Construction method for mucky soil supporting beam cushion layer

A technology of silty soil and construction method, applied in basic structure engineering, construction and other directions, can solve the problems of difficulty in ensuring the leveling of the cushion, affecting the excavation progress of the supporting beam pouring foundation pit, uneven subsidence of the cushion, etc. Work efficiency and quality of frame formwork, solve uneven settlement, and ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

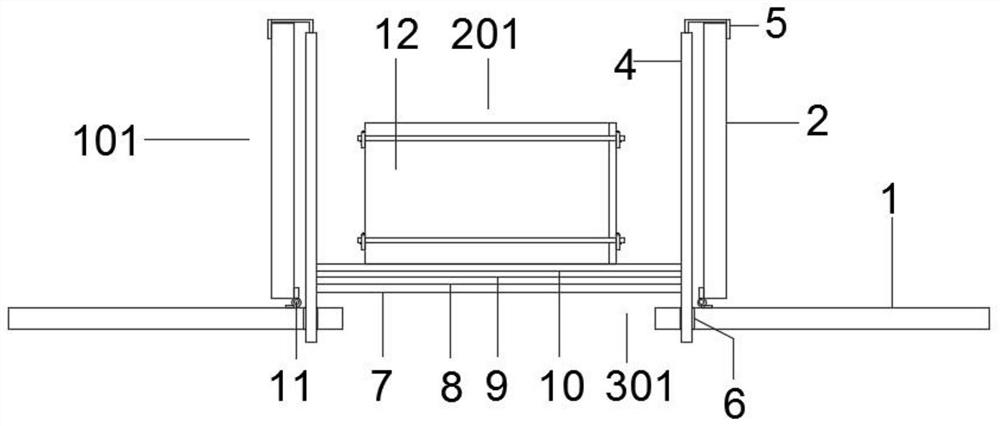

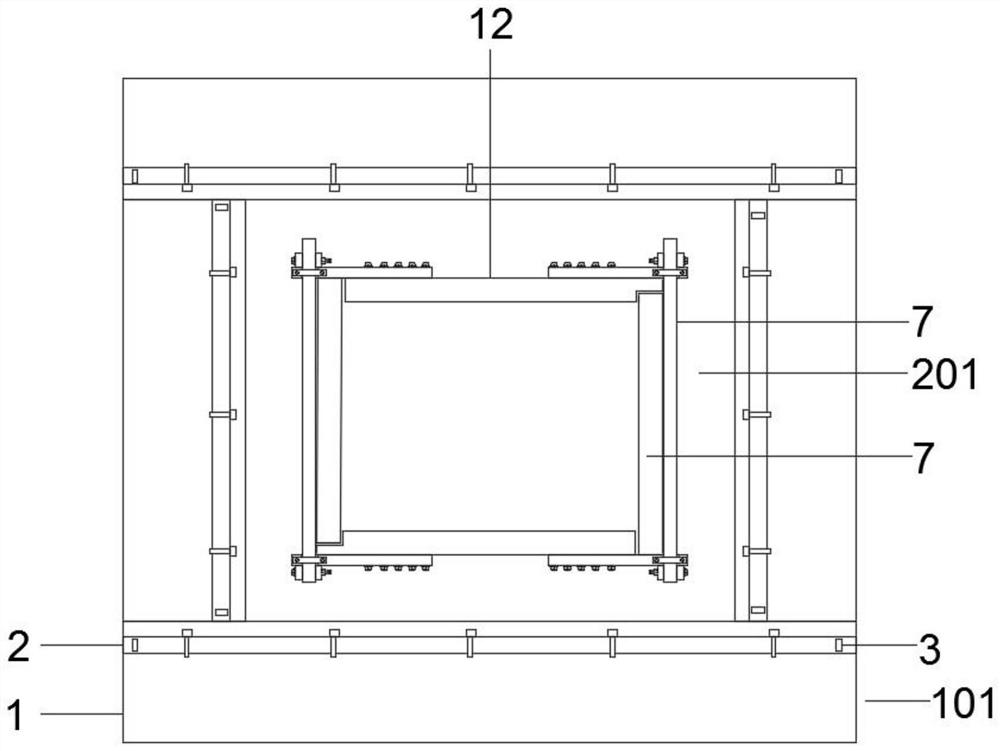

[0035] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

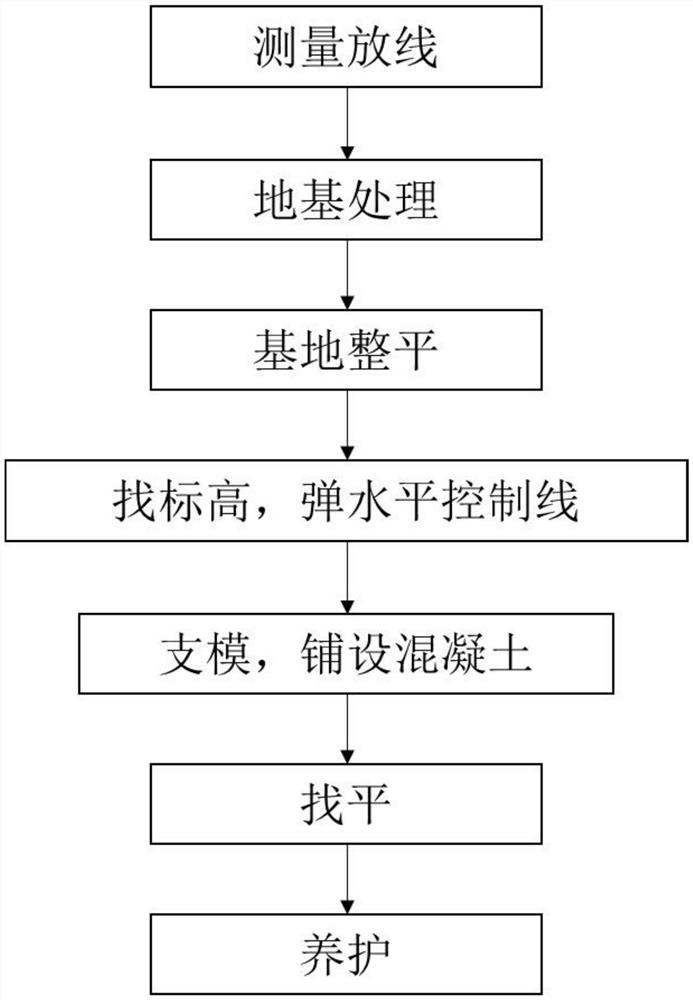

[0036] Refer to attached Figure 1-5 , a kind of silty soil support beam cushion construction method provided by the invention, comprises concrete steps as follows:

[0037] S1, measuring and setting out: measure and set out according to the design drawings and site conditions, and mark the position of the supporting beam and the cushion area, where the two sides of the cushion are 100mm wider than the beam;

[0038] S2, clean up the muddy soil at the marked support beam and cushion area, and place the baffle member 101 outside the marked support beam and cushion area;

[0039] S3, foundation treatment: fill the foundation component 301 in the marked cushion area, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Block diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com