Steel-wood combined bridge deck structure and paving method thereof

A steel-wood combination and steel bridge deck technology, applied in bridges, bridge parts, bridge construction, etc., to achieve the effects of preventing detachment between layers, reducing fatigue damage, and reducing shear deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

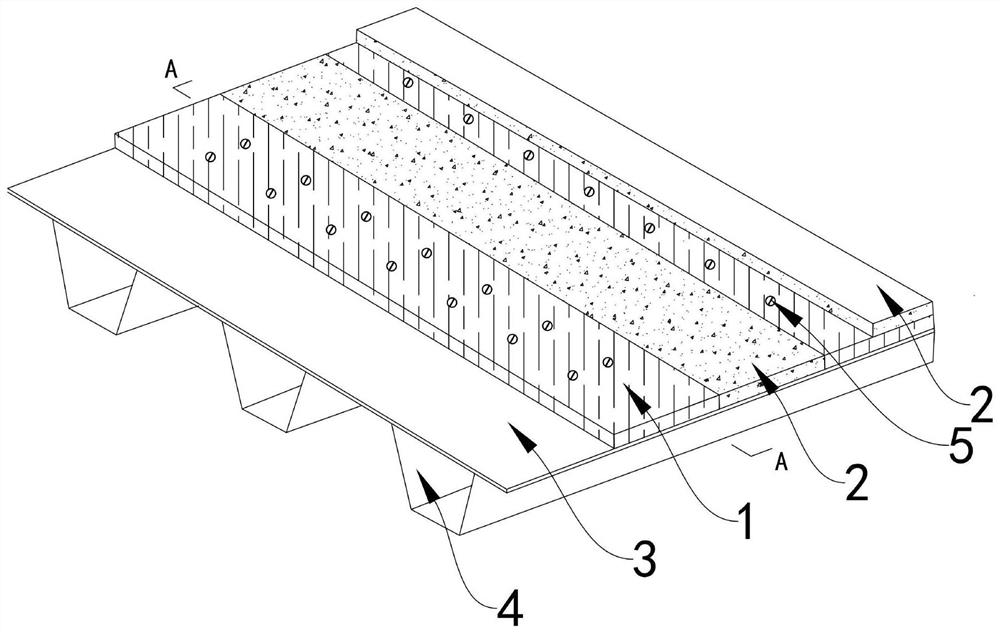

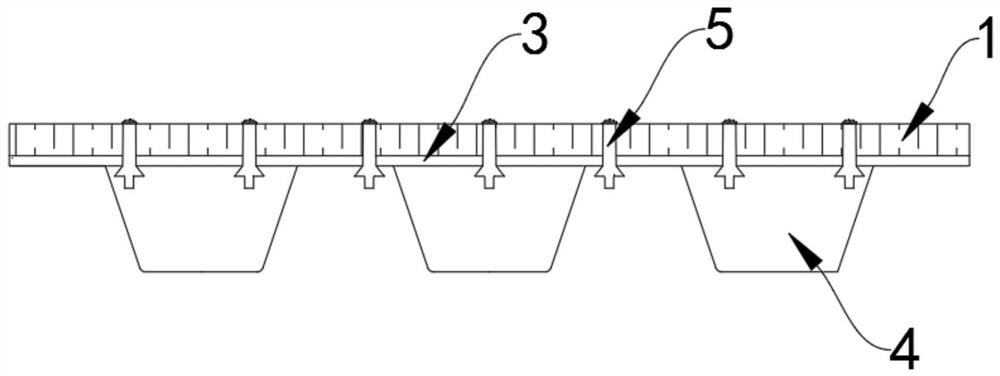

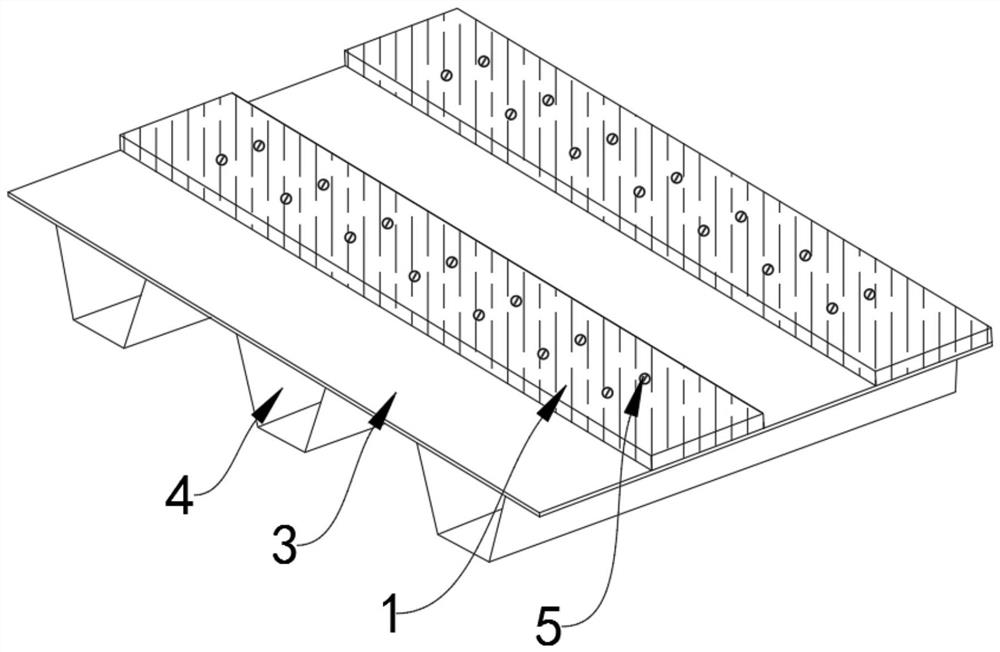

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, a steel-wood composite bridge deck structure includes a steel bridge deck 3, and several U-ribs 4 are uniformly fixed on the bottom of the steel bridge deck 3, and adjacent U-ribs 4 are arranged at intervals, and the steel bridge deck The upper and lower surfaces of 3 are evenly coated with inorganic zinc-rich primer, and several wooden laths 1 are evenly distributed and fixed on the upper surface of the steel bridge deck 3. , the preferred treatment standard LY / T3228-2020 "Pressure anti-corrosion treatment of glued wood". Adjacent wooden laths 1 are arranged at a certain distance, and the distance between two adjacent wooden laths 1 is 500±10mm. The plank 1 is cross-laminated timber (CLT), the thickness of the plank 1 is 50±2mm, and the width is 600-1200mm, the bonding of the plank 1 and the asphalt concrete 2 can be fully obtained by the design of such size and spacing Assur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com