Cast-in-place concrete pile with mixing layer wrapped pile section, drill bit for pile forming and construction method

A technology for concrete and cast-in-place piles, which is applied to drill bits, earthwork drilling, sheet pile walls, etc., can solve the problems of the stress between piles and soil not being fully exerted, and the energy-saving requirements cannot be well met, so as to reduce pile formation. Cost, side resistance increase, and the effect of increasing pile end resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

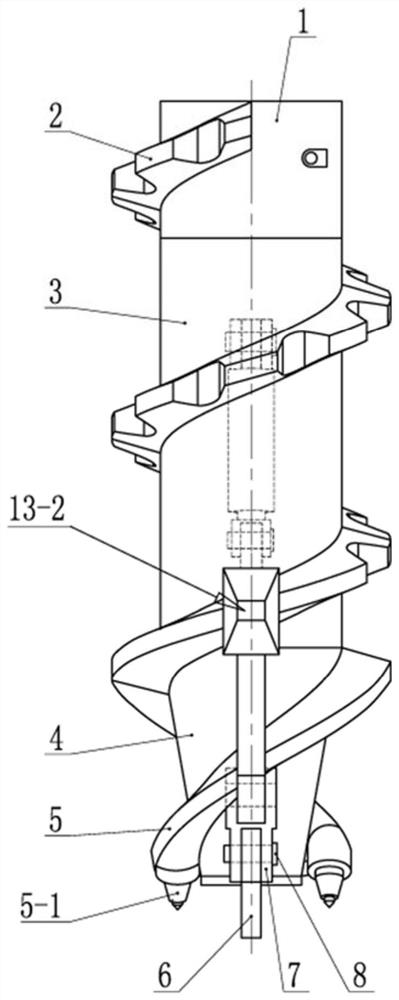

[0067] Embodiment 1 Drill bit for forming piles with double leads

[0068] 1. Structure

[0069] Such as Figure 1-Figure 3 As shown, a drill bit for piling with double lead, including a joint 1, a helical cylinder soil extruding blade 2, a cylinder core tube 3, a cone core tube 4, two helical cone soil extruding blades 5, a drill tip assembly Become 6, seat 7, pin 8, oil cylinder ear plate 10 and expanding diameter slide block device.

[0070] The joint 1, the cylindrical core tube 3, and the cone core tube 4 are fixed together with the axial center in turn, and the inner cavity can be used for concrete to pass through, and the spiral cylindrical extruding blade 2 is spirally wound on the outer surface of the joint 1 and the cylindrical core tube 3 , 2 identical helical cone soil-extruding blades 5 are symmetrically wound on the outer surface of the cone core tube 4, the overall outer edge of the cone core tube 4 is in the shape of a truncated cone, and the upper end of one...

Embodiment 2

[0090] Embodiment 2 Single-lead pile-forming drill bit

[0091] Such as Figure 6-Figure 8 As shown, a drill bit for single-lead pile forming includes a joint 1, a helical cylinder soil extruding blade 2, a cylinder core tube 3, a cone core tube 4, a helical cone soil extruding blade 5, a drill tip assembly Become 6, seat 7, pin 8, oil cylinder ear plate 10 and expanding diameter slide block device.

[0092] Other structures are exactly the same as in Embodiment 1, the difference is that a spiral cone soil squeezing blade 5 is provided, and a spiral cone soil squeezing blade 5 is spirally wound on the outer surface of the cone core tube 4, and the upper end and the spiral cylinder The lower ends of the earth-squeezing blades 2 are correspondingly connected. After the outer surface of the cone-shaped core tube 4 is wound with the spiral cone-shaped earth-extruding blade 5, the overall outer edge is cylindrical.

[0093] Such as Figure 9 As shown, in one embodiment, after t...

Embodiment 3

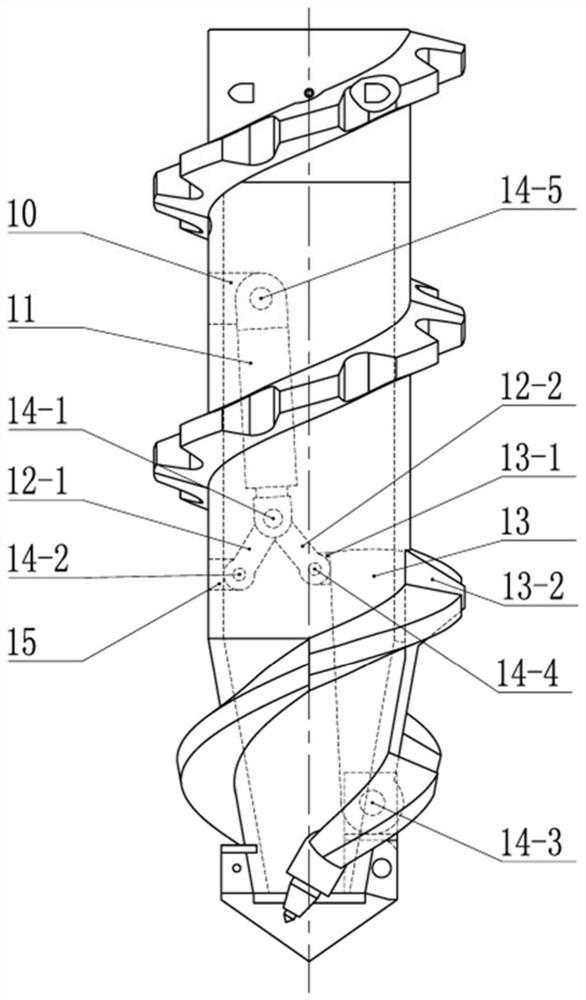

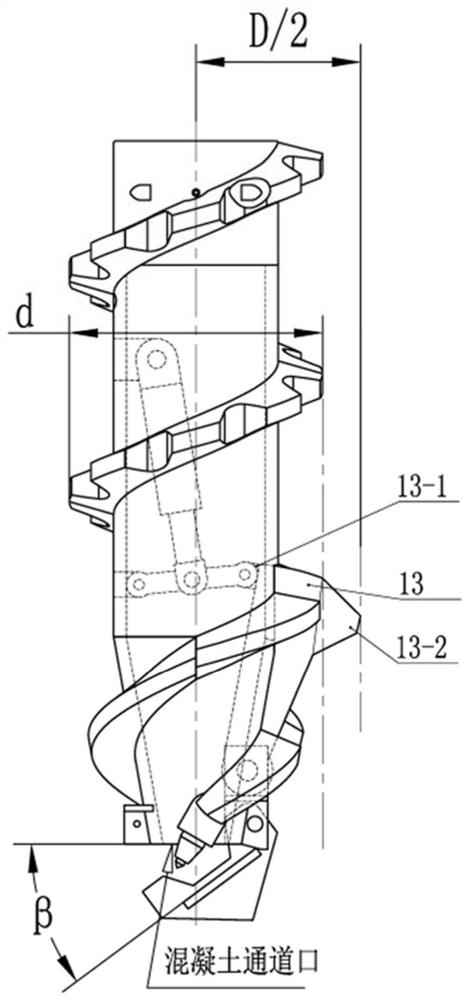

[0094] Embodiment 3 Drill bit for pile forming with single lead

[0095] Such as Figure 10-Figure 12 As shown, a drill bit for single-lead pile forming includes a joint 1, a helical cylinder soil extruding blade 2, a cylinder core tube 3, a cone core tube 4, a helical cone soil extruding blade 5, a drill tip assembly Become 6, seat 7, pin 8 and expanding diameter slide block device.

[0096] The joint 1, the cylindrical core tube 3, and the cone core tube 4 are fixed together with the axial center in turn, and the inner cavity can be used for concrete to pass through, and the spiral cylindrical extruding blade 2 is spirally wound on the outer surface of the joint 1 and the cylindrical core tube 3 1 piece of spiral cone soil extrusion blade 5 is helically wound on the outer surface of the cone core tube 4, the upper end is connected with the lower end of the spiral cylinder soil extrusion blade 2 correspondingly, and the lower end of the spiral cone soil extrusion blade 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com