Four-limb steel column for connection of cellular connection plates

A connecting plate and honeycomb-shaped technology, applied in the field of steel columns for limbs, can solve the problems of large difference in stability between virtual and real shafts, increased steel consumption and construction difficulty, and increased overall project cost, achieving a remarkable appearance and good transformation Foreground, the effect of reducing the difficulty of construction

Inactive Publication Date: 2014-12-24

NANJING UNIV OF TECH

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the cross-section of the lattice steel column is composed of single limbs connected by embroidered materials. The fabrication and construction are relatively cumbersome, the workload of the connection is too large, and the shear deformation of the imaginary axis is relatively large, which will cause certain additional deflection. It will reduce its working performance; especially the difference between the stability of the virtual and real shafts is large, resulting in the inability of its materials to be fully utilized, and it will inevitably increase the overall cost of the project; moreover, when there is a large horizontal concentration somewhere in the column When the force acts, in order to avoid the bending of the column limb, it is necessary to set a diaphragm at this place, which will increase the steel consumption and construction difficulty, reduce the construction speed, and increase the construction period, thereby further increasing the overall cost of the project

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0025] Usually finished in the steel structure processing factory. Its basic production procedure is:

[0026] Make the honeycomb connection plate → make the limbs → weld.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

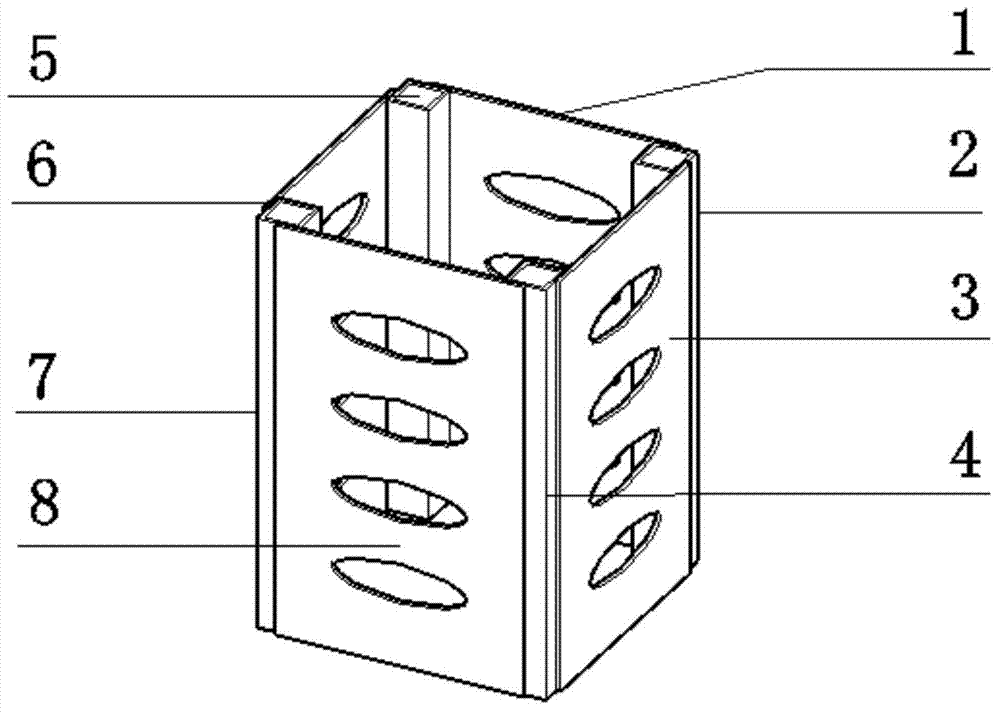

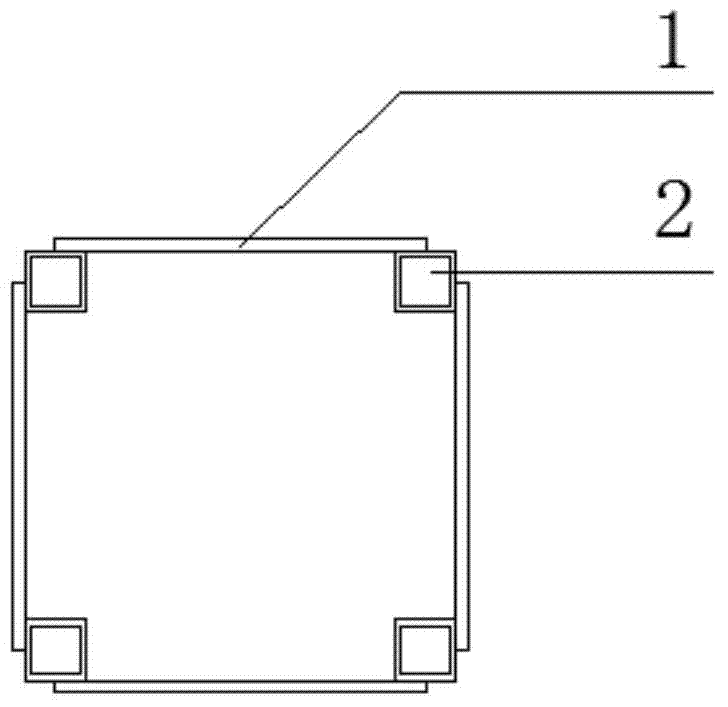

The invention discloses a four-limb steel column for connection of cellular connection plates. The four-limb steel column for connection of cellular connection plates comprises a steel tube limb I, a steel tube limb II, a steel tube limb III, a steel tube limb IV, a steel connection plate I, a steel connection plate II, a steel connection plate III and a steel connection plate IV, wherein the steel tube limb I, the steel tube limb II, the steel tube limb III and the steel tube limb IV are connected together through the steel connection plate I, the steel connection plate II, the steel connection plate III and the steel connection plate IV to form a rectangular section column; the steel connection plate I, the steel connection plate II, the steel connection plate III and the steel connection plate IV are cellular connection plates, the middles of which are provided with holes; the steel connection plate I, the steel connection plate II, the steel connection plate III and the steel connection plate IV are respectively formed by two steel plates which are provided with gaps at the boundary zones and of the same shape; every two steel plates are welded through butt welds to form each cellular connection plate. The four-limb steel column for connection of cellular connection plates is capable of improving the stress property of the latticed columns and improving the rigidity and the buckling strength of the steel columns in a relatively economic manner.

Description

technical field [0001] The invention relates to the technical field of a novel building structure, in particular to a limb steel column connected by a honeycomb connecting plate. Background technique [0002] Compared with traditional concrete structures, steel structures have the advantages of light weight, short construction period, and good seismic performance, and are more and more favored by people, thus being widely used. [0003] Steel columns can be divided into two categories: solid-web type and lattice type according to their cross-sectional forms. Relatively speaking, the solid-web column has a simple structure and is more convenient to connect with other components. However, with the development of multi-high-rise buildings, long-span structures, and heavy-duty factory buildings, when the number of building floors gradually increases and the upper load increases, it will inevitably lead to an increase in the cross-sectional size of the steel column, thereby incr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04C3/32

Inventor 郑廷银邵连俊许惠斌

Owner NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com