Preparation method of high stability bio-carbon based iron carbide for degrading dyes

A high-stability, biochar technology, used in chemical instruments and methods, water pollutants, alkali metal oxides/hydroxides, etc. problems, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

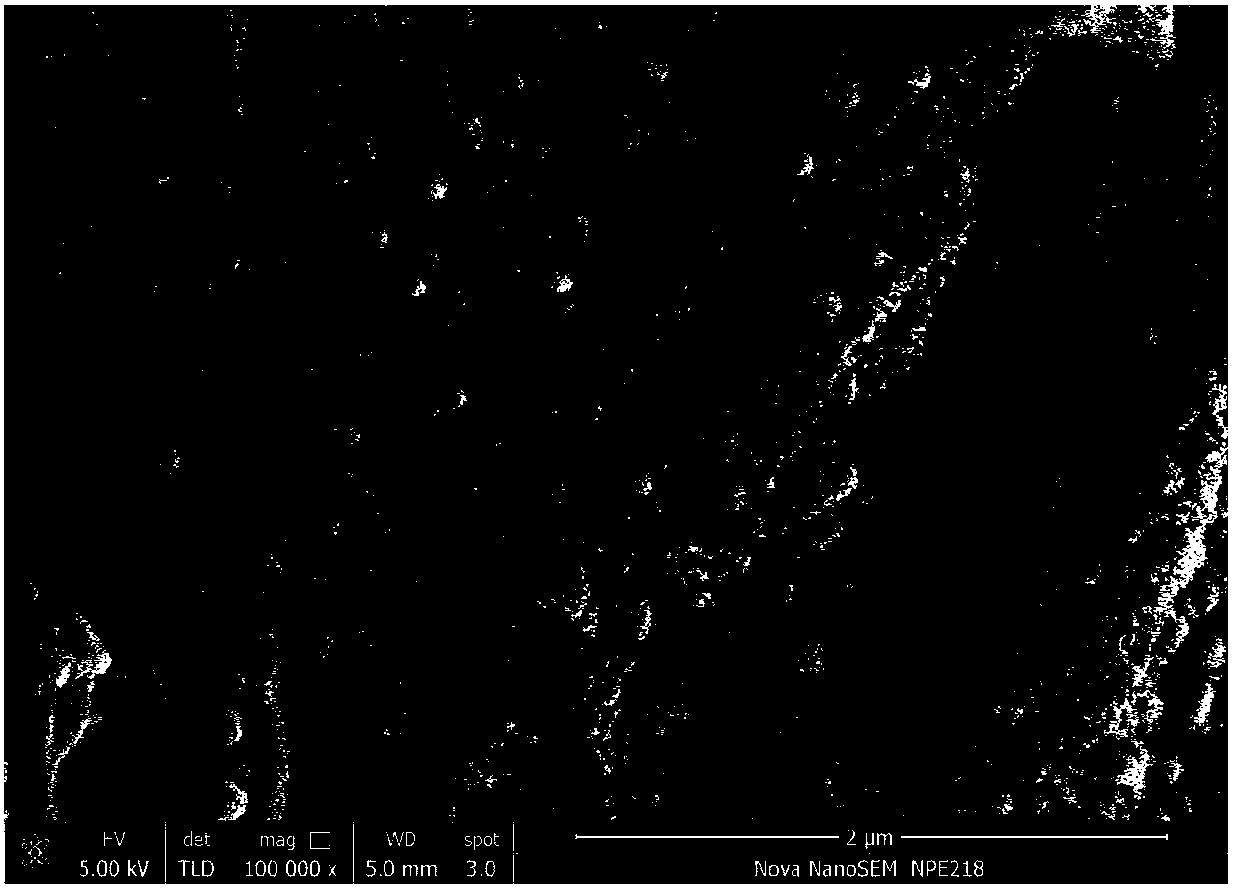

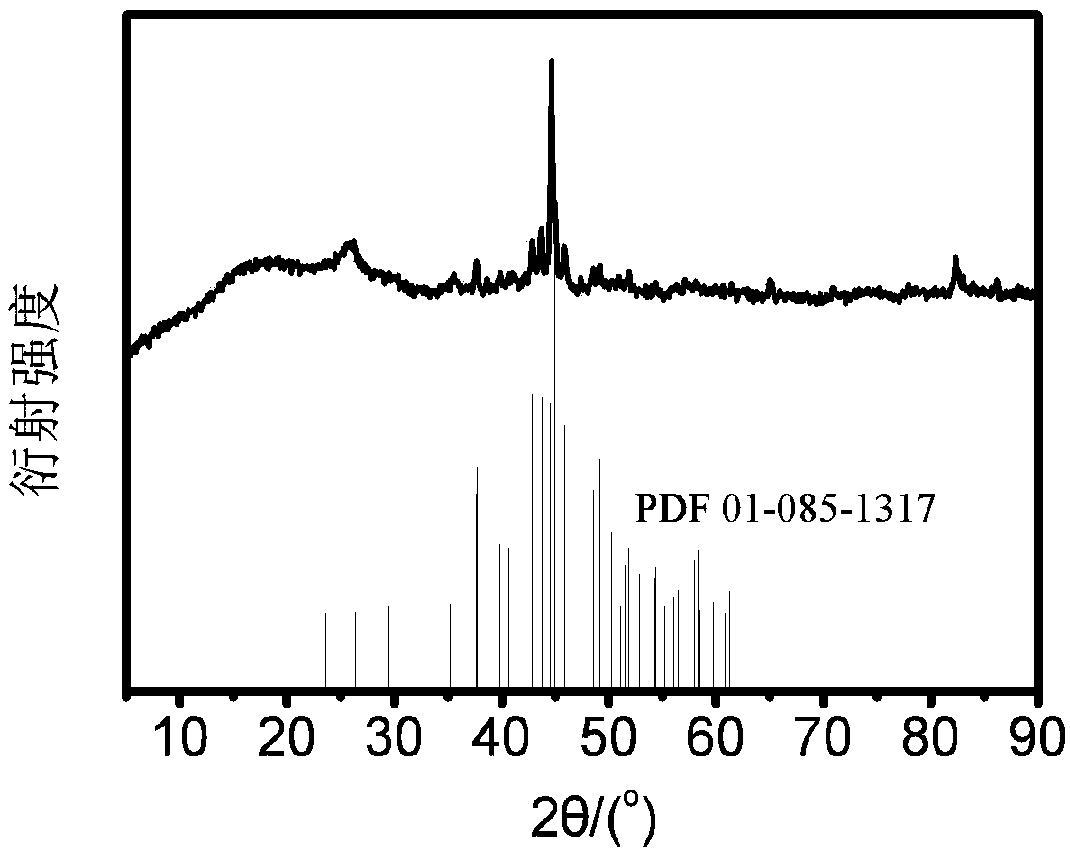

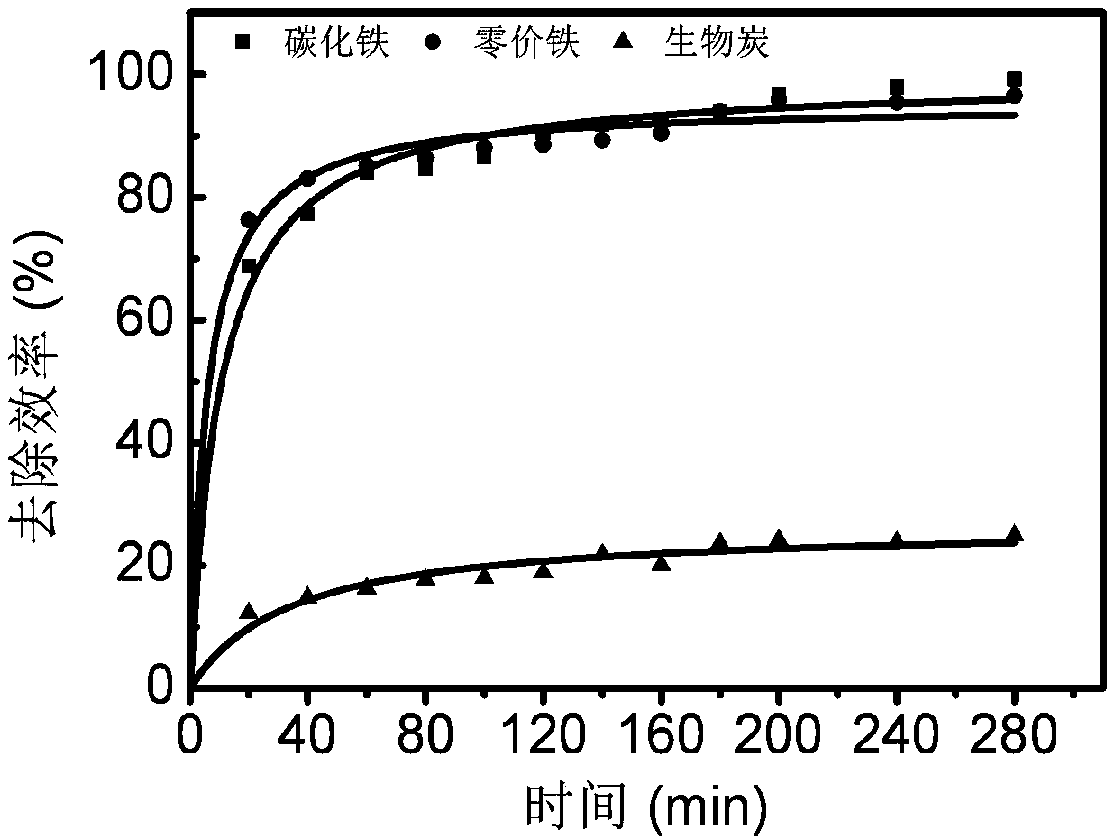

Image

Examples

Embodiment 1

[0038] Example 1 A highly stable biochar-based iron carbide material for degrading dyes, which is made by mixing biomass raw materials and iron precursors at a mass ratio of 1:2.

[0039] Among them: the iron precursor is Fe(NO 3 ) 3 9H 2 O, the biomass raw material is corn stalks.

[0040] The preparation method of the highly stable biochar-based iron carbide material of the degradation dye comprises the following steps:

[0041] (1) Grinding the biomass raw material, activating the raw material with phosphoric acid after the crushing, preparing phosphoric acid-modified biochar, and passing the obtained biochar through an 80-mesh sieve.

[0042] (2) The phosphoric acid modified biochar and the iron precursor were weighed according to the ratio.

[0043] (3) Fully immerse the phosphoric acid-modified biochar in the solution containing the iron precursor, and stir for 20 hours.

[0044] (4) The impregnated mixture was dried in an oven at 105° C. for 48 hours to obtain drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com