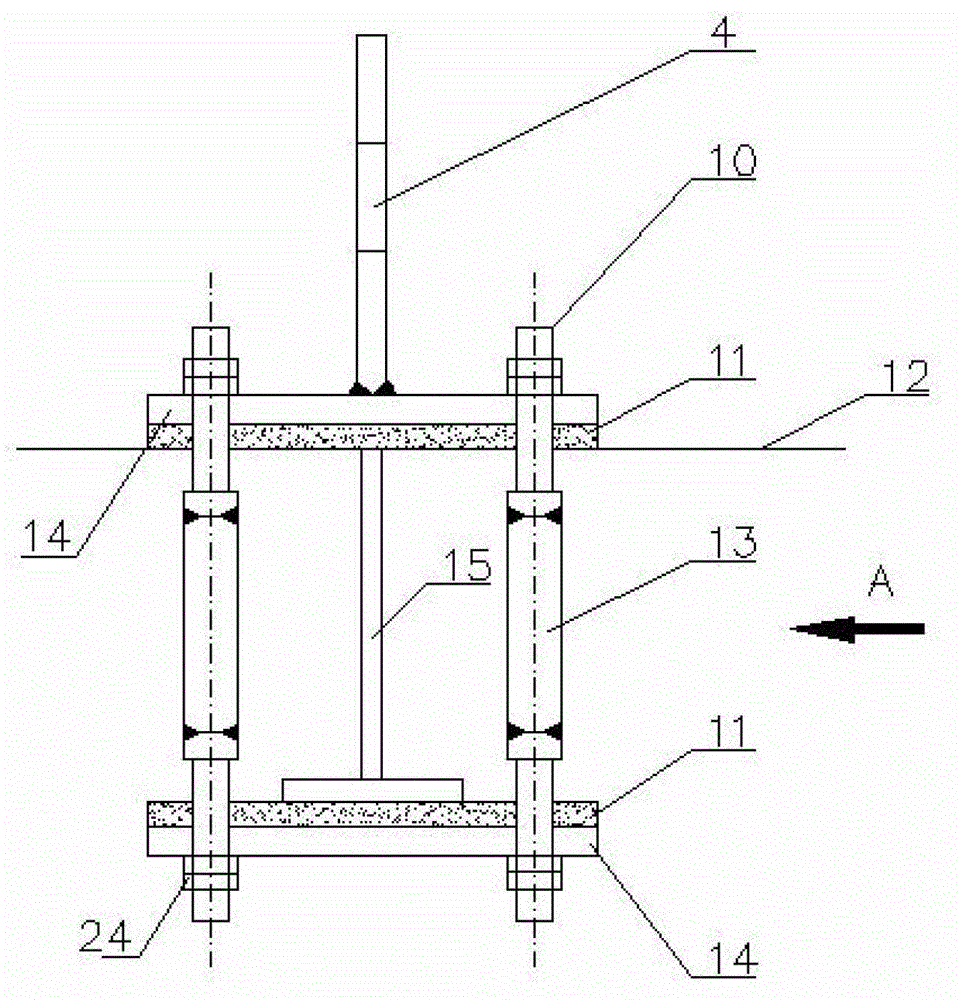

[0032] Secondly, make the hoisting hanger 6 of the general section of the aluminum alloy superstructure to control the hoisting deformation. The hoisting hanger 6 here is assembled from profiles such as channel steel, and its structure is as follows: figure 1 It is shown that three rectangles are connected in sequence, because figure 1 The total section shown is divided into three sections, that is, the first section 1 and the second section 2 that are juxtaposed on the bottom floor, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com