Cross head of crank rod type piston compressor

A crank connecting rod and compressor technology, which is applied to reciprocating piston engines, crossheads, variable displacement engines, etc., can solve the problems of affecting the overall size of the machine, high production cost, and large size, so as to facilitate installation and on-site The effect of maintenance operation, elimination of shear force, and reduction of strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the content of the present invention will be further described:

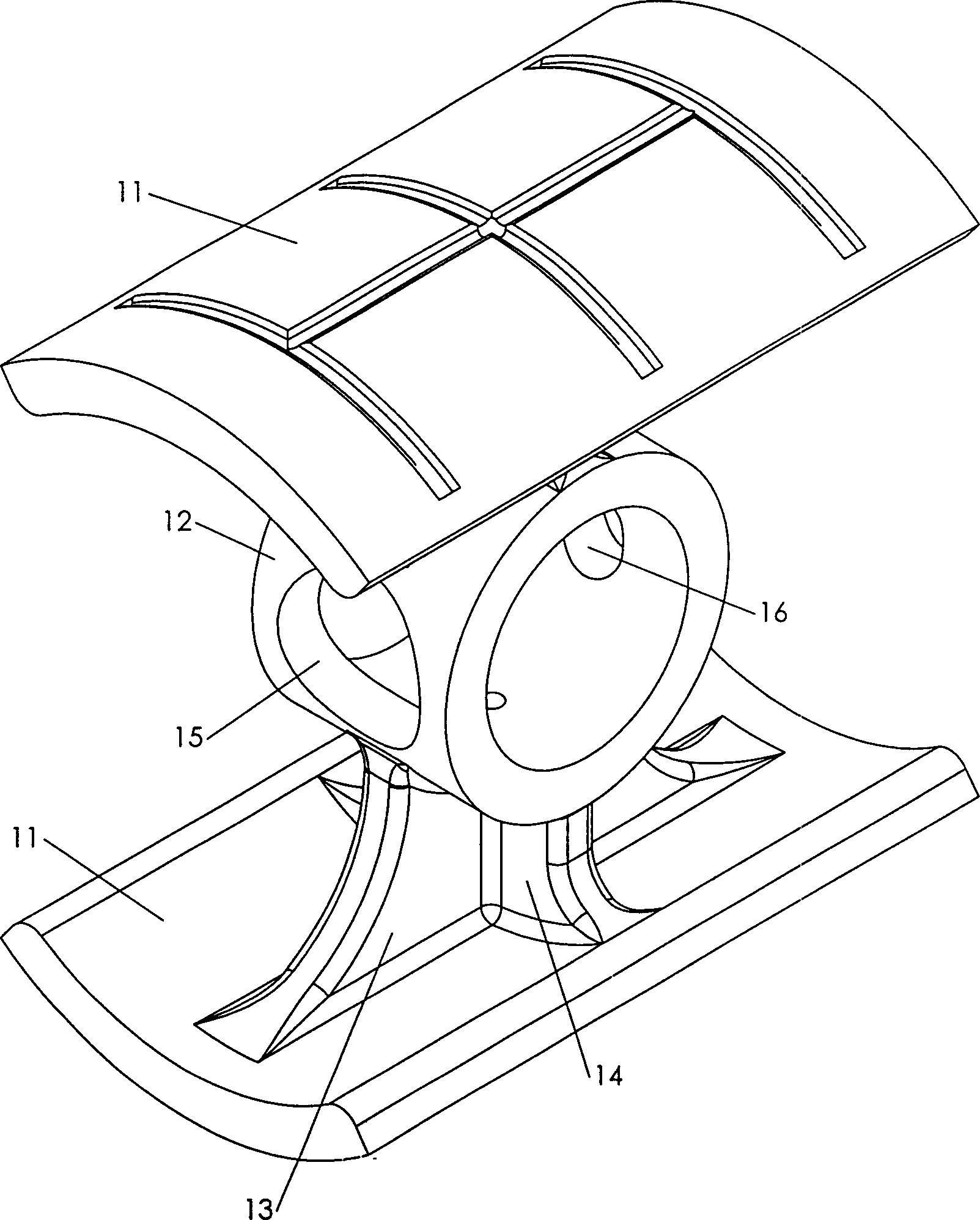

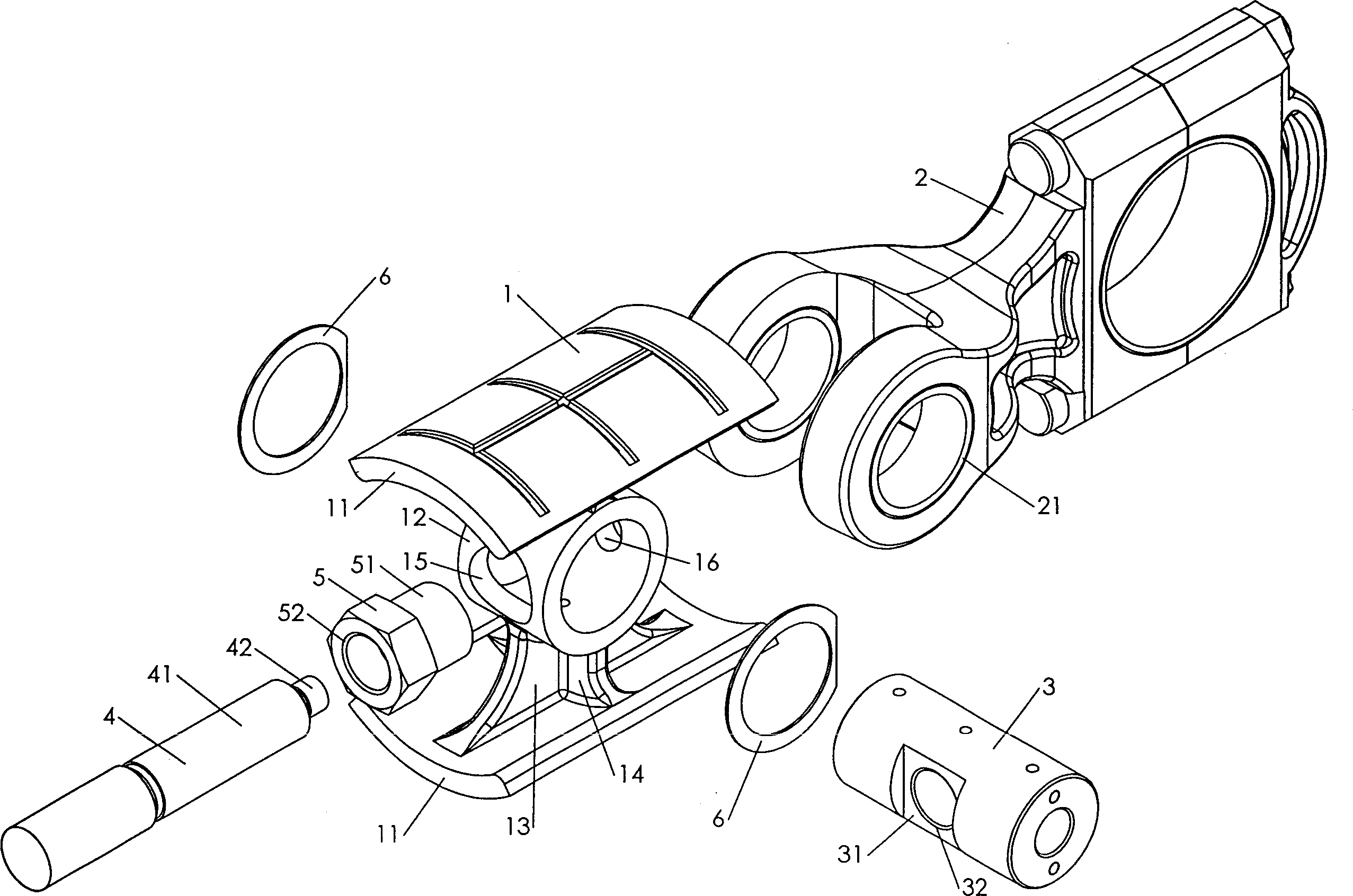

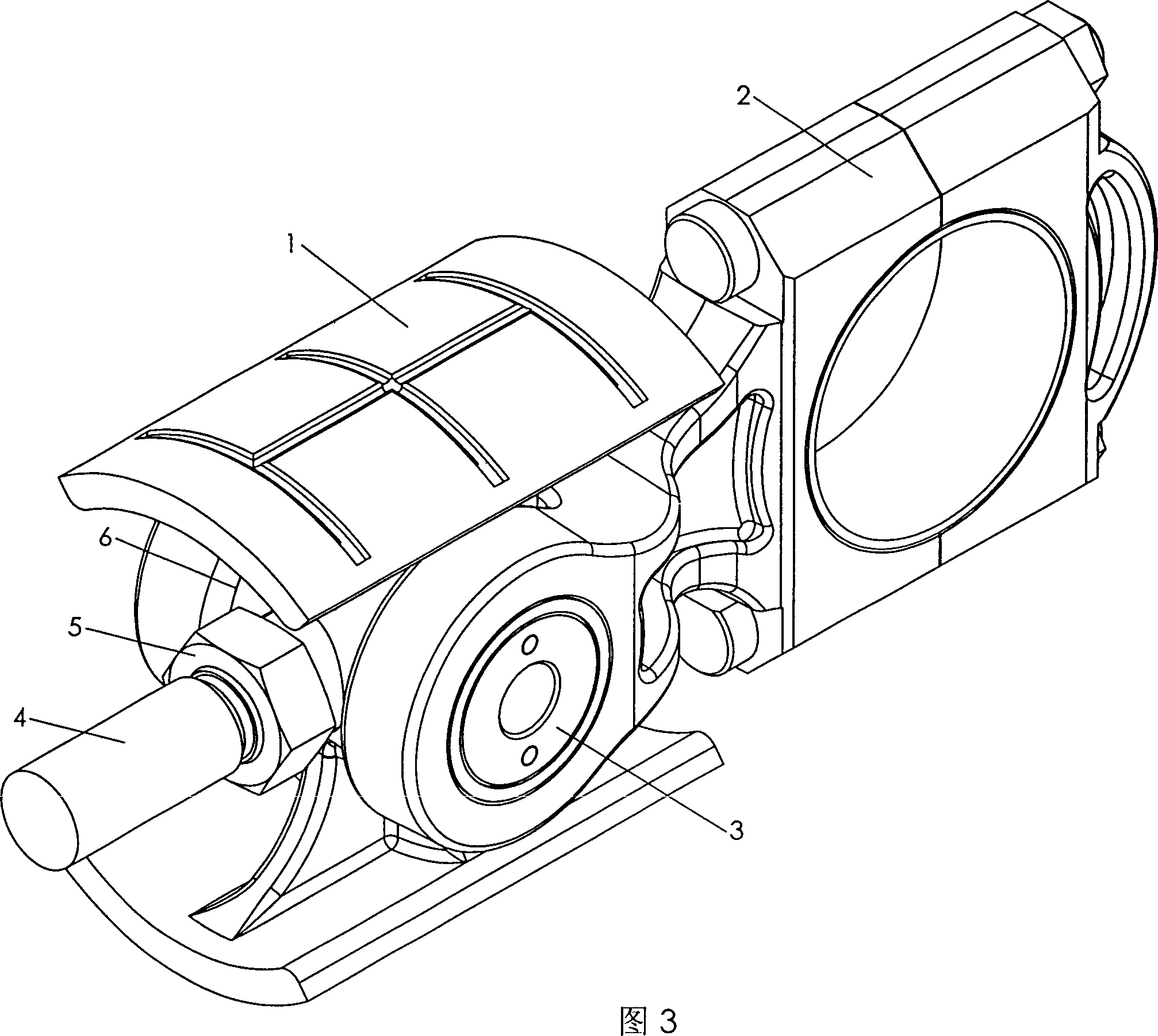

[0028] figure 1 ~Among Fig. 3: 1-crosshead body, 2-connecting rod, 3-crosshead pin, 4-piston rod, 5-crosshead nut, 6-friction-reducing locating ring.

[0029] refer to figure 1 As shown, the crosshead body 1 proposed by the present invention includes: two arc-shaped sliding shoes 11 that share a cylindrical surface and are symmetrical to the center of the cylindrical axis, and a pin located in the middle of the length and width directions of the sliding shoe. Hole seat 12, two vertical and horizontal ribs 13 and 14 that connect said pin hole seat 12 with said arc-shaped sliding shoes 11. The two arc-shaped sliding shoes 11 are symmetrical to the axis of the pin hole seat 12, and a larger circular through hole 15 and a smaller oblong hole are respectively opened on the two side walls of the pin hole seat 12. Shaped hole 16, two holes are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com