Small-diameter pile cluster used for pile foundation and construction method of small-diameter pile cluster

A construction method and small-diameter technology, which can be applied to foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of high technical difficulty, waste of material compressive strength, and high construction cost, so as to avoid environmental pollution and reduce the cost of cleaning soil Links of transportation, strong economic and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below by specific examples.

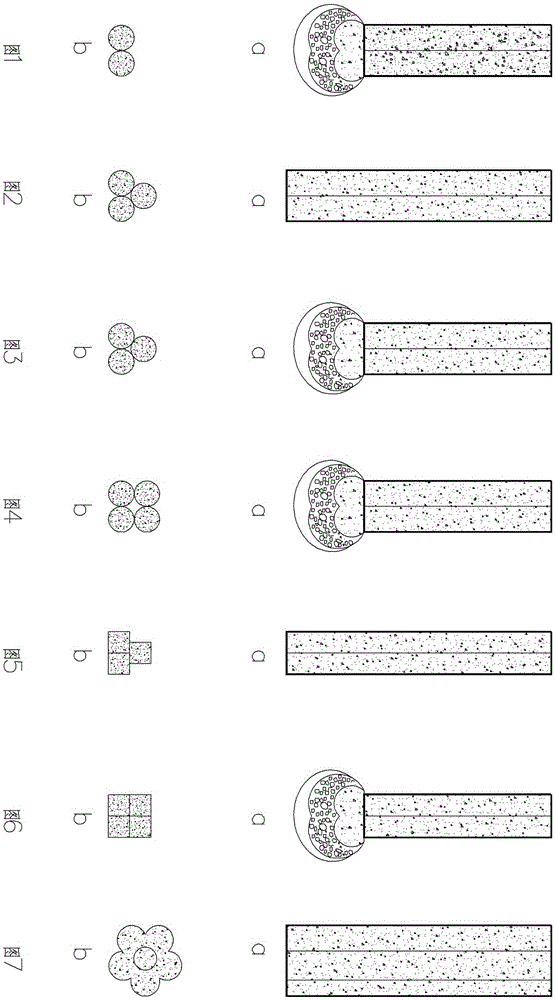

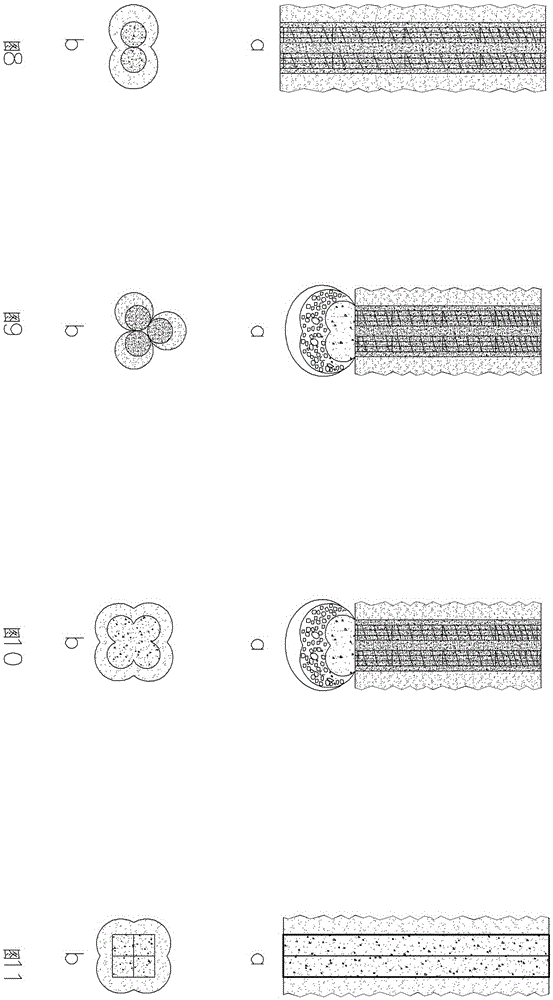

[0028] figure 1 The described embodiment consists of two cylindrical piles forming a pile cluster with a maximum diameter of 900 mm and a length of 8000 mm. The pile tops are in contact with each other and include a pile end carrier.

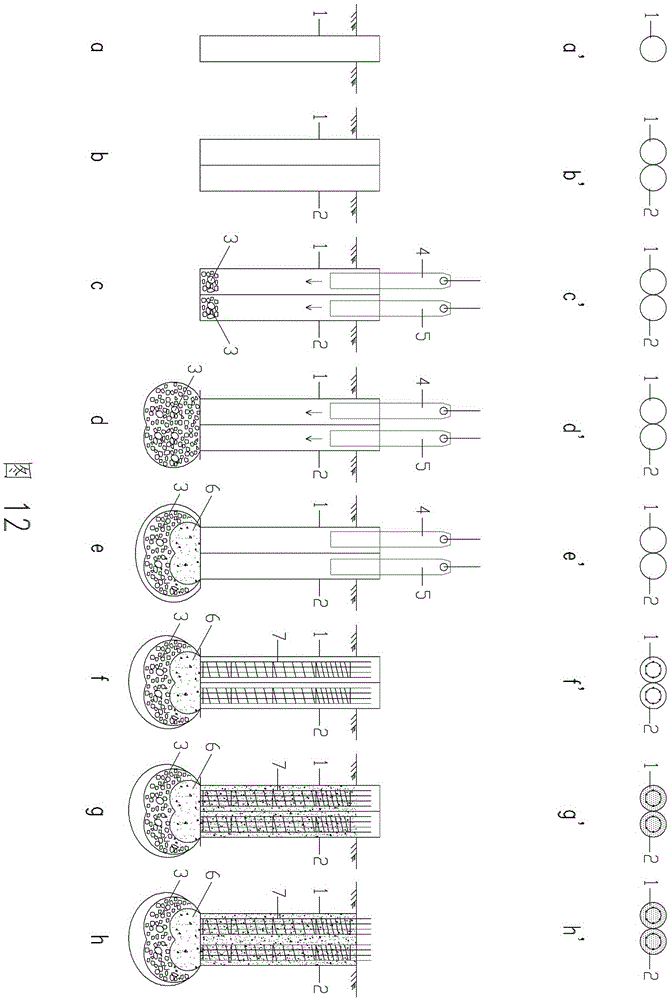

[0029] Figure 12 yes figure 1 The operation figure of the construction method of described embodiment, at first, as Figure 12 As shown in a, vertically sink into the first circular casing 1 with a diameter of 450mm and a length of 9000mm to the set depth; then, as Figure 12 As shown in middle b, sink into the second casing 2 of the same specification and size along the side wall of casing 1; then, as Figure 12 As shown in middle c, fill 0.2m in casings 1 and 2 3 Reinforcing material 3; put slender heavy hammers 4 and 5 with a weight of 3.5T in the casings 1 and 2, and use the lifting movement of the heavy hammers 4 and 5 in the casings 1 and 2 to stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com