Device for solving problem of local differential settlement of pipeline through two rotating compensation devices

A rotary compensator and pipeline technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as uneven settlement, pipeline cracking, etc., and achieve small support, ensure operation, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

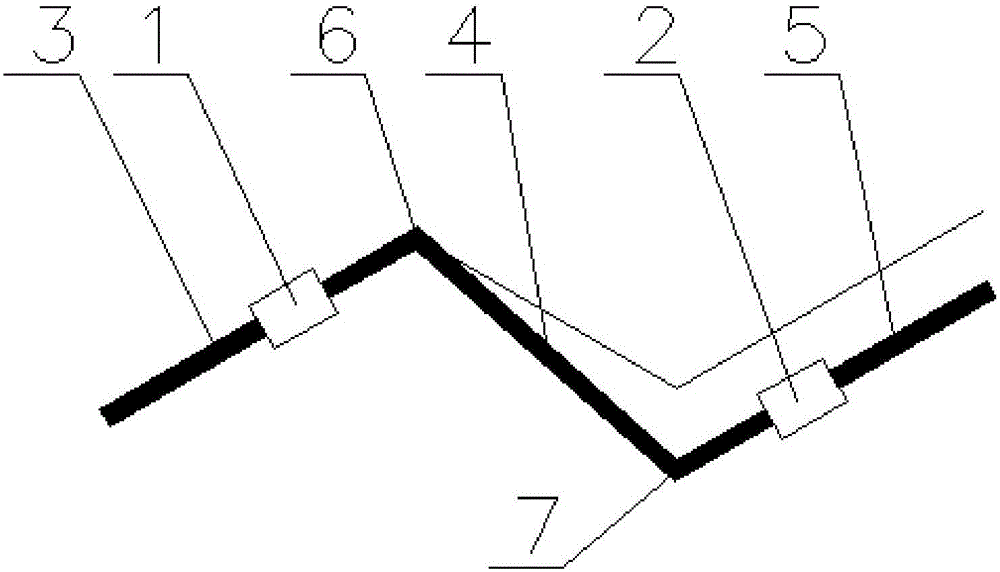

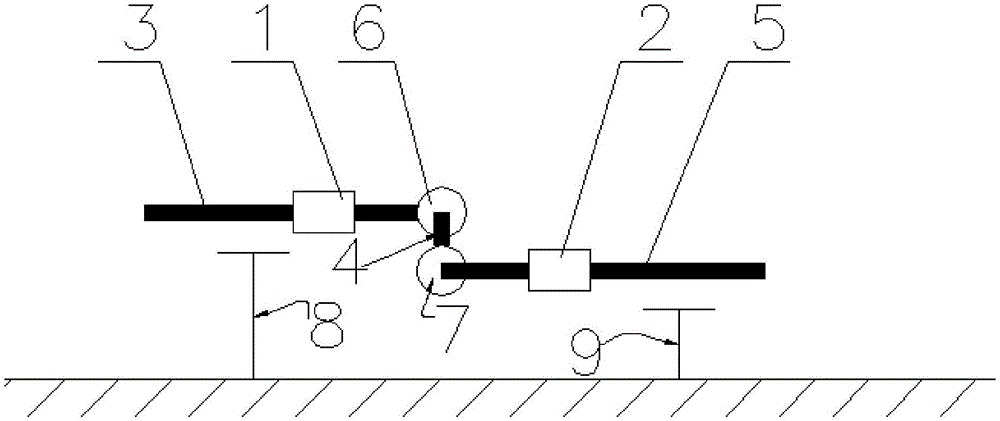

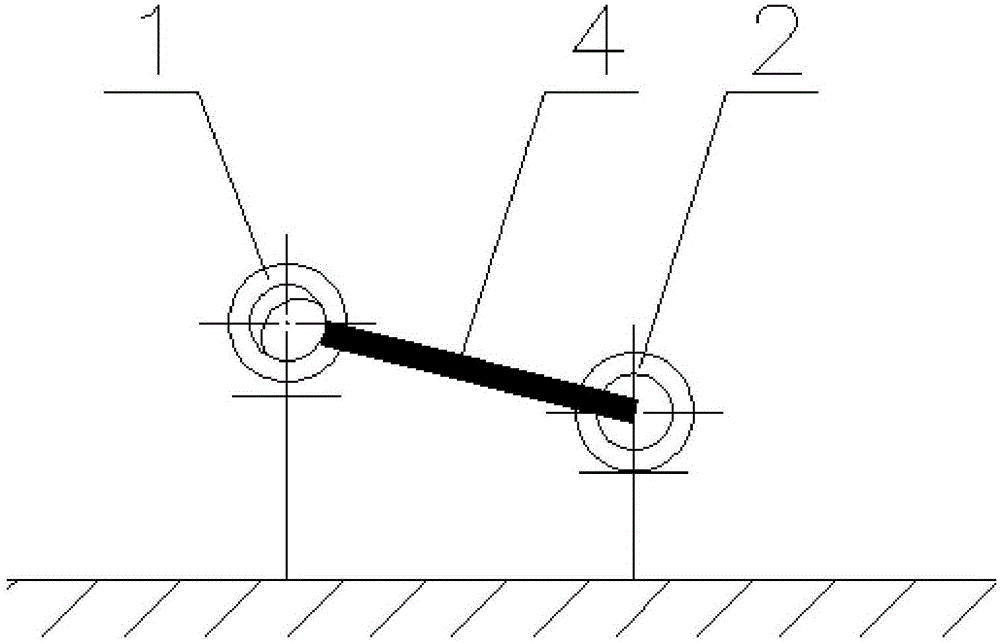

[0031] Such as figure 1 , figure 2 with image 3 Shown: The device adopts two rotary compensators to solve the local uneven settlement of the pipeline. The axes of the first horizontal pipeline 3 and the second pipeline 5 are parallel. The first pipeline 3 is equipped with the first rotary compensator 1 and the second pipeline 5 The second rotary compensator 2 is installed on it, and the axes of the first rotary compensator 1 and the second rotary compensator 2 are guaranteed to be parallel. One end of the first pipe 3 is connected to the short pipe 4 through the first elbow 6 , and one end of the second pipe 5 is connected to the short pipe 4 through the second elbow 7 . Therefore, it is ensured that the first pipeline 3 communicates with the second pipeline 5 .

[0032] The first support 8 with support function is installed under the first pipeline 3, and the first support 8 is installed on the ground surface; the second support 9 with support function is installed at th...

Embodiment 2

[0035] Such as Image 6 with image 3 As shown in the figure, two rotary compensators are used to solve the problem of local non-subsidence of the pipeline. The horizontal first pipeline 3 and the second pipeline 5 are parallel in axis. The second rotary compensator 2 is installed, and the axes of the first rotary compensator 1 and the second rotary compensator 2 are guaranteed to be parallel. One end of the first pipe 3 is connected to the short pipe 4 through the first elbow 6 , and one end of the second pipe 5 is connected to the short pipe 4 through the second elbow 7 . Therefore, it is ensured that the first pipeline 3 communicates with the second pipeline 5 .

[0036] A method for solving local uneven settlement of pipelines by using two rotating compensators, the method includes the following steps:

[0037] 1) Install two pipes and ensure that the axes of the two pipes are parallel to each other;

[0038] 2) Install rotary compensators on the two pipes, and ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com