Pneumatic radial tire

A radial tire and tire technology, applied in the reinforcement layer of pneumatic tires, heavy-duty tires, special tires, etc., can solve the problems of poor durability of the belt layer, prevent air bubbles, reduce shear stress, and inhibit separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

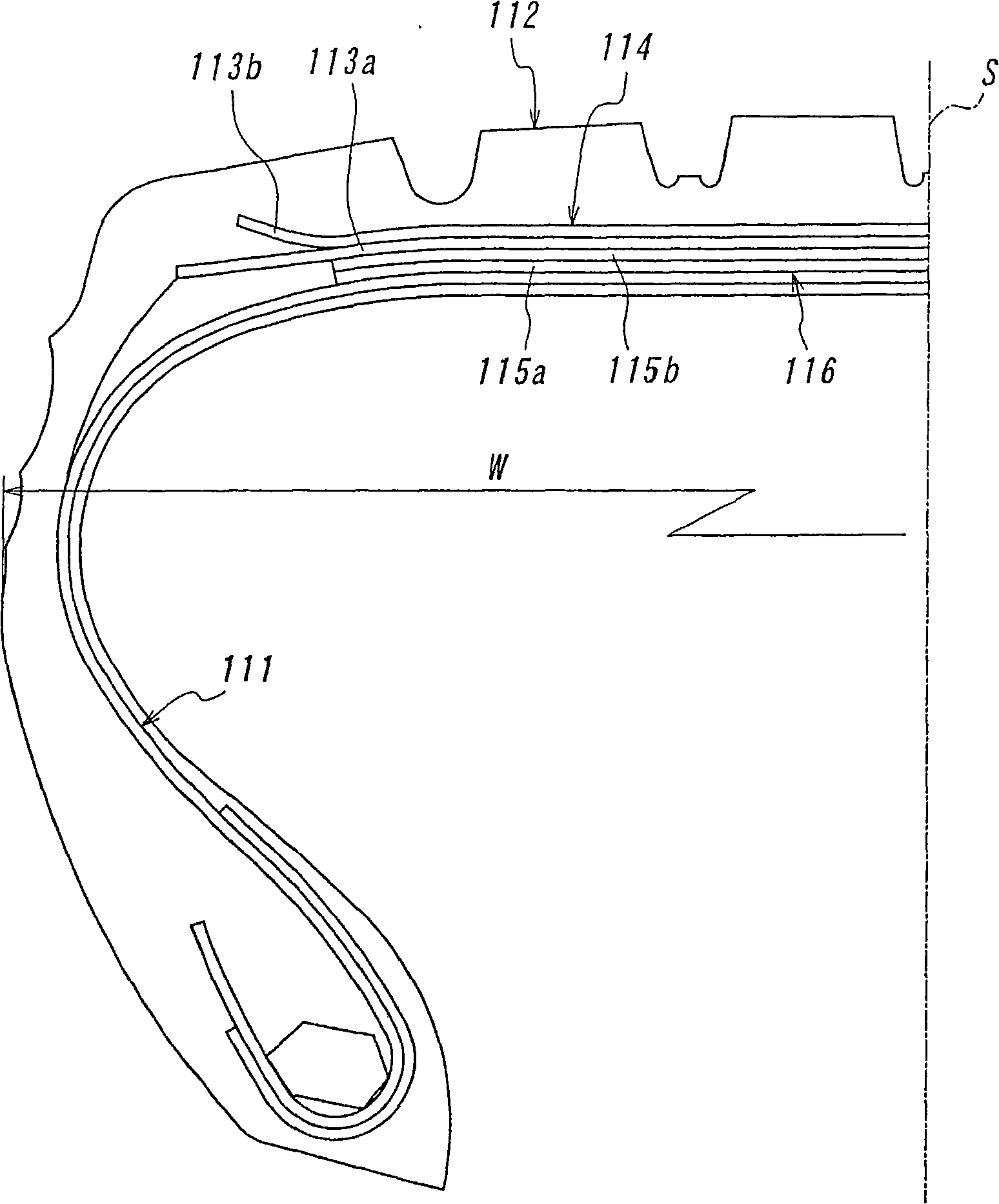

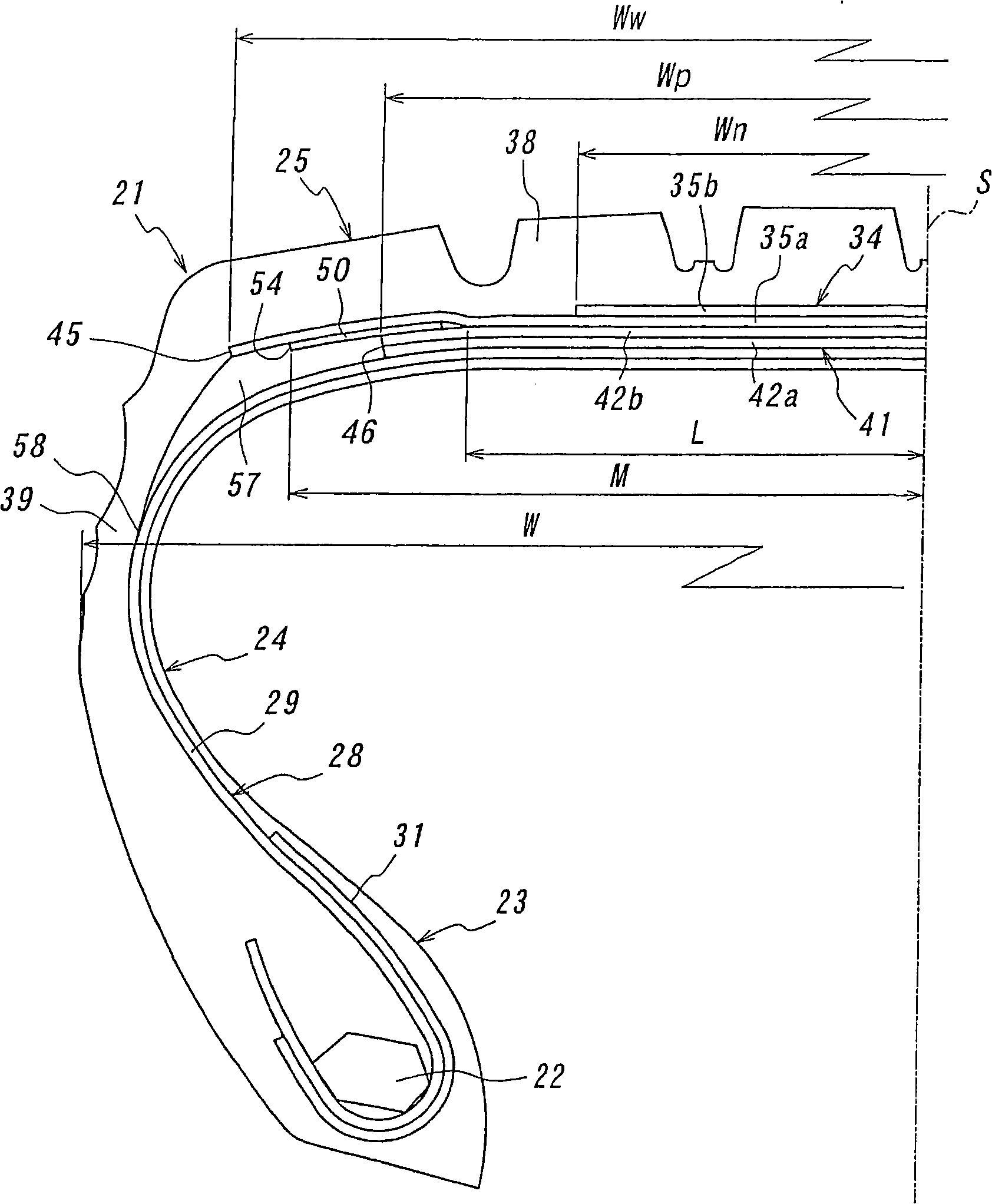

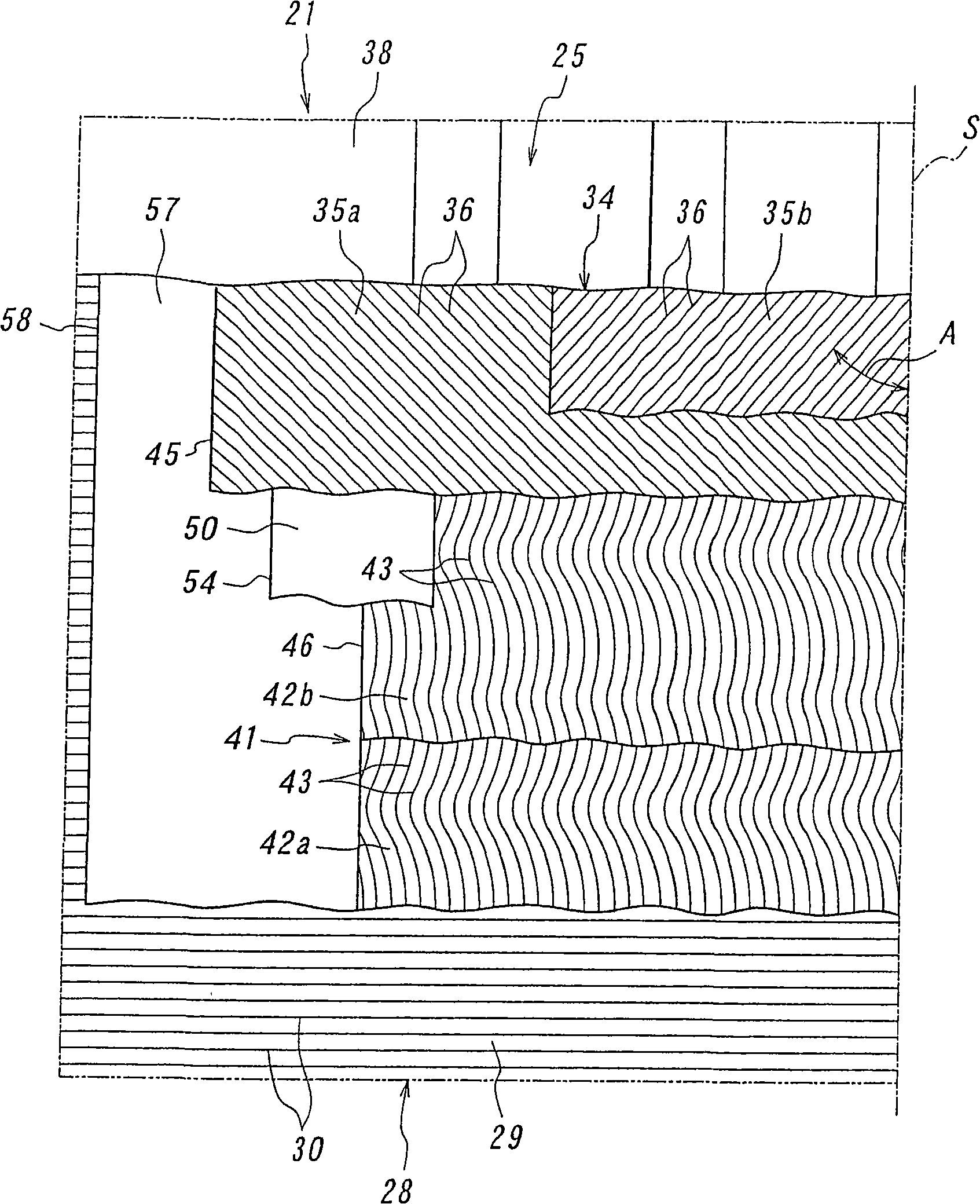

[0055] A test example will be described below. The following tires are provided for this test: A conventional tire in which all reinforcements constituting the belt reinforcement have a width of figure 1 narrower than the width of the belt layer as shown; the tire in Example 1, wherein only the inner belt layer is wider than the width of the belt reinforcement layer, and the elastic rubber layer is not provided therebetween; the tire in Example 2, Among them, only the width of the inner belt layer is wider than that of the belt reinforcement layer, and the elastic rubber layer such as figure 2 set therebetween as shown; the tire in embodiment 3, wherein only the width of the inner belt layer is wider than the width of the belt reinforcement layer, and as Figure 5 As shown, the elastic rubber layer is disposed therebetween on the entire area; tires in embodiments 4, 5, and 6, wherein only the width of the outer belt layer is wider than the width of the belt reinforcement lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com