Optical fiber micro-bending displacement sensor

A technology of displacement sensor and fiber optic coupler, which is applied in the field of sensors in the field of testing technology, to achieve the effects of prolonging service life, small shear deformation, and improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

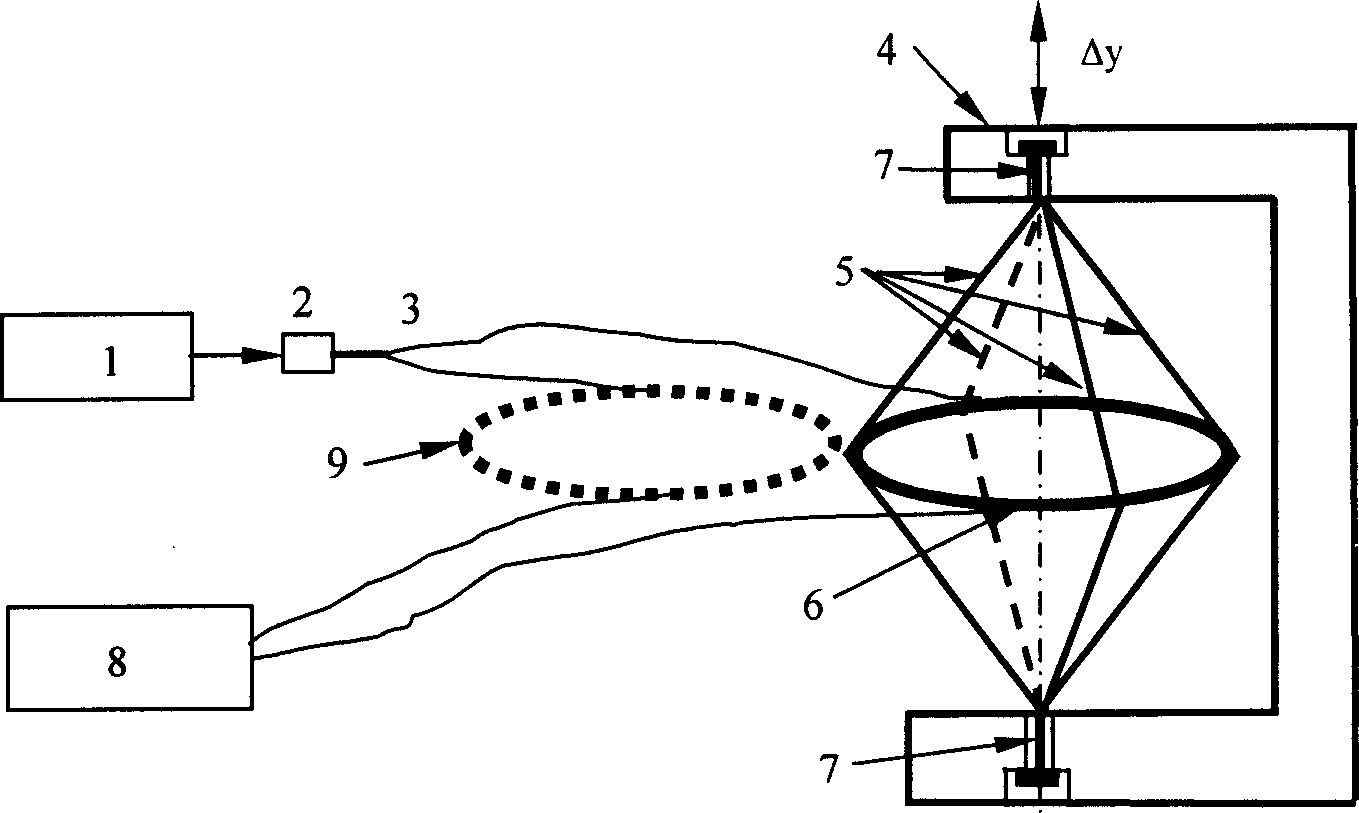

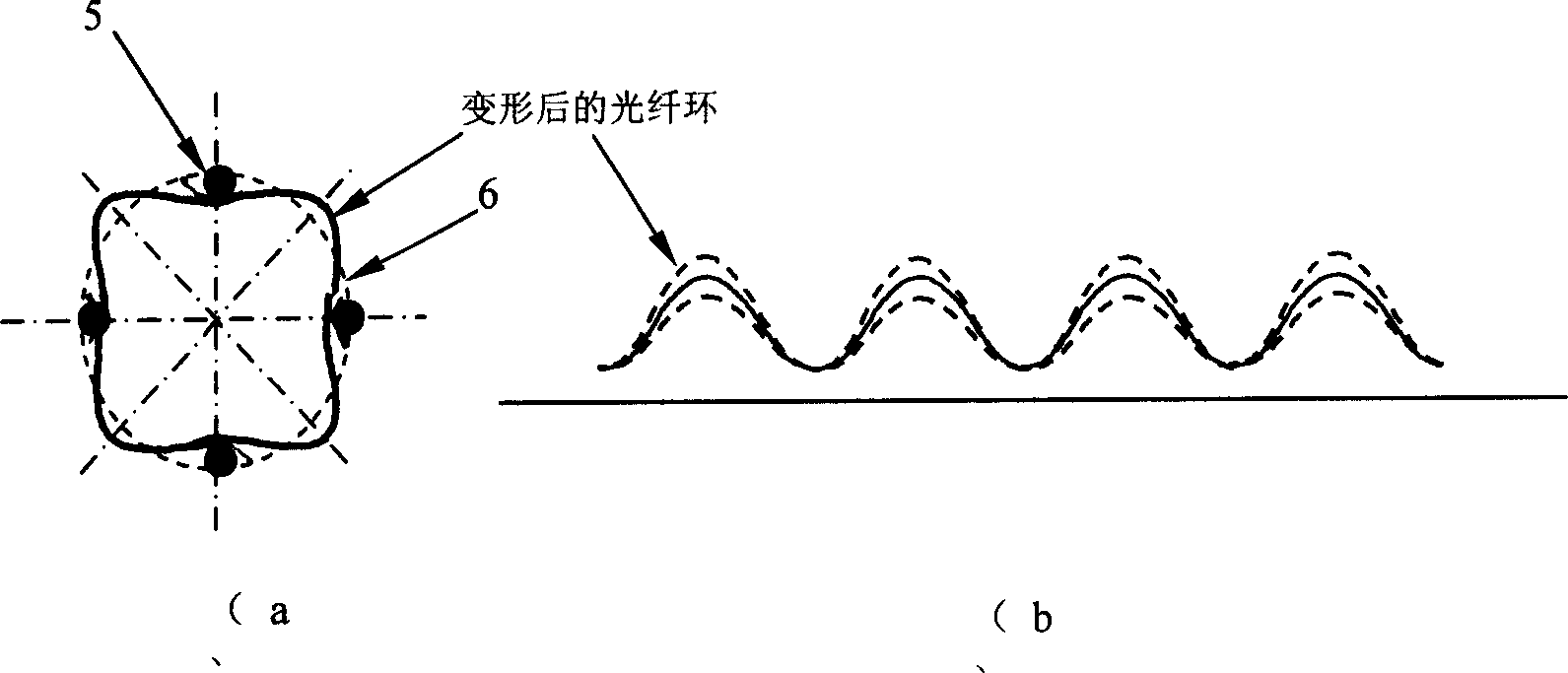

[0011] Such as figure 1 , 2 As shown, the present invention includes: a light source 1, an optical fiber coupler 2, a Y-shaped optical fiber 3, an overall deformation device 4, an optical fiber micro-bending deformation device 5, two optical fiber rings 6 and 9, two pre-tightening bolts 7 and an optical power meter 8 . The connection relationship is: the light emitted by the light source 1 enters the input end of the Y-shaped optical fiber 3 through the optical fiber coupler 2, and the optical fibers at the two output ends of the Y-shaped optical fiber 3 are made into two optical fiber rings 6, 9 with the same size and the same number of turns. One of the optical fiber rings 6 is installed in the optical fiber micro-bending deformation device 5, and the optical fiber micro-bending deformation device 5 and the optical fiber ring 6 are installed together in the overall deformation device 4 through two pre-tightening bolts 7, and the other optical fiber ring 9 is placed freely. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com