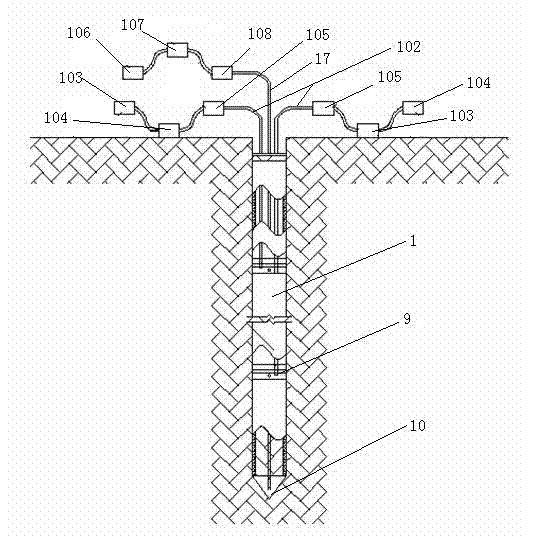

Joint grouting method from bottom and side of prestressed pipe pile

A technology of prestressed pipe piles and pile sides, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering. The effect of prestress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

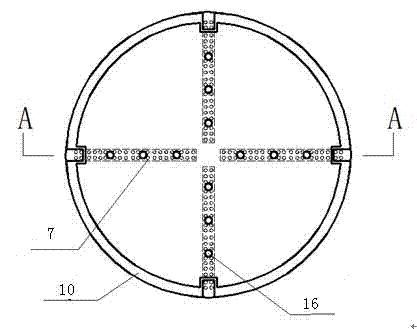

Embodiment Construction

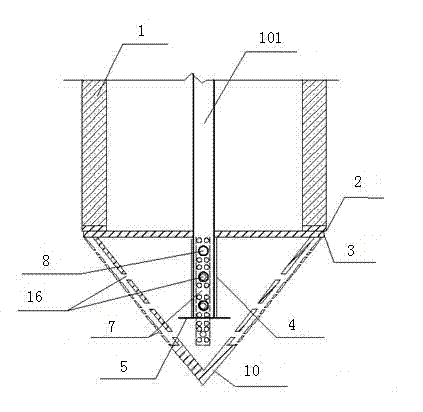

[0030] (1) Processing of the end plate: On the annular end plate 9, a plurality of threaded grouting holes 11 are drilled in the radial direction of the ring; the diameter of the threaded grouting hole is 4-5cm;

[0031] (2) Fabrication of the prestressed pipe pile: welding the end plate 9 to the end of the pile section 1;

[0032] (3) Processing and installation of the conical pile shoe 6: fix the end iron piece 2 at the bottom of the bottom pile section 1, weld the back cover steel plate 3 on the end iron piece 2, and pass the pile bottom grouting conduit 101 through the back cover steel plate The central positioning hole reserved on 3 extends to the bottom, and the extension section is provided with three rows of A grouting holes 8. The diameter of A grouting holes 8 is 8mm, and they are arranged symmetrically at 90° on the same section. Put it on the grouting pipe of the extension section, weld the A back cover steel sheet 5 at the bottom end of the extension section pipe;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com