Lift facility, belt for such a lift facility, method for manufacturing such a belt, combination of such a belt and method for assembling such a combination in a lift facility

A combination and elevator technology, applied to elevators, applications, belts and other directions in buildings, can solve the problems of increasing belt dynamic load, elevator equipment failure, noise, etc., to reduce shear deformation, improve service life, and suppress vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

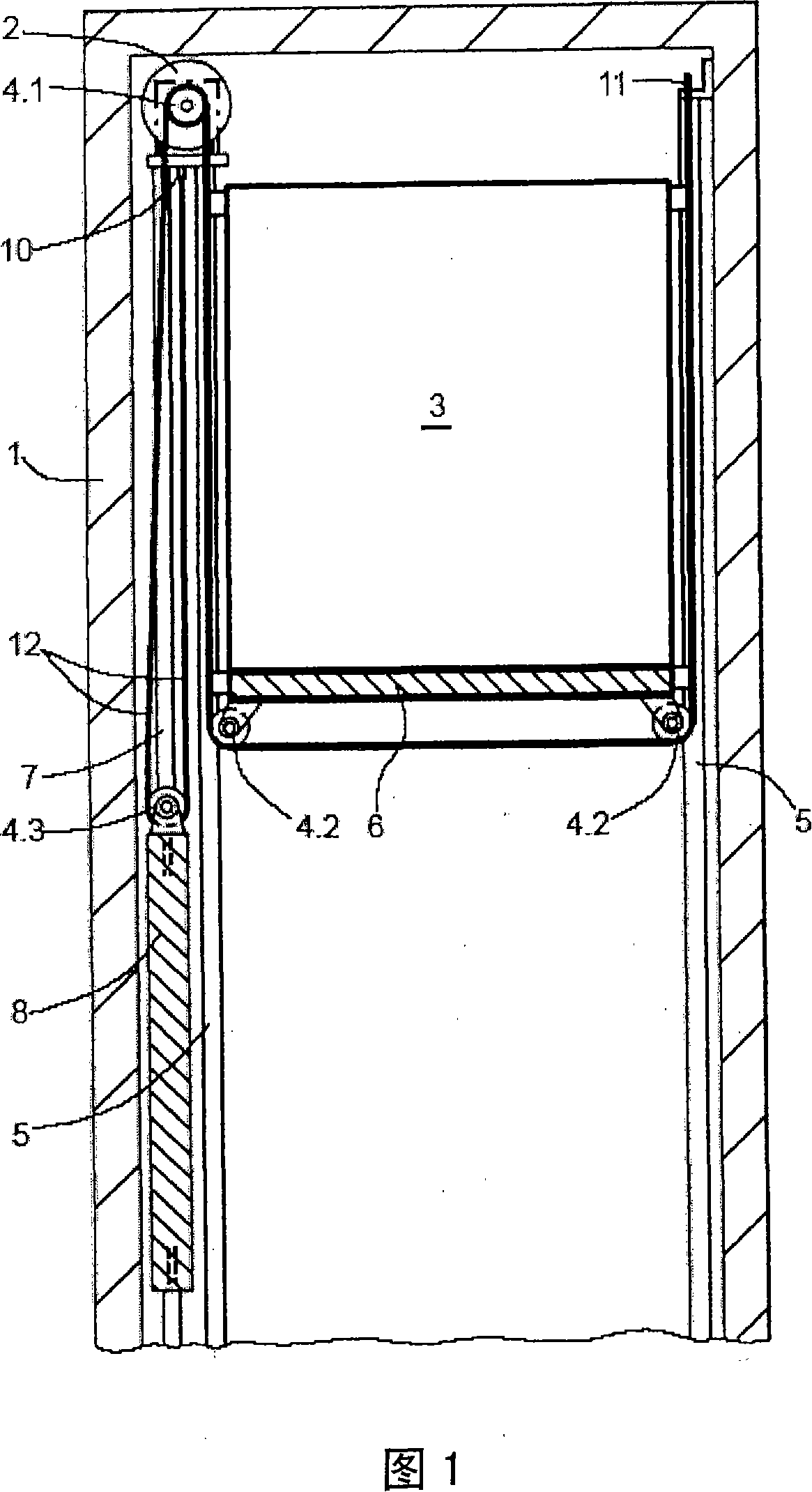

[0048] Figure 1 shows a cross-sectional view of an elevator installation installed in an elevator shaft 1 according to an embodiment of the present invention. The equipment includes: a driving device 2 fixed in the elevator shaft 1, the driving device 2 has a driving pulley or a driving shaft 4.1; the elevator car 3 guided at the car guide rail 5 has a car floor 6 The lower deflection roller, and the deflection roller takes the form of the car support roller 4.2; the counterweight 8 guided at the counterweight guide rail 7 has another deflection roller in the form of the counterweight support roller 4.3; and is configured as a wedge-shaped rib belt The support belt 12 is used for the elevator car 3 and the counterweight 8. This belt transmits the driving force from the drive pulley of the drive unit 2 or the drive shaft 4.1 to the elevator car and the counterweight.

[0049] Below the drive pulley or drive shaft 4.1, one end of the wedge-shaped rib belt 12 is fastened to the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com