Large-scale tank body foundation provided with communication channels, and construction method of large-scale tank body foundation

A channel and tank technology, applied in infrastructure engineering, construction, etc., can solve the problems of easy tilting and dumping of large tanks, and achieve the effects of low construction difficulty, low investment cost, and solving uneven settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

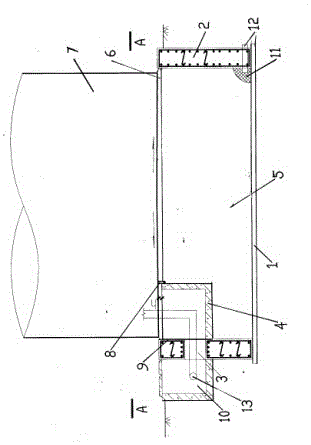

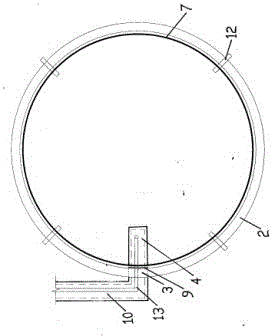

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

[0018] A large-scale tank foundation provided with communication channels, including a foundation cushion 1, a rigid concrete annular wall 2 is arranged on the foundation cushion 1, and an inner and outer channel communication hole 3 is arranged on the rigid concrete annular wall 2. An independently poured box-shaped concrete inner channel 4 is arranged inside the inner and outer channel communication holes 3, and linoleum is arranged between the box-shaped concrete inner channel 4 and the inner side wall of the rigid concrete annular wall 2 next to the inner and outer channel communication holes 3 9. A box-shaped concrete outer channel 10 is provided on the outside of the inner and outer channel communication holes 3, and the rigid concrete annular wall 2 outside the independently poured box-shaped concrete inner channel 4 is filled with graded sand pebbles 5. An asphaltic sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com