Warehousing terrace sedimentation control system and construction method thereof

A settlement control and floor technology, which is applied in the direction of foundation structure engineering, soil protection, sheet pile walls, etc., can solve the problems of large floor settlement in storage, reduce foundation settlement, obvious uneven settlement, and improve tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

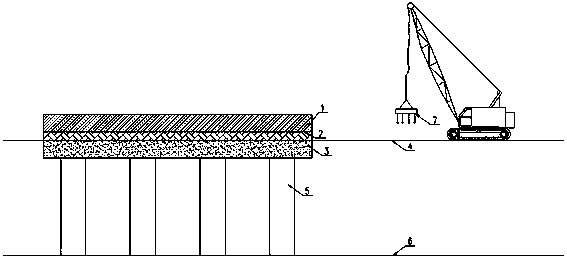

[0027] Such as figure 1 As shown, a storage floor settlement control system includes a floor surface layer 1, a leveling layer 2, a reinforced mattress layer 3 and a reinforced composite foundation; the reinforced composite foundation is sequentially provided with a reinforced mattress layer 3, Leveling layer 2, floor surface layer 1; the reinforced composite foundation is reinforced by combining the deep cement mixing pile method 5 and the dynamic compaction method 7; wherein, the floor surface layer 1 is a steel fiber concrete floor surface layer 1, Its thickness is 195mm-205mm; Described leveling layer 2 is plain concrete leveling layer 2, and its thickness is 95mm-105mm; Described reinforced cushion layer 3 is the geotextile reinforced cushion layer filled with fine sand, and its thickness is 195mm-205mm.

[0028] The embodiment of the present invention is illustrated by taking a large-area heavy-duty warehouse as an example. In this embodiment, the natural foundation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com