Pure bending test system for automobile steel having thin gauge and high strength and test method

A test system, high-strength technology, applied in the direction of strength characteristics, using a stable bending force to test the strength of materials, measuring devices, etc., can solve problems such as the inability to measure the bending moment in real time, the fracture of the sample, and the inability to obtain the bending deflection of the plate. , to solve additional stress interference, eliminate excessive deformation, and avoid downward bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

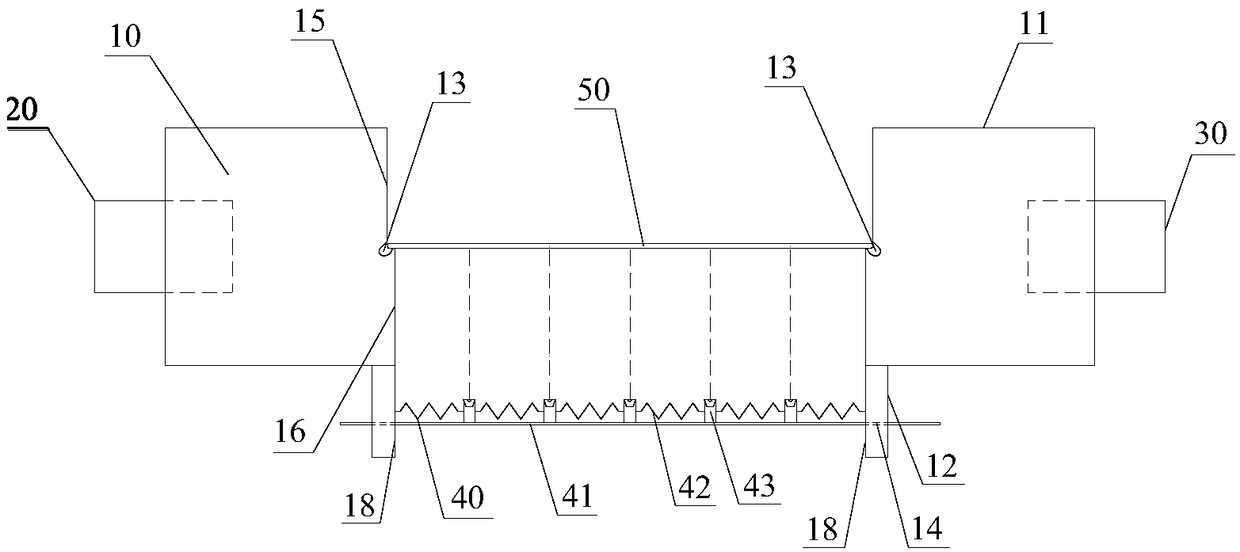

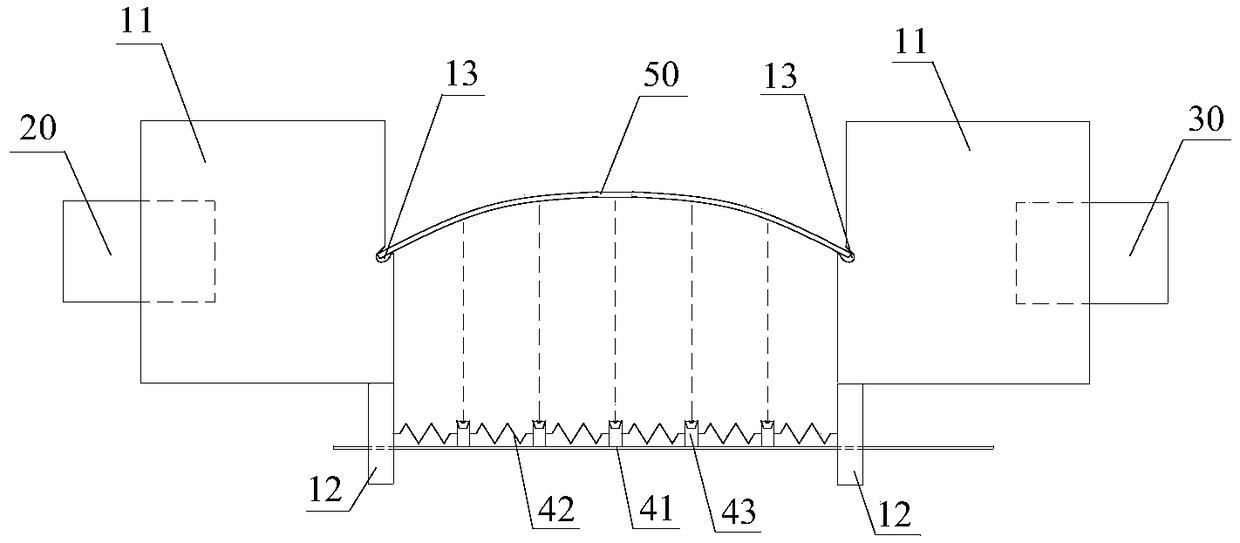

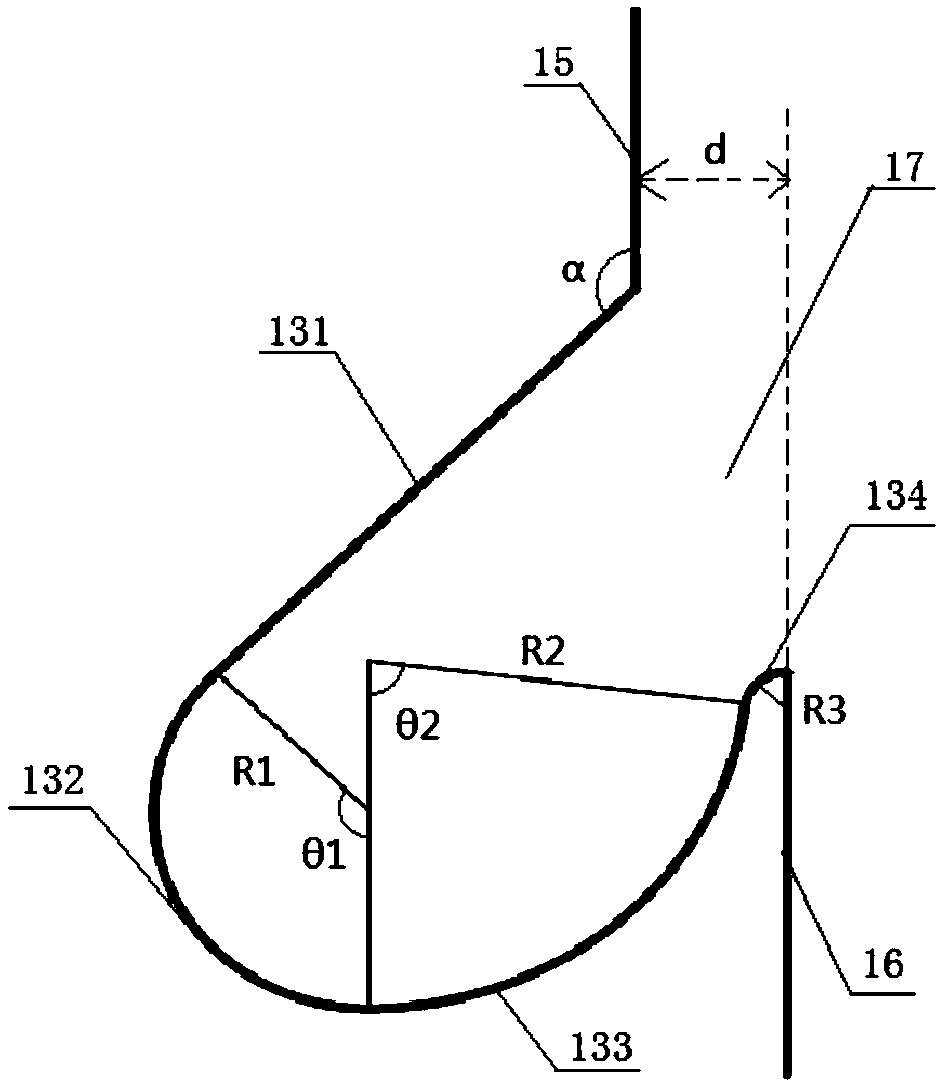

[0039] Such as figure 1 , figure 2 Shown is a pure bending test system for thin-gauge high-strength automotive steel, including two symmetrically arranged fixtures 10 , a force sensor 20 and a laser displacement testing device 40 . Wherein, each set of fixtures 10 includes a fixture body 11, a baffle plate 12 fixed on the bottom of the working side of the fixture body 11, and a connecting groove 13 provided on the working side of the fixture body 11. The connecting groove 13 of one set of fixtures 10 is connected with another set of fixtures. The connection grooves 13 of 10 are arranged oppositely, and the inner surface 18 of each baffle plate 12 is flush with the side surface 16 of the working side below the notch of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com