Wet treatment method to accelerate settlement stability of coal gangue filling reclamation

A treatment method and coal gangue technology, which is applied in the field of coal gangue agriculture or forestry reclamation, can solve problems such as uneven surface settlement and unfavorable engineering characteristics of coal gangue, so as to solve the problem of uneven surface settlement and reduce instability and instability. Effect of uniform settlement and reduction of reclamation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Applicable conditions

[0021] The invention is particularly suitable for agricultural / forestry reclamation in high-water-level coal mining areas in eastern my country, because these coal mining subsidence areas often have accumulated water, and water is a necessary condition for wet treatment.

2. Specific implementation

[0022] (1) Site construction preparation; including removing sundries, reeds and cattails in the basin, removing silt, transplanting trees, demolishing or relocating waterways and certain buildings and structures, etc., to prepare a good external environment for the construction of earthmoving machinery .

[0023] (2) Stripping the topsoil layer; during agricultural reclamation, strip off the topsoil layer (cultivation layer) first, and stack them together. Then peel off the core soil layer and stack it in another place; the thickness of the peeling should not be less than 1 meter.

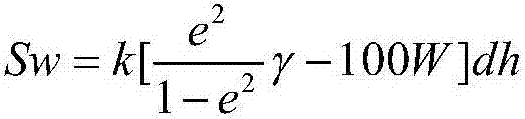

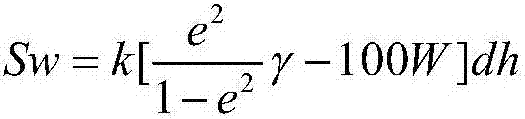

[0024] (3) Fill coal gangue to the design elevation of 1-Sw f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com