Manufacturing method for large-diameter austenitic stainless steel thick-wall pipe

A technology of austenitic stainless steel and a manufacturing method, which is applied in the directions of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of large-diameter thick-walled tubes with coarse grain size, long production cycle, and low yield, etc. The effect of reducing the manufacturing process, improving the yield and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Homogenization heat treatment of embodiment 1 hot-rolled tube billet

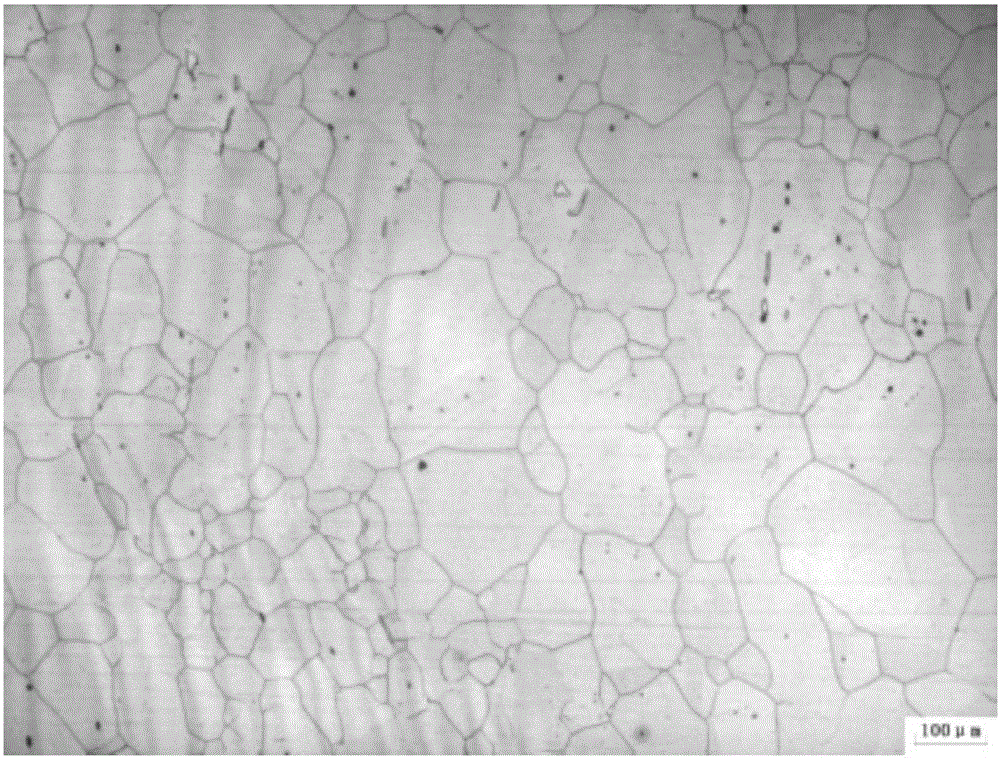

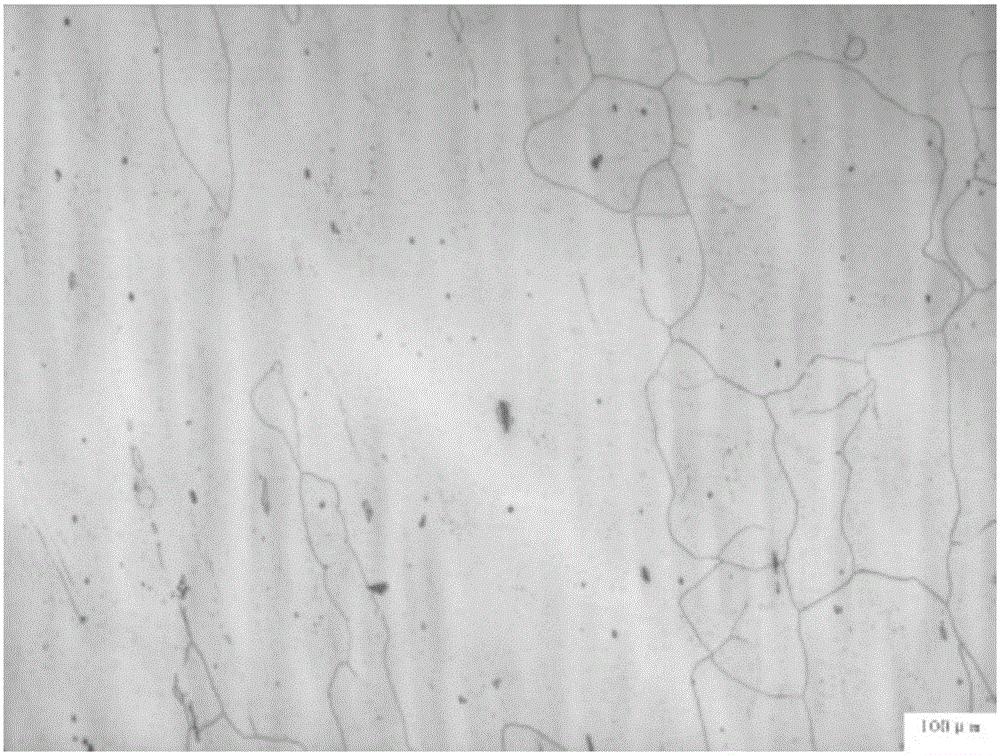

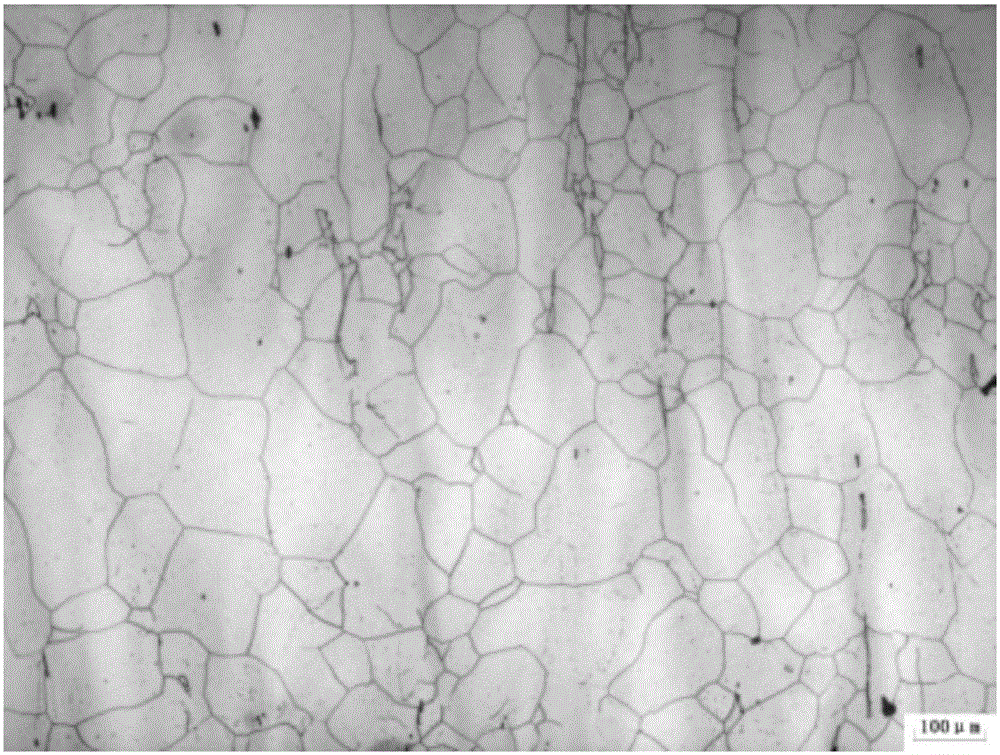

[0054] figure 1 , figure 2 and image 3 The grain structures of the inner wall, core and outer wall of the hot-rolled billet with furnace number 1# after heat treatment at 1080°C are shown respectively; Figure 4 , Figure 5 and Figure 6 The grain structures of the inner wall, core and outer wall of the hot-rolled billet with heat number 1# after homogenization heat treatment at 1180°C are shown respectively. After the hot-rolled tube blank is heat-treated at 1080°C, the inner and outer walls are completely recrystallized, the recrystallized grain size is small, the recrystallization in the core is not complete, and there is still an incompletely recrystallized as-cast structure; after 1180°C high temperature uniformity After the heat treatment, the inner wall, outer wall and core have completely recrystallized structure, and the grain size is relatively uniform. It can be seen that increasin...

Embodiment 2

[0055] Embodiment 2 Microstructure regulation and annealing heat treatment of cold-rolled tube billet

[0056] Figure 9 , Figure 10 and Figure 11 The grain structure of the core part of the tube wall after the heat treatment of the cold-rolled tube blank with the furnace number 2# after the microstructure control heat treatment at 830°C, 930°C and 1050°C respectively is shown. After heat treatment at 930°C and 1050°C, the cold-rolled tube billet has undergone complete recrystallization. After heat treatment at 1050°C, the recrystallized grain size in the core of the tube wall is large, and its grain size is 3.5. After heat treatment at 930°C, the tube wall The recrystallized grain size in the core is small, and the grain size is 4.5; after heat treatment at 830 ℃, the cold-rolled tube billet is not completely recrystallized, and the grain is coarse, which is 2.0. Figure 8 The relationship between the annealing heat treatment temperature and the grain size of the core of...

Embodiment 3

[0059] Embodiment 3 roll diameter

[0060] Rolled by cold rolls with diameters of 600mm, 800mm and 1000mm The grain size of the core part of the pipe wall of the cold-rolled finished pipe is 4.5, 5.0 and 5.5 respectively, Figure 18 , Figure 19 and Figure 20 The grain structures of the inner wall, core and outer wall of the finished pipe rolled by 1000 mm cold roll are shown respectively. It can be seen that increasing the diameter of the cold rolling roll of the finished pipe has a good beneficial effect on refining the grains in the core of the pipe wall. Further control the roll diameter between 700-1200mm, the grain size of the finished pipe can be controlled at 5.0 and above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com