Corrugated web plate L-shaped section specially-shaped steel column

A technology of profiled cross-section and corrugated web, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of limited shear bearing capacity, seismic performance and overall stability, increase the comprehensive cost of the project, and increase the project cost, etc., to achieve The overall stable bearing capacity is superior, the effect of reducing the cost of the comprehensive project and improving the mechanical performance

Inactive Publication Date: 2015-03-11

NANJING TECH UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the traditional flat-web solid-web L-shaped cross-section special-shaped steel column is selected, the shear strength of the web will be much surplus, but in order to ensure the local stability of the web, the web height and thickness specified in the "Code for Design of Steel Structures" must be met. It is usually necessary to increase the thickness of its web, which will lead to an increase in steel consumption and project cost, thereby increasing the overall cost of the project; , seismic performance and overall stability are limited, the truss-type web members need to be welded with plates or strips, the construction is relatively cumbersome, the connection workload is large, and the construction cost is increased, which also increases the overall cost of the project.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0024] Usually the flat steel plate flange, corrugated steel web and its welding are finished in the factory.

[0025] The basic production procedure is: making corrugated steel webs→making steel flanges→welding→transporting to the construction site→hoisting in place.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

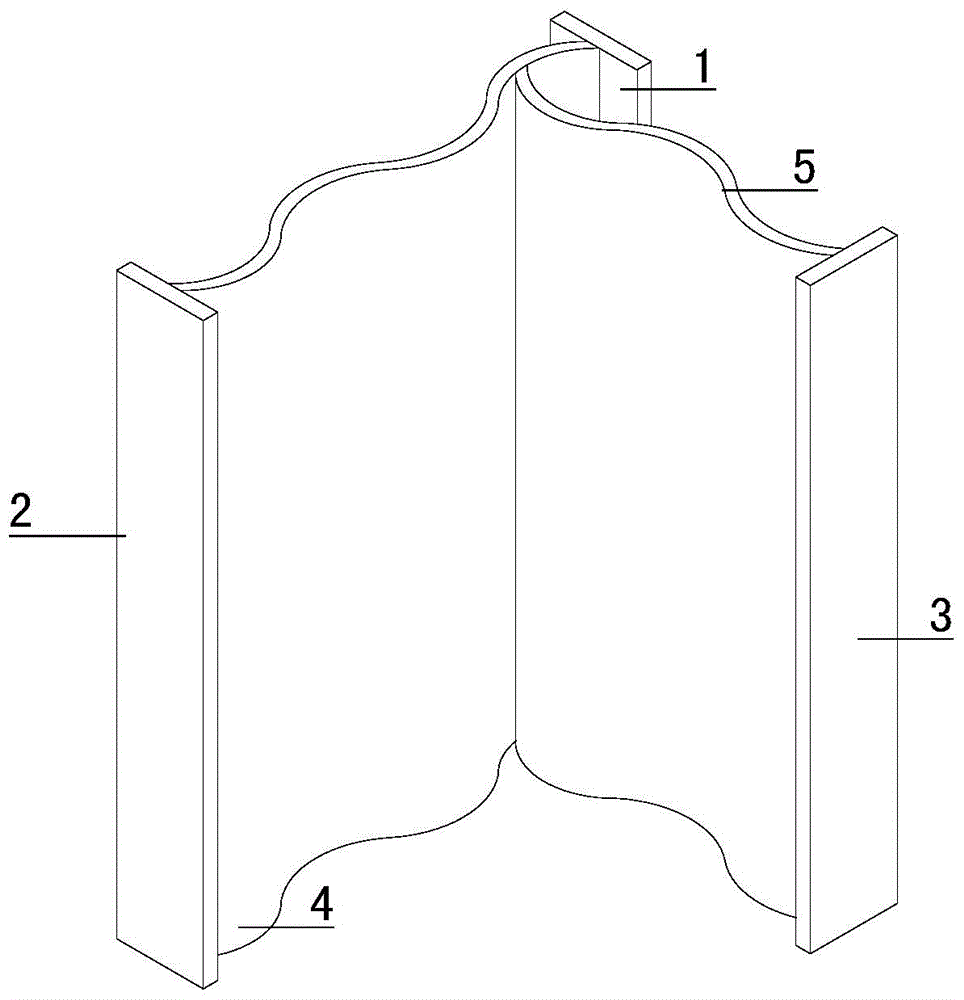

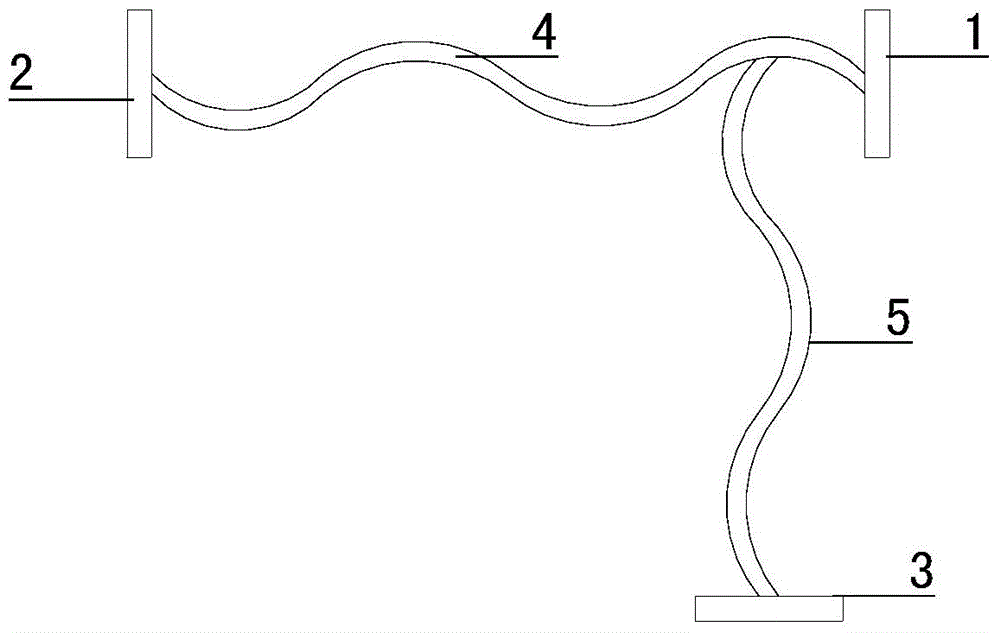

The invention discloses a corrugated web plate L-shaped section specially-shaped steel column. The corrugated web plate specially-shaped steel column comprises a flat steel plate flange I, a flat steel plate flange II, a flat steel plate flange III, a steel web plate I and a steel web plate II, wherein one side edge of the steel web plate II is perpendicularly connected with the edge of the steel web plate I so as to form the specially-shaped steel column with the L-shaped section; the steel web plate I and the steel web plate II are corrugated steel web plates; the corrugated steel web plates are curvilinear, polygonal-shaped or trapezoid; the periodically repeated corrugated edges of the corrugated steel web plates are perpendicular to the length direction of a member; the non-corrugated edges of the corrugated steel web plates are respectively welded with the middle points in the width directions of the steel plate flange I, the steel plate flange II and the steel plate flange III. According to the corrugated web plate L-shaped section specially-shaped steel column, the stress performance of an existing L-shaped section specially-shaped steel column is improved, and the comprehensive manufacturing cost of engineering is not obviously increased, so that the corrugated web plate L-shaped section specially-shaped steel column can be widely applied to the engineering.

Description

technical field [0001] The invention relates to the technical field of a novel building structure, in particular to a special-shaped steel column with an L-shaped cross-section of a corrugated web. Background technique [0002] In the modern construction of multi-high-rise steel structure residences, the advantages of special-shaped column structures have become more and more prominent, and their status has become increasingly prominent. In recent years, they have been highly valued by academic circles and engineering technicians at home and abroad. The application is also more and more extensive. [0003] In the actual engineering of multi-story steel structure residences, the corner columns usually adopt traditional flat-web solid-web L-shaped cross-section special-shaped steel columns or truss-type L-shaped cross-section special-shaped steel columns. In order to meet the requirements of compressive bending performance, larger section size, especially web size, is usually...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04C3/32

Inventor 郑廷银殷辰豪许惠斌

Owner NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com