Optimum Filling Thickness Control Method of Coal Gangue

A technology for thickness control and coal gangue, which is applied in the field of coal gangue agricultural reclamation, can solve the problems of unfavorable engineering characteristics of coal gangue, uneven settlement of the surface, etc., so as to solve the problem of uneven settlement of the surface and solve the control of unfavorable engineering characteristics of coal gangue. problems, the effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: The control method is to first determine the critical layer thickness of coal gangue during engineering design, then determine the optimal layer thickness, and finally calculate the filling superelevation; The leveling method controls the layer thickness; the method steps include:

[0049] (1) Equal thickness layered filling

[0050] This is the most economical and homogeneous filling method; the so-called equal-thickness layered filling is to improve the relative compaction of coal gangue and increase the bearing capacity of gangue. When backfilling gangue, fill it with the same thickness from bottom to top. So as to reach the design level;

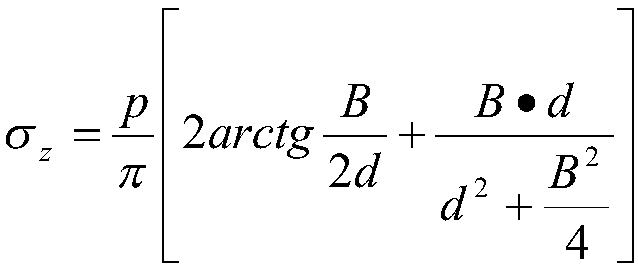

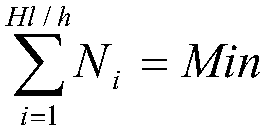

[0051] The so-called most economical is the total number of compaction times ΣN=Min, thus setting:

[0052] 1) at h≤h L , that is, when the layer thickness is less than the critical thickness, h can take h i (i=1,2,...,k), the corresponding compaction times N i (i=1,2,...,k); when h i >h j , with N i >N j es...

Embodiment 2

[0100] 1. Applicable conditions

[0101] (1) Natural environmental conditions

[0102] Layered filling is most suitable for areas without water accumulation or seasonal water accumulation and subsidence land with small amount of water accumulation. For subsidence land with a large amount of accumulated water, the accumulated water must be drained first. It is difficult to implement stratification if the topographical conditions are too complex, so the degree of water accumulation in the subsidence and the complexity of the topographical conditions constitute the prerequisites for this method.

[0103] (2) Special basin conditions

[0104] Here it mainly refers to the characteristics of the basin. Mining in steeply inclined coal seams, ultra-shallow mining and other special geological conditions make the shape of the basin extremely complex. Some basins have extremely deep and steep bottoms, the so-called funnel-shaped basins, and some basins are discontinuous with steps, cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com