Pavement structure with comprehensive waterproof reinforced roadbed as well as construction method of pavement structure

A subgrade and comprehensive technology, applied in the direction of roads, roads, on-site paved condensate pavements, etc., can solve problems such as uneven settlement, large footprint, deepening surface water and groundwater’s adverse effects on road structures, and achieve reduction The effects of small subgrade disease and damage, avoiding mud pumping on the road surface, and preventing road surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

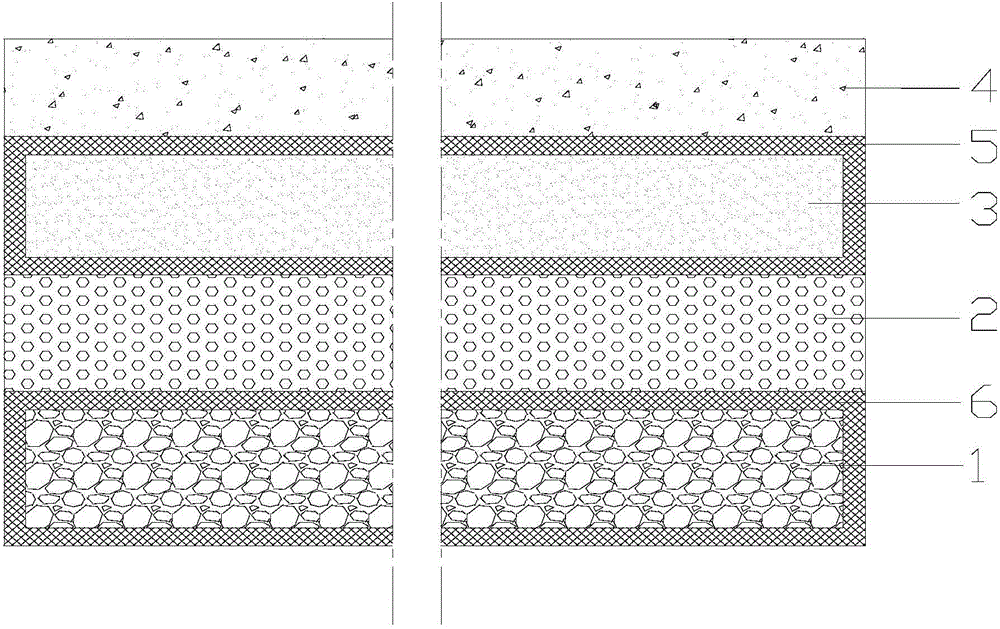

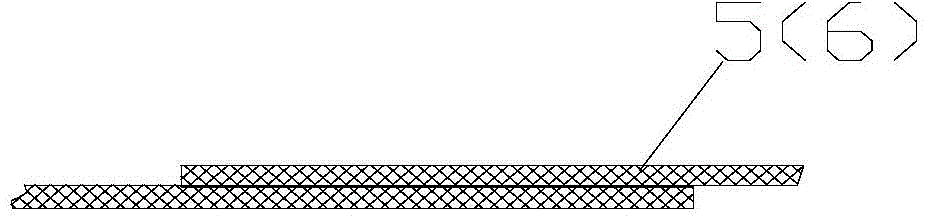

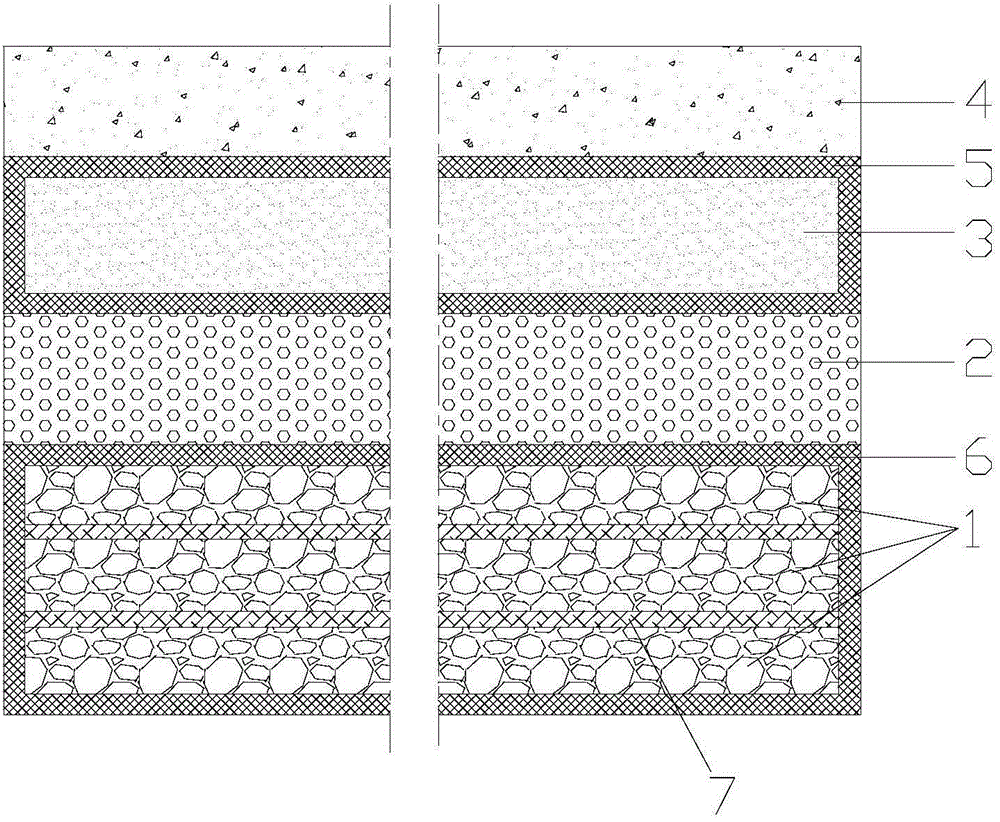

[0035] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the overlapping connection structure of the roadbed waterproof reinforcement layer and the waterproof vibration-damping functional layer of the present invention; as shown in the figure: the pavement structure of the comprehensive waterproof reinforcement roadbed of the present invention includes a surface layer 4, a base layer 3, and a cushion layer from top to bottom 2 and the roadbed 1, the roadbed 1 is fully covered with a roadbed waterproof reinforcement layer 6 in a sealed manner; the roadbed waterproof reinforcement layer 6 can adopt a structure that is completely covered or layered and then superimposed, all of which can achieve the purpose of the invention.

[0036] In this embodiment, the roadbed 1 is a multi-layer structure, and the layers are separated by the reinforcement layer 7 and have a relatively large friction coefficient with the reinforcement layer 7. A large fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com