Wood-concrete composite beam shear connector pushing-out testing sample

A technology of shear connectors and concrete, which is applied to bridge parts, bridges, bridge construction, etc., can solve the problems of low efficiency of wood and concrete combination, limited shear bearing capacity and stiffness, cumbersome manufacturing and construction process, etc., to achieve Good social benefits and transformation prospects, improved shear strength, and superior structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

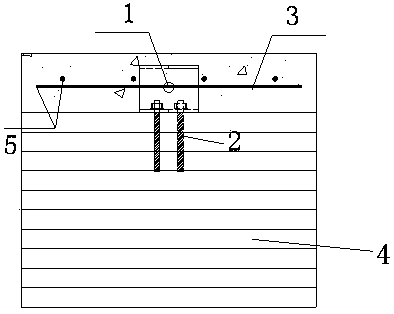

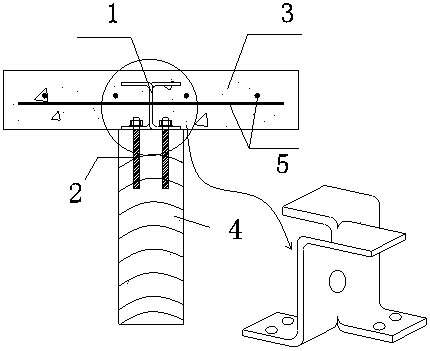

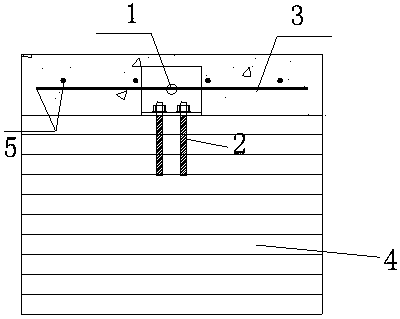

[0038] Such as Figure 1 to Figure 10 As shown, a wood-concrete composite beam shear connector pushes out the test specimen, including a wooden beam 4, a concrete slab 3, a shear connector 1, an anchor 2 and a steel mesh 5, and the shear connector 1 passes through The anchor piece 2 is anchored on the upper part of the wooden beam 4, and the upper part of the wooden beam 4 is laid with a steel mesh 5 through the supporting formwork, and the transverse reinforcement in the steel mesh 5 passes through the reserved space on the shear connector 1. The holes are perforated, and the concrete slab 3 is poured in the formwork with the steel mesh 5 and the shear connector 1 as the skeleton to form a wood-concrete composite beam.

[0039] The shear connector 1 at least includes a web and a bottom plate, the web and the bottom plate are preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com