Patents

Literature

42results about How to "Solve the problem of uneven settlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

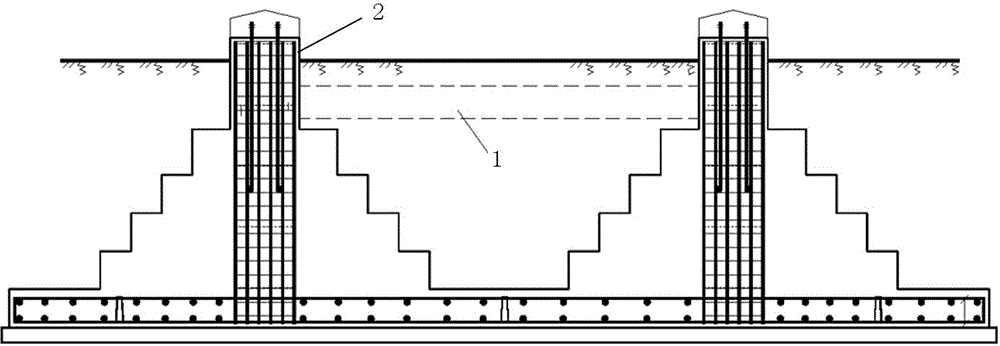

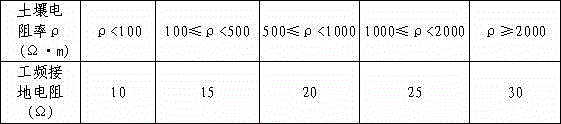

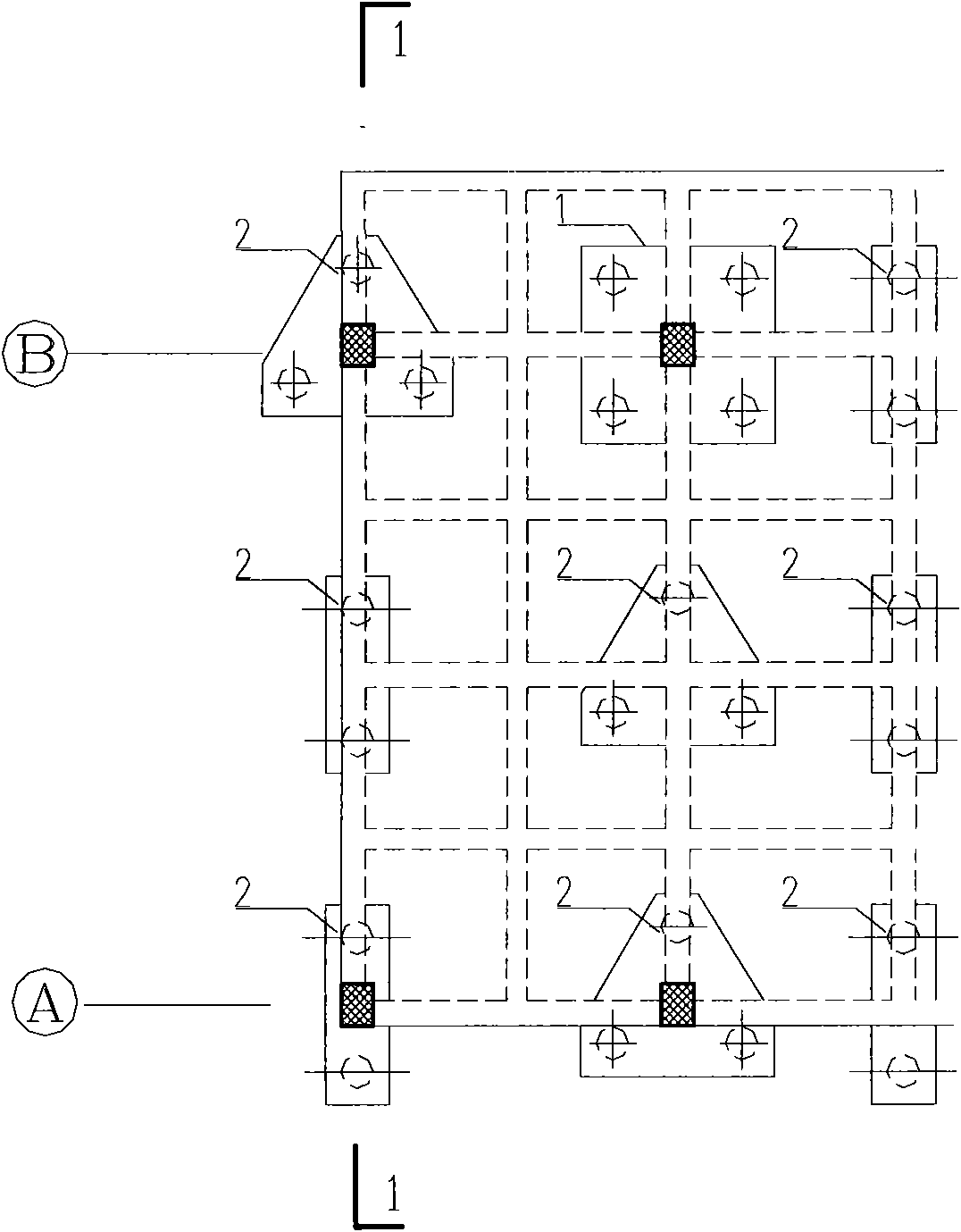

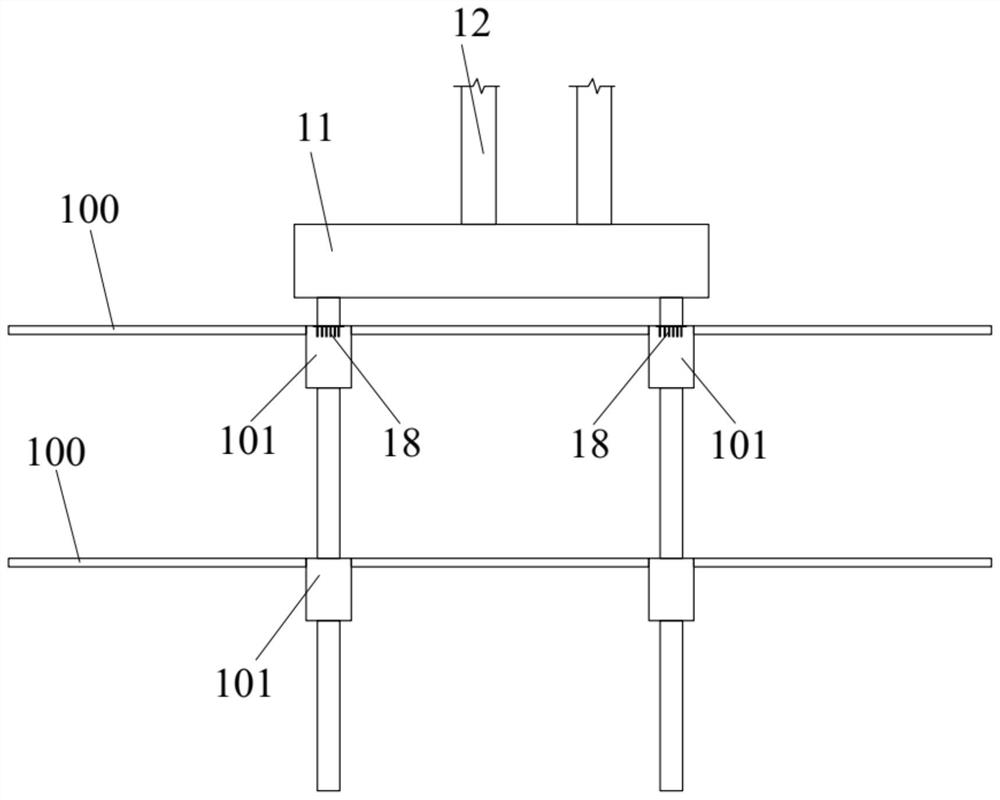

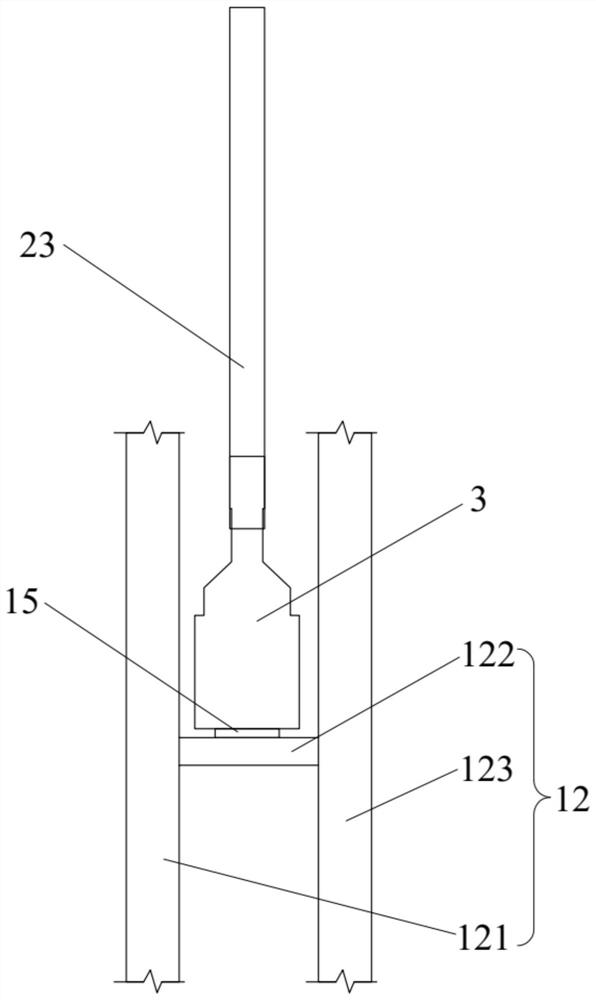

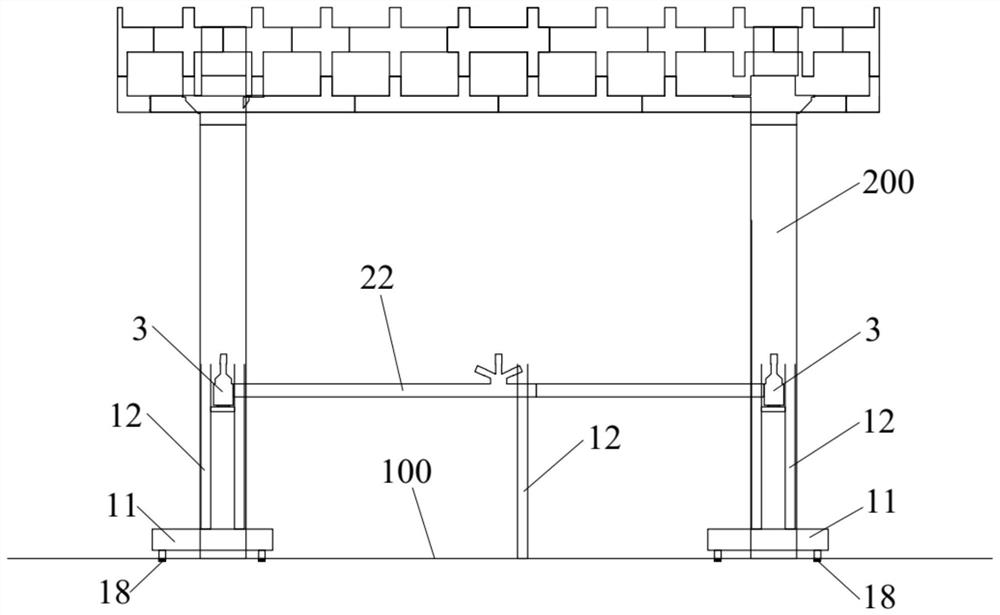

Method for erecting poles and towers of power transmission lines passing through coal gangue area

ActiveCN103266620BAvoid uneven settlementReduce environmental costsFoundation engineeringEngineeringCoal gangue

The invention relates to a method for assembling electric transmission lines through coal gangue area towers. The method comprises that the electric transmission lines are erected according to an overhead method; when the electric transmission lines pass dumping areas, combined step foundations of which foundation pads are connected with column heads through connecting beams serve as tower foundations, and meanwhile, protection slopes and retaining walls are built in a masonry mode; and soil substitutes for silty clay to be tamped, and SDF-I type graphite grounding modules are grounded, so that the towers are grounded. According to the method, paths are reasonable, work periods are short, the investment is low, the implementation and the maintenance are convenient, gaps of erection of the towers under the geological conditions of coal gangue areas are filled, and a solid foundation is laid for providing of technical support for assembly of concrete poles, communication poles, crossing frames, ring-network cabinets and box-type substations and even construction of new substations under the geological conditions of coal gangue, oil shale, strong weathered rocks and the like in the future.

Owner:STATE GRID CORP OF CHINA +1

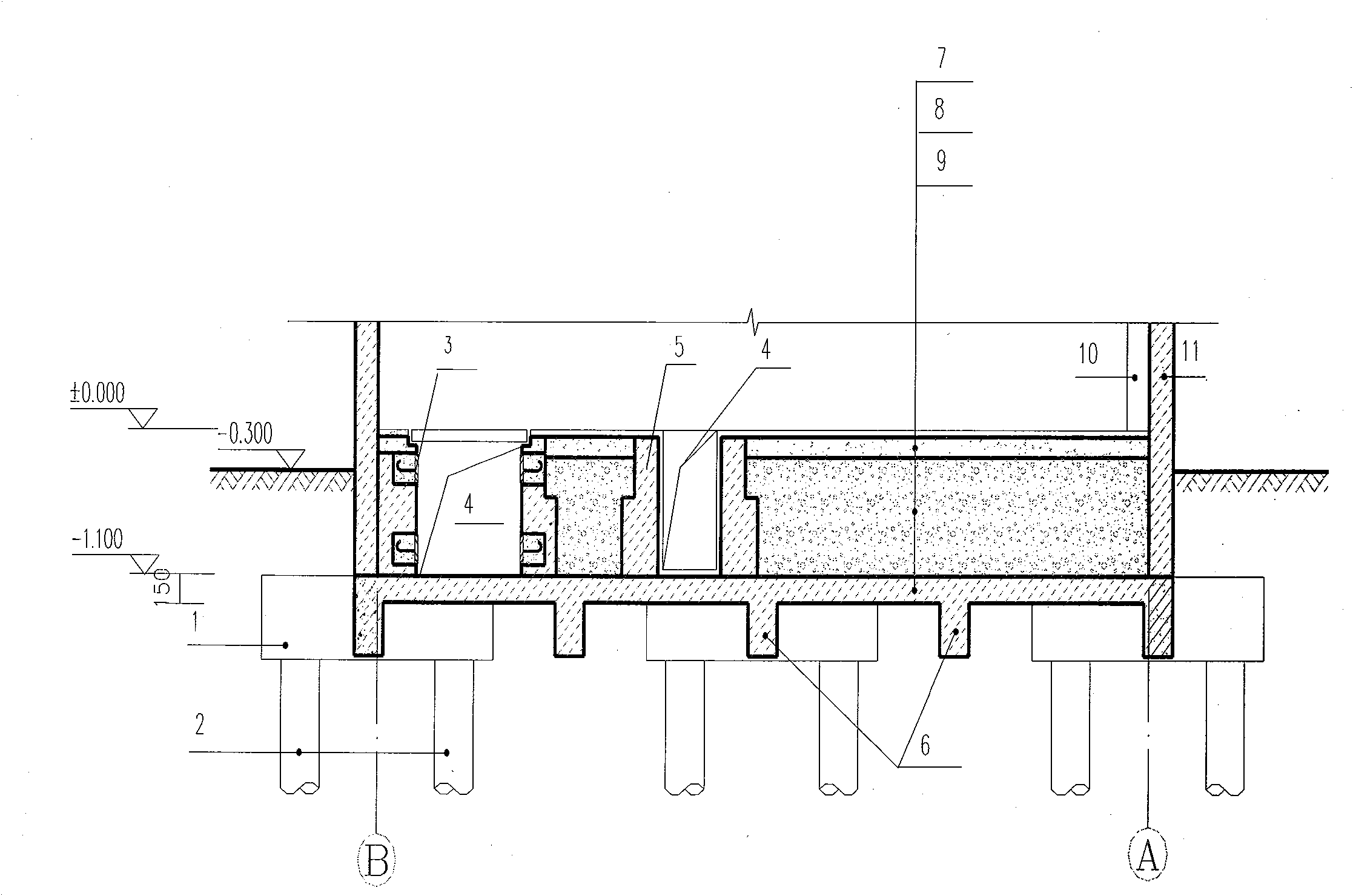

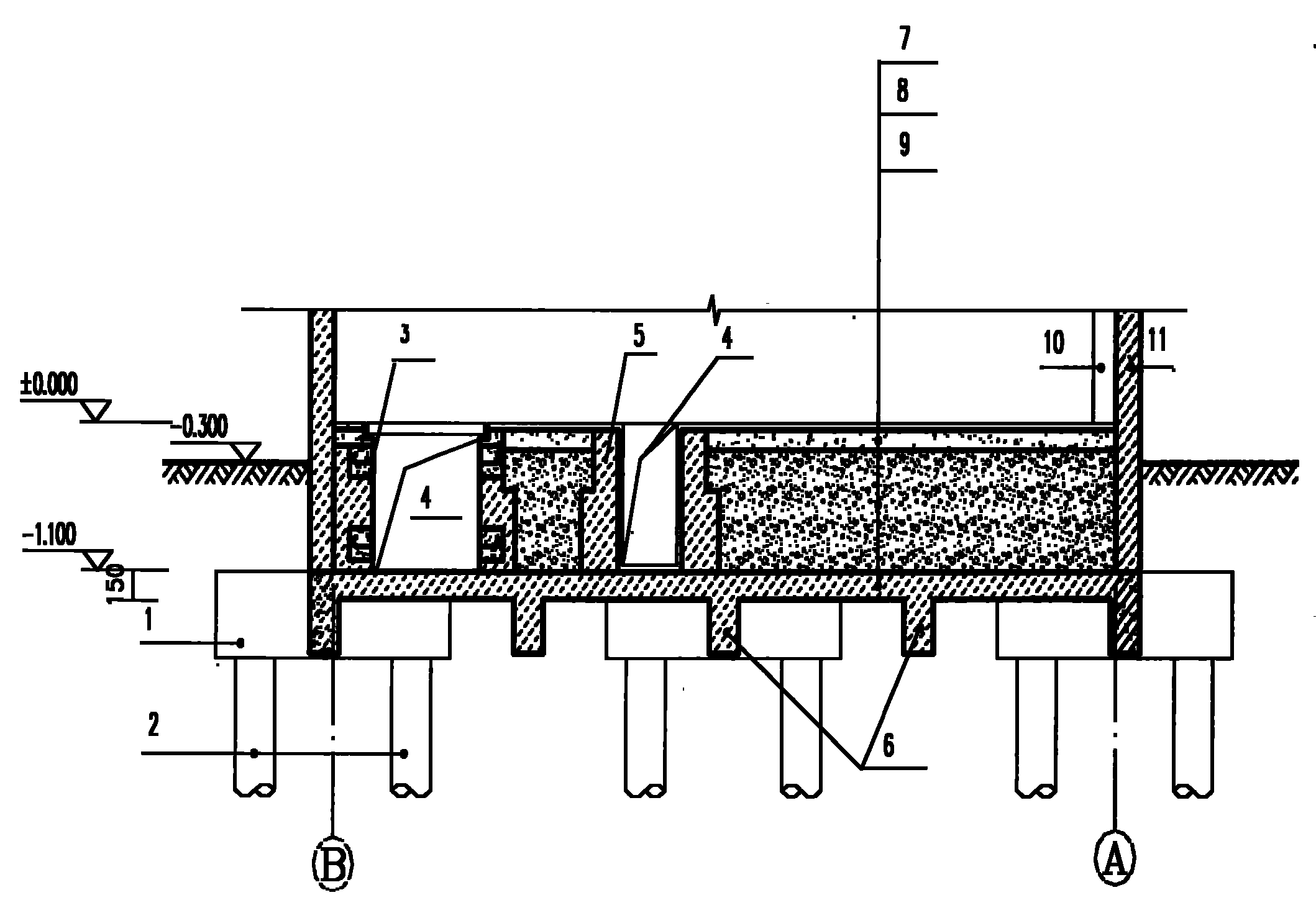

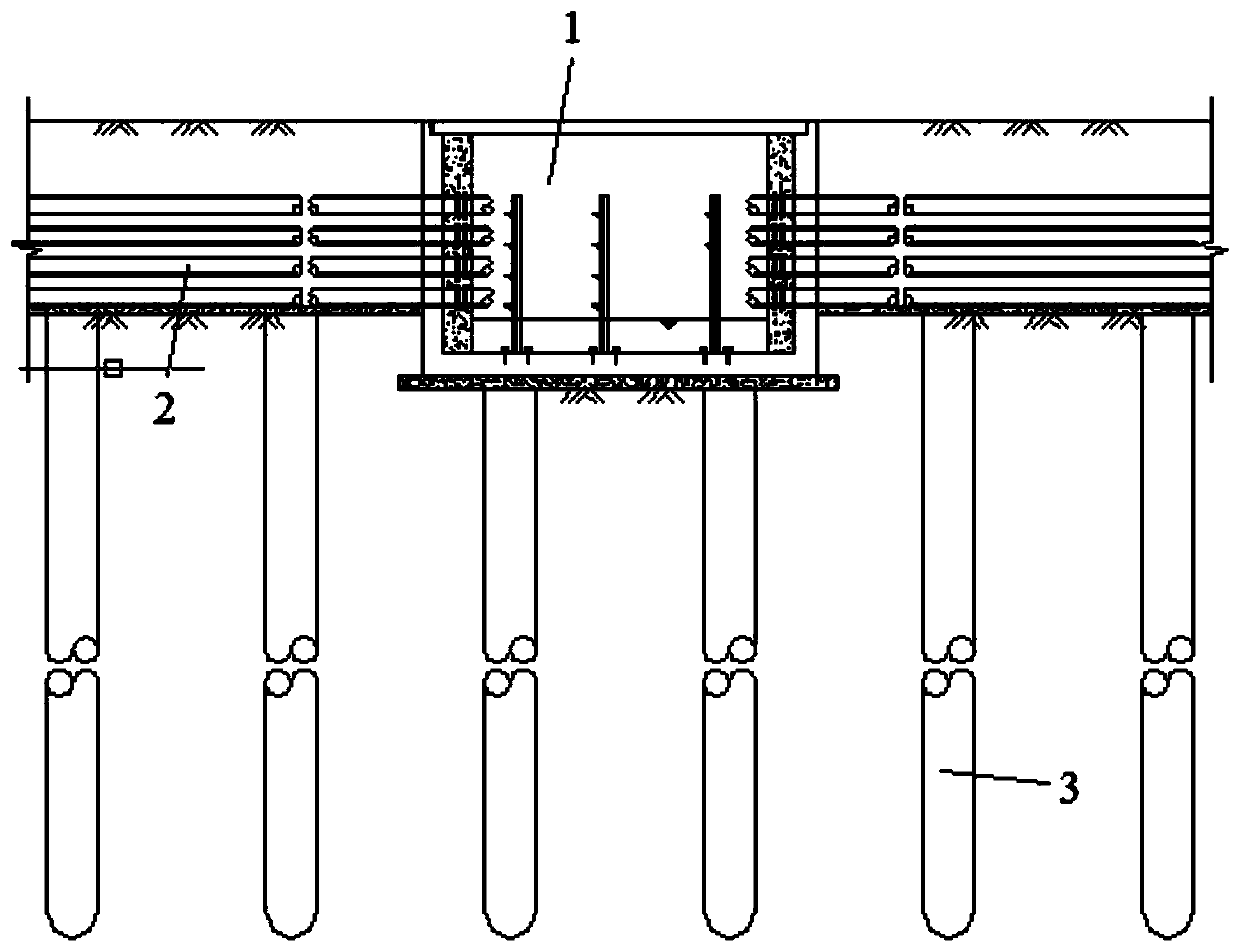

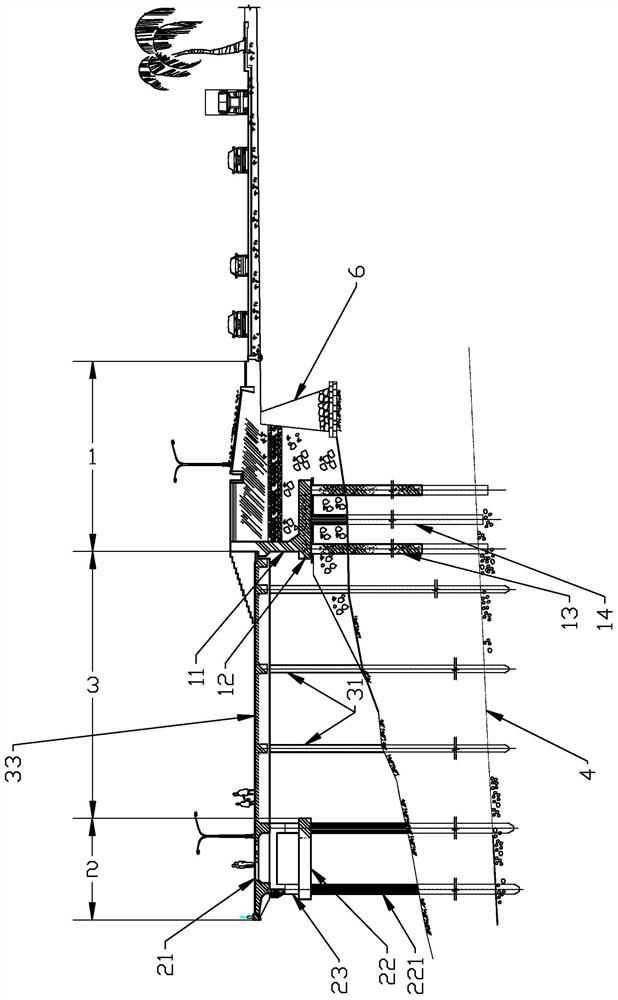

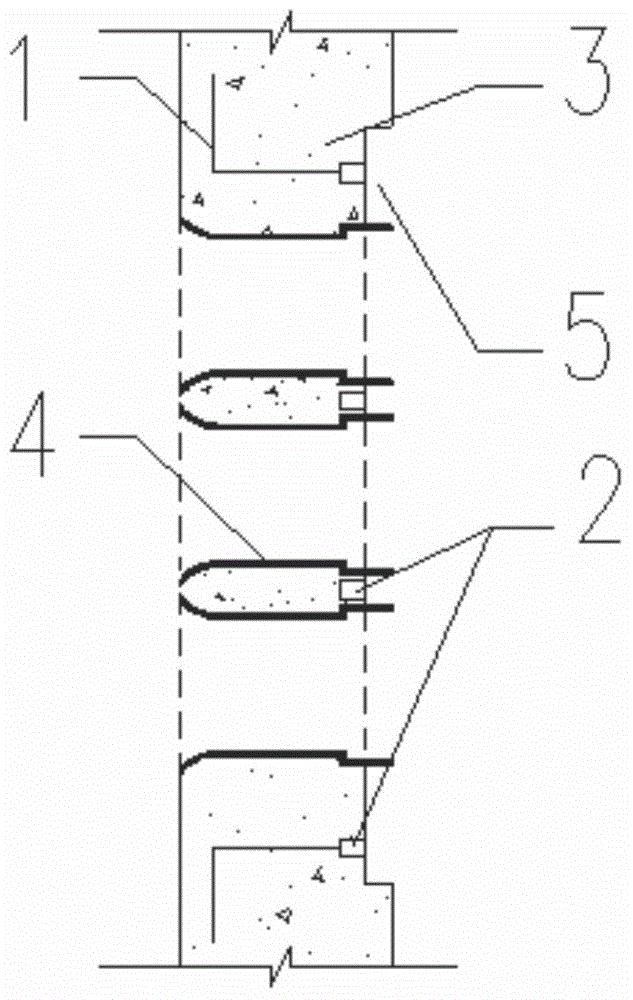

Method for treating bottom structure of building in substation

ActiveCN101967832ASatisfy normal operation and operationSolve the problem of uneven settlementFoundation engineeringReinforced concrete

The invention discloses a method for treating the bottom structure of a building in a substation. In the method, a bearing platform, a foundation beam positioned above the bearing platform and a reinforced concrete board structural layer positioned above the foundation beam are arranged at the bottom of the building. The treatment method is easy to construct and thoroughly solves the problem of the differential settlement of the building bottom in the substation on a soft soil foundation.

Owner:SHANGHAI INTELLIGENCE POWER ENG CO LTD

Application of finished plastic inspection well in outdoor drainage system

InactiveCN102864833APrevent leakageAvoid secondary pollutionSewerage structuresEngineeringBuilding construction

The invention discloses application of a finished plastic inspection well in an outdoor drainage system. The application includes the steps of pit and foundation construction, inspection well connecting pipe mounting, shaft mounting, backfilling, well lid mounting, closed water test and the like. The application of the finished plastic inspection well in the outdoor drainage system is convenient to construct and good in construction quality.

Owner:成张佳宁

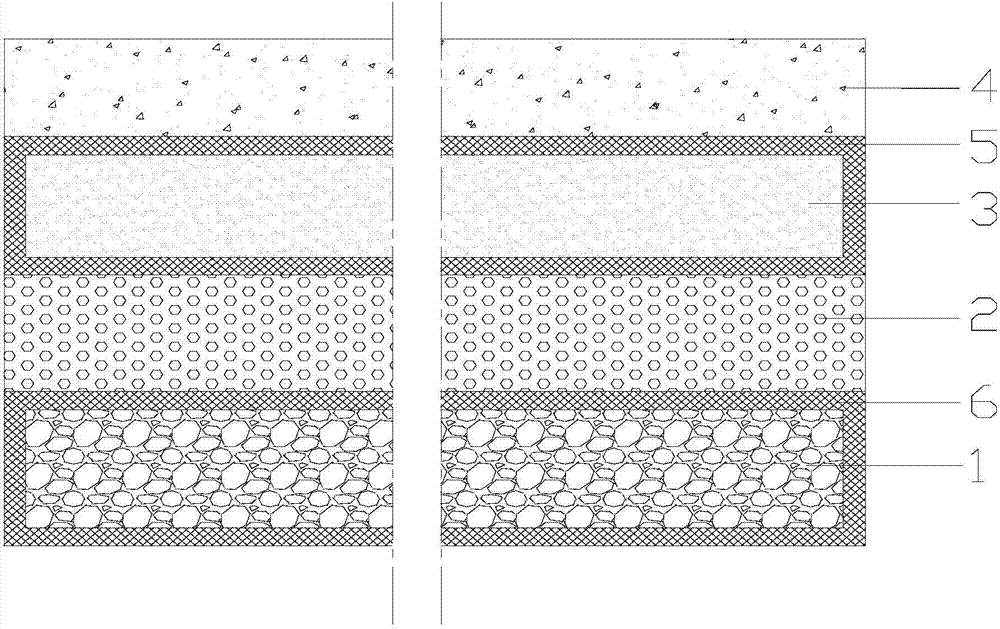

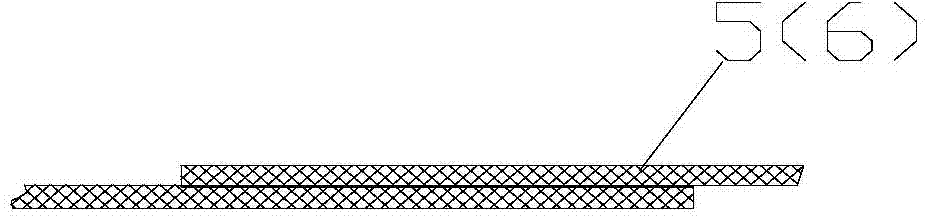

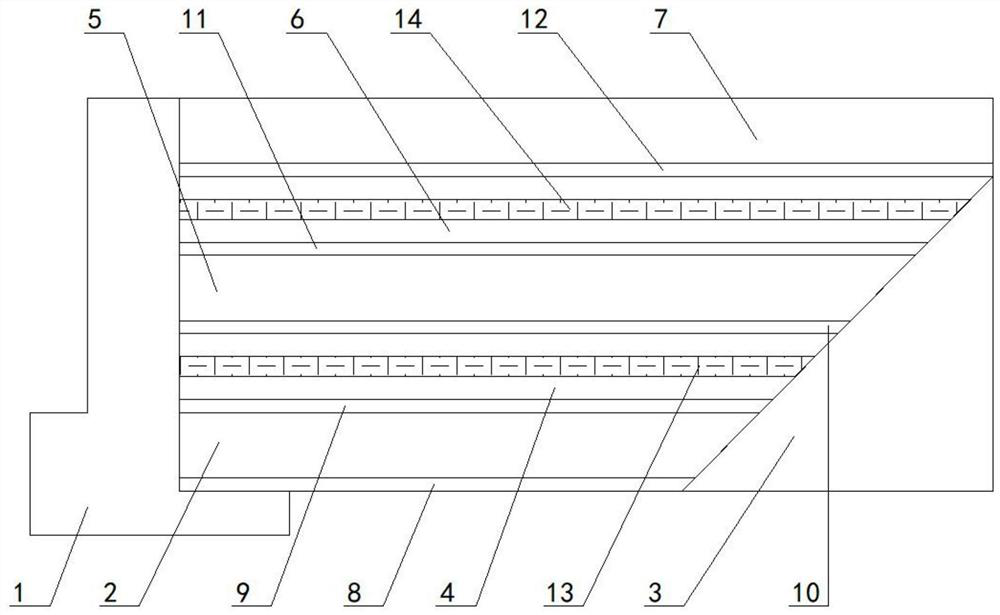

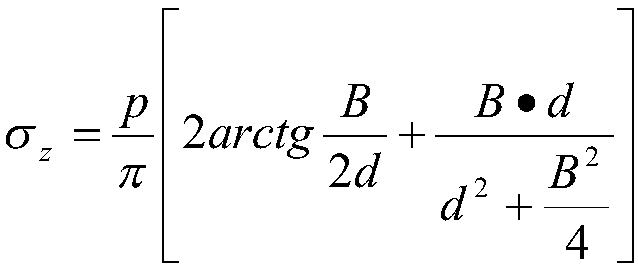

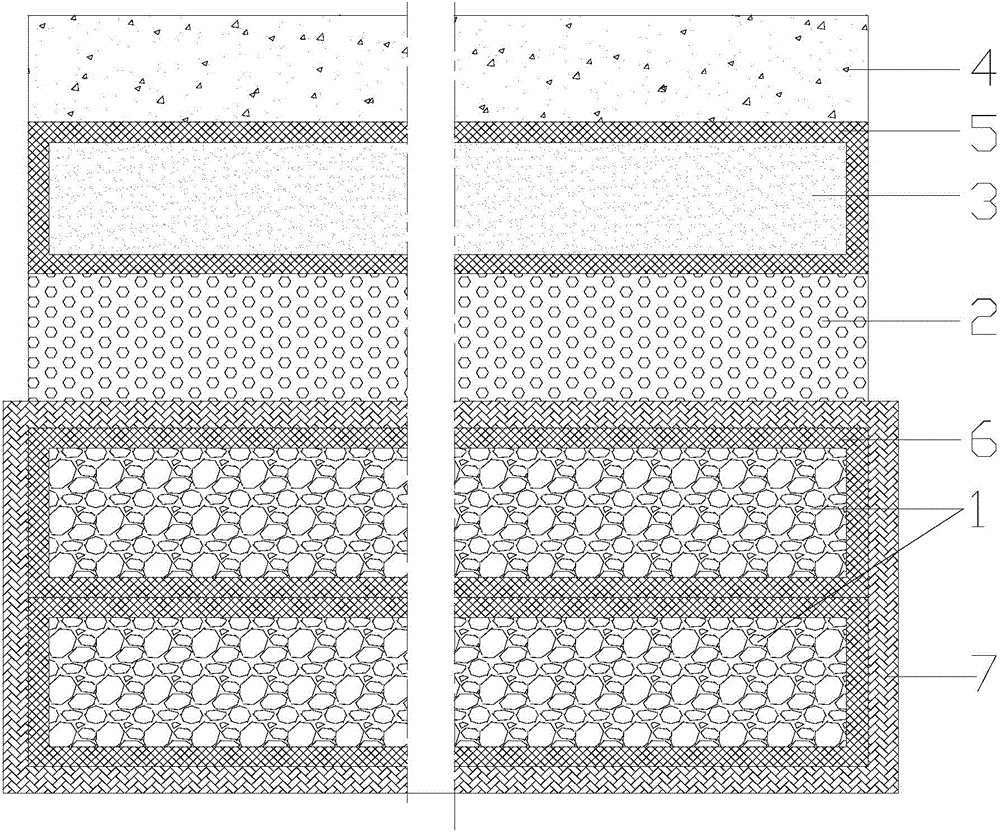

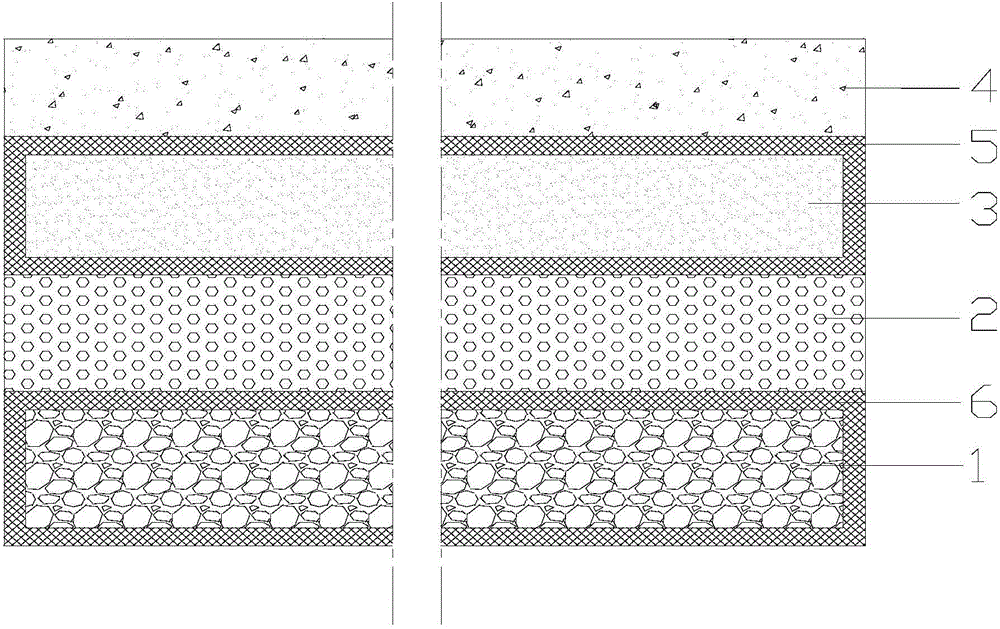

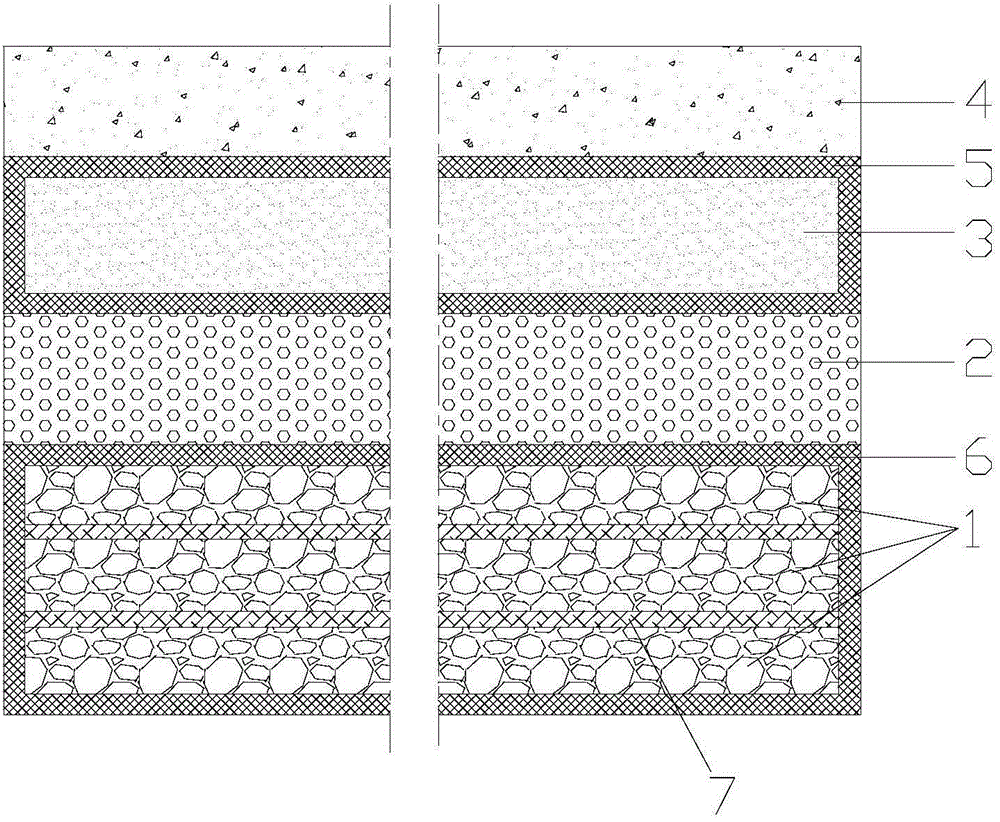

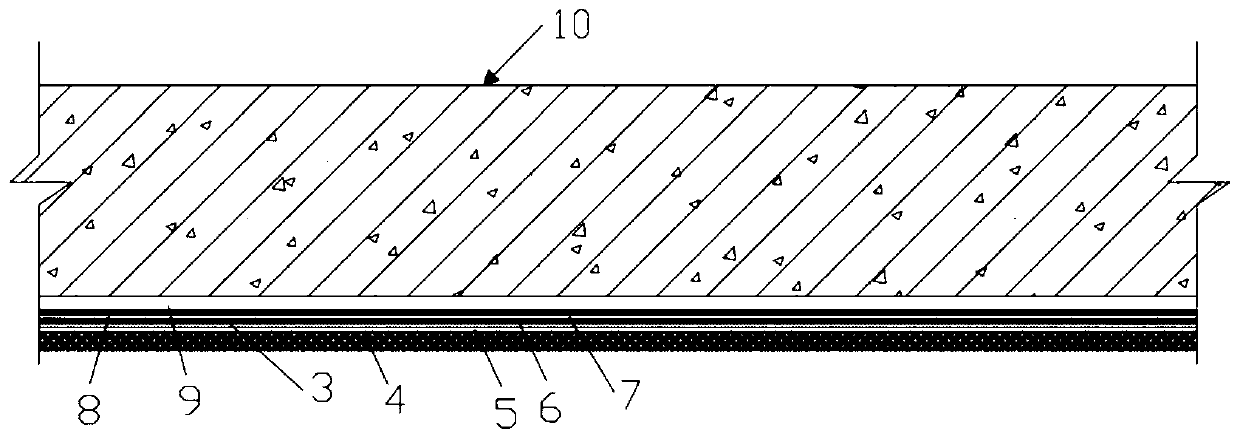

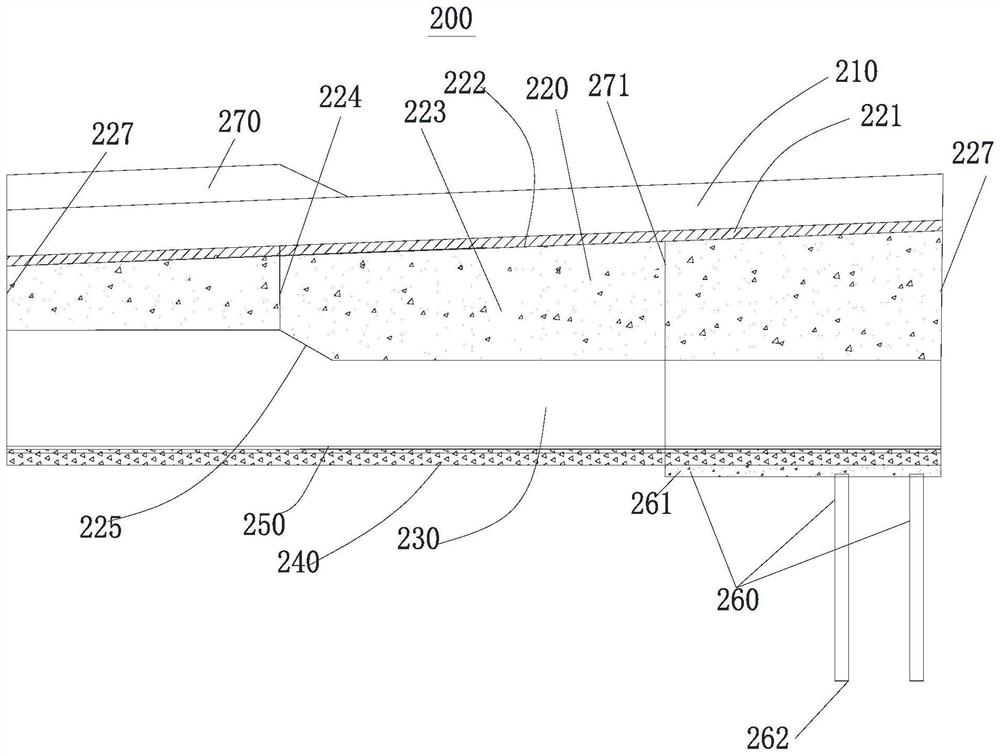

Pavement structure with comprehensive waterproof reinforced roadbed as well as construction method of pavement structure

InactiveCN103541287AImprove bearing capacityImprove stabilityIn situ pavingsClimate change adaptationStructural engineeringRoad surface

The invention provides a pavement structure with a comprehensive waterproof reinforced roadbed as well as a construction method of the pavement structure. The pavement structure comprises a roadbed, wherein the roadbed is fully covered with a roadbed waterproof reinforced layer in a sealing manner. The pavement structure disclosed by the invention blocks water exchange between a roadbed force-bearing layer and the outside while improving bearing force and stability of the roadbed, and not only can prevent bearing force and stability from being influenced by surface water, roadbed side-slope seeped water and underground water which enter the roadbed force-bearing layer and the inside of the pavement structure so as to effectively solve water damages, but also can ensure moisture content control of a roadbed material, so that the roadbed can normally work under optimal moisture content in construction control for long time, thereby avoiding bearing force and stability deterioration as well as severe differential settlement caused by moisture content evaporation loss and non-homogeneous migration of the roadbed; the roadbed moisture content is stably controlled, and roadbed buildings in areas with swelling soil having strong water sensibility, collapsible soil and the like can use local materials sufficiently, so that excavation spoil, filling and borrowing materials and transfer are avoided, thereby not only reducing project cost, but also saving energy and protecting environment.

Owner:CHONGQING JIAOTONG UNIVERSITY

'Three-step three-layer method' landfill filling construction process of dimension stone high-fill dynamic compaction treatment foundation

ActiveCN102561364ADeal with a vast marketSolve the problem of uneven settlementEmbankmentsDynamic compactionNatural material

The invention belongs to the technical field of construction foundation treatment and particularly relates to a 'three-step three-layer method' landfill filling construction process of a dimension stone high-fill dynamic compaction treatment foundation, and the process can be used for solving the problems that the existing dynamic compaction packing layer throwing padding method can not meet the requirements on the uniformity, compactness and stability of the dimension stone high-fill dynamic compaction foundation and therefore causes non-uniform settlement or collapse. The process comprises the following steps of: dividing the foundation into three filling sublayers, using a reverse method to fill a first sublayer, and forming natural material piles which are intersected; using a forward method to fill a second sublayer on the natural material pile surface of the first sublayer, unloading paddings to recessions among the material piles of the first sublayer and coarsely flatting; and filling a third sublayer in a reverse manner on the stratification plane of the second sublayer after coarse flatting, and discharging and leveling so as to form a dynamic compaction packing layer. The process provided by the invention has the beneficial effects of effectively solving the problem of non-uniform settlement of the foundation due to padding isolation, poor gradation and uncompacted grains easily caused when the throwing padding method is adopted for a dimension stone high-fill dynamic compaction foundation filling body.

Owner:山西机械化建设集团有限公司

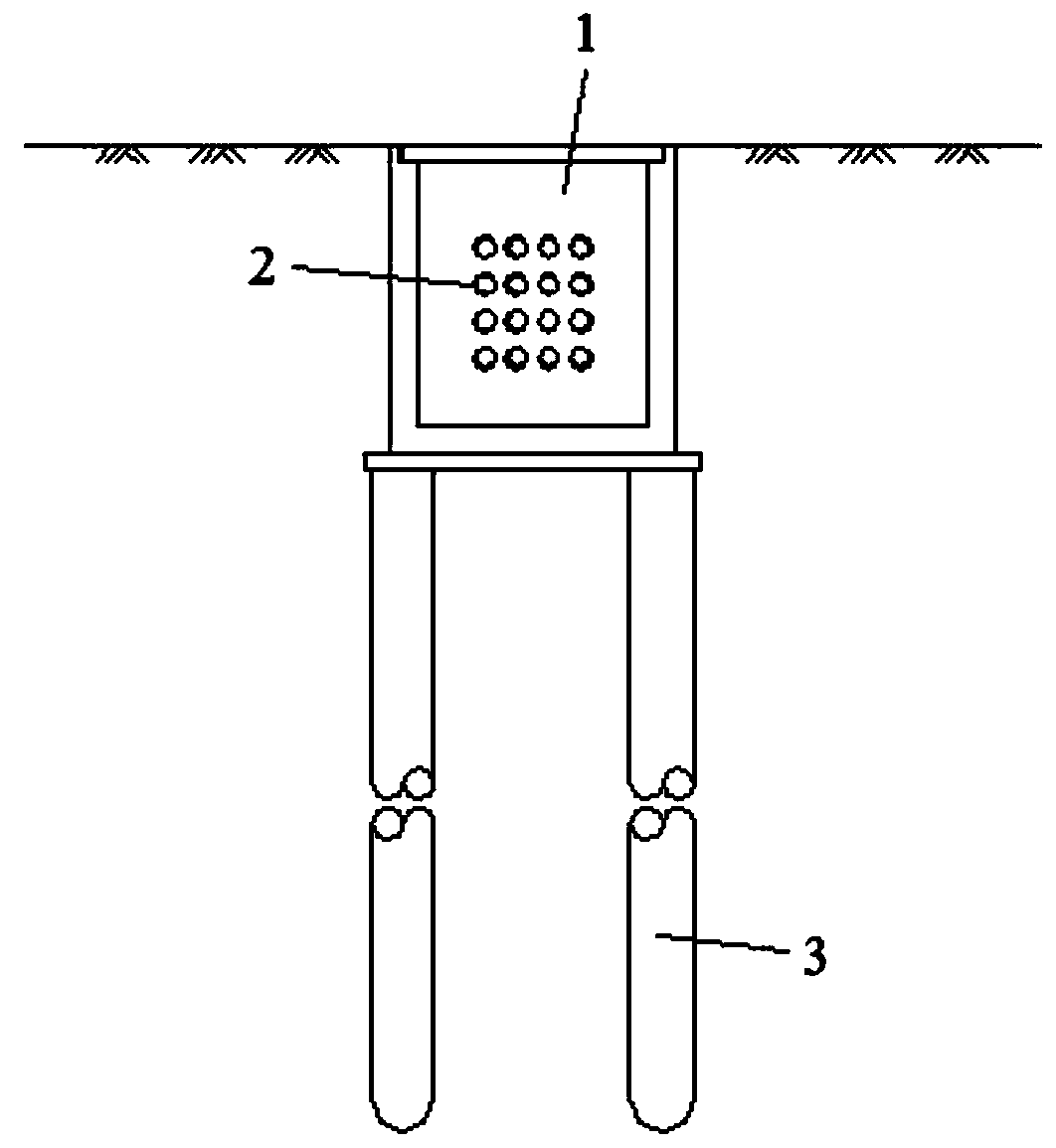

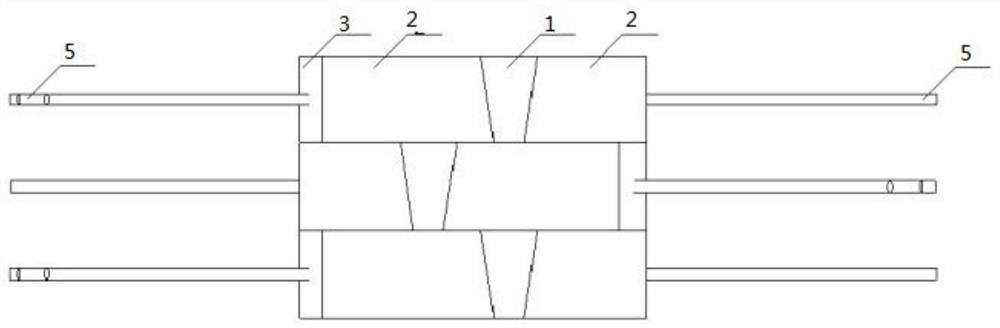

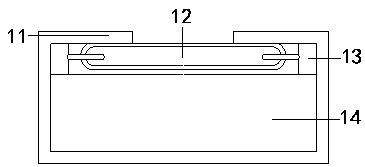

Cable working well

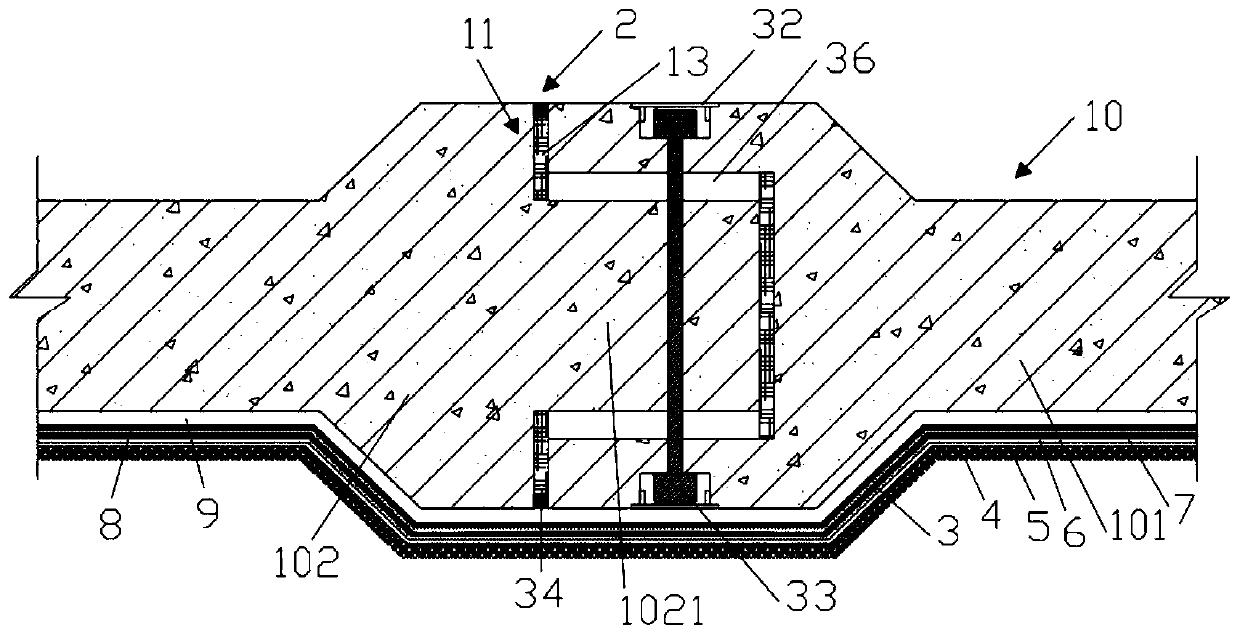

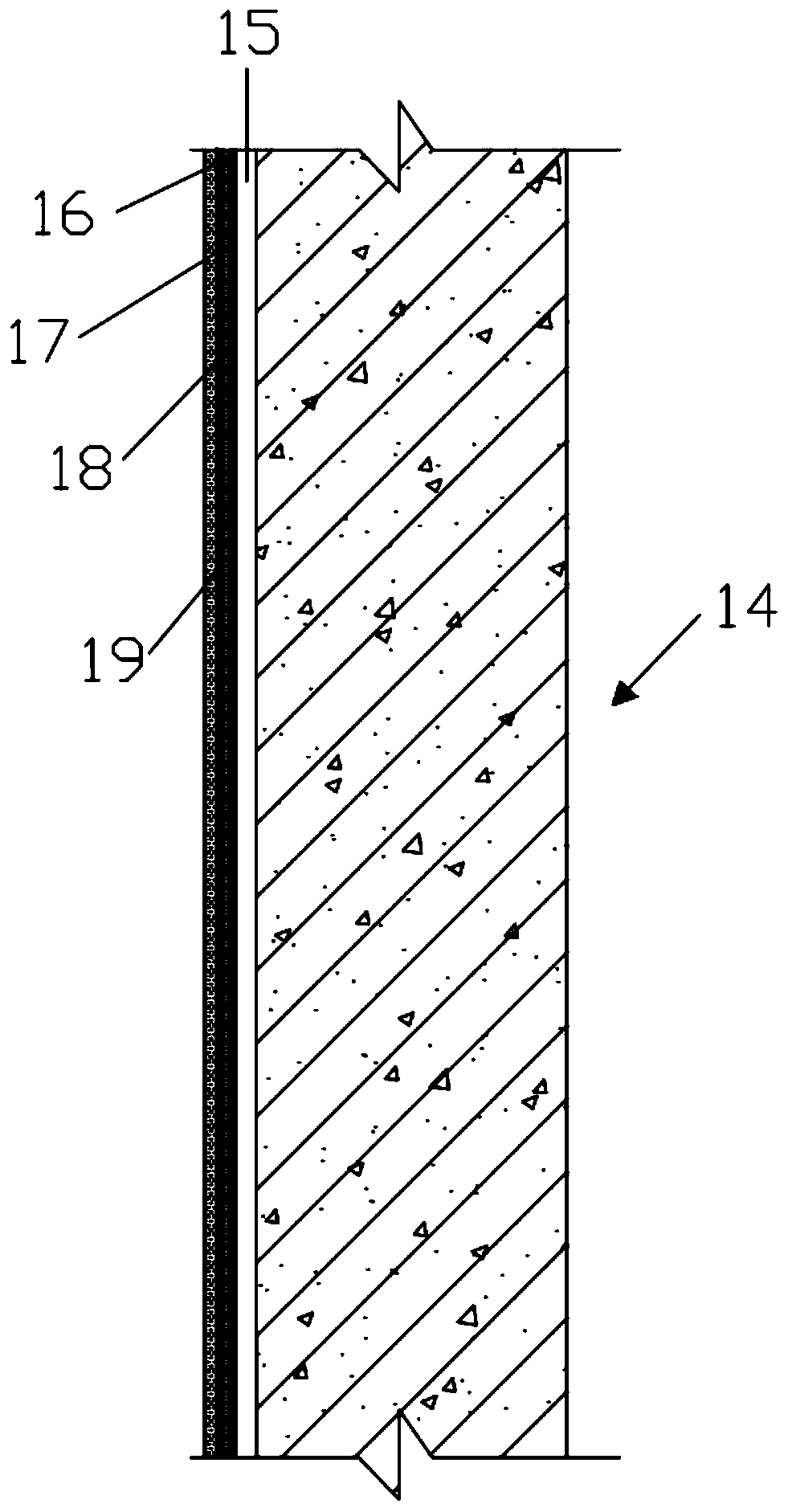

PendingCN110943422ASolve the problem of uneven settlementEasy constructionCable installations in cable chambersCable installations in underground tubesEngineeringStructural engineering

The invention relates to a cable working well which comprises a bottom plate, a side wall and a cover plate which define a space in the well, the side wall is used for being connected with a cable duct bank, the bottom plate is provided with an outwards-extending part extending out of the outer edge of the side wall in the extending direction of the cable duct bank, and the cable duct bank furthercomprises a balance part arranged on the outwards-extending part of the bottom plate and used for balancing stress and supporting the cable duct bank. According to the invention, the problem of differential settlement between the cable duct bank and the cable working well can be well solved, the construction is convenient, the period is short, and the required investment is less.

Owner:苏州电力设计研究院有限公司

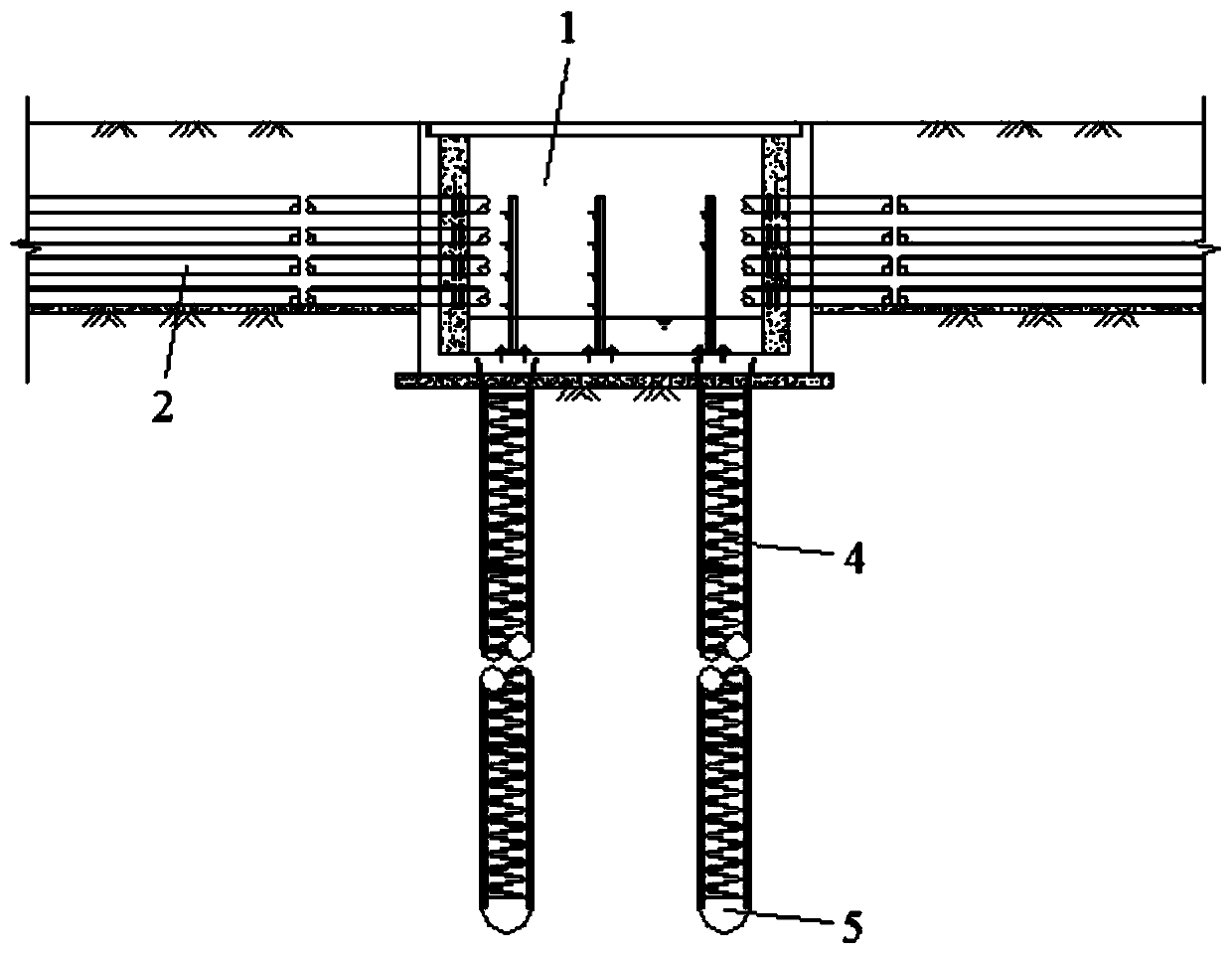

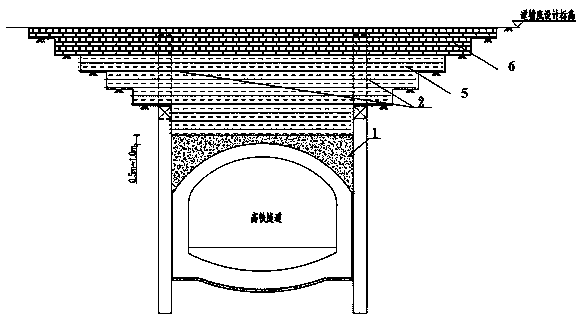

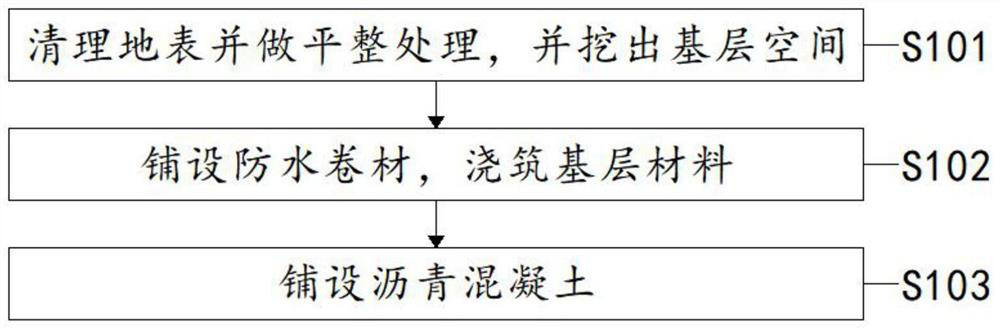

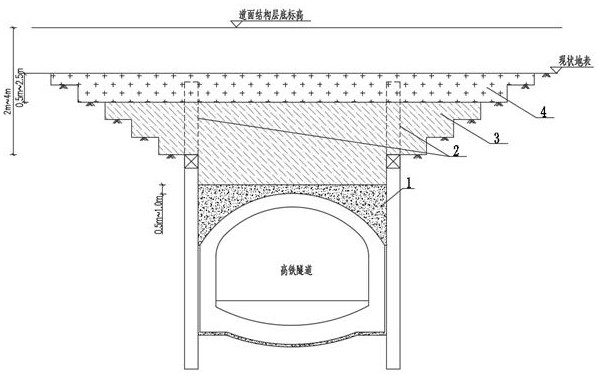

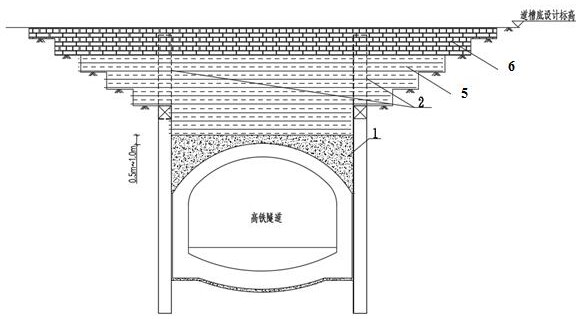

A non-uniform settlement control structure for an airfield pavement roadbed passed by a high-speed rail tunnel and a construction process

The invention discloses a construction process of a non-uniform settlement control structure for an airfield pavement roadbed passed by a high-speed rail tunnel. The construction process comprises thefollowing steps: cleaning and leveling a construction site, and pouring plain concrete; dismantling part of foundation pit maintenance walls; filling a plain soil above the plain concrete in a layered mode, pouring a foam light soil foundation on the plain soil in a segmented, partitioned and layered mode, or laying reinforced soil layers in a layered mode, laying geogrids between the reinforcedsoil layers in a layered mode, laying geocells on the reinforced soil layers in a layered mode, laying broken stones on the geocells, and setting a plurality of deformation joints in the longitudinaldirection; carrying out construction of a pavement structure layer and other ancillary facilities, and forming the roadbed non-uniform settlement control structure after the construction process is finished. The construction process has the advantages that the overall uniformity of the soil foundation is improved, and the non-uniform settlement volume of the soil foundation is adjusted; the construction process is convenient, the construction period is shortened and the problem of uneven settlement of the roadbed when the high-speed rail tunnel passes through the airfield pavement is successfully solved.

Owner:TONGJI UNIV +2

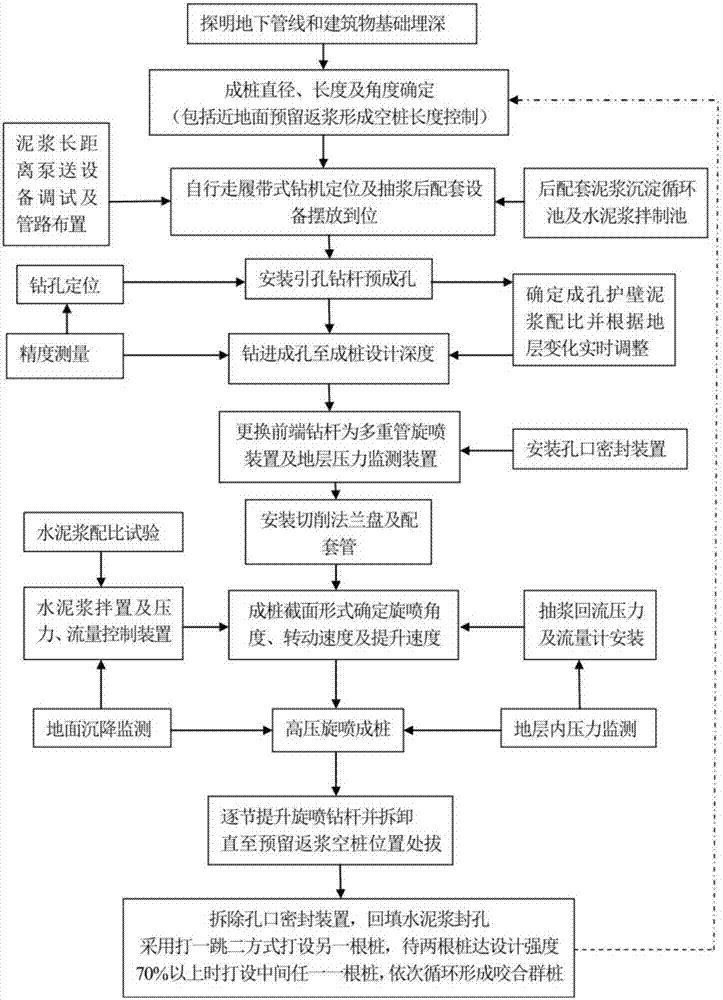

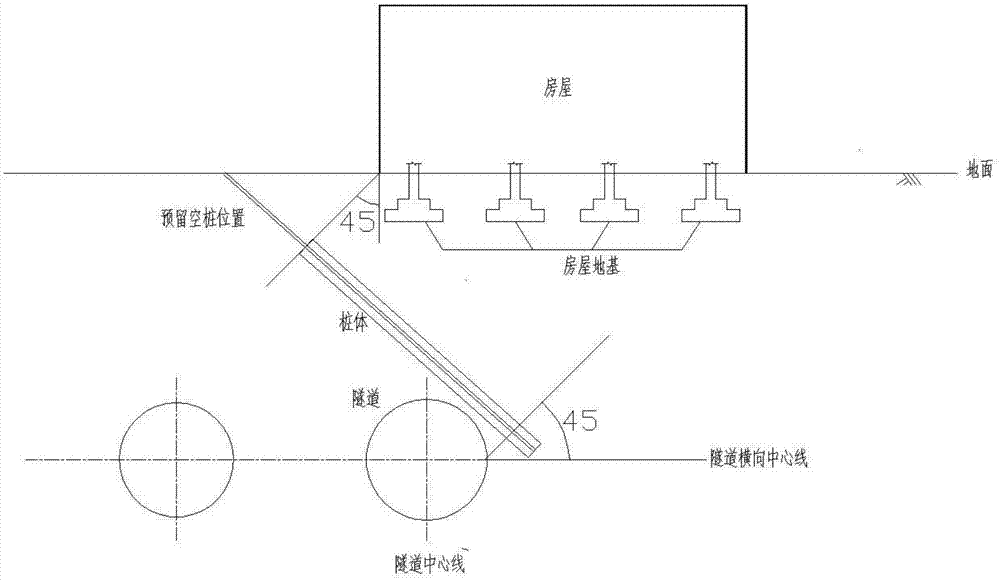

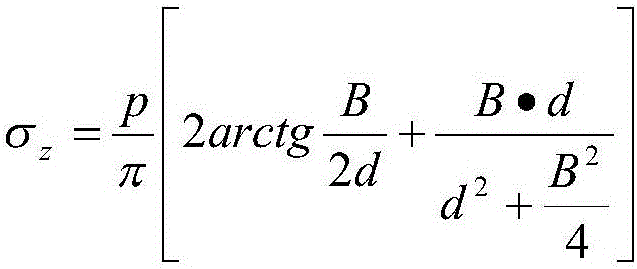

Weak perturbation inclined rotary jet group pile occlusion strengthening method used for shield passing underneath house

InactiveCN107152042ASolve the problem of uneven settlementProtection hysteresisFoundation repairBulkheads/pilesGround subsidenceSlurry

The invention discloses a weak perturbation inclined rotary jet group pile occlusion strengthening method used for a shield passing underneath a house. The method includes the steps that the driven position, the pile forming angle, the driven depth and the reserved empty pile position of a rotary jet pile are determined according to the position relationship of the house and a tunnel; the hole drilling parameter is determined, and an inclined hole is drilled; the ground initial height within a preset scope is detected; and the lower portion of a drilling rod is driven into the inclined hole for rotary jet pile construction, the drilling rod at least comprises one suction multiple pipe, the ground height is detected in real time in the work progress, if the rising amount of the ground height of any position within the preset scope is larger than a first threshold value, the suction multiple pipe is used for slurry pumping until the ground height does not rise any more, and if the falling amount of the ground height of any position within the preset scope is smaller than a second threshold value, the suction multiple pipe is used for injecting water or air until the ground height is not reduced any more. By means of the weak perturbation inclined rotary jet group pile occlusion strengthening method, stratum disturbance influences can be reduced to the maximum degree, the technological process is simple, and ground subsidence caused by the shield underneath pass house can be effectively reduced.

Owner:CCCC SECOND HARBOR ENG

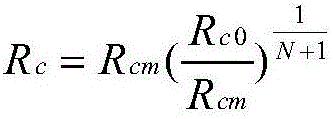

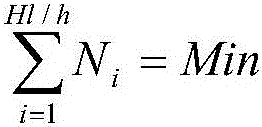

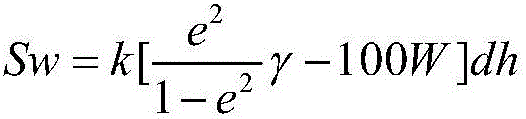

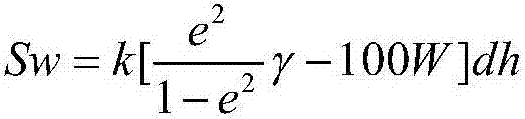

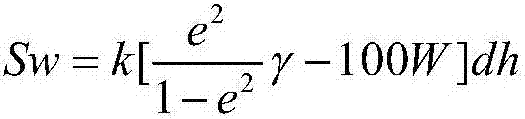

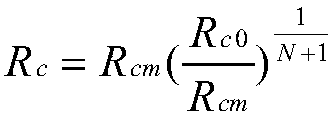

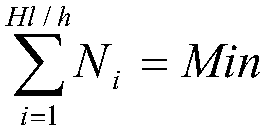

Optimal filling thickness control method for coal gangue

ActiveCN105917777ASolve control problems of unfavorable engineering characteristicsSolve the problem of uneven settlementSoil-working methodsCoal gangueInstability

The invention relates to an optimal filling thickness control method for coal gangue and belongs to agricultural reclamation methods for the coal gangue. The control method comprises the steps: under the condition of selected compacting equipment, firstly, determining critical layering thickness of the coal gangue, then, determining the optimal layering thickness according to an object function model with minimal total compacting times, and finally, calculating filling super high amount; and during construction, carrying out filling by adopting a strip stacking method, and controlling the quality of filling and compacting by adopting a leveling method. The method has the advantages that uniform-thickness layered filling is carried out, and thus, the filling effect is the best; and the uniformity is guaranteed to the maximum, the compacting times are reduced to the maximum, the instability and non-uniform settlement of the gangue are lowered, and the leveling of farmland is guaranteed. Critical thickness control is carried out; during the layered filling, the filling thickness cannot exceed critical thickness, so that the control method is the most effective control method for disadvantageous engineering characteristics of the gangue, and disadvantageous characteristics such as weathering, swelling-shrinkage, spontaneous combustion and corrosion of the gangue are effectively controlled. The filling cost of the coal gangue is reduced; and on one hand, the engineering quality is guaranteed, and on the other hand, the engineering cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

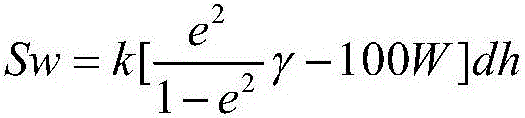

Moist curing method for accelerating subsidence and stability of coal gangue filling reclamation

ActiveCN105798052ASolve the problem of uneven settlementAccelerated settlementSolid waste disposalForest industryWater table

The invention provides a moist curing method for accelerating subsidence and stability of coal gangue filling reclamation, and belongs to the method for agricultural or forestry reclamation of coal gangues. The moist curing method comprises the following steps: after filling a subsidence land by using the coal gangues, consciously filling water to soak a coal gangue aggregate, and accelerating subsidence and stability of the coal gangues; and stripping collapse surface soil by 1.0 meter at first before the rainy season, pouring the coal gangues in a collapse pit until the distance from the coal gangues to an earth surface by a designed elevation, leveling a coal gangue site, filling water in the site until coal gangue bodies are submerged, maintaining until the rainy season is finished, compacting for 4-5 times by using compacting equipment, and finally refilling the collapse pit by using the surface soil and leveling the site. The moist curing method has the advantages that (1) the collapse pit is refilled with the coal gangues at a time, and layered filling compaction is not required, so that reclamation cost is greatly reduced; (2) adverse effects of hydrophilic substances in the coal gangues to subsidence are eliminated, uniformity of subsidence is guaranteed to a maximum extent, compaction times are reduced, and leveling of a farmland is guaranteed; and (3) effects of rising and falling of groundwater level to coal gangue filling reclamation lands are reduced.

Owner:CHINA UNIV OF MINING & TECH

Down-the-hole hammer and guide hole matched construction method for vibro-replacement stone column composite foundation

InactiveCN105862708AImprove bearing capacitySolve the problem of uneven settlementSoil preservationCrushed stoneEngineering

The invention discloses a construction method of a vibro-impact gravel pile composite foundation with a down-the-hole hammer combined with a pilot hole, comprising the following steps: 1. Leading hole: using a pneumatic down-the-hole hammer to penetrate the mountain riprap stratum to establish a leading hole; 2. 1. Move the machine: After establishing the lead hole at a certain pile point, move the down-the-hole hammer drilling rig to the next pile point, and continue to build the lead hole; Introducing the hole; 4. Forming the hole: control the high-pressure water pump and the vibrating device and forming the hole to the set depth; 1.0 ~ 1.5m away from the bottom of the hole; 6. Filling: put gravel into the hole one by one, and carry out vibratory compaction; 7. Pile formation: repeat step 6 until the filler is densified to the top of the pile; 8. Follow steps 1 to 7 , until all the set pile points of the foundation are finished making piles. The invention has the advantages of simple process, convenient operation and fast construction speed, and can increase the bearing capacity of the foundation by 3 to 5 times.

Owner:BEIJING VIBROFLOTATION ENG MACHINERY

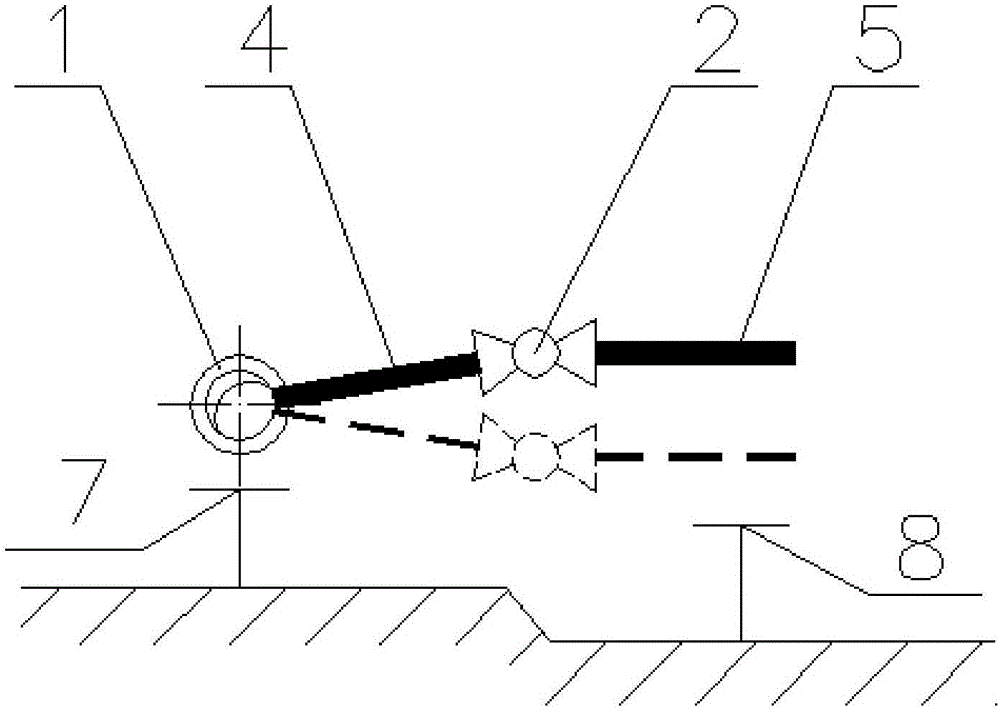

Device for solving problem of local differential settlement of pipeline through combination of rotating compensation device and hinge compensation device

ActiveCN106764212ASolve the problem of uneven settlementAny settlementPipe supportsPipeline expansion-compensationEngineeringHinge angle

Owner:武汉德威工程技术有限公司

Wet treatment method to accelerate settlement stability of coal gangue filling reclamation

ActiveCN105798052BSolve the problem of uneven settlementAccelerated settlementSolid waste disposalWater tableWater level

The invention provides a moist curing method for accelerating subsidence and stability of coal gangue filling reclamation, and belongs to the method for agricultural or forestry reclamation of coal gangues. The moist curing method comprises the following steps: after filling a subsidence land by using the coal gangues, consciously filling water to soak a coal gangue aggregate, and accelerating subsidence and stability of the coal gangues; and stripping collapse surface soil by 1.0 meter at first before the rainy season, pouring the coal gangues in a collapse pit until the distance from the coal gangues to an earth surface by a designed elevation, leveling a coal gangue site, filling water in the site until coal gangue bodies are submerged, maintaining until the rainy season is finished, compacting for 4-5 times by using compacting equipment, and finally refilling the collapse pit by using the surface soil and leveling the site. The moist curing method has the advantages that (1) the collapse pit is refilled with the coal gangues at a time, and layered filling compaction is not required, so that reclamation cost is greatly reduced; (2) adverse effects of hydrophilic substances in the coal gangues to subsidence are eliminated, uniformity of subsidence is guaranteed to a maximum extent, compaction times are reduced, and leveling of a farmland is guaranteed; and (3) effects of rising and falling of groundwater level to coal gangue filling reclamation lands are reduced.

Owner:CHINA UNIV OF MINING & TECH

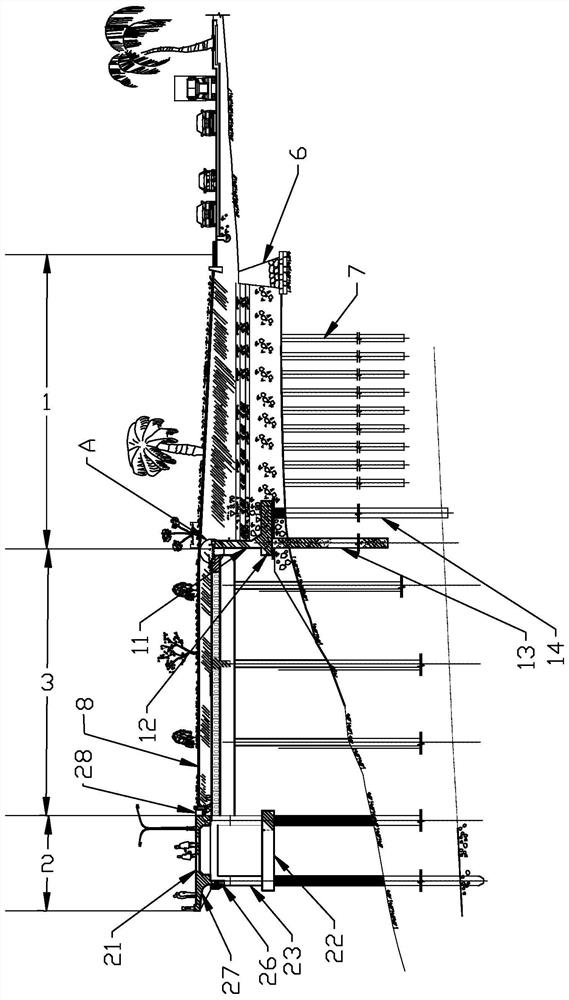

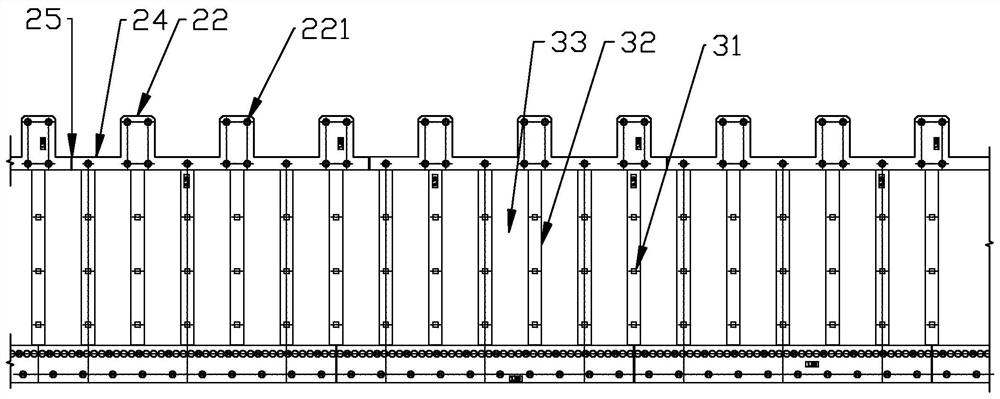

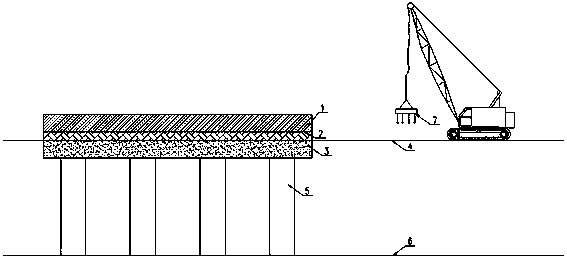

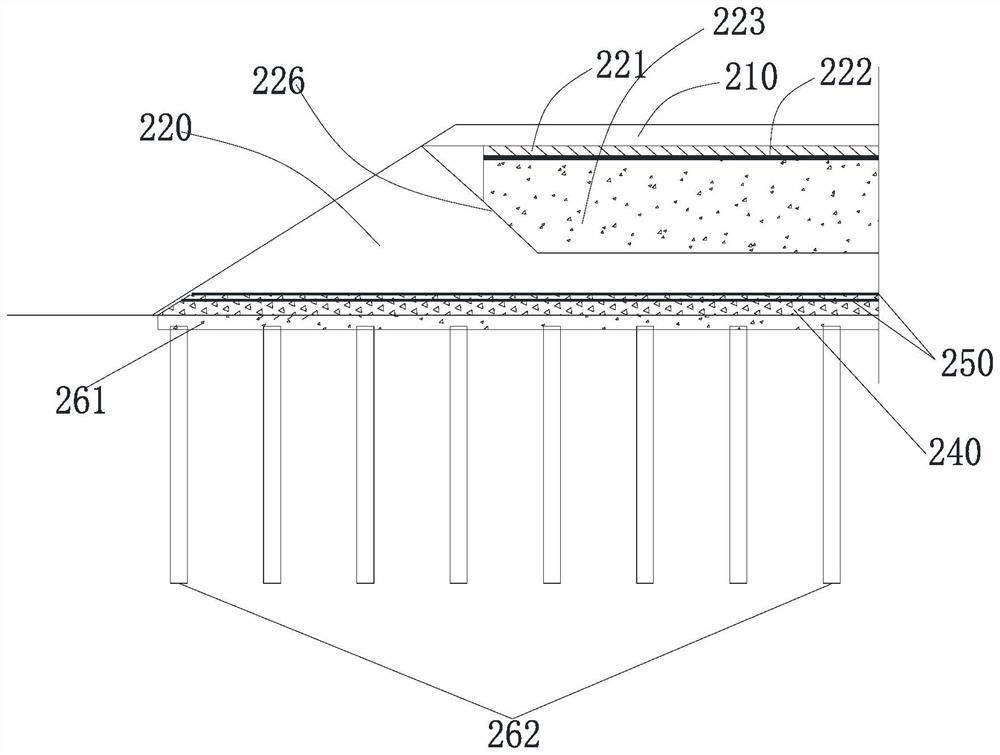

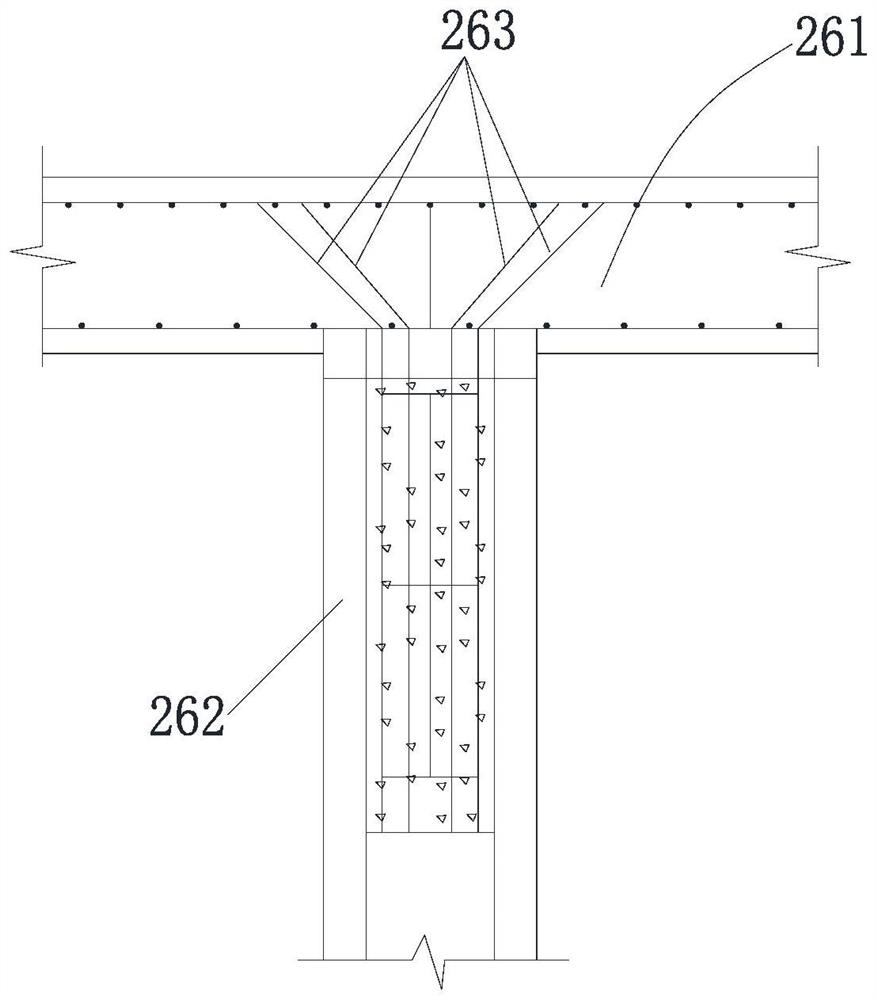

Frame type embankment pond structure

ActiveCN113373865AImprove Frontier FlowImprove impact performanceDamsBarrages/weirsSteel platesShore

The invention discloses a frame type embankment pond structure. The frame type embankment pond structure comprises a solid filling section arranged at an existing shoreline, a bearing platform section arranged in a deep water area and a frame section connecting the solid filling section, wherein the solid filling section comprises a wave wall and a fixed base, the fixed base is sequentially provided with a densely-arranged cast-in-place pile wall entering a pebble bearing layer and a plurality of cast-in-place piles in the direction from water to the shore, the bearing platform section comprises an embankment top platform, a plurality of bearing platforms and a plurality of supporting columns, the supporting columns are arranged between the bearing platforms and the embankment top platform and support the embankment top platform, a plurality of PHC piles entering a pebble bearing layer are arranged on the bearing platforms, the frame section comprises a plurality of prefabricated square piles entering the pebble bearing layer, a concrete cast-in-place top girder arranged at the tops of the prefabricated square piles and a concrete cast-in-place top plate laid on the concrete cast-in-place top girder, the concrete cast-in-place top plate is connected with the embankment top platform and the wave wall, pile tips of the prefabricated square piles are H-shaped steel sheet pile shoes, the wave wall and the concrete cast-in-place top girder are arranged in a split mode, connecting bosses are arranged at the adjacent positions of the wave wall and the concrete cast-in-place top girder, and a concrete cast-in-place top plate is laid between the connecting bosses.

Owner:温州市水利电力勘测设计院有限公司

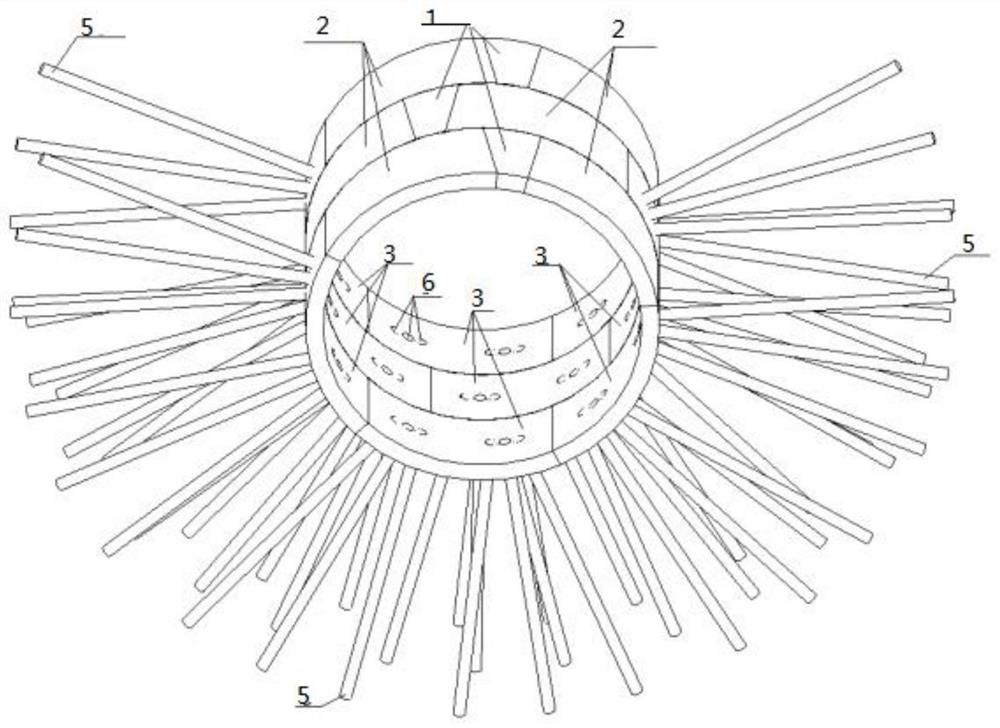

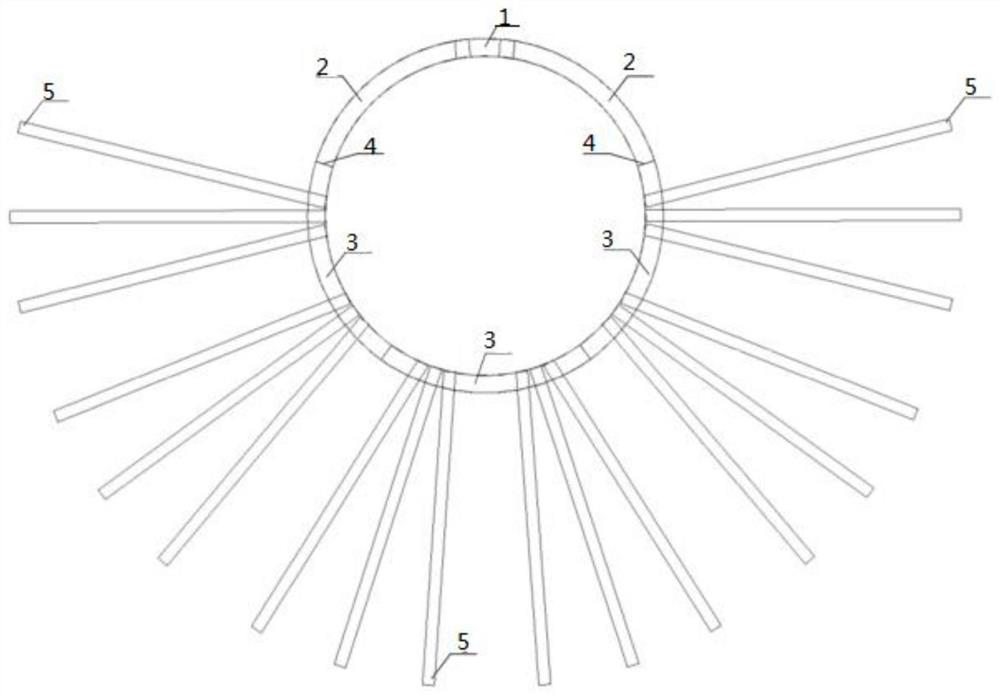

Reinforcing structure and reinforcing method for surrounding stratum of shield and pipe-jacking tunnel

PendingCN112901203AAffect normal operationFirmly connectedUnderground chambersTunnel liningStructural engineeringPipe

The invention discloses a reinforcing structure and reinforcing method for a surrounding stratum of a shield and pipe-jacking tunnel. The reinforcing structure comprises a reinforcing pile and a connecting piece, the connecting piece is arranged in a pipe piece, the reinforcing pile is of a hollow structure, the reinforcing pile penetrates through the connecting piece to be driven into the surrounding stratum of the tunnel and is fixedly connected with the pipe piece through the connecting piece, grouting holes are formed in the pile wall of the reinforcing pile, and grouting is conducted on the surrounding stratum of the tunnel through the grouting holes. The reinforcing structure is constructed in the tunnel, is simple in structure and low in cost, is not limited by conditions such as ground traffic, pipelines and buildings, and is capable of guaranteeing the reinforcing effect and exerting the settlement reduction effect of a root pile composite foundation, so that the situation that normal operation of the tunnel is affected due to the fact that settlement of the later operation tunnel is increased and even the pipe piece is damaged due to the poor reinforcing effect of a soft foundation is avoided.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Semi-rigid base layer for preventing bumping at bridgehead and construction process

PendingCN113668362ASolve the problem of uneven settlementRoadwaysBridge structural detailsArchitectural engineeringCrushed stone

The invention discloses a semi-rigid base layer for preventing bumping at bridgehead and a construction process. A first rigid base layer is fixedly connected with a bridgehead transition slab, a common base layer is fixedly connected with the first rigid base layer, a first semi-rigid base layer is fixedly connected with the first rigid base layer, and a second rigid base layer is fixedly connected with the first semi-rigid base layer; the first semi-rigid base layer is fixedly connected with the first rigid base layer, the second semi-rigid base layer is fixedly connected with the second rigid base layer, an asphalt concrete surface layer is fixedly connected with the second semi-rigid base layer, a first geogrid is fixedly connected with the first semi-rigid base layer, and a second geogrid is fixedly connected with the second semi-rigid base layer; the first semi-rigid base layer and the second semi-rigid base layer are formed by matching lime, fly ash and gravel, one side of the first semi-rigid base layer and one side of the second semi-rigid base layer are connected with the bridge end transition slab, and the other side of the first semi-rigid base layer and the other side of the second semi-rigid base layer are connected with the common base layer, so borne loads are evenly distributed, and a real transition section is formed between the bridge end transition slab and the common base layer; and a problem of non-uniform settlement between the bridge abutment and the embankment is solved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Optimum Filling Thickness Control Method of Coal Gangue

ActiveCN105917777BSolve control problems of unfavorable engineering characteristicsSolve the problem of uneven settlementSoil-working methodsSpontaneous combustionMining engineering

The invention relates to an optimal filling thickness control method for coal gangue and belongs to agricultural reclamation methods for the coal gangue. The control method comprises the steps: under the condition of selected compacting equipment, firstly, determining critical layering thickness of the coal gangue, then, determining the optimal layering thickness according to an object function model with minimal total compacting times, and finally, calculating filling super high amount; and during construction, carrying out filling by adopting a strip stacking method, and controlling the quality of filling and compacting by adopting a leveling method. The method has the advantages that uniform-thickness layered filling is carried out, and thus, the filling effect is the best; and the uniformity is guaranteed to the maximum, the compacting times are reduced to the maximum, the instability and non-uniform settlement of the gangue are lowered, and the leveling of farmland is guaranteed. Critical thickness control is carried out; during the layered filling, the filling thickness cannot exceed critical thickness, so that the control method is the most effective control method for disadvantageous engineering characteristics of the gangue, and disadvantageous characteristics such as weathering, swelling-shrinkage, spontaneous combustion and corrosion of the gangue are effectively controlled. The filling cost of the coal gangue is reduced; and on one hand, the engineering quality is guaranteed, and on the other hand, the engineering cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

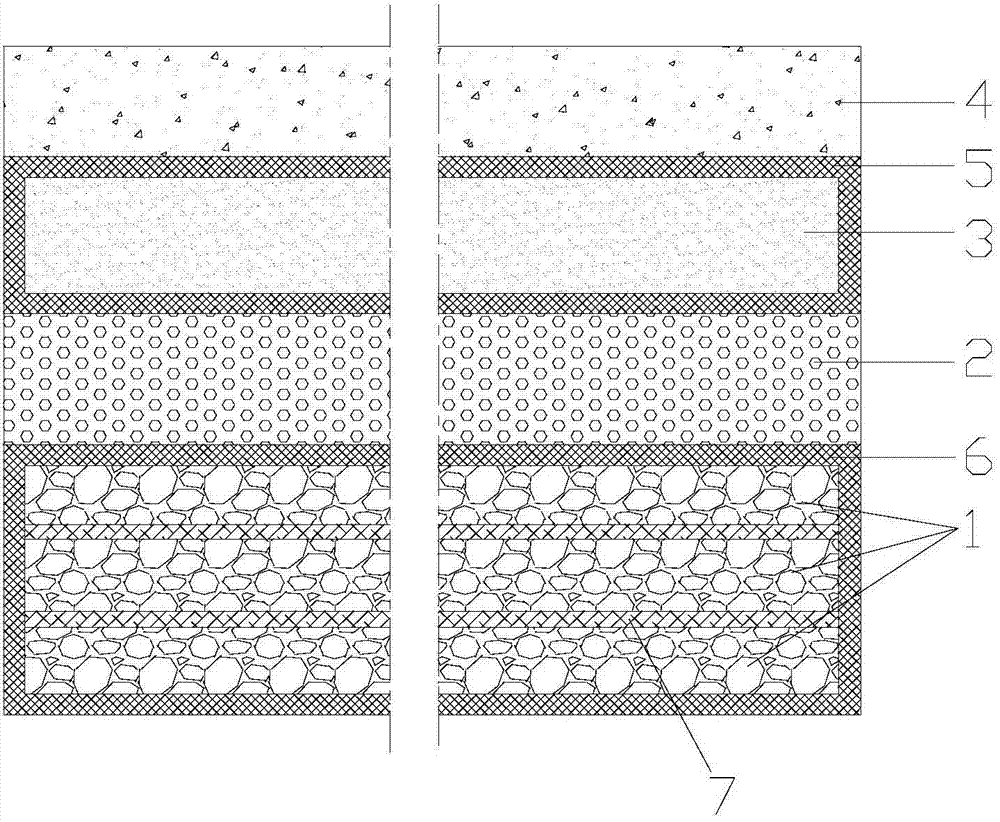

Pavement construction with hierarchically completely encapsulated roadbed and construction method thereof

InactiveCN103556558BAvoid damageAvoid water damageIn situ pavingsClimate change adaptationStructural engineeringRoad surface

Owner:CHONGQING JIAOTONG UNIVERSITY

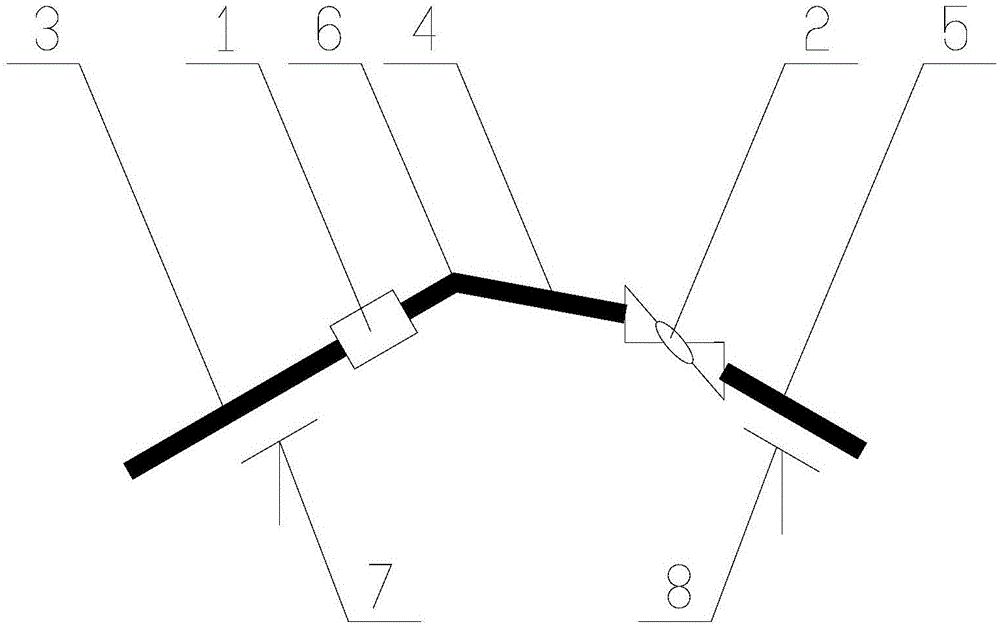

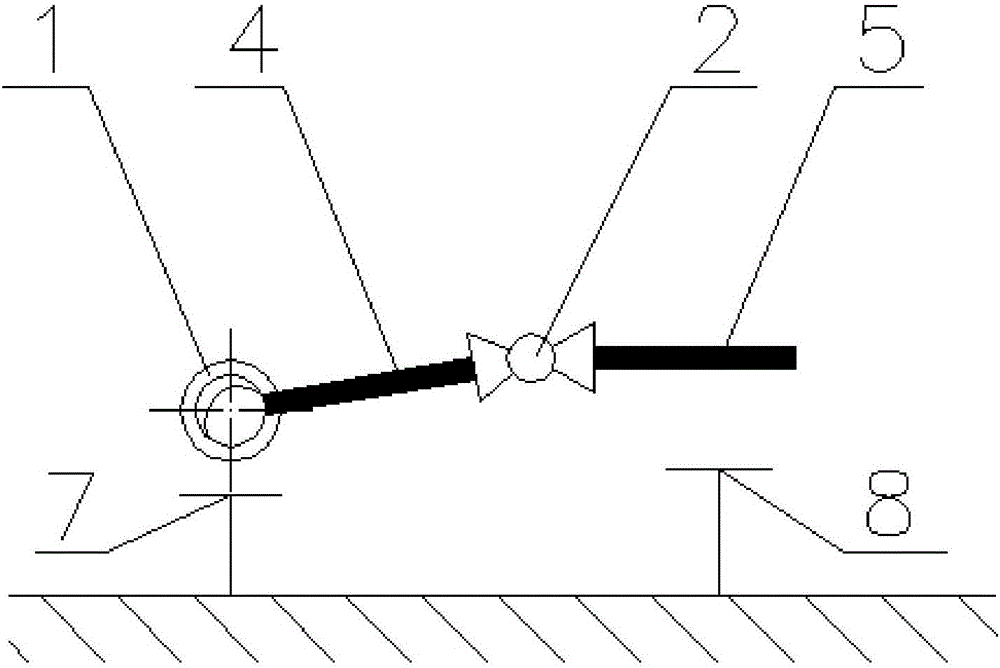

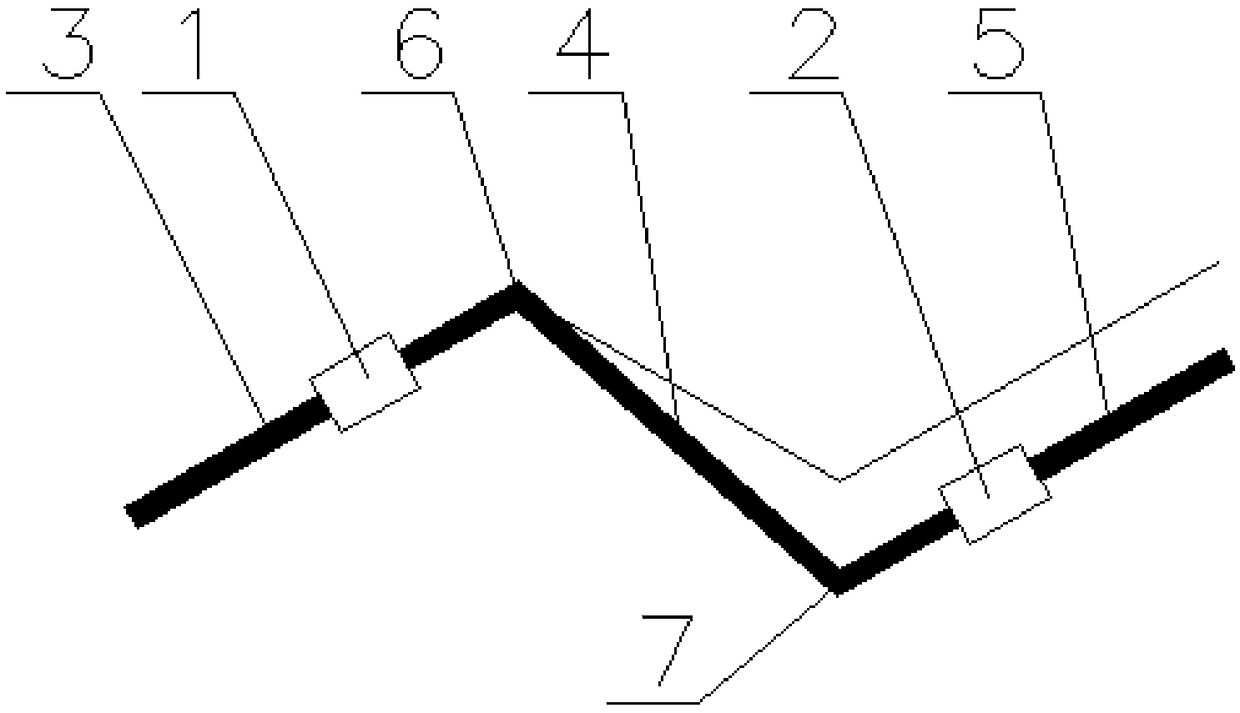

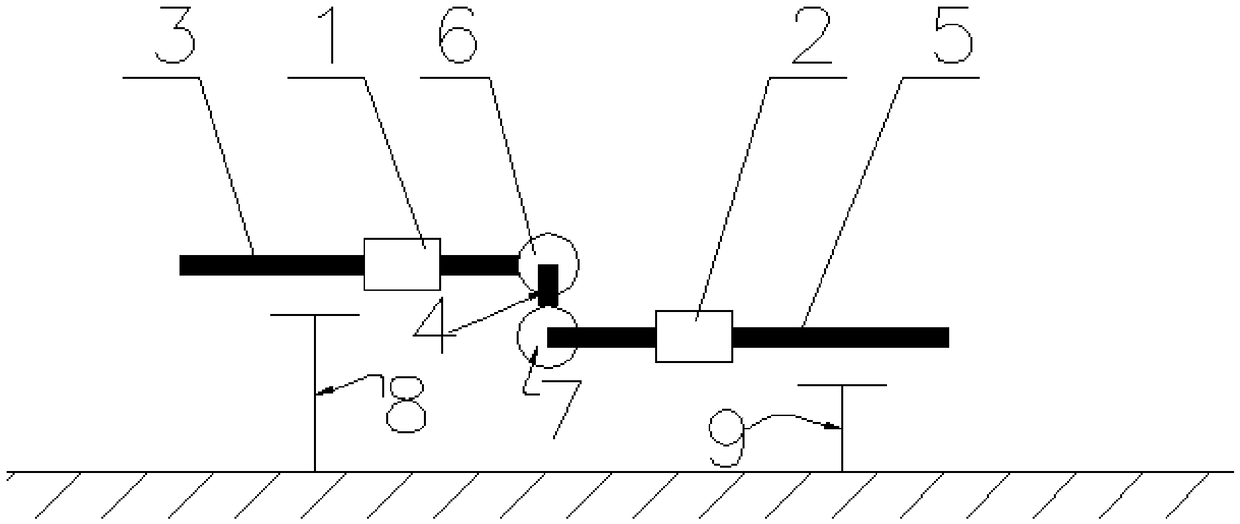

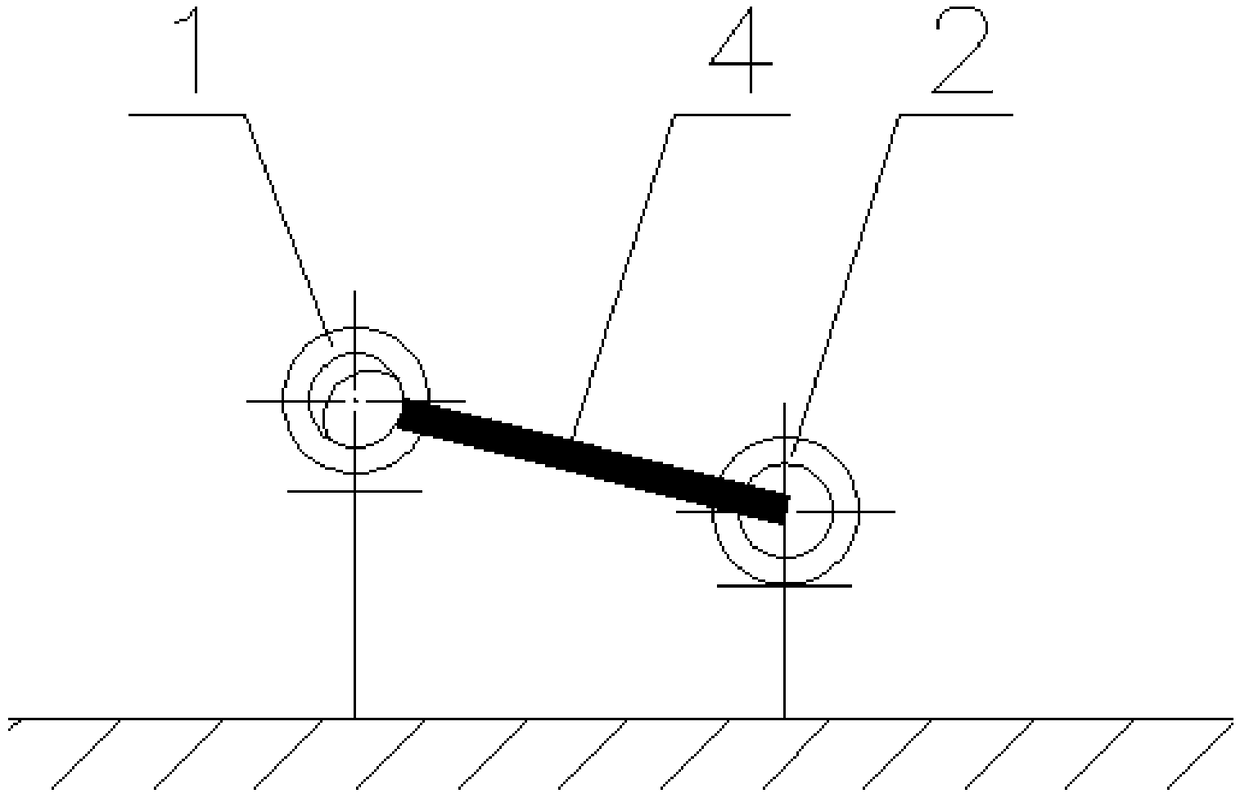

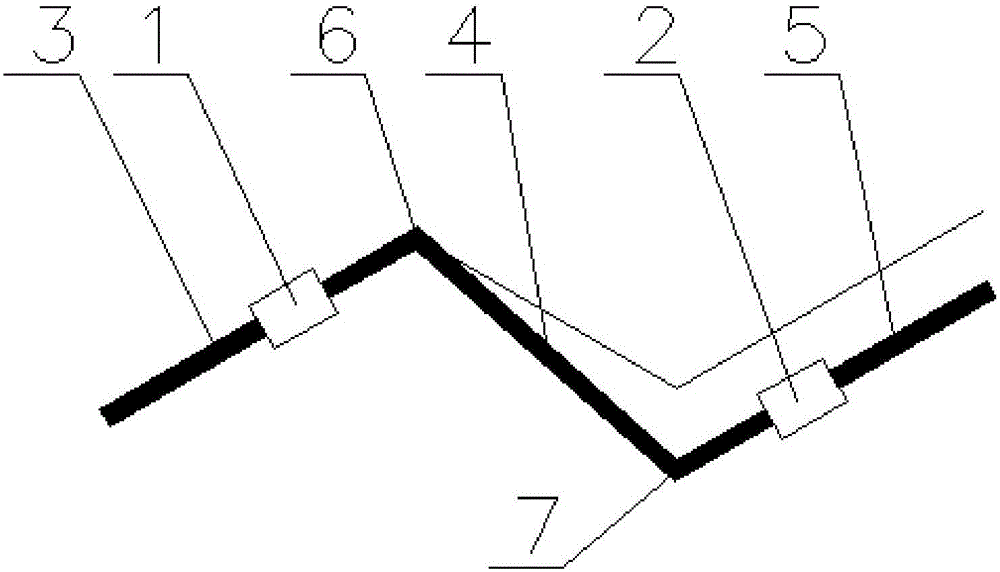

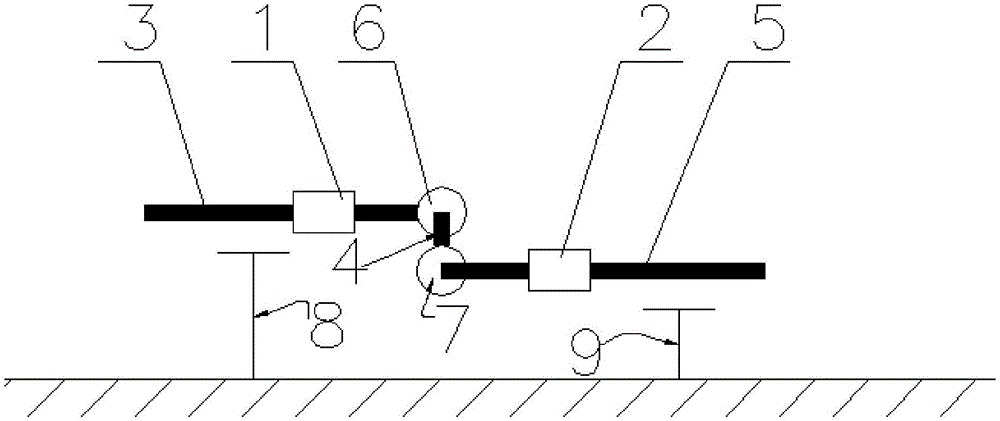

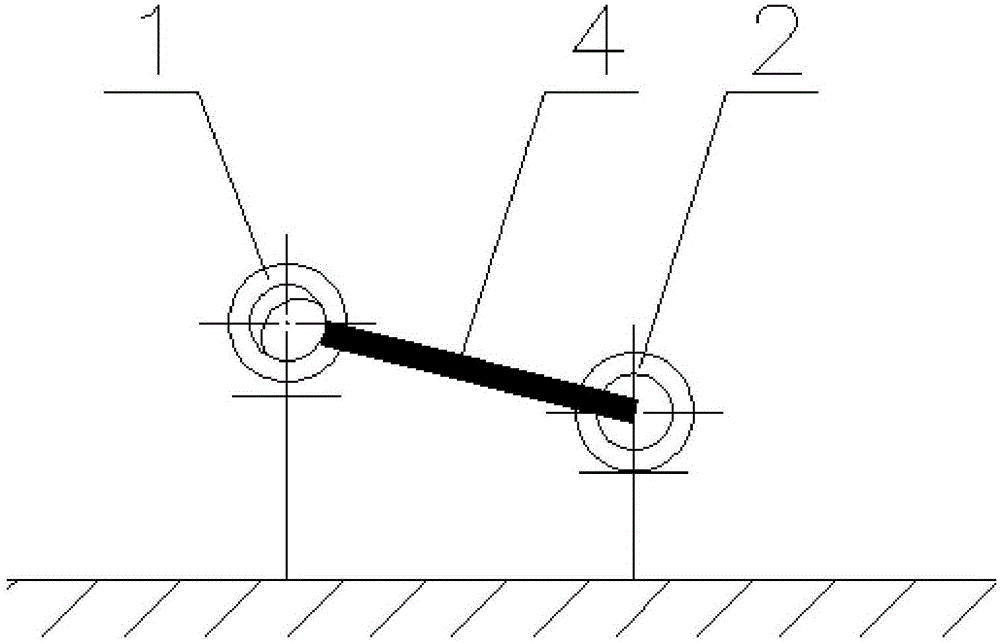

A device for solving local uneven settlement of pipelines by using two rotary compensators

ActiveCN106764049BSolve the problem of uneven settlementAny settlementPipe laying and repairFree rotationEngineering

The invention discloses a device for solving the problem of local differential settlement of a pipeline through two rotating compensation devices. The device comprises a first pipeline body (3) and a second pipeline body (5). The first rotating compensation device (1) is mounted on the first pipeline body, and the second rotating compensation device (2) is mounted on the second pipeline body. The axes of the first pipeline body and the second pipeline body are parallel, and the axes of the first rotating compensation device and the second rotating compensation device are parallel. The first pipeline body is connected with the second pipeline body through a short pipe (4). By arranging a heating pipeline in the mode, the problem of differential settlement of the pipeline can be effectively solved; and through rotation of the rotating compensation devices, the short pipe and a bend form a force arm, accordingly, free rotation in a pipeline constraint range is achieved, and free settlement of the two pipeline bodies in a designed range is ensured.

Owner:武汉德威工程技术有限公司

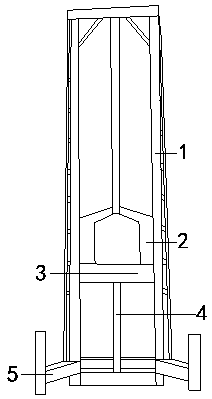

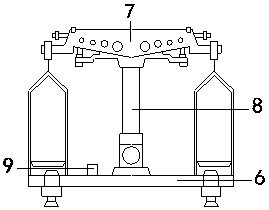

Drilling equipment for construction in bridge engineering field

InactiveCN110984875ASolve the problem of uneven settlementPreventing no-hole eventsSurveyDrilling rodsBridge engineeringBalancing machine

The invention discloses drilling equipment for construction in bridge engineering field. The drilling equipment comprises a machine frame body, a vertical balancing mechanism, a vertical correcting mechanism, a drill rod and a supporting foot stool. The inner side of the machine frame body is connected with the vertical balancing mechanism. The vertical balancing mechanism is connected with the drill rod through the vertical correcting mechanism, and the vertical balancing mechanism, the vertical correcting mechanism and the drill rod communicate with one another. The drilling equipment has the beneficial effects that firstly, the horizontal state of the mechanism is in a normal value range through a plane structure of the vertical balancing mechanism, inclination data of the mechanism arejudged according to the inclination degree of a caliper frame so that the vertical and horizontal line angle of the drill rod can be adjusted, according to accurate numeric values obtained through amodifying electrode holder and a correcting vesicle, the machine frame body is further adjusted, so that the drill rod can drill downwards continuously in the mode of being perpendicular to the horizontal line, and the situation that a reinforcing cage cannot be put into the hole after drilling is completed is avoided.

Owner:周志谦

Pavement structure with comprehensive waterproof reinforced roadbed as well as construction method of pavement structure

InactiveCN103541287BImprove bearing capacityImprove stabilityIn situ pavingsClimate change adaptationEvaporationRoad surface

The invention provides a pavement structure with a comprehensive waterproof reinforced roadbed as well as a construction method of the pavement structure. The pavement structure comprises a roadbed, wherein the roadbed is fully covered with a roadbed waterproof reinforced layer in a sealing manner. The pavement structure disclosed by the invention blocks water exchange between a roadbed force-bearing layer and the outside while improving bearing force and stability of the roadbed, and not only can prevent bearing force and stability from being influenced by surface water, roadbed side-slope seeped water and underground water which enter the roadbed force-bearing layer and the inside of the pavement structure so as to effectively solve water damages, but also can ensure moisture content control of a roadbed material, so that the roadbed can normally work under optimal moisture content in construction control for long time, thereby avoiding bearing force and stability deterioration as well as severe differential settlement caused by moisture content evaporation loss and non-homogeneous migration of the roadbed; the roadbed moisture content is stably controlled, and roadbed buildings in areas with swelling soil having strong water sensibility, collapsible soil and the like can use local materials sufficiently, so that excavation spoil, filling and borrowing materials and transfer are avoided, thereby not only reducing project cost, but also saving energy and protecting environment.

Owner:CHONGQING JIAOTONG UNIVERSITY

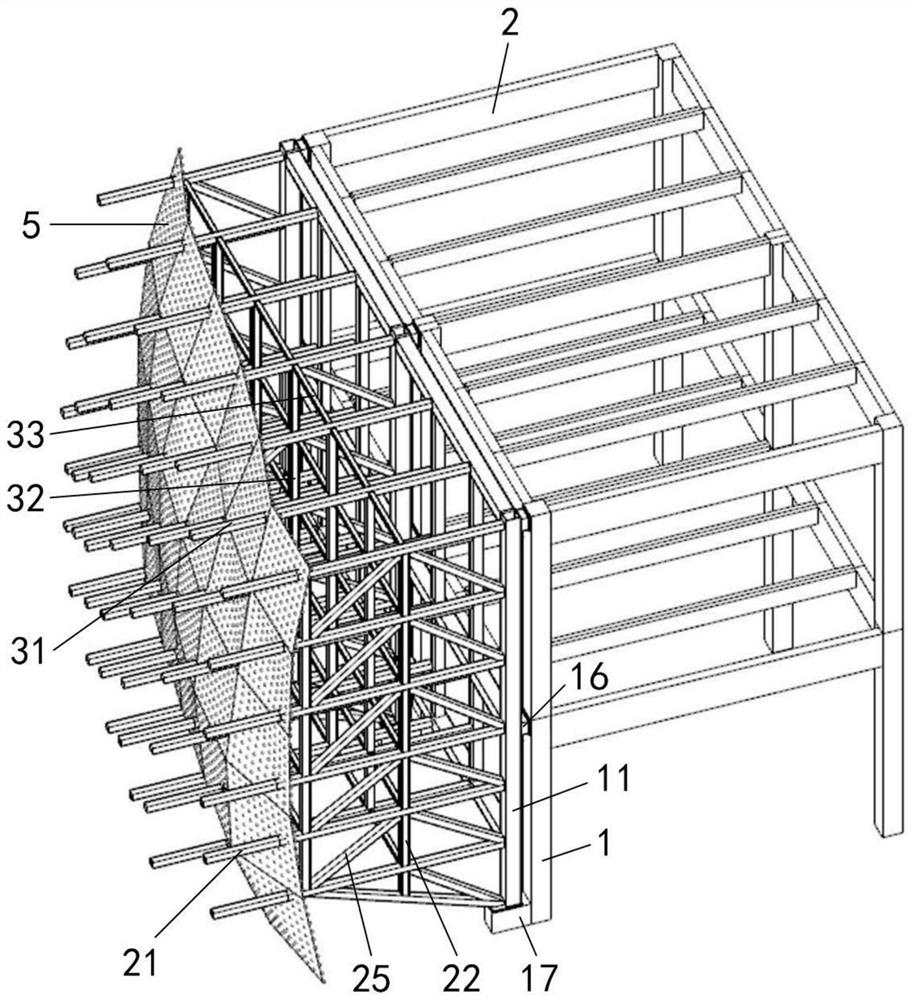

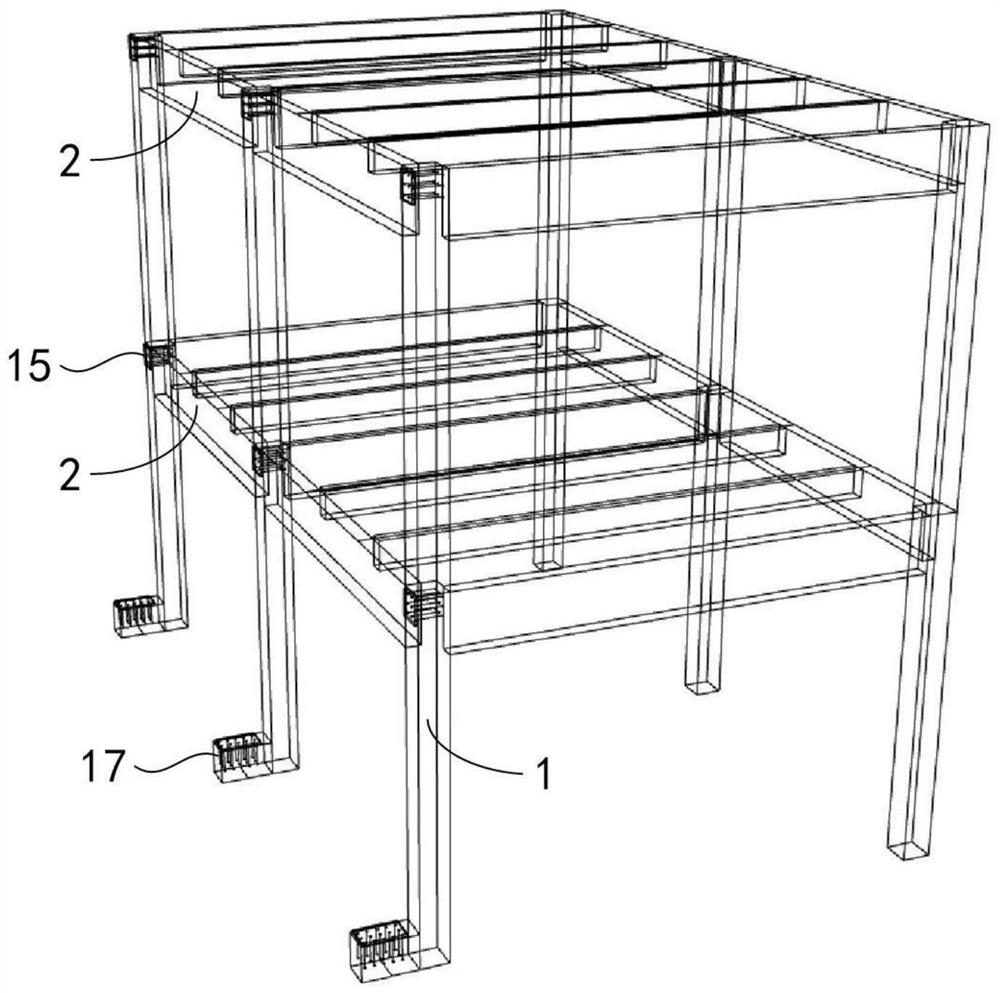

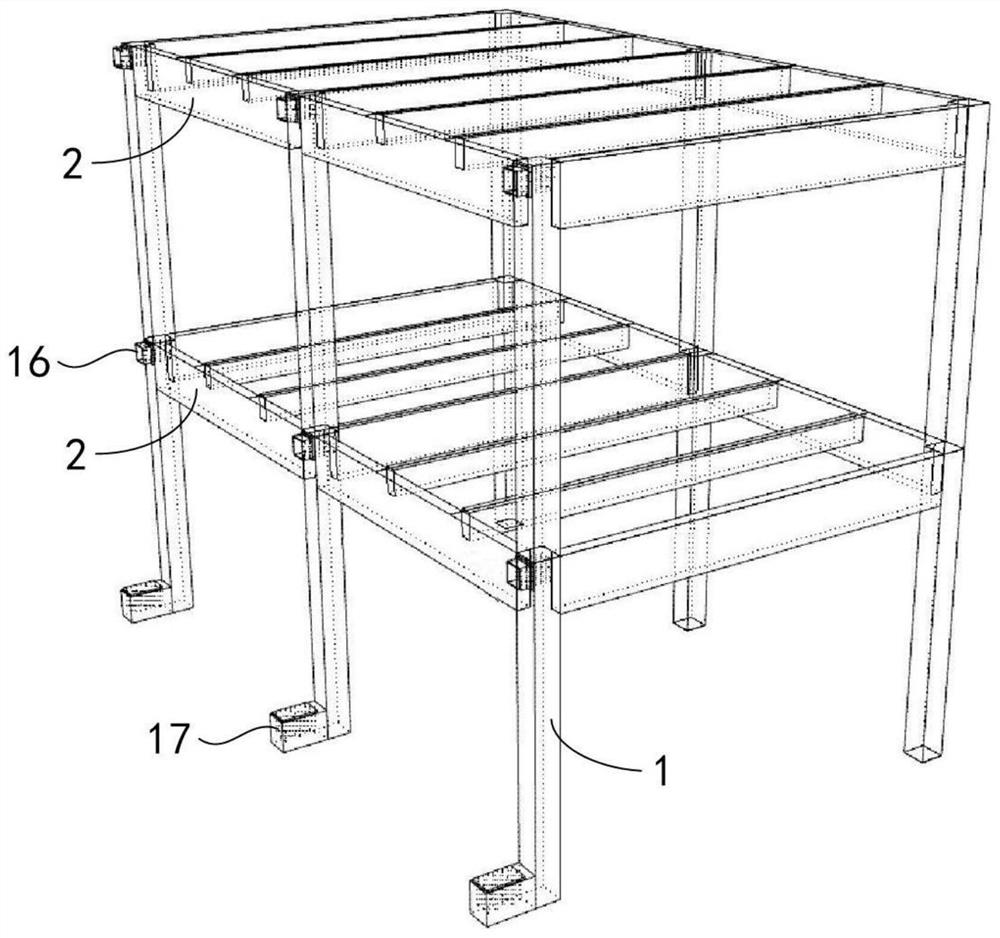

Large rockery outer package first-layer supporting structure and construction method thereof

PendingCN114232795ASolve the problem of uneven settlementClear structural force transmissionSpecial ornamental structuresBuilding material handlingStructure supportArchitectural engineering

The invention relates to a large rockery outer package first-layer supporting structure and a construction method thereof, and aims to solve the problem of non-uniform settlement between an existing rockery outer package and a main building. The device comprises a main body frame, a plurality of shape-finding supporting trusses and shape-finding supporting frames, the main body frame is fixedly connected to the side face of a building main body structure, the multiple shape-finding supporting trusses are vertically arranged at intervals, the shape-finding supporting frames are arranged between every two adjacent shape-finding supporting trusses, and one sides of the shape-finding supporting trusses and one sides of the shape-finding supporting frames are connected to the main body frame; and the other side of the connecting piece is matched with and fixedly connected with the outer packing of the rockery. The construction method comprises the steps that the main body frame is fixedly connected to the side face of a building main body structure, the multiple shape-finding supporting trusses are vertically arranged at intervals, the shape-finding supporting frames are arranged between every two adjacent shape-finding supporting trusses, one sides of the shape-finding supporting trusses and the shape-finding supporting frames are connected to the main body frame, and the other sides of the shape-finding supporting trusses and the shape-finding supporting frames penetrate through rockery outer packages and extend to the outer sides of the rockery outer packages; and after construction is completed, the exposed parts of the chord members and the transverse rods are cut off.

Owner:上海市建工设计研究总院有限公司

Installation and unloading method for large-span cantilever corridor

ActiveCN114134990ASolve the problem of uneven settlementAvoid uneven settlementArtificial islandsUnderwater structuresSupporting systemArchitectural engineering

The invention relates to the technical field of building construction, and discloses an installation and unloading method of a large-span cantilever corridor, a numerical simulation method is adopted to carry out modeling analysis on the corridor and a temporary supporting system, and the self-weight load effect of a corridor truss structure, the support reaction force before and after the temporary supporting system is unloaded and the stress between rods can be comprehensively considered. The deformation pre-adjustment value and the stress monitoring value of each construction stage are obtained, so that the implementation process of each construction stage of the construction site is guided. In addition, through early-stage numerical simulation analysis, the influence on the surrounding environment in the construction process is weakened, it is ensured that construction is safe and controllable, and the construction cost is saved. The temporary supporting system is unloaded in a multi-stage synchronous unloading mode, the problem of differential settlement generated in the cantilever corridor construction process can be effectively solved, and universality and generalization performance are achieved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

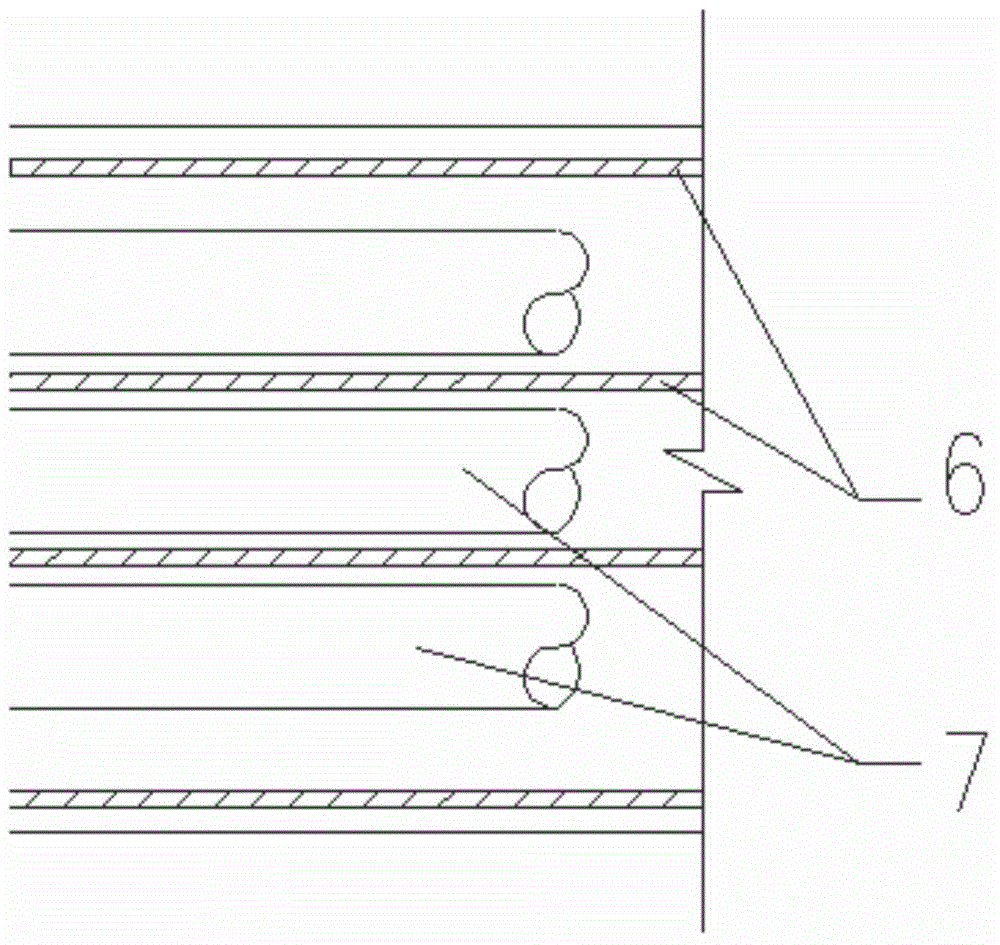

A prefabricated assembly pipe gallery structure

ActiveCN108678002BResistance to settlement differenceSolve the problem of uneven settlementArtificial islandsUnderwater structuresClassical mechanicsPipe

The invention discloses a prefabricated assembly pipe gallery structure which comprises a prefabricated bottom plate, a prefabricated wall and a prefabricated top plate. The prefabricated wall is connected between the prefabricated bottom plate and the prefabricated top plate, the prefabricated wall forms a first connecting piece, and the prefabricated bottom plate or the prefabricated top plate forms a second connecting piece. A first connecting structure is arranged at the connecting end of the first connecting piece, a second connecting structure is arranged at the connecting end of the second connecting piece, the first connecting structure and the second connecting structure are matched with each other in an inserted mode with an overlapped area, and a deformation joint is arranged between the matching surfaces of the first connection structure and the second connection structure; and a fastener which is connected with the first connecting piece and the second connecting piece isfurther arranged in the overlapped area. The adverse effects caused by thermal expansion and cold shrinkage and uneven foundation settlement to the structure can be avoided.

Owner:XIANGTAN UNIV +2

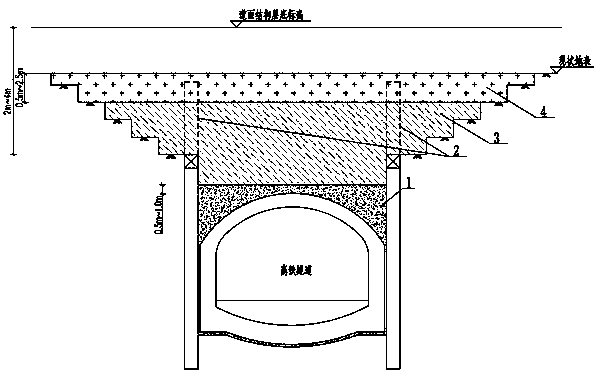

Control structure and construction technology of uneven settlement of roadbed subgrade under high-speed railway tunnel passing through airport

The invention discloses a construction process of a non-uniform settlement control structure for a high-speed railway tunnel passing through an airport road surface. To build plain soil, on-site pouring foam lightweight soil foundation in sections, partitions, and layers on the plain soil, or fill reinforced soil layers layer by layer, lay geogrids between the reinforced soil layers, and lay geogrids between the reinforced soil layers. Pave the geocell on the upper layer, pave gravel on the geocell, and set multiple deformation joints along the longitudinal direction; carry out the construction of the pavement structure layer and other auxiliary facilities, and adopt the above-mentioned construction technology to form uneven settlement of the subgrade control structure. The invention has the advantages of improving the overall uniformity of the soil foundation, adjusting the uneven settlement of the soil foundation, convenient construction, saving construction period, and successfully solving the problem of uneven settlement of the roadbed when the high-speed railway tunnel crosses the airport pavement.

Owner:TONGJI UNIV +2

Warehousing terrace sedimentation control system and construction method thereof

PendingCN108411886AReduce shear deformationReduce settlementBulkheads/pilesSoil preservationSurface layerControl system

The invention discloses a warehousing terrace sedimentation control system and a construction method thereof. The warehousing terrace sedimentation control system comprises a terrace surface layer, aleveling layer, a ribbed mattress layer and a reinforced composite foundation; the ribbed mattress layer, the leveling layer and the terrace surface layer are arranged on the reinforced composite foundation in sequence; and the warehousing terrace sedimentation control system can effectively solve the problem of nonuniform sedimentation of a warehousing terrace of a deep new-soil-filled foundation, and meets use requirements of the warehousing terrace. Compared with a conventional engineering pile scheme, a dynamic consolidation method and a deep stirring pile method are lower in production cost, and are both conventional foundation treatment methods; and a deep cement stirring pile adopting the ribbed mattress layer is combined with the dynamic consolidation method to reinforce the deep new-soil-filled foundation, so that the effects of reducing the foundation sedimentation and nonuniform sedimentation and homogenizing the foundation stress are more obvious.

Owner:中交物流规划设计研究院有限公司

Road rigid pile and preloading soft foundation treatment transition structure and construction method

PendingCN114575209AReduce equivalent loadSolve the problem of uneven settlementRoadwaysClimate change adaptationStructural engineeringGeotechnical engineering

The embodiment of the invention provides a road rigid pile and preloading soft foundation treatment transition structure and a construction method, and belongs to the technical field of road foundation treatment. The transition structure sequentially comprises a base rigid pile transition layer, a first embankment filling layer and a first pre-pressing layer from bottom to top, and the base rigid pile transition layer is inserted into a foundation; the first embankment filling layer comprises a common embankment filling layer filled with common filler; the first prepressing layer is laid above the first embankment filling layer; wherein the first embankment filling layer further internally comprises a light embankment structure layer, the light embankment structure layer is laid on the common embankment filling layer, and the density of filler in the light embankment structure layer is smaller than that of filler in the common embankment filling layer; and in the extending direction from the rigid pile processing section to the preloading section, the ratio of the light embankment structure layer in the first embankment filling layer is gradually reduced. The transition structure can solve the problem of differential settlement of the transition section roadbed in two different soft foundation treatment forms.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

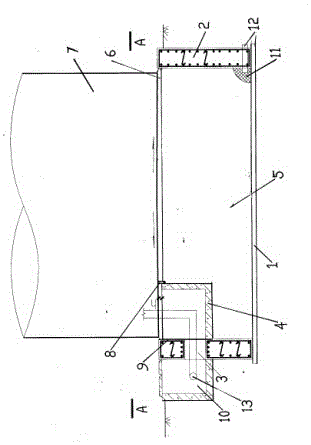

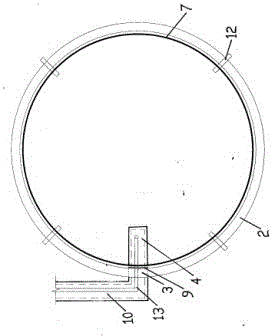

Large-scale tank body foundation provided with communication channels, and construction method of large-scale tank body foundation

InactiveCN106759428ASolve uneven settlementReduce construction difficultyFoundation engineeringRebarReinforced concrete

The invention discloses a large-scale tank body foundation provided with communication channels, and a construction method of the large-scale tank body foundation, and solves the problem that a conventional large-scale tank body provided with reinforced concrete channels which communicate with each other is liable to incline and topple over. A box-shaped concrete inner channel (4) which is independently cast is formed in the inner side of an inner and outer channel communication hole (3); asphaltic felt (9) is arranged between the box-shaped concrete inner channel (4) and the inner side wall of a rigid concrete annular wall (2) near the inner and outer channel communication hole (3); a box-shaped concrete outer channel (10) is arranged on the outer side of the inner and outer channel communication hole (3); the rigid concrete annular wall (2) outside the box-shaped concrete inner channel (4) which is independently cast is filled with grading sandy gravel (5); an asphaltic sand pad layer (6) is arranged on the top end surface of the grading sandy gravel (5); and a large-scale tank body (7) is arranged on the asphaltic sand pad layer (6). The large-scale tank body foundation is low in construction difficulty, and low in investment cost.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

Device for solving problem of local differential settlement of pipeline through two rotating compensation devices

ActiveCN106764049ASolve the problem of uneven settlementAny settlementPipe laying and repairFree rotationEngineering

The invention discloses a device for solving the problem of local differential settlement of a pipeline through two rotating compensation devices. The device comprises a first pipeline body (3) and a second pipeline body (5). The first rotating compensation device (1) is mounted on the first pipeline body, and the second rotating compensation device (2) is mounted on the second pipeline body. The axes of the first pipeline body and the second pipeline body are parallel, and the axes of the first rotating compensation device and the second rotating compensation device are parallel. The first pipeline body is connected with the second pipeline body through a short pipe (4). By arranging a heating pipeline in the mode, the problem of differential settlement of the pipeline can be effectively solved; and through rotation of the rotating compensation devices, the short pipe and a bend form a force arm, accordingly, free rotation in a pipeline constraint range is achieved, and free settlement of the two pipeline bodies in a designed range is ensured.

Owner:武汉德威工程技术有限公司

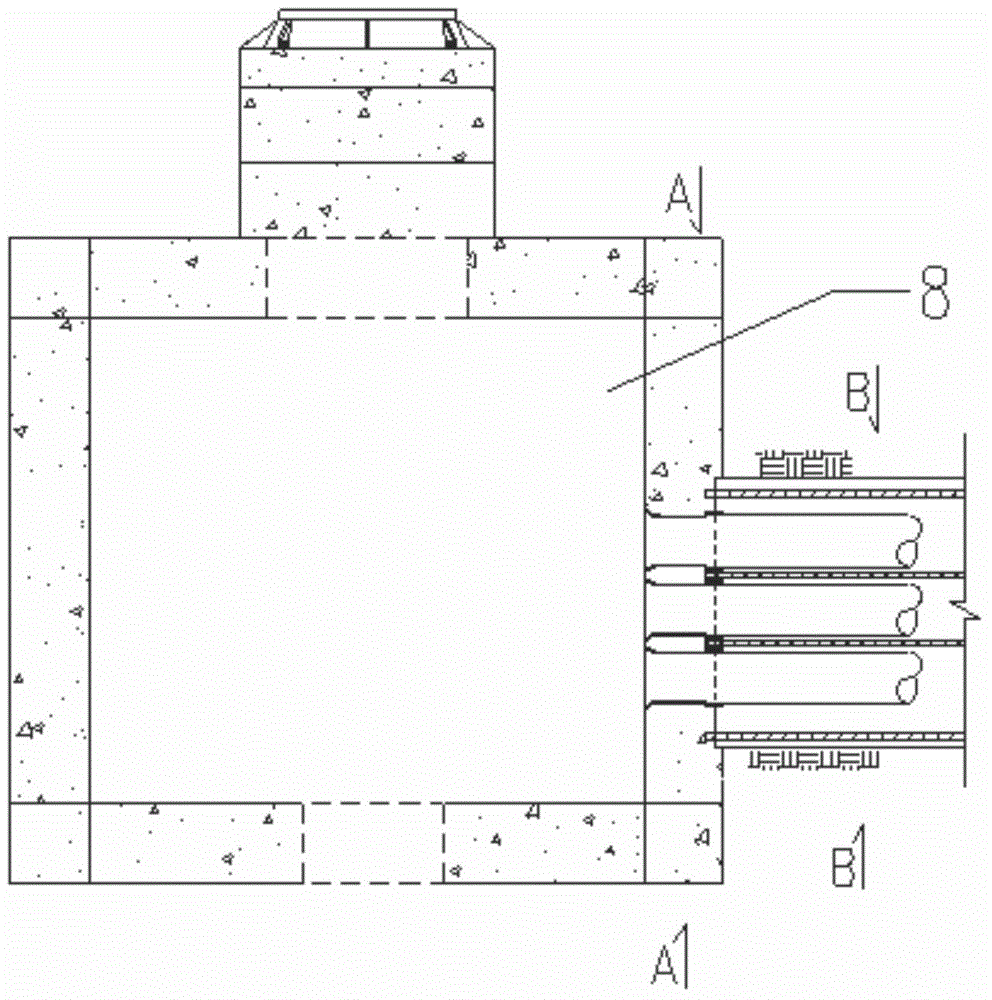

Connection structure and construction method of prefabricated cable well and cable pipe cast-in-place structure

ActiveCN103469818BGuaranteed integritySolve waterproof requirementsArtificial islandsUnderwater structuresRebarBuilding construction

The invention relates to a connecting structure for a prefabricated cable well and cable duct cast-in-place structure and a construction method thereof. The connecting structure comprises rebar connectors, duct reinforcing bars, cable sleeves and cable ducts. One end of each rebar connector is connected with an L-shaped rebar embedded in a well wall, and the other end of each rebar is connected with one duct reinforcing bar. The cable ducts are nested in the cable sleeves disposed inside the well wall, respectively. A form recess outside the well wall and the ducts are in concrete encapsulation fit. The connecting structure and the construction method thereof have the advantages that the prefabricated cable well and concrete encapsulation can be integrated, the water proofing requirement is met through the use of the cable sleeves, and the problem of possible differential settlement can be solved through the use of the form recess reserved in a prefabricated well.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com