Patents

Literature

33results about How to "Good pile effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

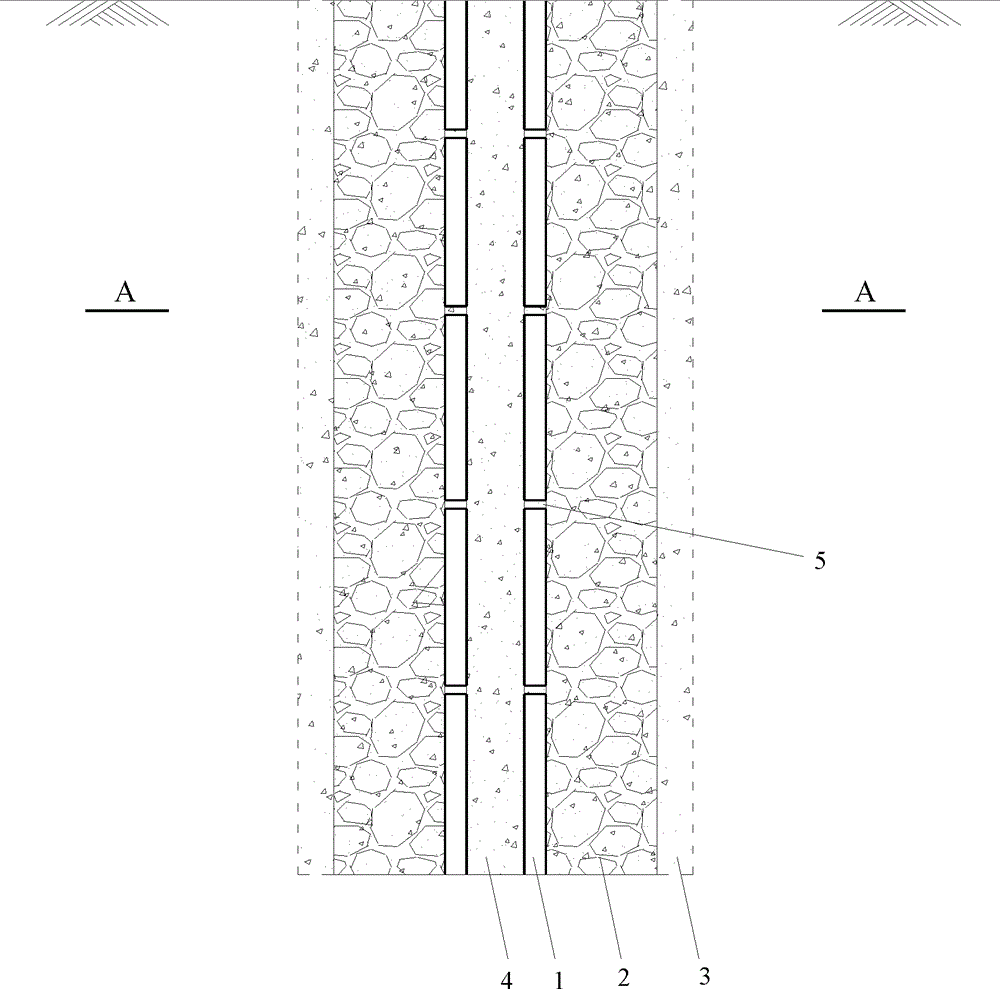

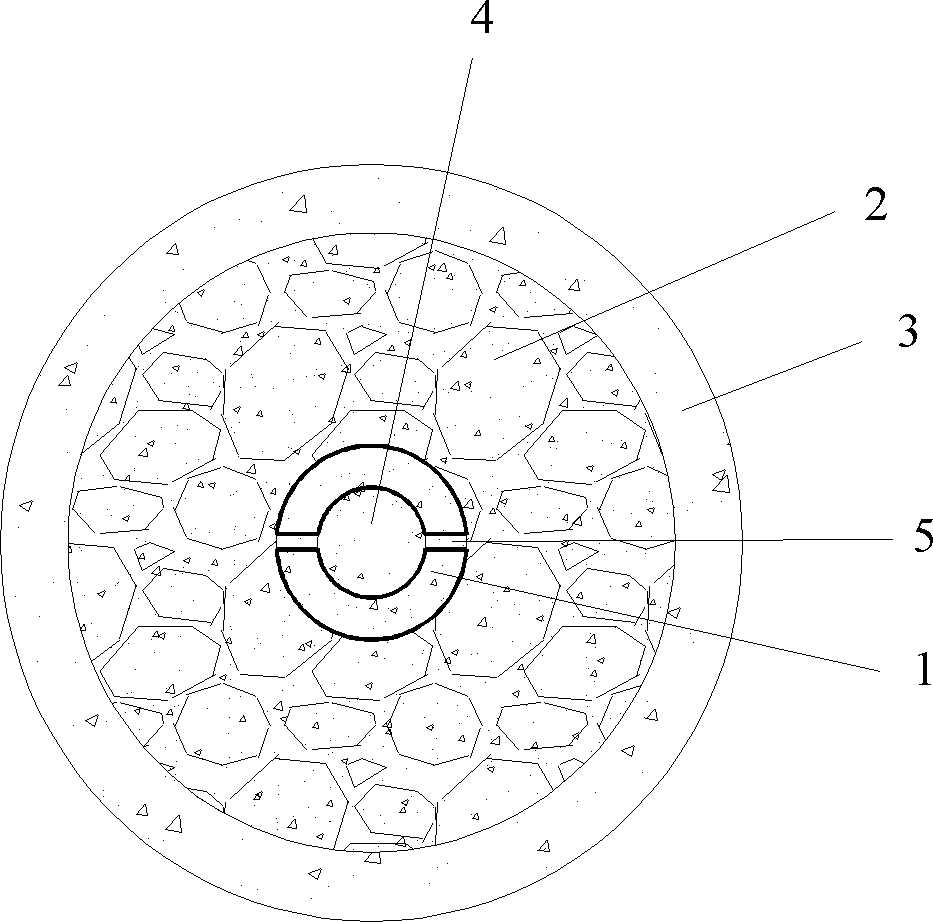

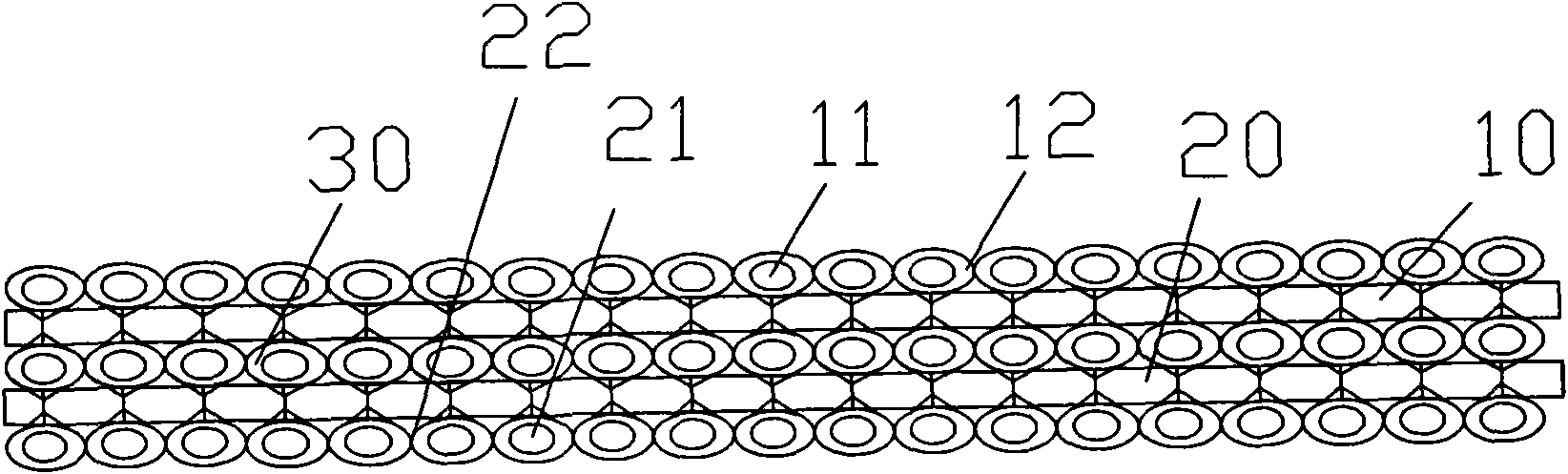

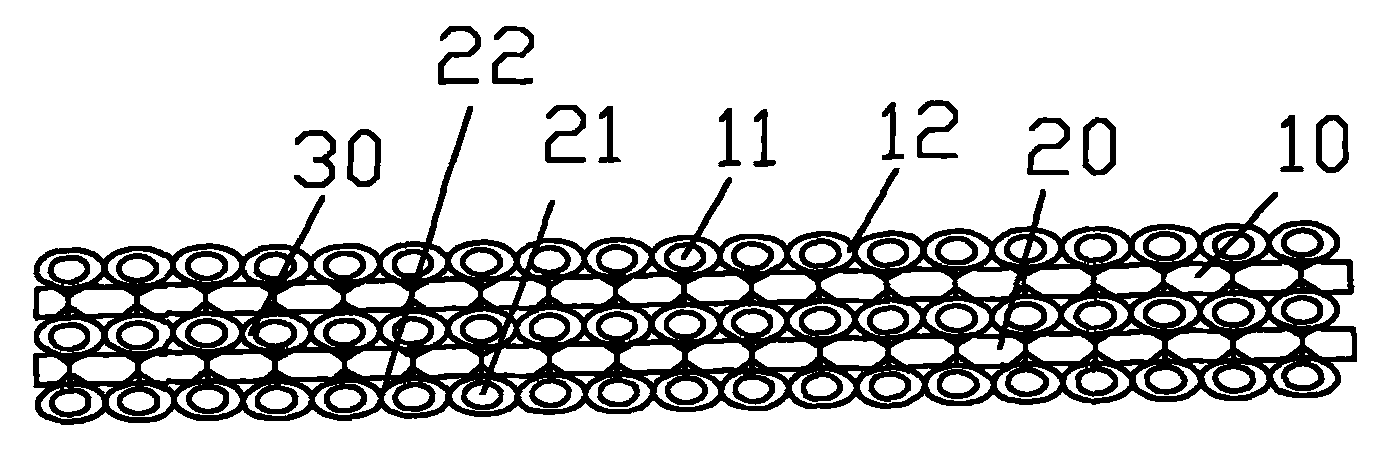

Hollow stiffness-core slurry-solidified discrete material pile and construction method thereof

ActiveCN102505684AImprove carrying capacityIncrease side frictionBulkheads/pilesCement slurryPrecast concrete

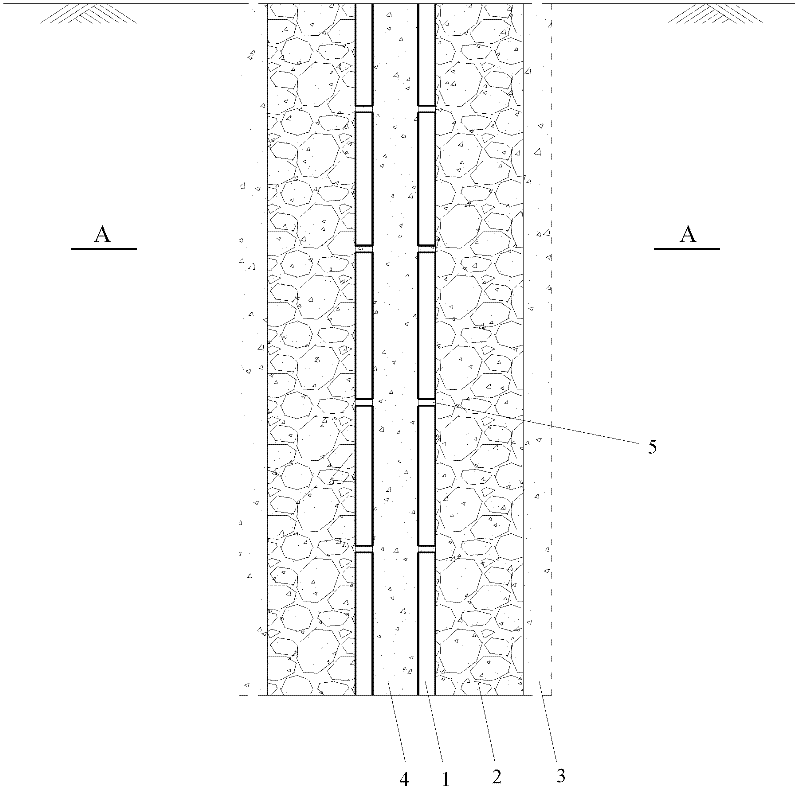

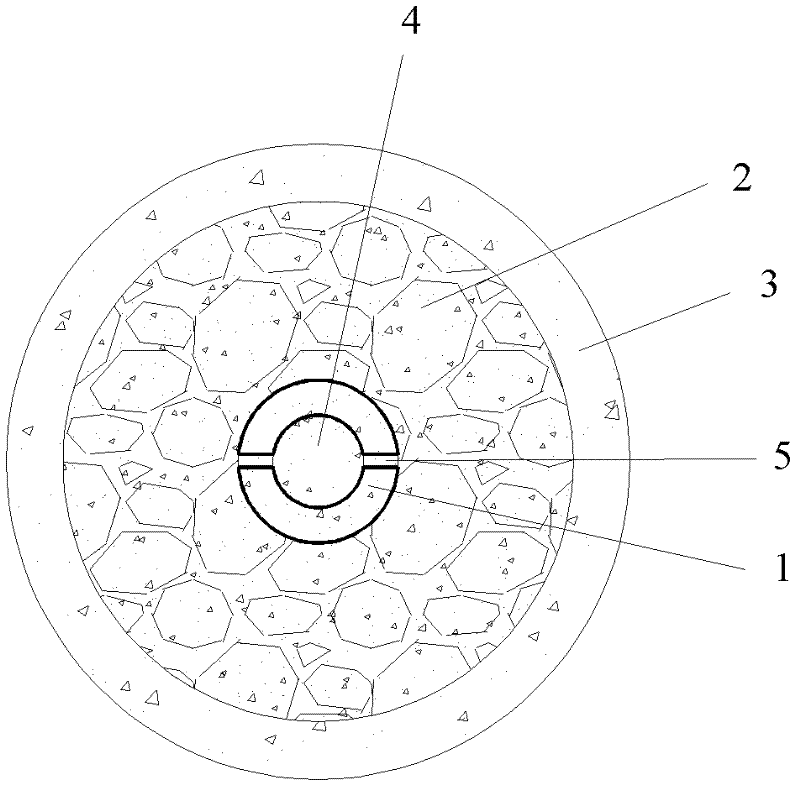

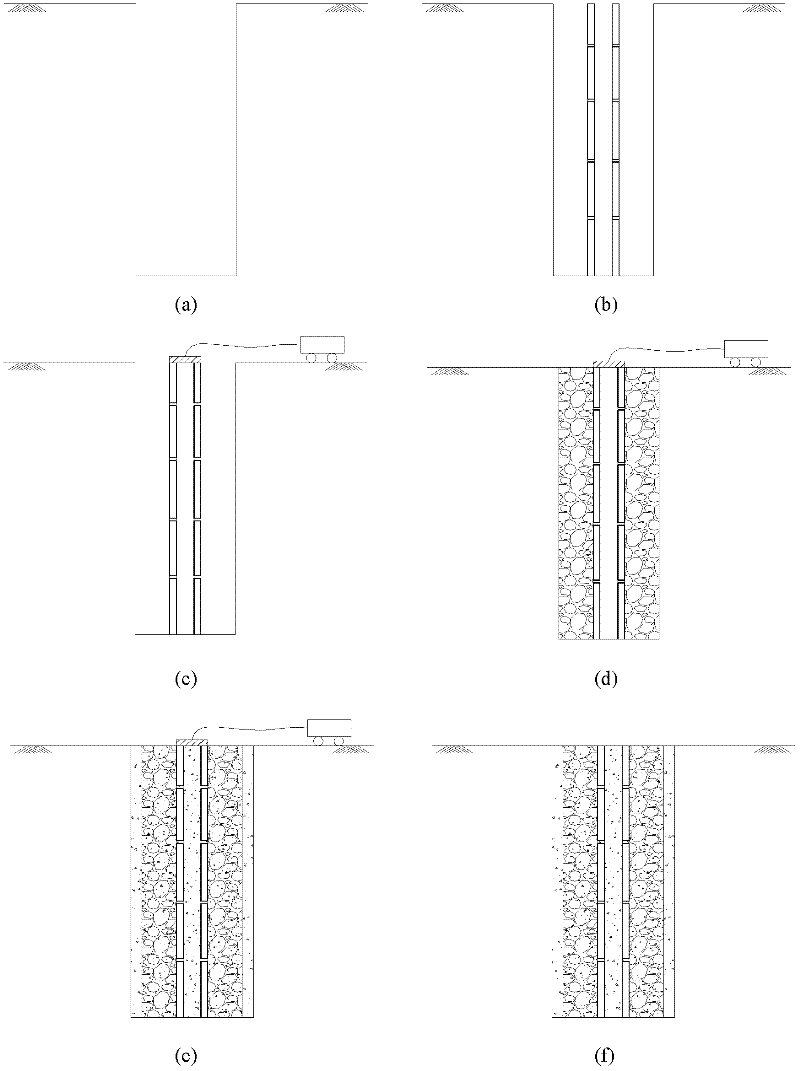

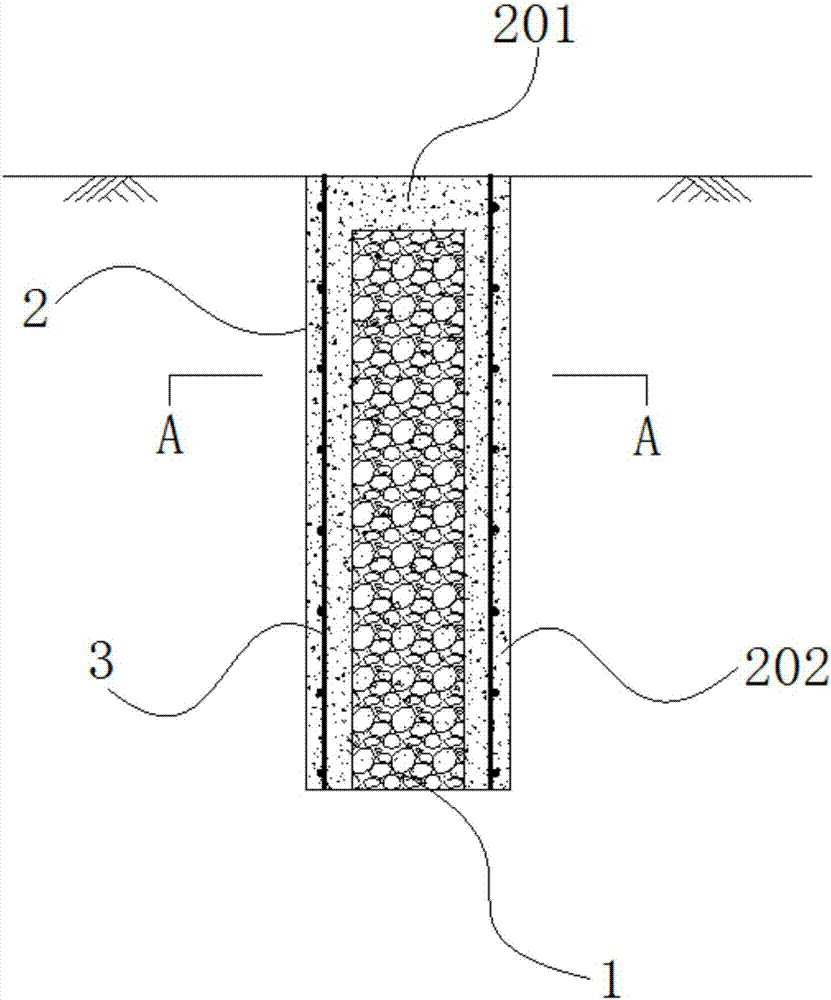

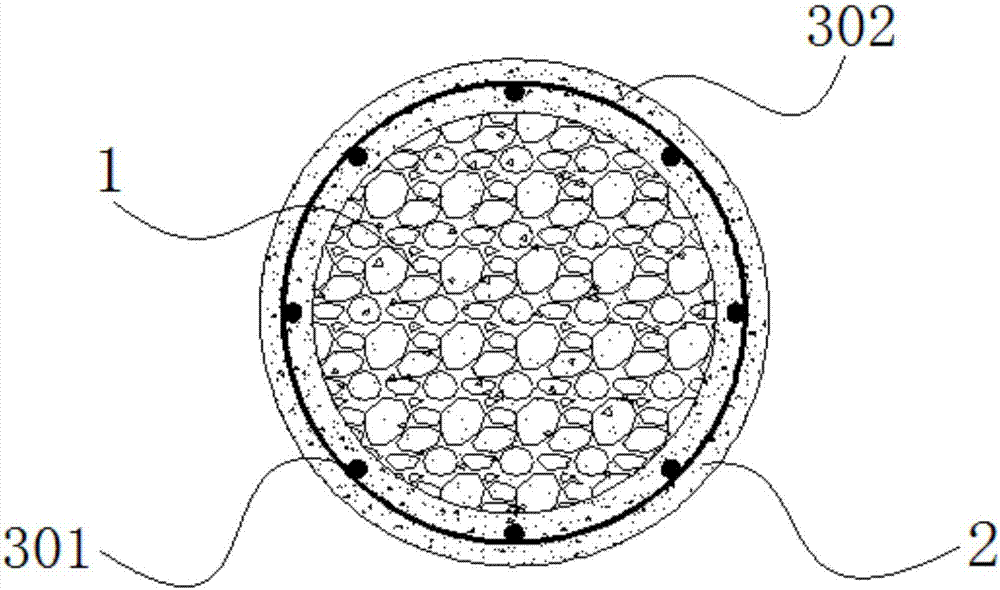

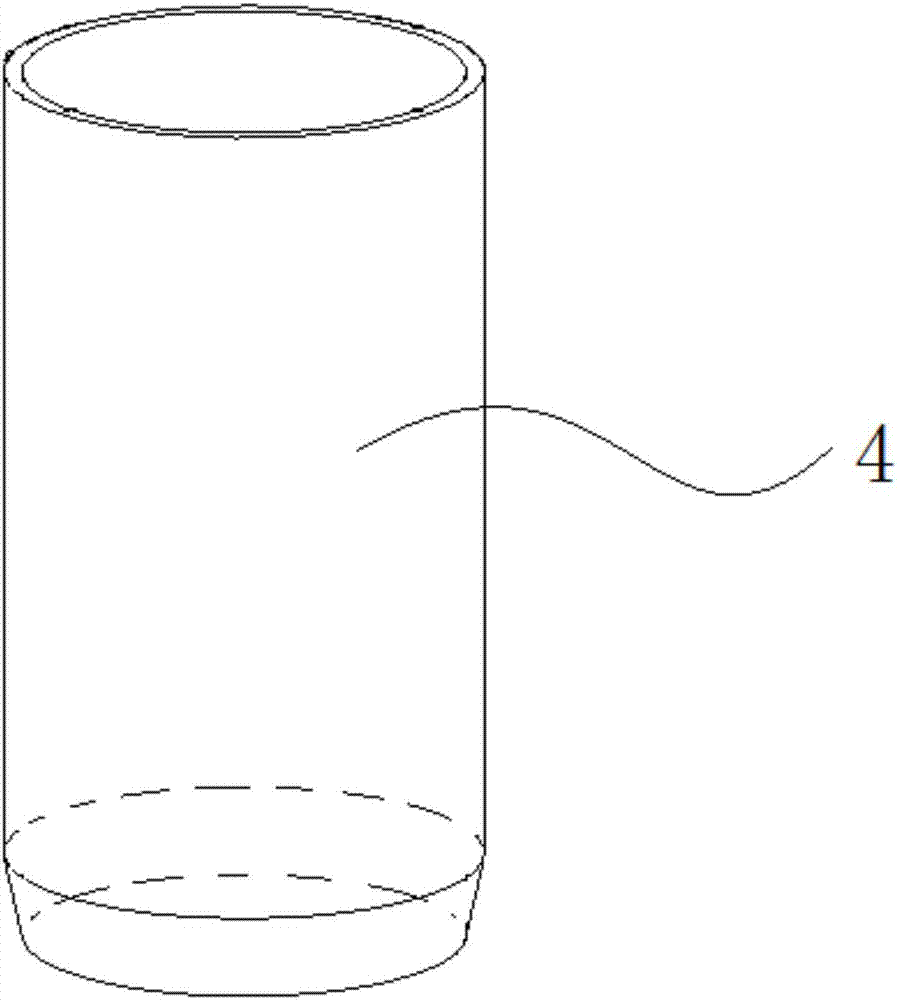

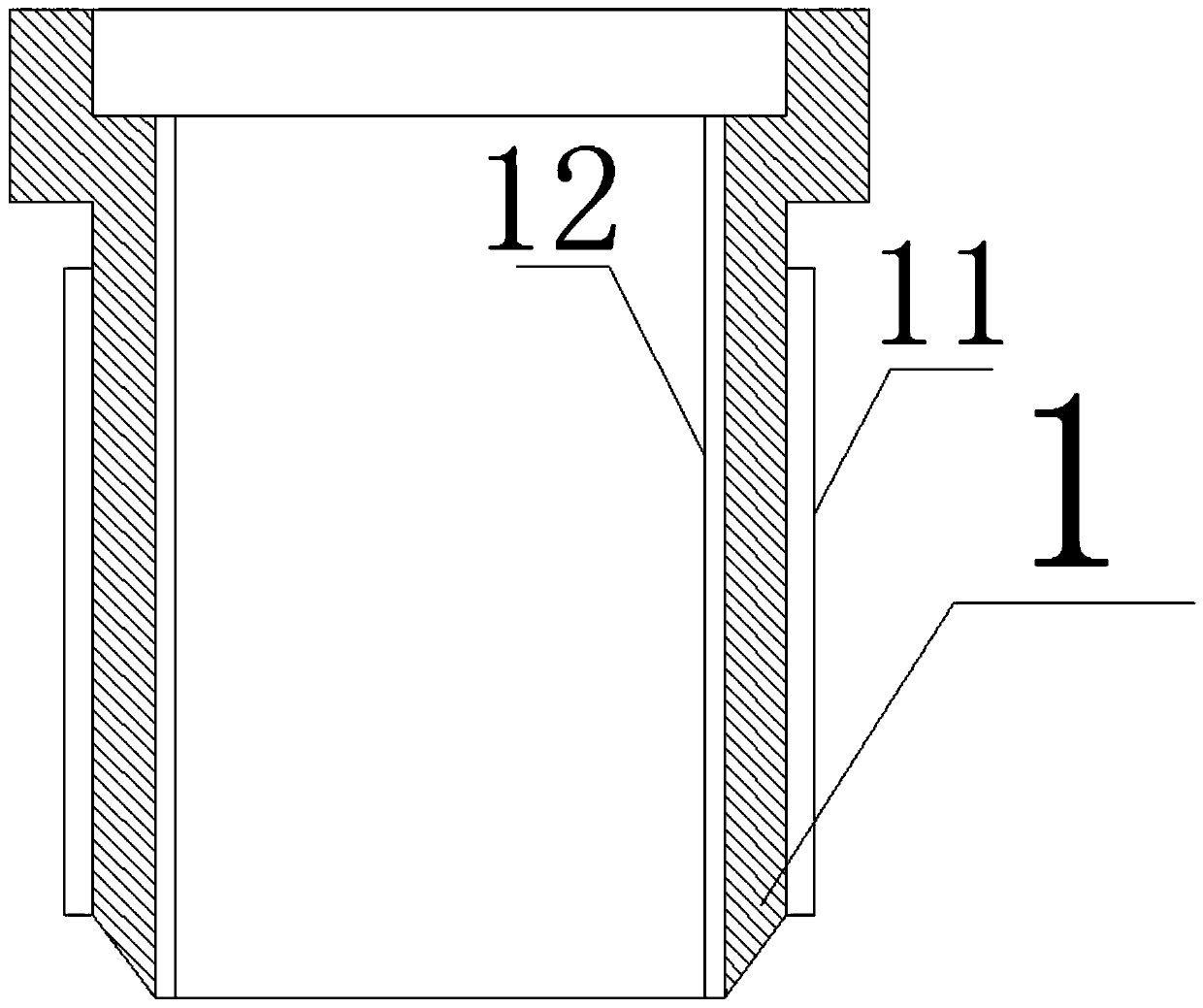

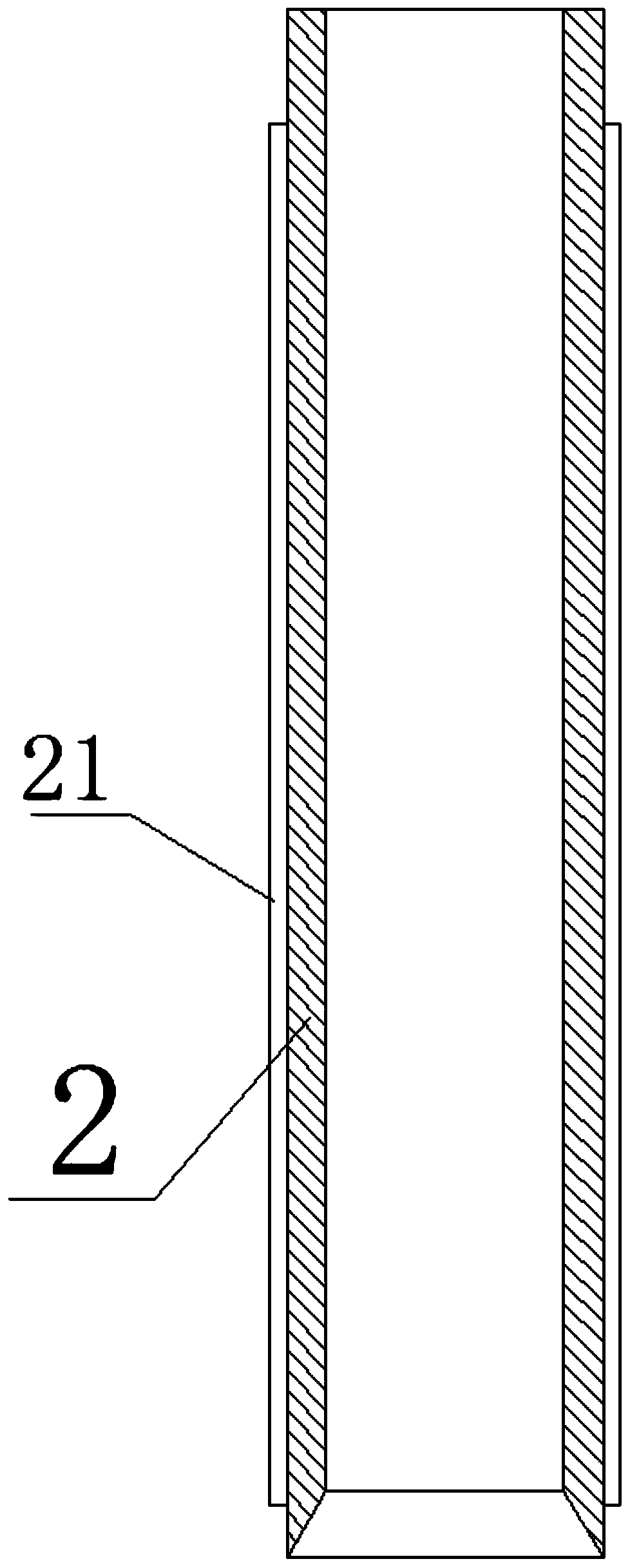

The invention discloses a hollow stiffness-core slurry-solidified discrete material pile and a construction method thereof. The periphery of a pile body is a slurry-solidified discrete material pile. The center of the pile body is a small-diameter prefabricated concrete pipe pile. Slurry filling holes are left on the pile wall of the prefabricated concrete pipe pile at intervals. Slurry enters discrete materials through holes in the middle of the concrete pipe pile and the slurry filling holes. Peripheral discrete materials are integrally cemented and solidified through cement slurry. At the same time, under the effect of slurry filling pressure, the slurry seeps into pile periphery soil bodies and the strength of the pile periphery soil is improved; the slurry fills the holes in the middle of the concrete pipe pile; and a prefabricated pipe pile can be formed by multiple sections which can be connected through bolts. The construction method comprises technical steps of: forming holes, placing the pipe pile, installing a sealing cover and a slurry filling pump, washing the holes by using clean wash, putting the discrete materials, filling the slurry, solidifying, forming the pile and the like. The hollow stiffness-core slurry-solidified discrete material pile and the construction method have the advantages that the construction processes are clear, the construction speed is fast, the pile forming effect is good, the bearing capacity is high, the manufacturing cost is low, the resources are fully utilized, the environment is protected and the energy is saved.

Owner:HOHAI UNIV

Ventilated wind screen clothing material

InactiveCN101451287AIncrease the number ofGood effectWeft knittingWarp knittingCivil engineeringTextile

Owner:SHANGHAI CHALLENGE TEXTILE

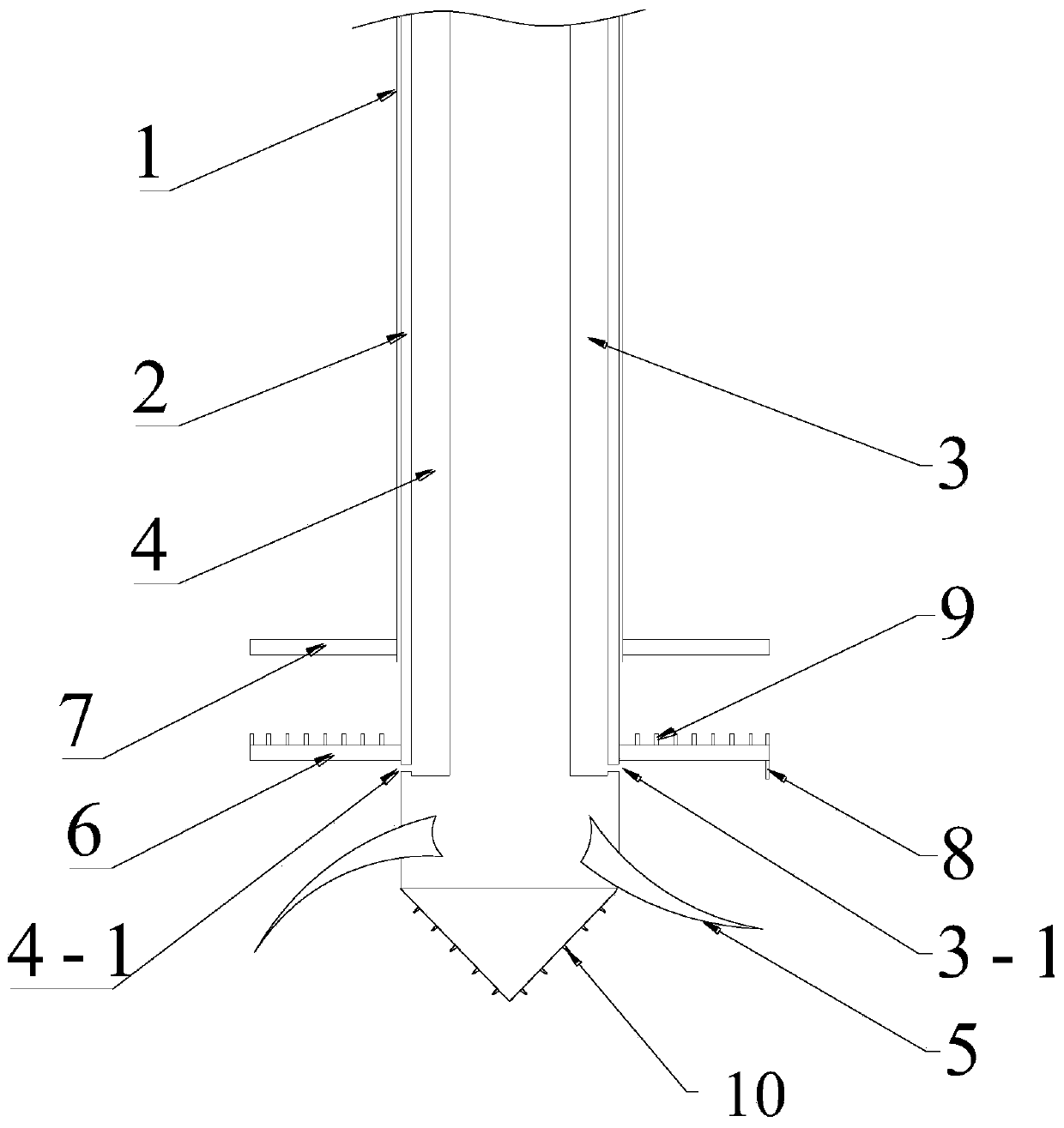

Double-spraying bidirectional cement mixing pile drill and construction method thereof

PendingCN110952522ASolve processing problemsGood processing effectDrill bitsBulkheads/pilesAir pumpHigh pressure water

The invention discloses a double-spraying bidirectional cement mixing pile drill and a construction method thereof. A main drill pipe comprises an outer main drill pipe and an inner main drill pipe; ahigh-pressure grout spraying tube and a high-pressure powder spraying tube are simultaneously arranged in the inner main drill pipe; the high-pressure grout spraying tube is connected with a high-pressure grout pump and grout manufacture equipment, which are controlled through a computer; the high-pressure powder spraying tube is connected with a high-pressure air pump and a cement storage tank,which are controlled through the computer; a first group of vanes and a second group of vanes are arranged on the inner main drill tube; the first group of vanes is positioned below the second groupof vanes; the first group of vanes adopts spiral alloy vanes; the grout spraying hole of the high-pressure grout spraying tube and the powder spraying hole of the high-pressure powder spraying tube are arranged on the lower part of the second group of vanes; and the outer end of the vane above the grout spraying hole is provided with a vertical baffle plate for blocking high-pressure cement grout.A high-pressure cement grout tube and a high-pressure cement powder tube are simultaneously arranged for effectively selecting cement under different states according to different soil layers, and working efficiency is reasonably improved to achieve an optimal foundation processing effect.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

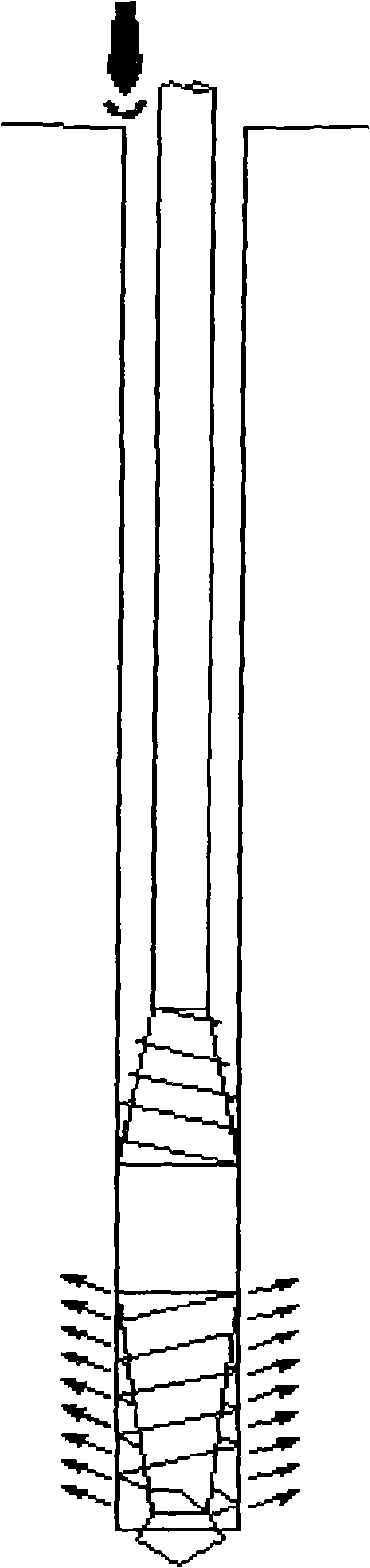

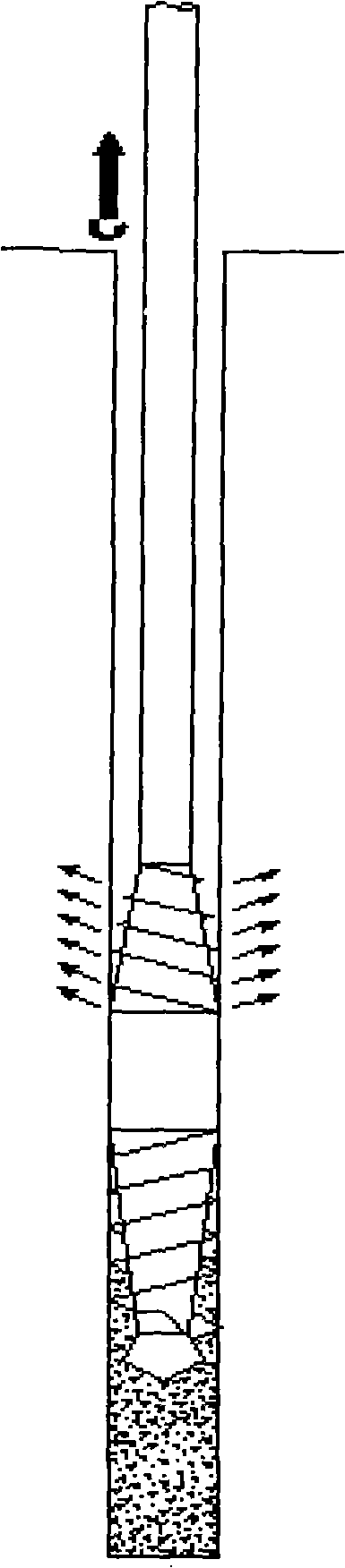

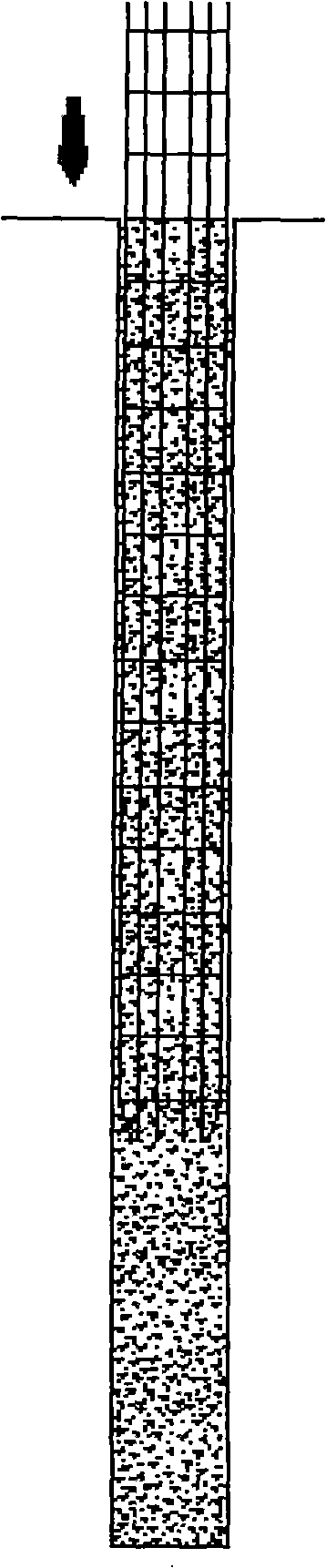

Rotating extrusion concrete filling pile construction method and equipment

InactiveCN101275396AGood pile effectImprove ergonomicsDrill bitsBulkheads/pilesSoil horizonDrill bit

A rotating squeezing concrete filling pile construction method, uses boring tool solid boring with olive type solid borer to drill, rotatably squeezes the soil body to form a solid boring whose surroundings soil body is pressed to the designed deepness, and then reversely turning and lifting the drill stem, meanwhile pumping ultra-fluid state concrete in the hollow-drill stem, vibratedly inserting the drill stem in a reinforcing steel cage after lifting out the drill stem. Boreholes are formed by using olive type solid borer to rotating squeeze the soil body, which does not need to take out earth, has a favorable pressing dense function to surroundings soil body, and rotatably squeezes the concrete filling pile borehole as an once creating pore. Adopting the inventive rotatably squeezing dense soil body pore-creating method, the pile surroundings soil body is stabilized by densification, the compactness of the pile surroundings soil body is improved about 30%, the pile side friction resistance is improved about 30%, the pile end support force is improved about 50-70%; the unconsolidated formation concrete filling coefficient is only 1.25, the construction cost is reduced, which has good pile-formation effect and can improve work efficiency for about 20-30%; the method is suitable for hard and compact clay layer, soil layer containing larger gravel amount and air slaking pulverize rock bedding, meanwhile has economy and environment protection effect; the invention has advantages of simple structure, low fabrication cost, being apt to popularize and spread, and being widely used in concrete filling pile construction.

Owner:邱树军

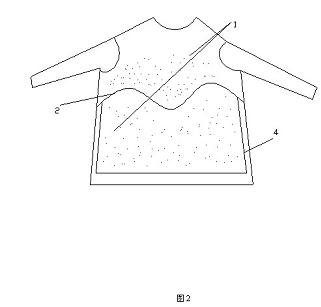

Wind-shield warm garment

InactiveCN102871232AHigh affinityIncrease health functionLayered productsOvergarmentsSoybean ProteinsCell function

The invention discloses a wind-shield warm garment which comprises an outer layer and an inner layer. The outer layer is composed of base cloth and fluff. The fluff is distributed on upper and lower surfaces of the base cloth. The fluff on the lower surface of the base cloth is connected with the inner layer. The inner layer is made of warm fabric made by blending, by weight percent, 55-65% of cotton fiber, 20-30% of soybean protein fiber, and 15-20% of composite carbon fiber. The fluff on the wind-shield warm garment is upright on the gauze, the fine effect of upright pile is generated, and fine wind-shielding performance is achieved. The fluff on the lower surface of the base cloth is woven together with the inner layer, so that warmth retention for bodies is achieved. The inner layer is made of the composite seaweed carbon fiber, is well skin-friendly and has functions of health caring, warmth retaining, cell energy enhancing, cell function and activity enhancing, and the like.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

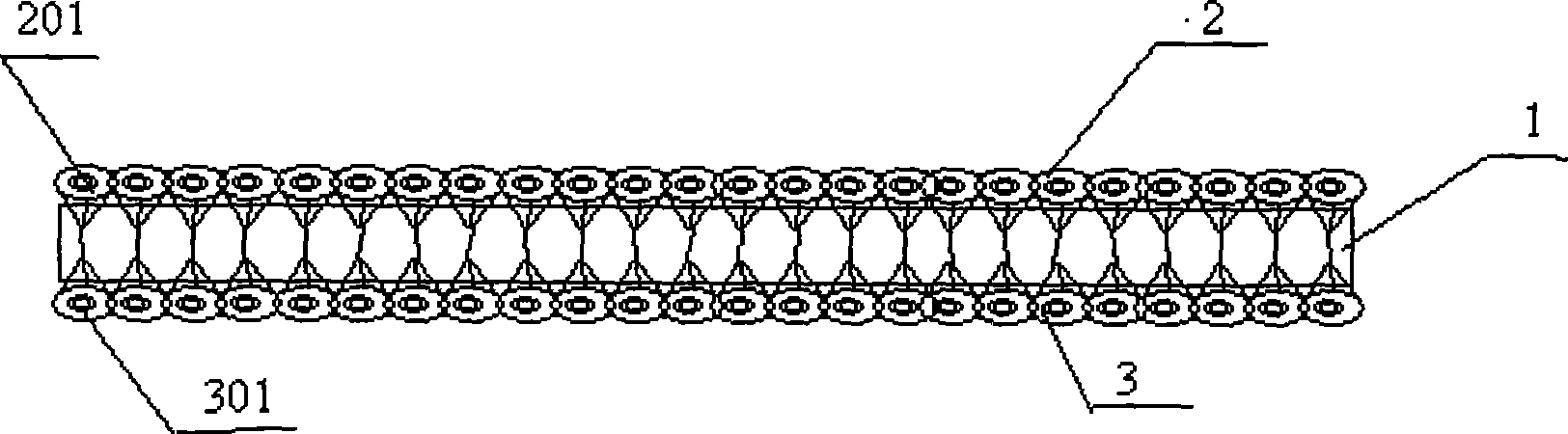

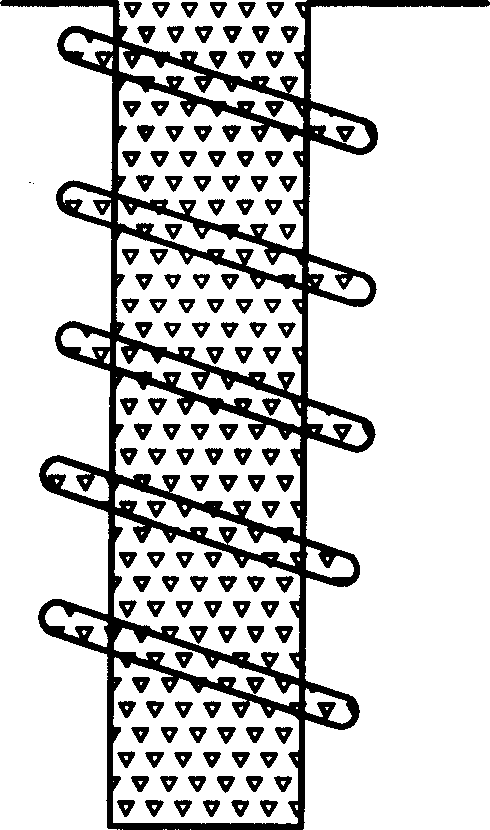

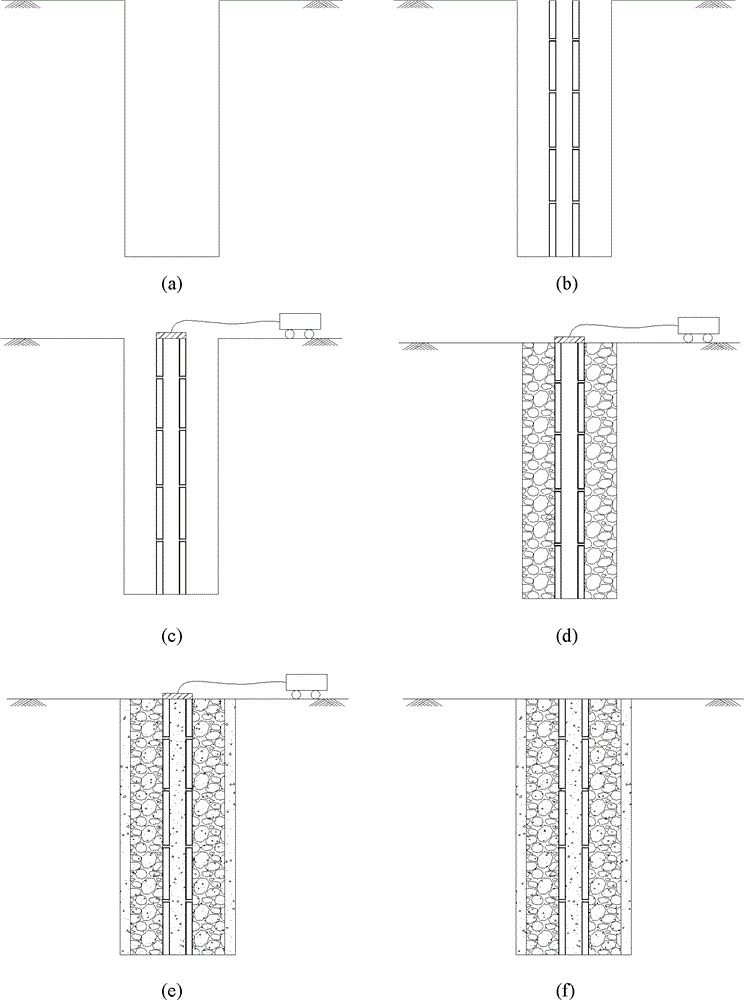

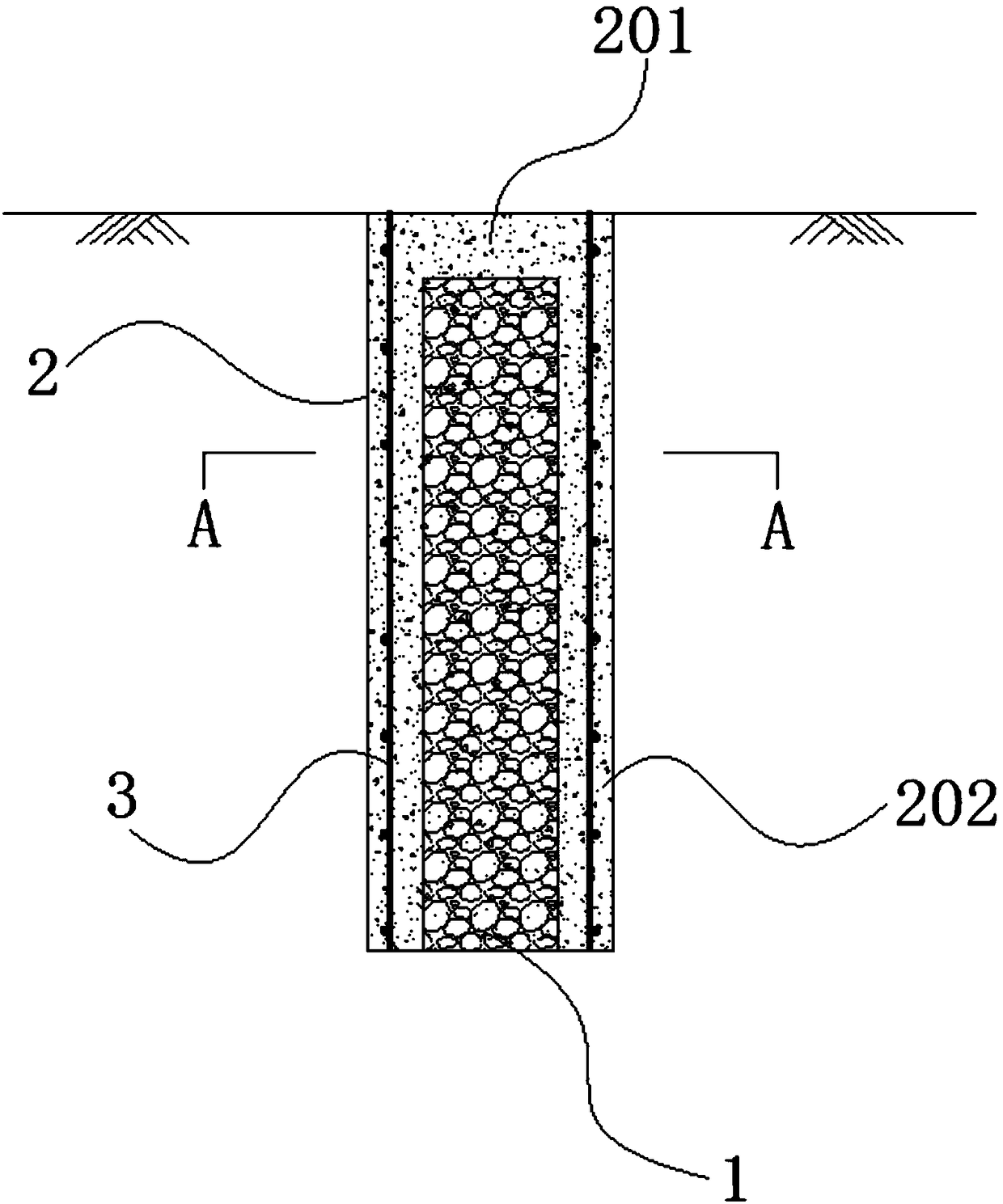

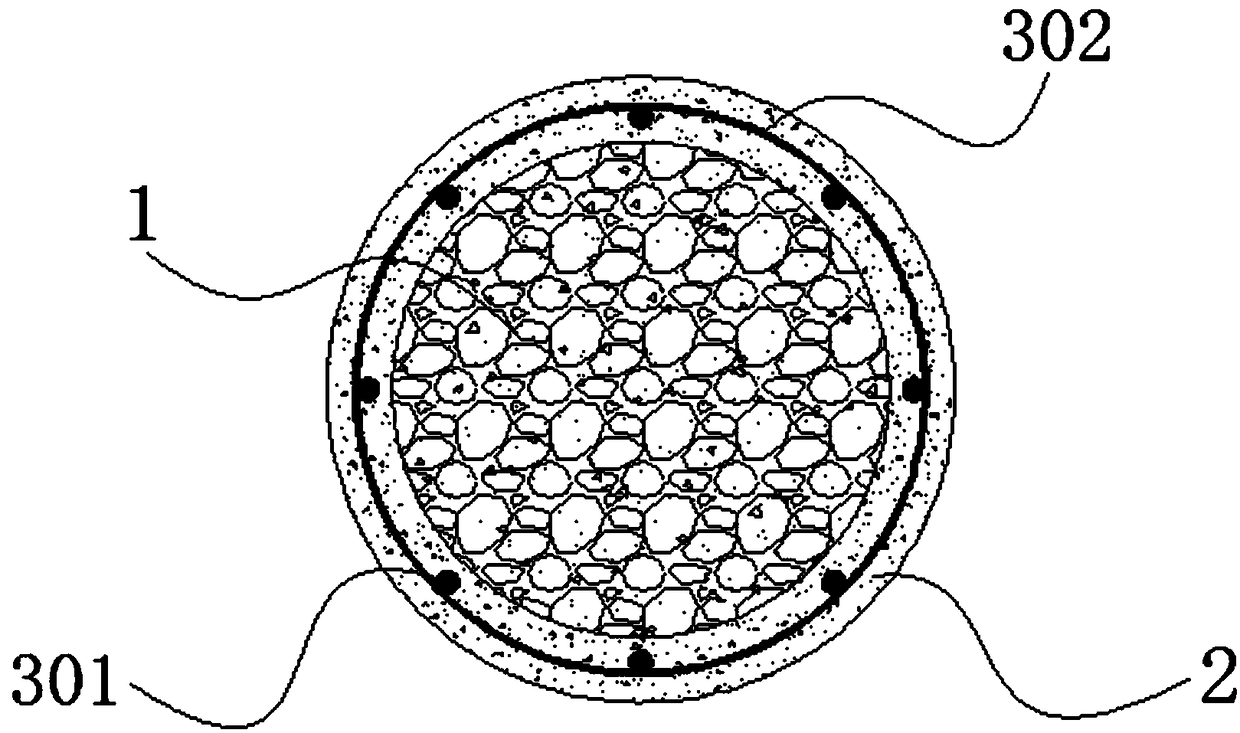

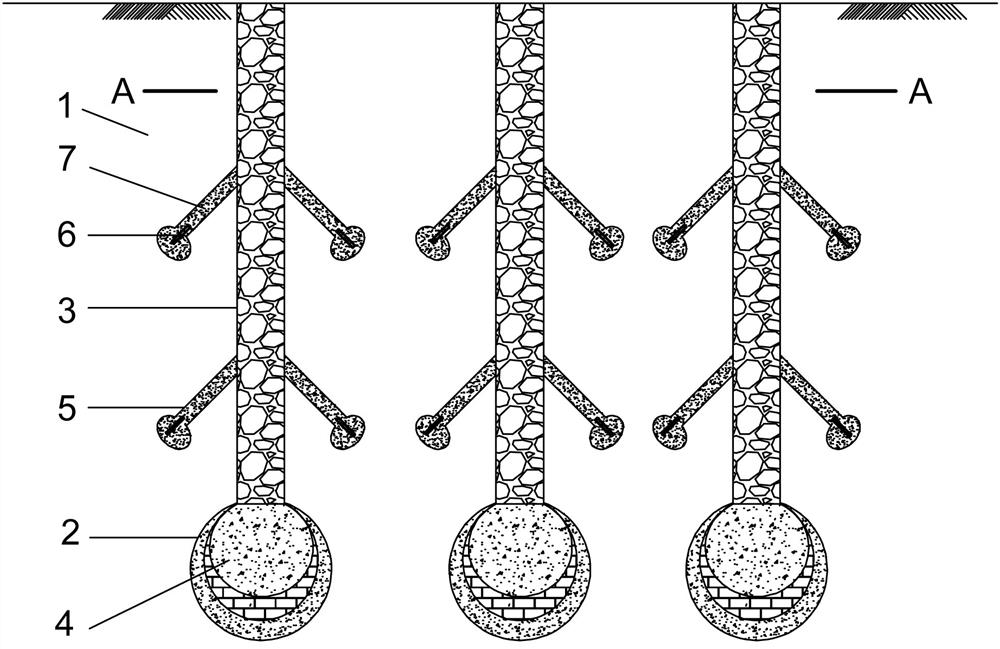

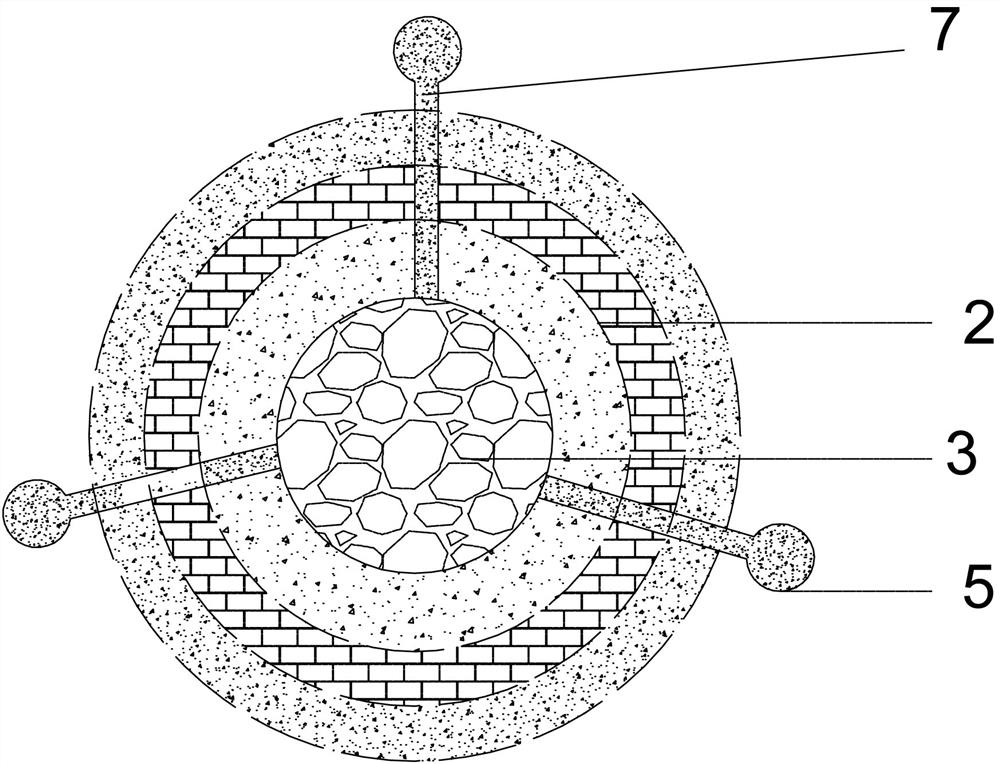

Discrete material core expansion concrete pile and construction method thereof

ActiveCN107012861AReduce construction costsThe construction process is simple and clearBulkheads/pilesUltimate tensile strengthBearing capacity

The invention provides a discrete material core expansion concrete pile and a construction method thereof. The discrete material core expansion concrete pile comprises a concrete semi-hollow pile and a discrete material pile core. An inner cavity of the concrete semi-hollow pile is filled with the discrete material pile core. The construction method of the discrete material core expansion concrete pile comprises the steps of hole forming, steel pipe pile die downward pressing, pile body periphery concrete pouring, pile body center discrete material throwing, vibration pile die pulling, pulp supplementing and pile forming and the like. The discrete material of the center of a pile body of the discrete material core expansion concrete pile is good in integrity and high in strength. The pile body is high in overall bearing force and large in rigidity. The construction cost is low, and low carbon and environment friendliness are achieved. The discrete material core expansion concrete pile and the construction method thereof can be widely applied to the foundation project.

Owner:CHONGQING UNIV +1

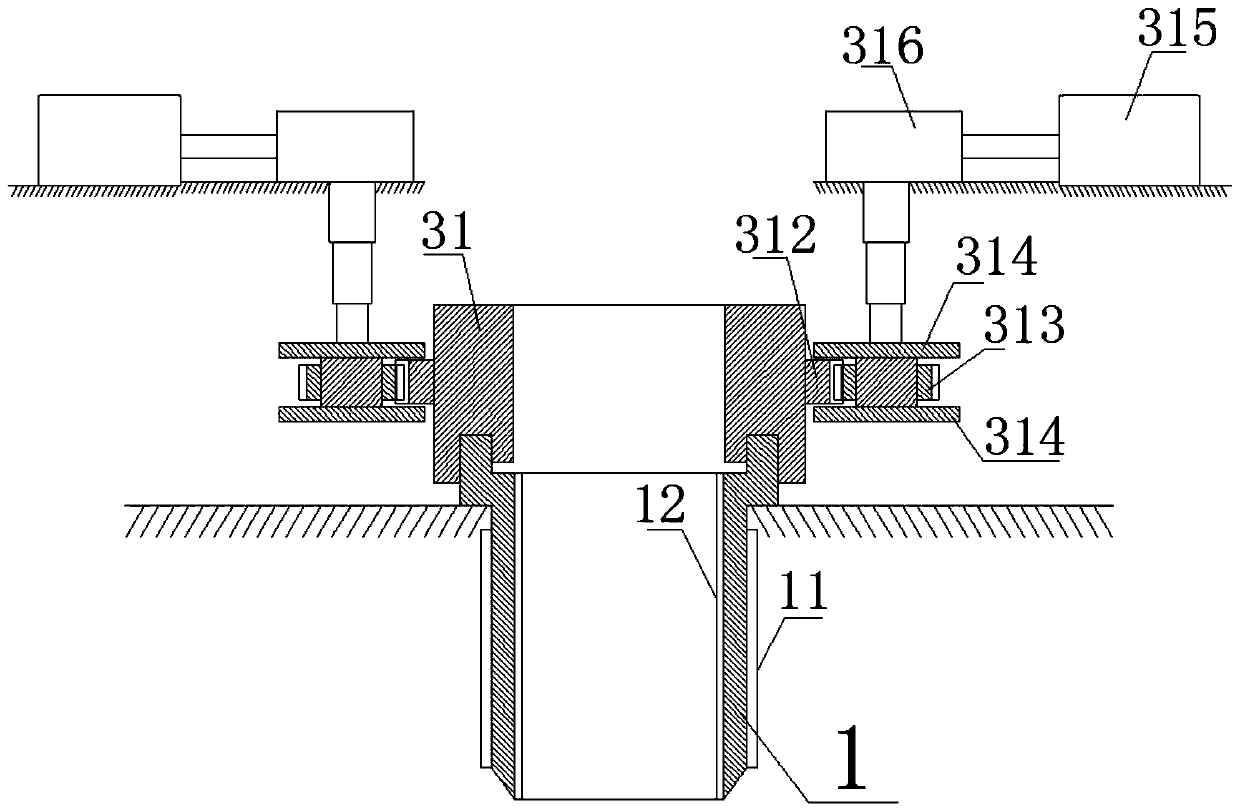

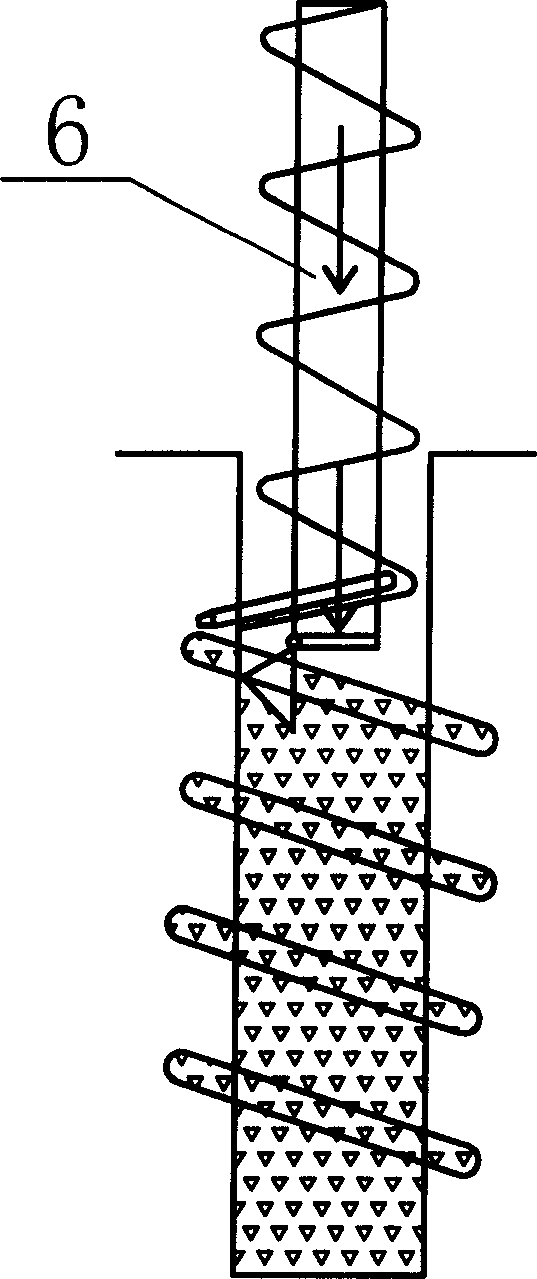

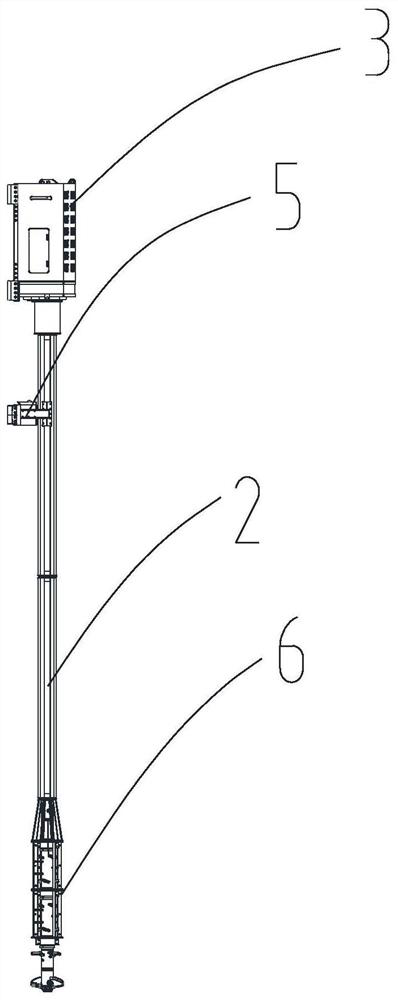

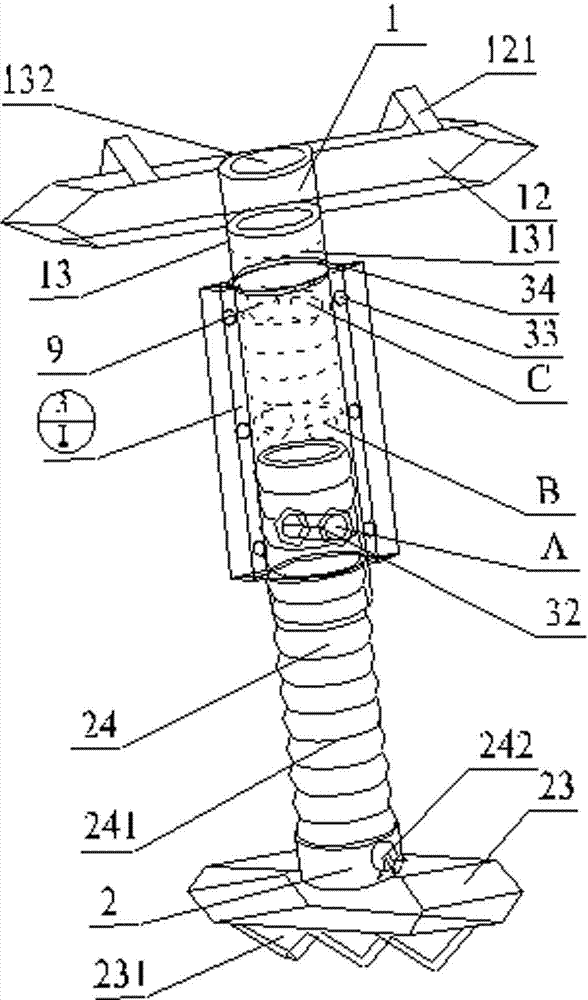

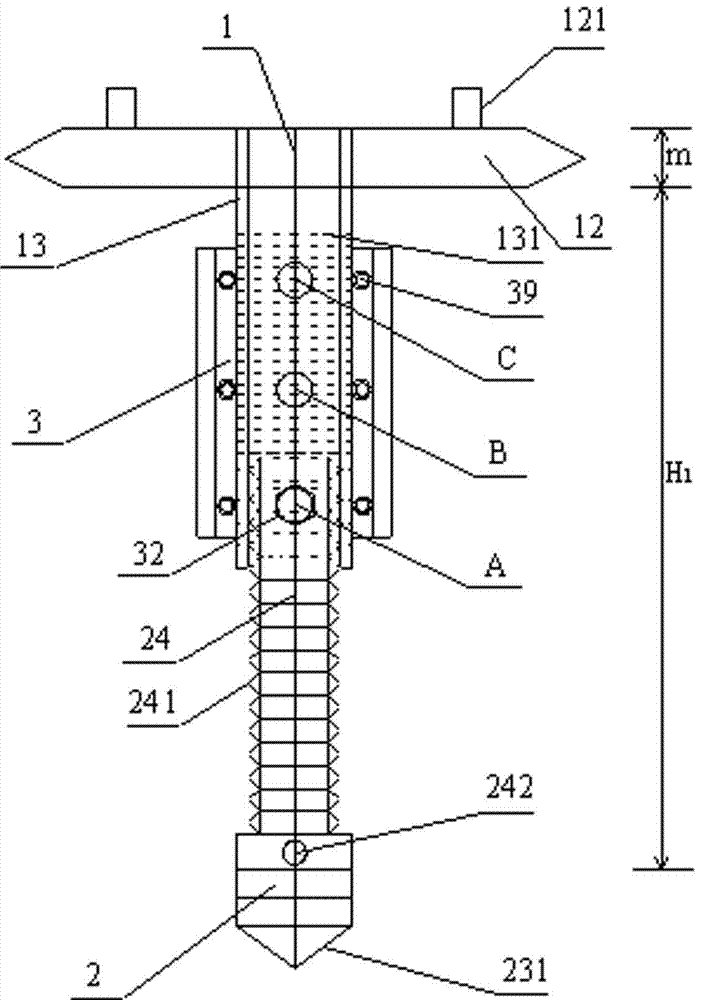

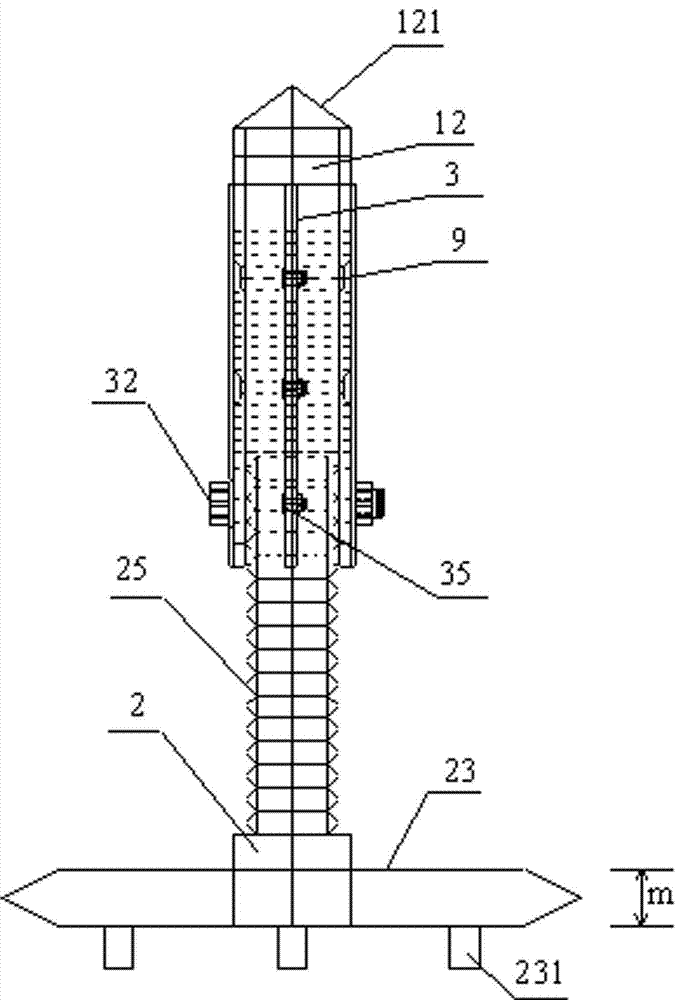

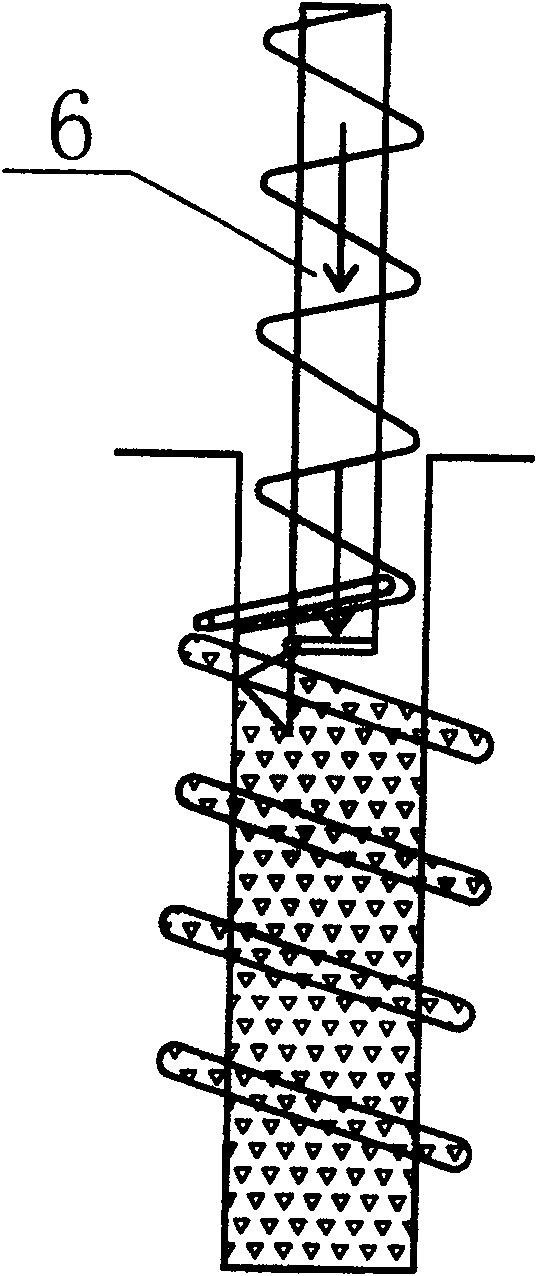

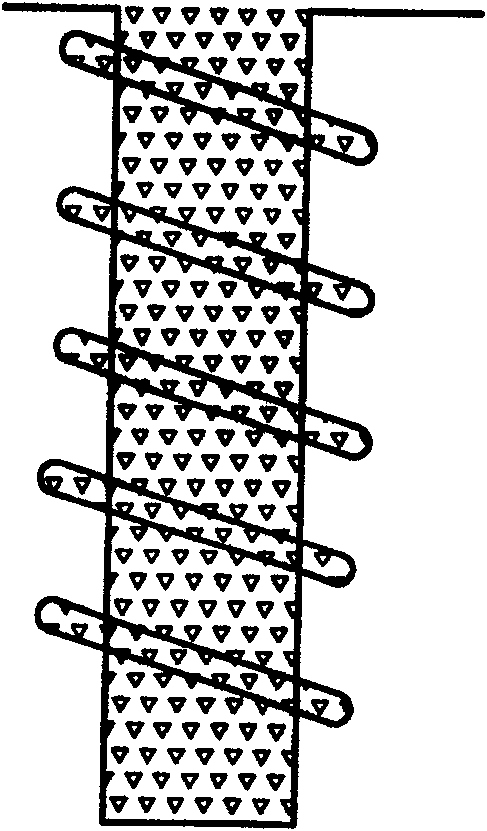

Screw pile lowering device applying force through ground, and pile lowering method

The invention relates to a screw pile lowering device applying force through the ground, and a pile lowering method. The screw pile lowering device comprises a pile body and a force applying mechanism; the pile body comprises a steel outer tube and a concrete pile body, wherein the horizontal sections of the steel outer tube and the concrete pile body are each in a ring shape; the length of the steel outer tube is smaller than the length of the concrete pile body; the outer circumferential face of the steel outer tube is provided with a first external thread in the length direction of the steel outer tube, and the inner circumferential face of the steel outer tube is provided with an internal thread in the length direction of the steel outer tube; the outer circumferential face of the concrete pile body is provided with a second external thread matched with the internal thread; and a tubular clamp clamps the steel outer tube from the upper end of the steel outer tube to drive the steelouter tube to be rotationally screwed into the ground, and a gravity device downwards presses the steel outer tube. Hammering and static pressing are not needed, the pile lowering effect is good, ground holding is firm, the speed is high, damage to a pipe pile is small, and the linearity of the pipe pile is good.

Owner:FUJIAN DADI CONCRETE PILE

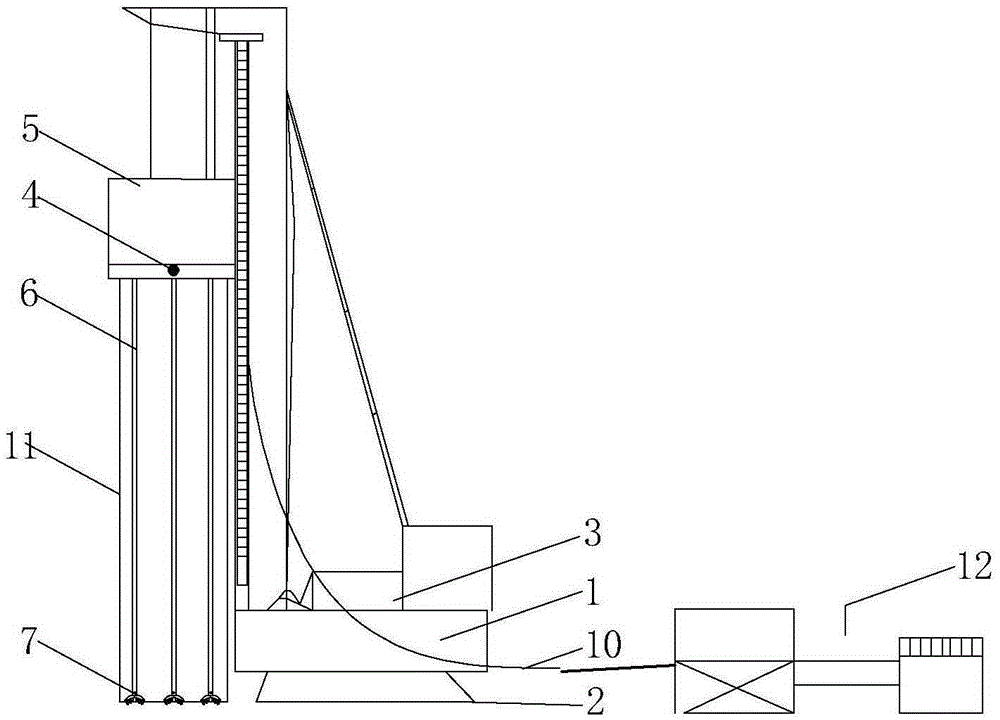

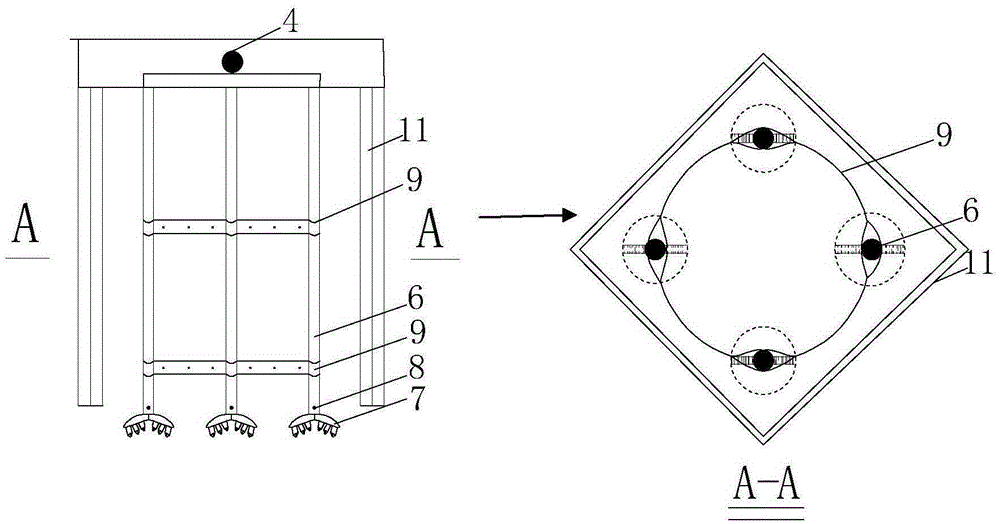

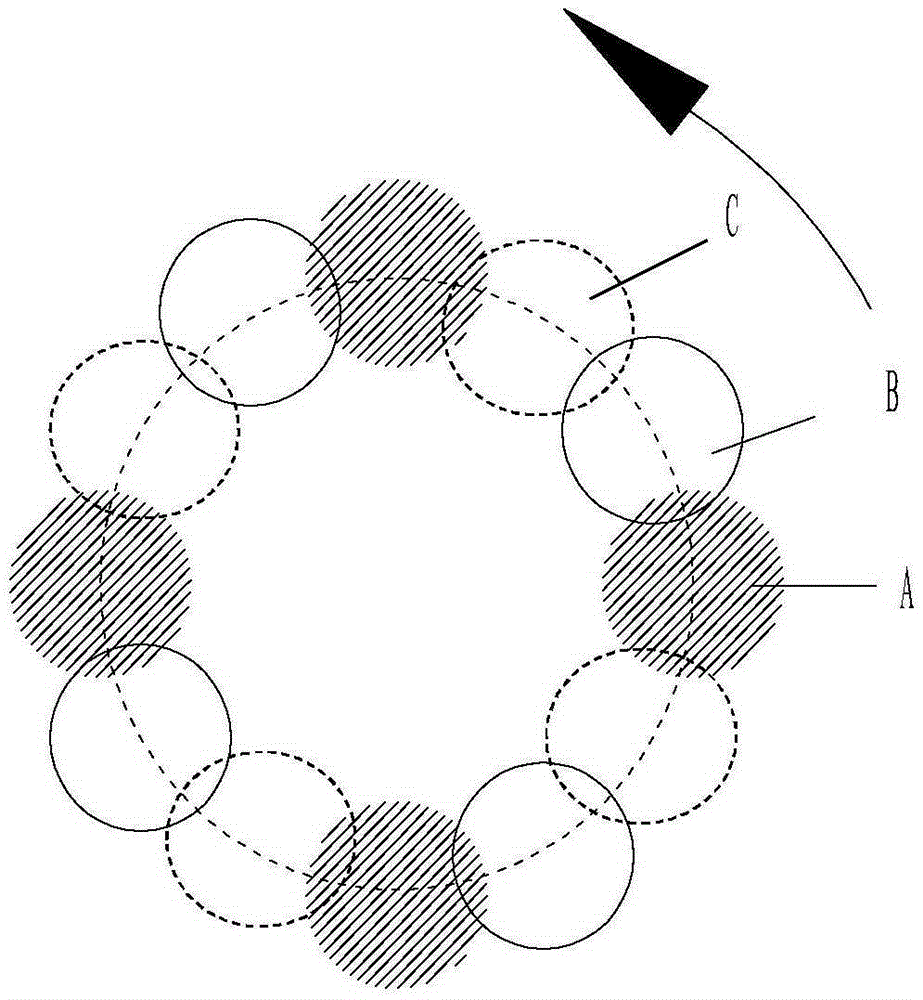

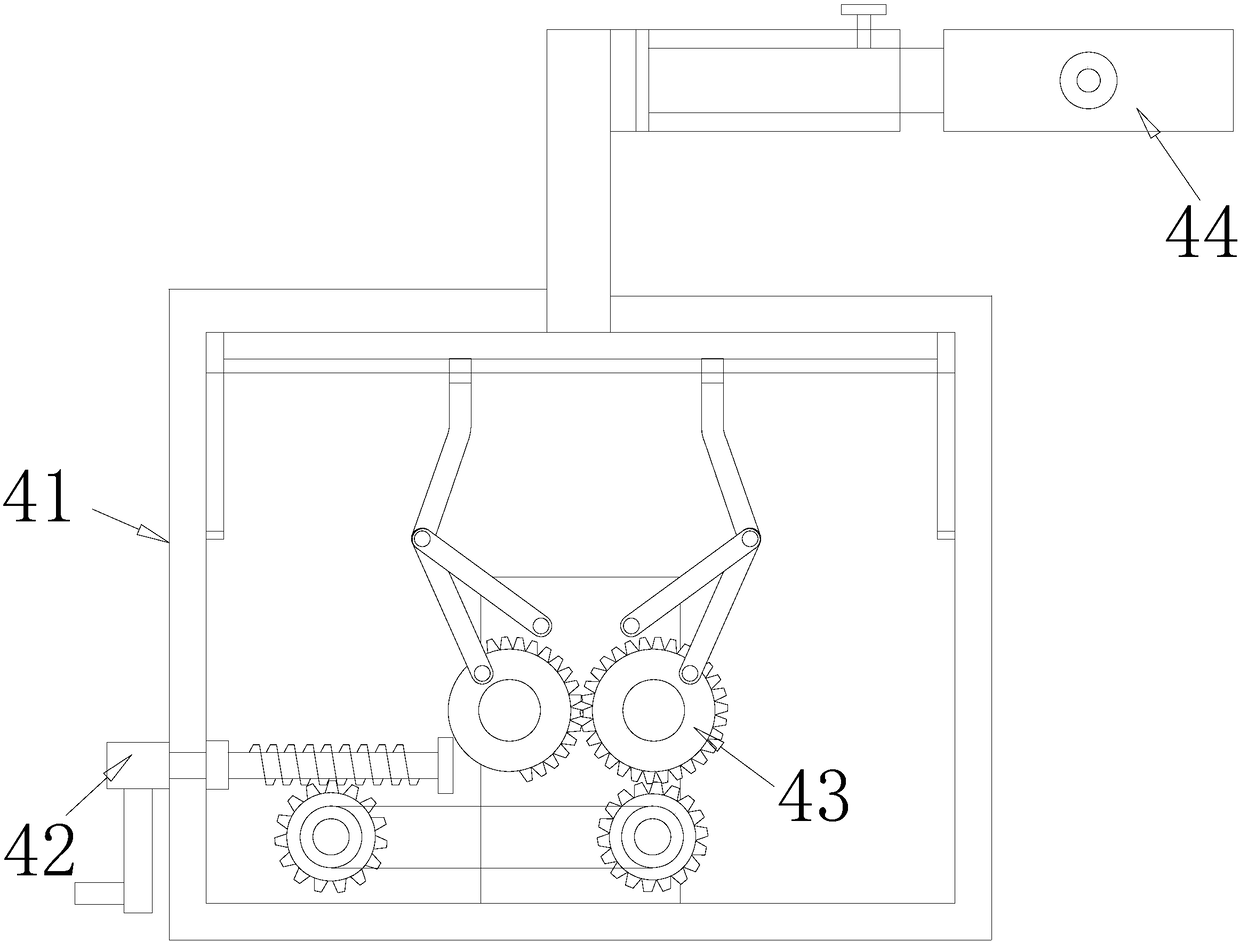

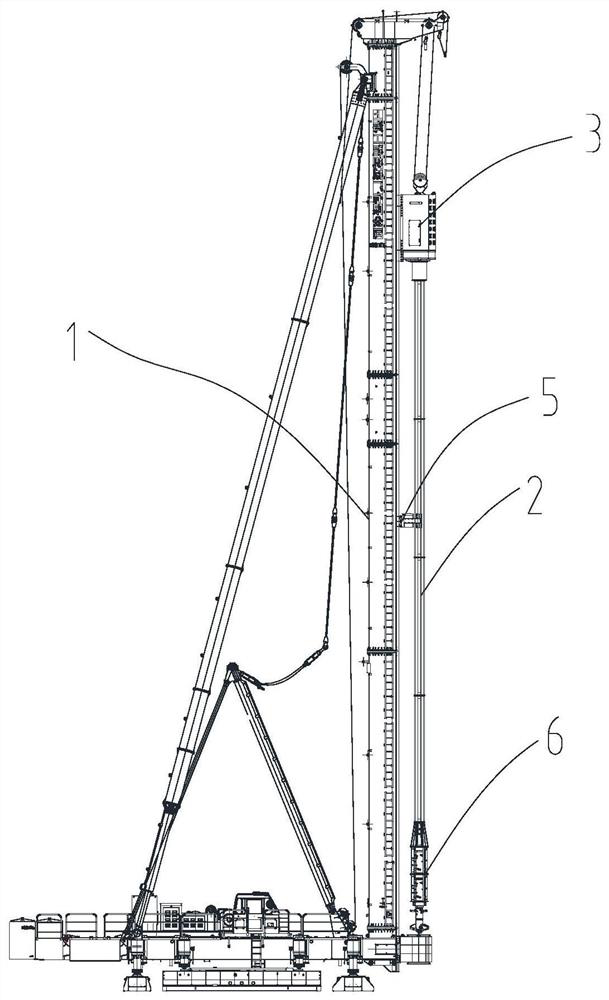

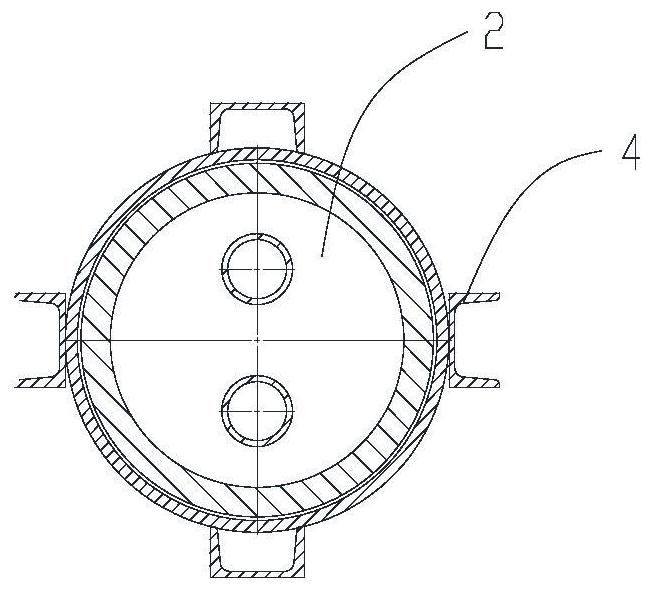

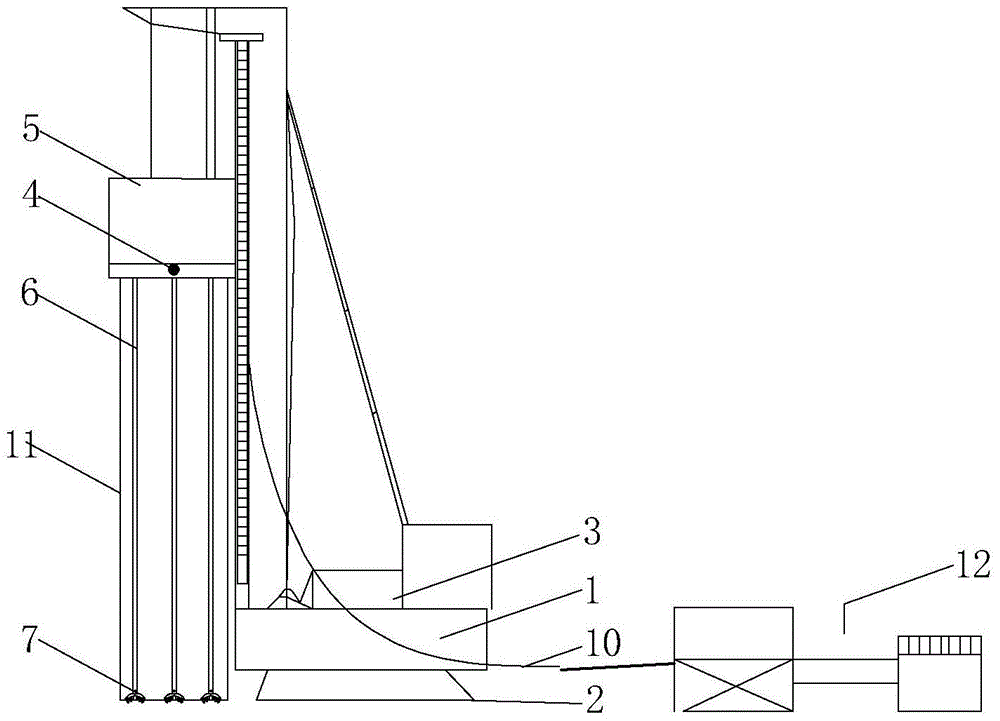

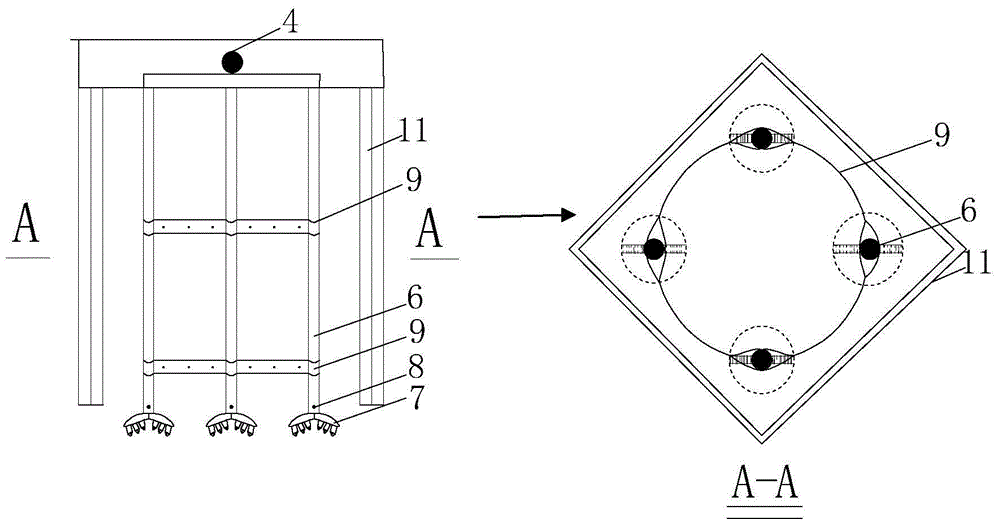

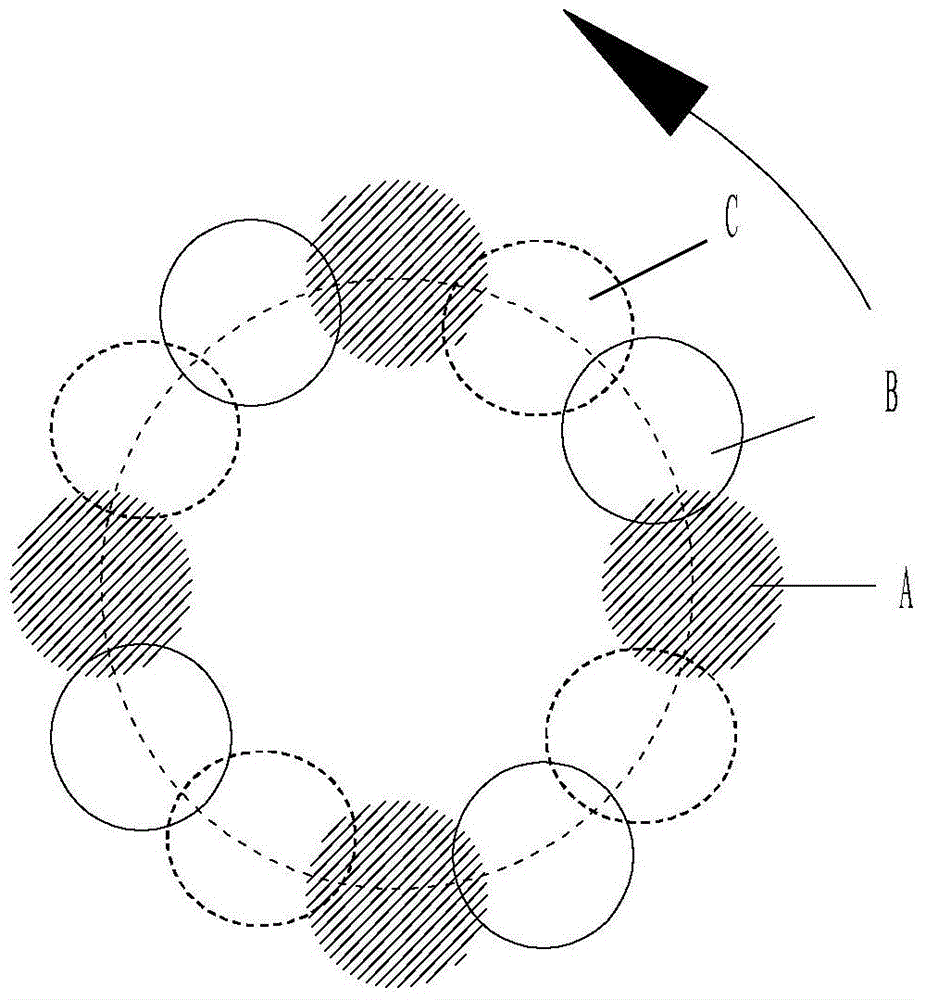

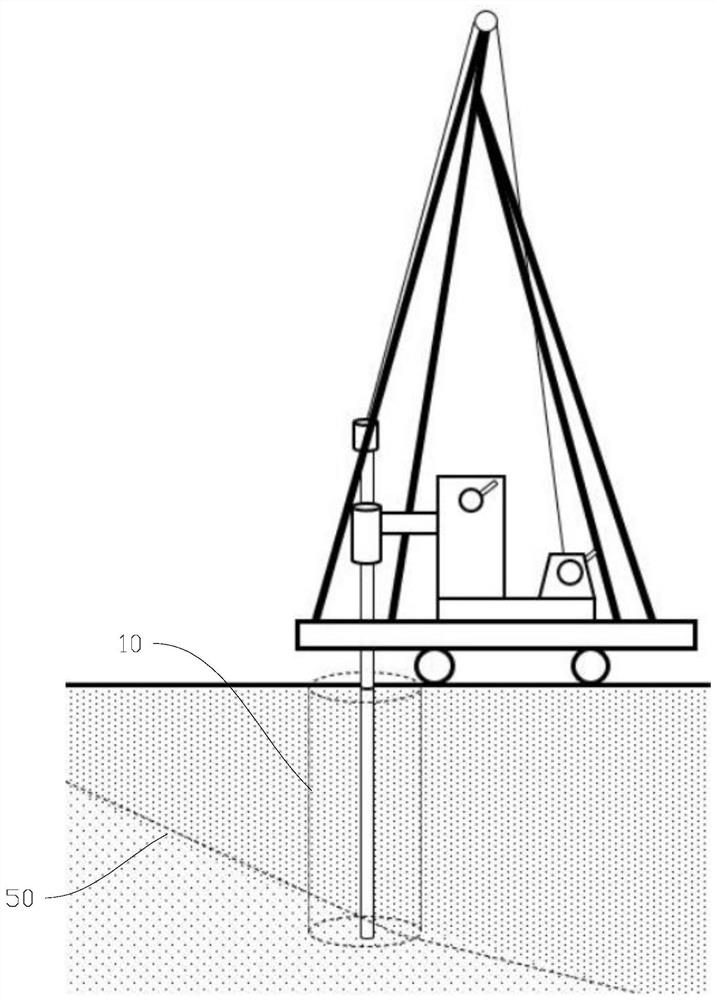

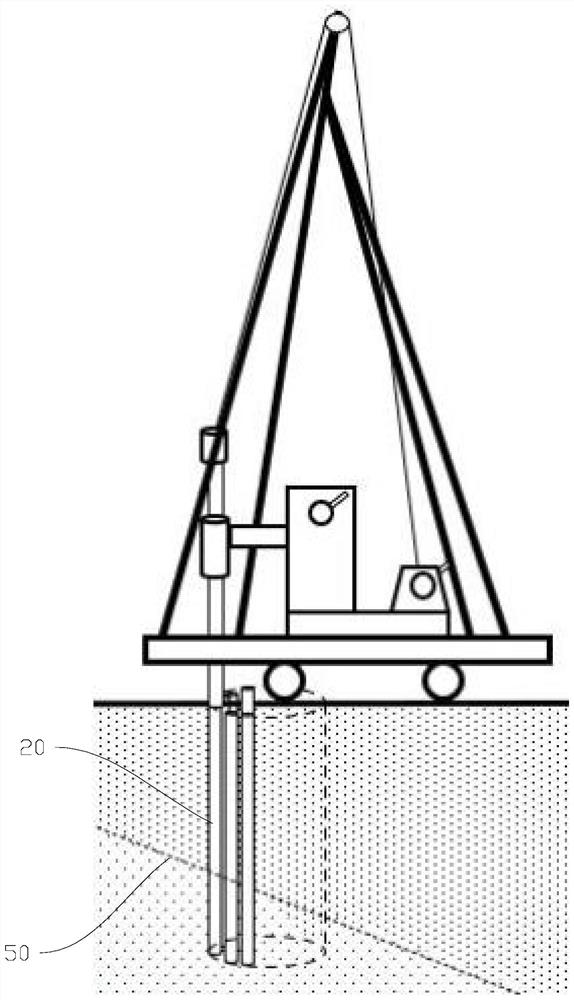

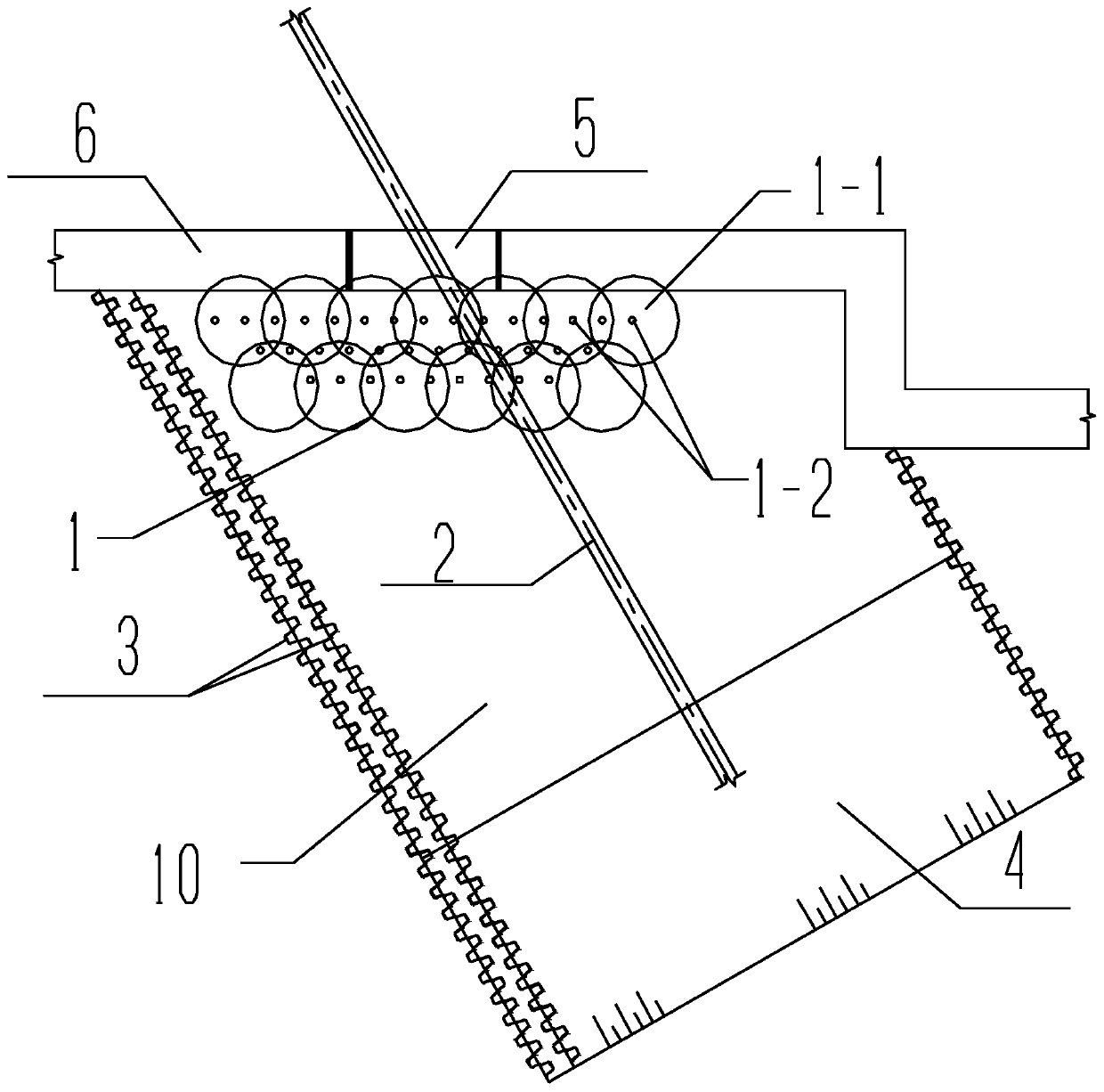

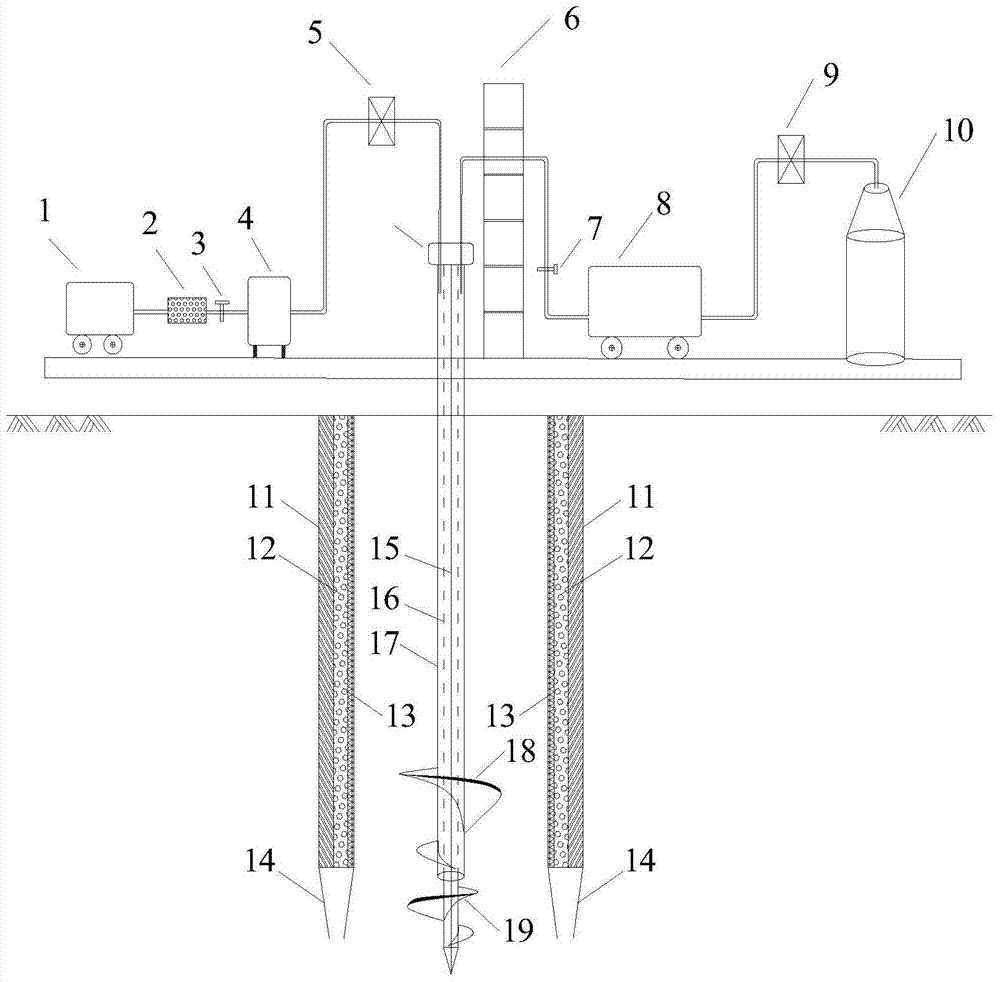

Multi-head stirring type large-diameter cast-in-situ pipe pile device and application thereof

ActiveCN105239566AImprove carrying capacityReduce the impactBorehole drivesBulkheads/pilesWinchDrill

The invention discloses a multi-head stirring type large-diameter cast-in-situ pipe pile device. The multi-head stirring type large-diameter cast-in-situ pipe pile device comprises a main unit, a winch, a drill stem assembly, a positioning frame, a power device and a background concrete processing system. The main unit and the winch are sequentially arranged on a base. The drill stem assembly is fixed to the top of the positioning frame, and all drill stems work at the same time during one-time drilling. The end-to-end closed multi-head stirring type large-diameter cast-in-situ pipe pile device is formed through simultaneous pile sinking of the multiple annular drill stems during construction by adjusting the angles of the drill stems. By means of the device, the application range of a cement mixing pile is widened; in addition, the outer wall of a multi-head stirring type large-diameter cast-in-situ pipe pile is in a wavy stripe shape, in this way, the contact area between the pile and soil is greatly increased, and the side friction resistance of the pile can be improved. According to the multi-head stirring type large-diameter cast-in-situ pipe pile device, the construction technique is clear, the construction speed is high, the pile forming effect is good, the bearing capacity is high, and manufacturing cost is low.

Owner:HOHAI UNIV

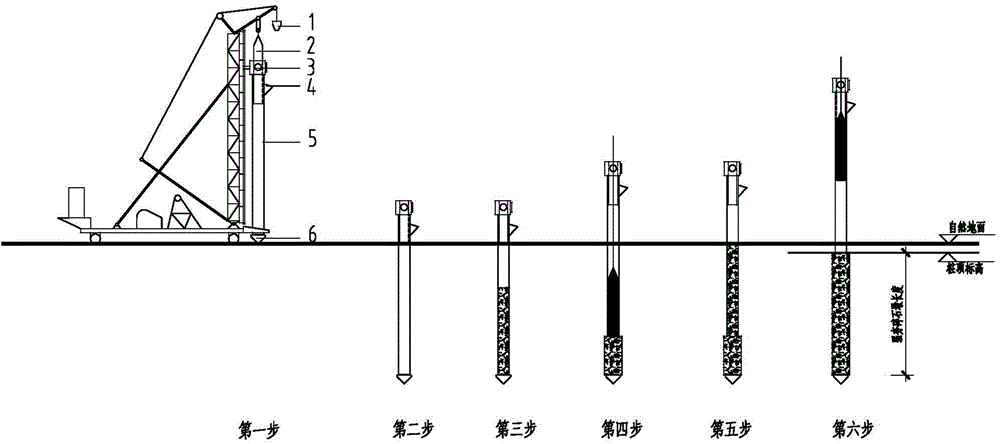

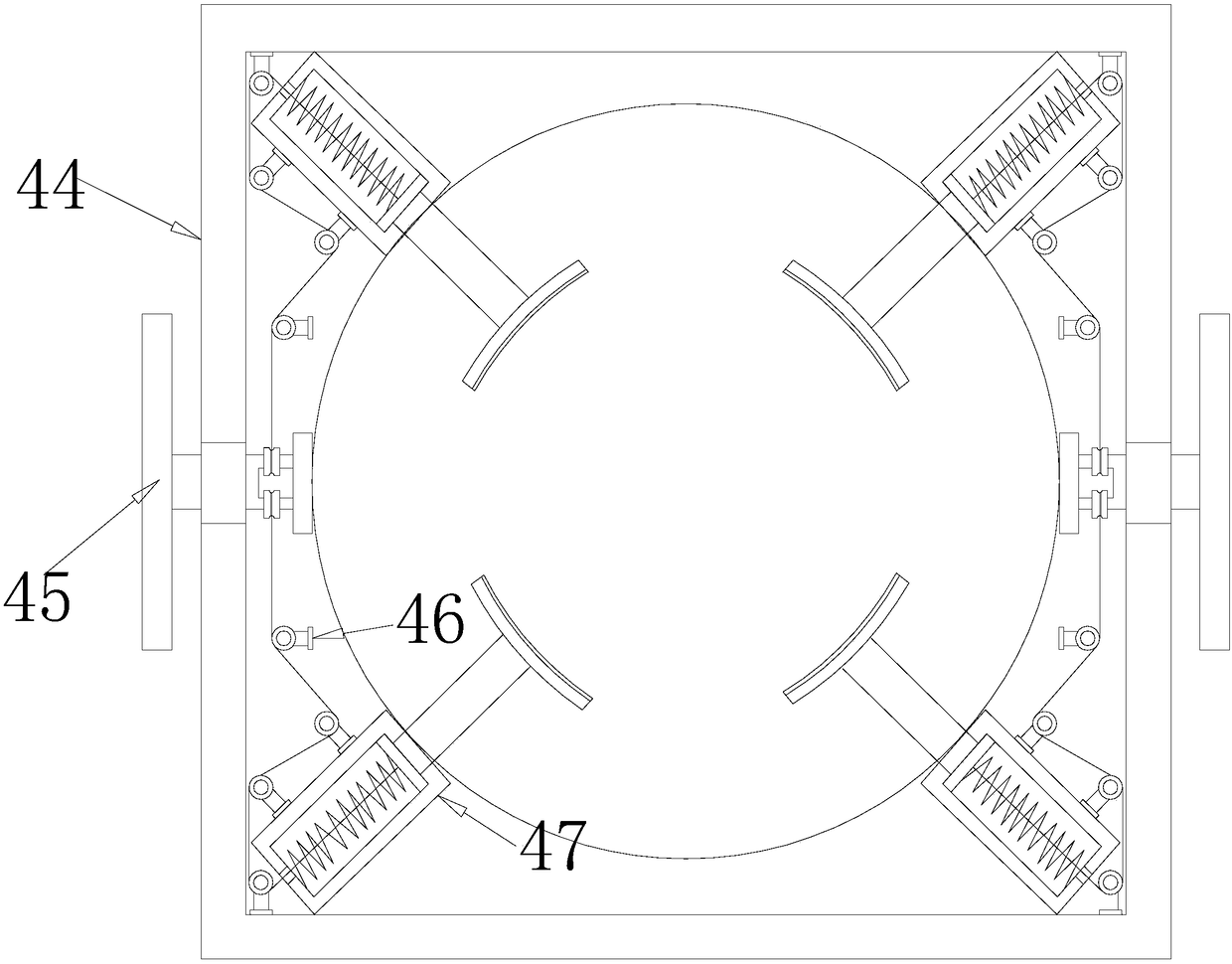

Deep replacement dynamic compaction gravel pile foundation reinforcement method

InactiveCN104947648ALarge pile diameterGood pile effectSoil preservationDynamic compactionEngineering

The invention discloses a deep replacement dynamic compaction gravel pile foundation reinforcement method. The method includes the following steps that firstly, a pile pipe (5) of a pile machine is aligned with a pile toe (6) in place at a pile position; secondly, a vibrating hammer (3) of the pile machine is started and vibrates to conduct countersinking operation downwards; thirdly, a hopper (1) of the pile machine is used for conducting filling for the first time from a feed port (4); fourthly, the pile pipe (5) of the pile machine ascends, dynamic compaction broaching is conducted, and a dynamic compaction gravel mound is formed; fifthly, the hopper (1) is used for conducting supplementary filling from the feed port (4); sixthly, the fourth step and the fifth step are repeated till the dynamic compaction gravel mound reaches pile tip elevation. Dynamic compaction energy can be effectively led to the foundation deep position through the pile pipe, the defects of the replacement dynamic compaction construction process and the vibration gravel pile process are overcome, quality is high, benefits are good, the construction period is short, and the foundation reinforcement effect is better.

Owner:SCEGC MECHANIZED CONSTR GRP COMPANY

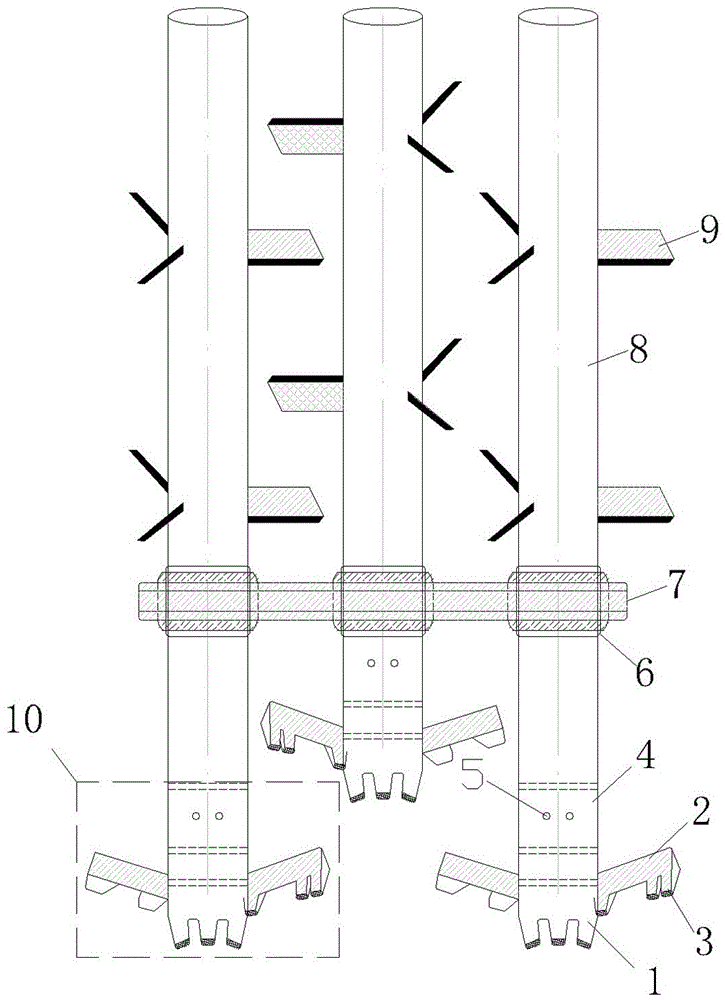

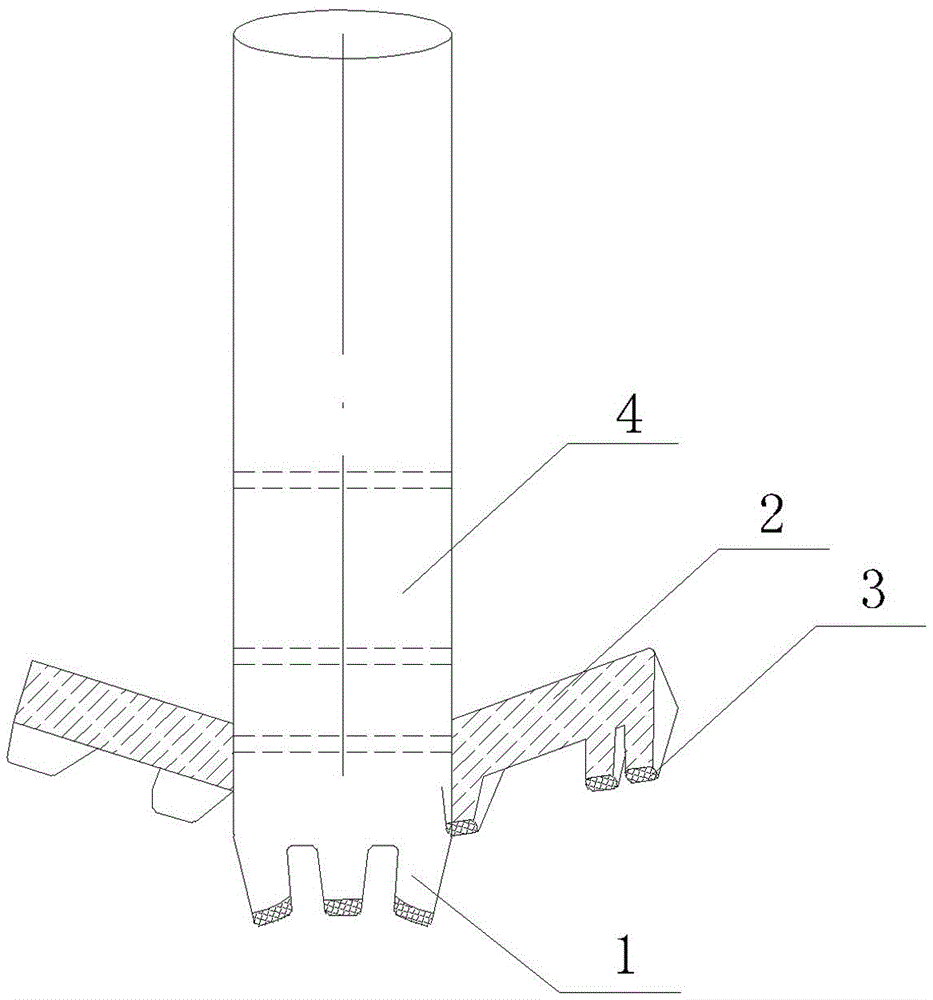

Cobble stratum super three-axis agitation stake and stirring method thereof

The invention belongs to the field of building pile foundation engineering construction, and particularly relates to a cobble stratum super three-axis agitation stake. The cobble stratum super three-axis agitation stake comprises three drill rods, a drill bit component fixed to the bottom of the drill rods, and a blade component connected to the drill rods, wherein the drill bit component is connected with a stepless speed change power head through the drill rods, and the drill rods are connected to a pile frame through a supporting frame; the drill bit component comprises a drill collar connected to the drill rods, a drilling rig connected to the drill collar, and a hollow drill bit, and three to four alloy tool bits are fixed to the drilling rig; the blade component comprises multiple sets of blades connected to the drill rods, and the blades are cutter type blades. The drilling bit component transmits the rotation moment of the power head through the drill rods and conducts drilling into soil mass, drilling capacity is high, abrasion of the drilling rig is small, and efficient construction of the three-axis agitation stake in hard stratums including cobble stratum is achieved; furthermore, pollution can not be caused during construction, construction site is clean and tidy, noise is low, mud recovery and treatment are not needed, and an environment-friendly construction technology is realized.

Owner:ZHEJIANG GEOFORE GEOTECHN TECH

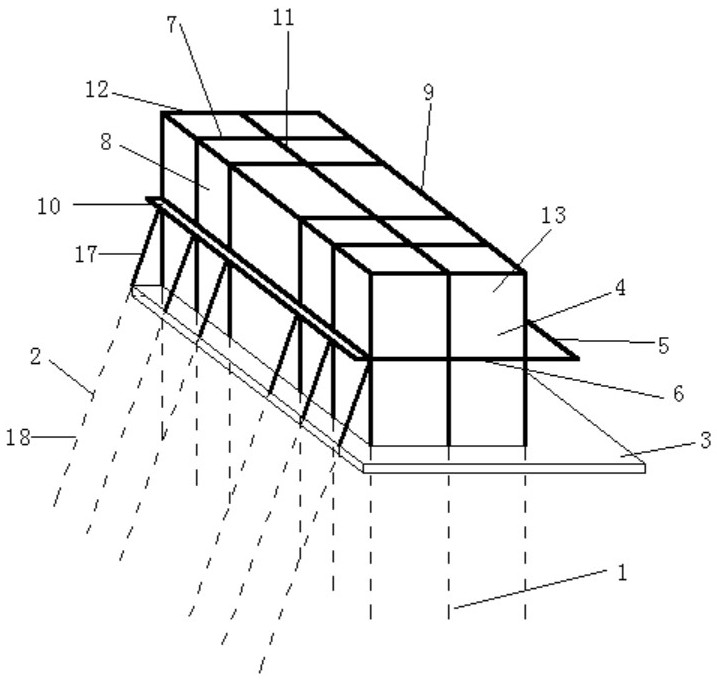

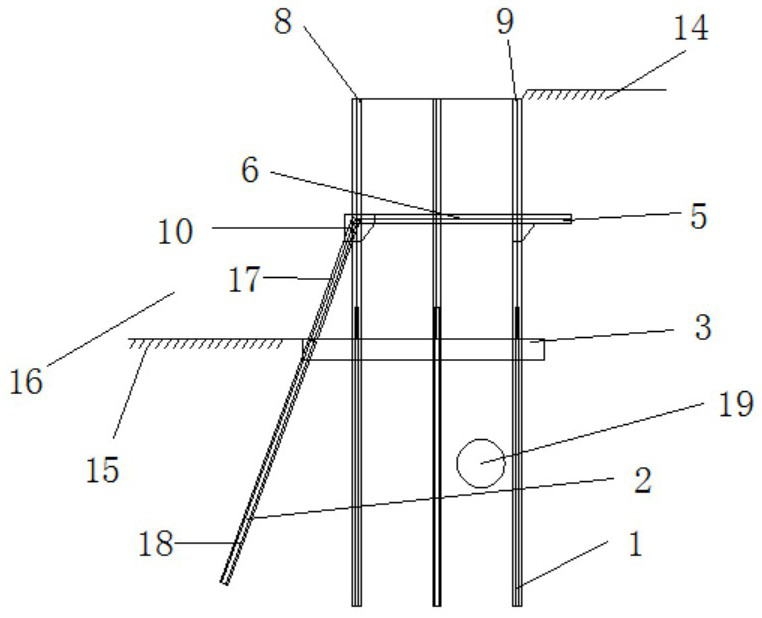

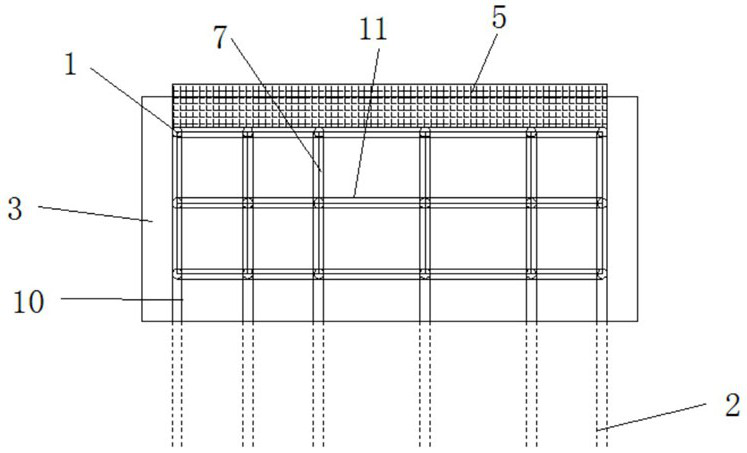

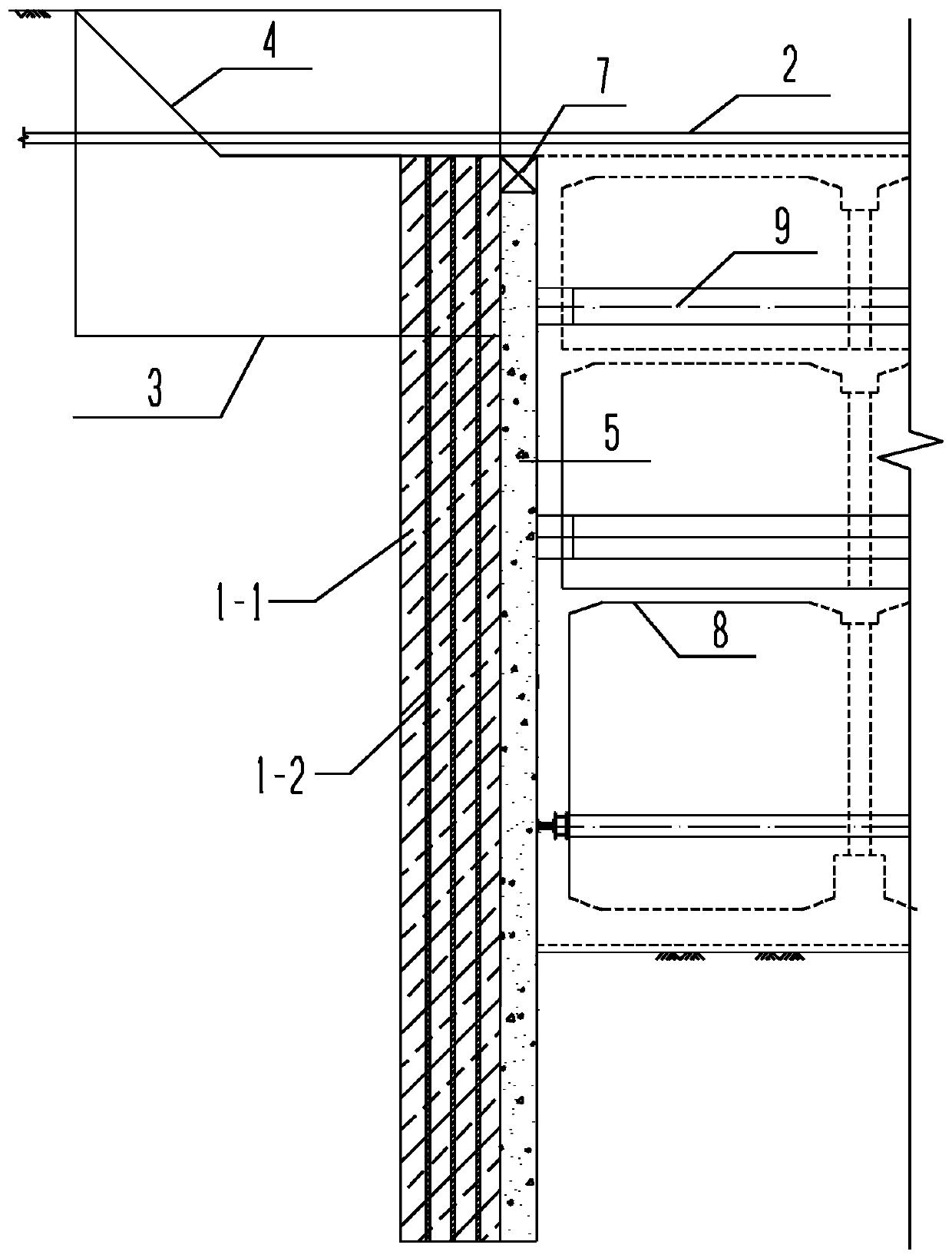

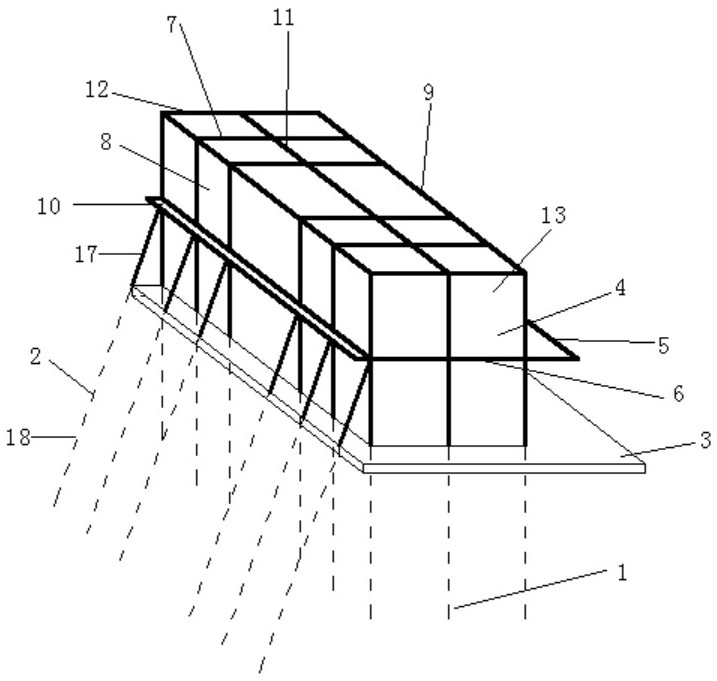

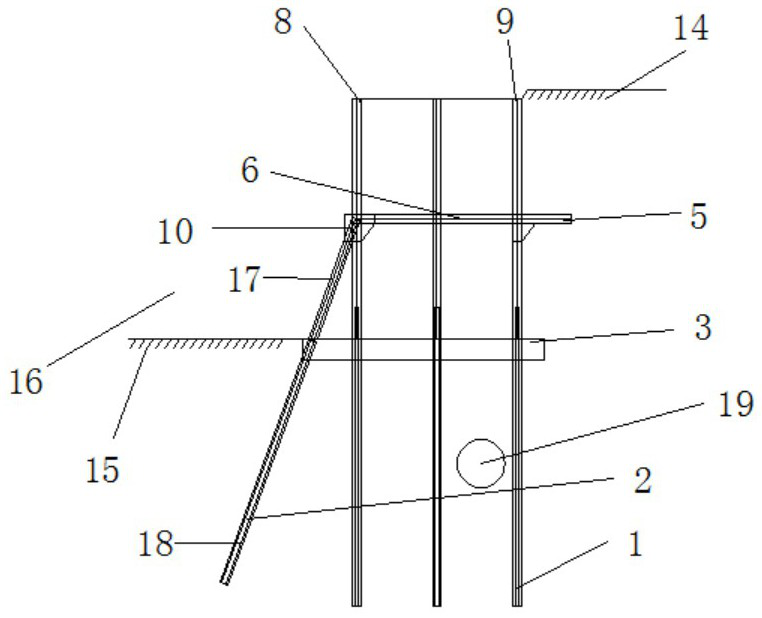

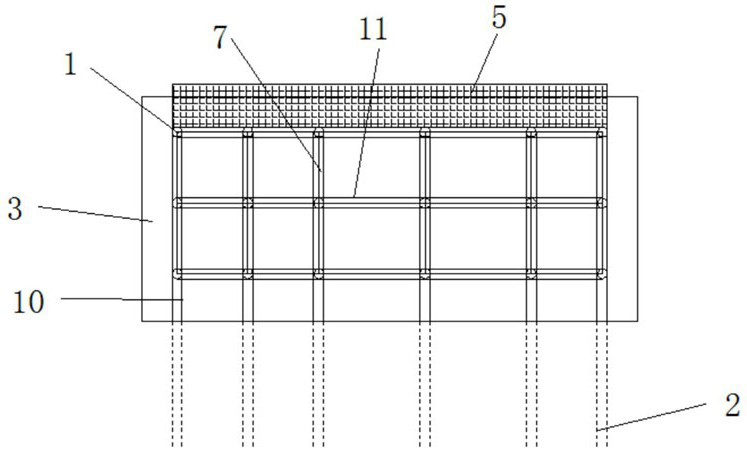

Unloading type thin-walled box dead walls borne by oblique vertical sectional steel tube piles and construction technology

ActiveCN111622234AAdaptableImprove playbackArtificial islandsExcavationsMechanical engineeringSteel tube

The invention discloses unloading type thin-walled box dead walls borne by oblique vertical sectional steel tube piles. The unloading type thin-walled box dead walls comprise a foundation pit, whereinbox wall modules are arranged at relative positions of the high-place floor and the lower-place floor, and each box wall module comprises a rear outer wall, a front outer wall, a left outer wall anda right outer wall; a plurality of lateral inner separation walls are arranged at opposite positions in the box wall modules; longitudinal inner separation walls are arranged at opposite positions inthe box wall modules; middle stress plates are arranged at opposite positions in the box wall modules; leftwards-projected haunched beams are arranged on the left side of the middle stress plates; rightwards-projected unloading plates are arranged on the right side of the middle stress plates; rafts in horizontal arrangement are arranged at the bottoms of the box wall modules, and a plurality of vertical steel pipe piles in vertical arrangement are arranged at the bottoms of the rafts; and a plurality of oblique steel pipe piles are arranged at opposite positions of the left sides of the rafts. The unloading type thin-walled box dead walls have the beneficial effects that the unloading type thin-walled box dead walls can be suitable for foundation pit edges formed in different complex terrains, and are good in stability and convenient to construct.

Owner:ZHONGYUN INTERNATIONAL ENGINEERING CO LTD

Efficient pile driving apparatus for road construction

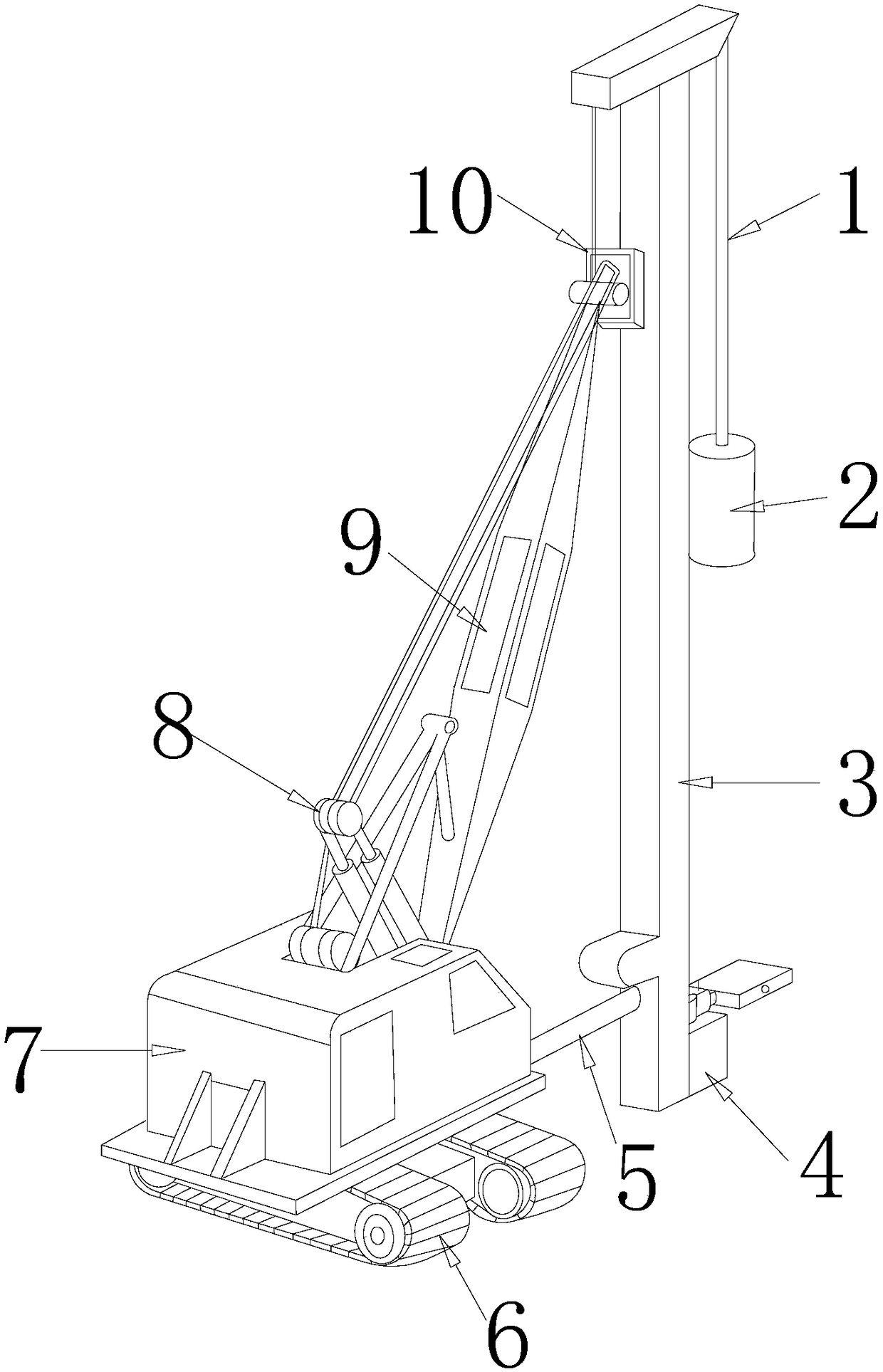

InactiveCN108374414AGuaranteed verticalitySimple and fast operationBulkheads/pilesMaterial resourcesRoad construction

The invention discloses an efficient pile driving apparatus for road construction. The efficient pile driving apparatus structurally comprises a steel wire rope, a heavy hammer, an upright frame, a pile supporting device, a cross rod, walking wheels, a car body, a hydraulic telescoping device, a supporting frame and a guide wheel device, wherein the bottom of the car body is provided with the walking wheels; the car body is connected with the upright frame through the cross rod; the upright frame is mutually perpendicular to the cross rod; one side, which is far away from the cross rod, of theupright frame is perpendicularly connected with the pile supporting device; the heavy hammer is arranged above the pile supporting device; the heavy hammer is connected with one end of the steel wirerope. The efficient pile driving apparatus for the road construction, which is disclosed by the invention, has the beneficial effects that the pile driving apparatus is provided with the pile supporting device, has a pile supporting function, a pile does not need to be manually supported, and the efficient pile driving apparatus is simple and convenient to operate, can be used for guaranteeing the perpendicularity of a wood pile while being used for saving manpower and a material resource, and is good in pile driving-into effect.

Owner:徐玉林

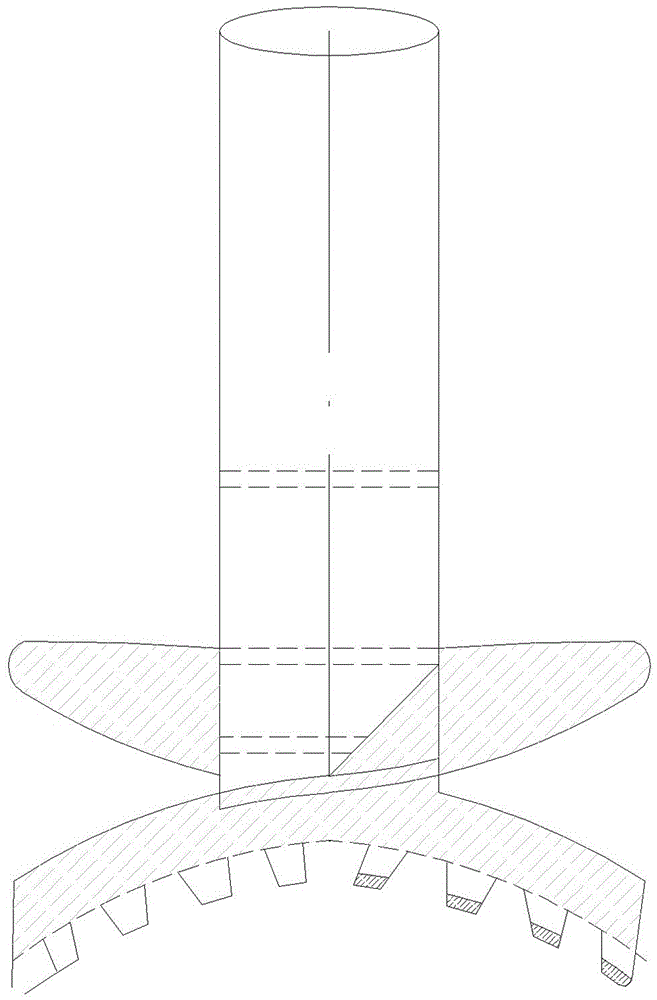

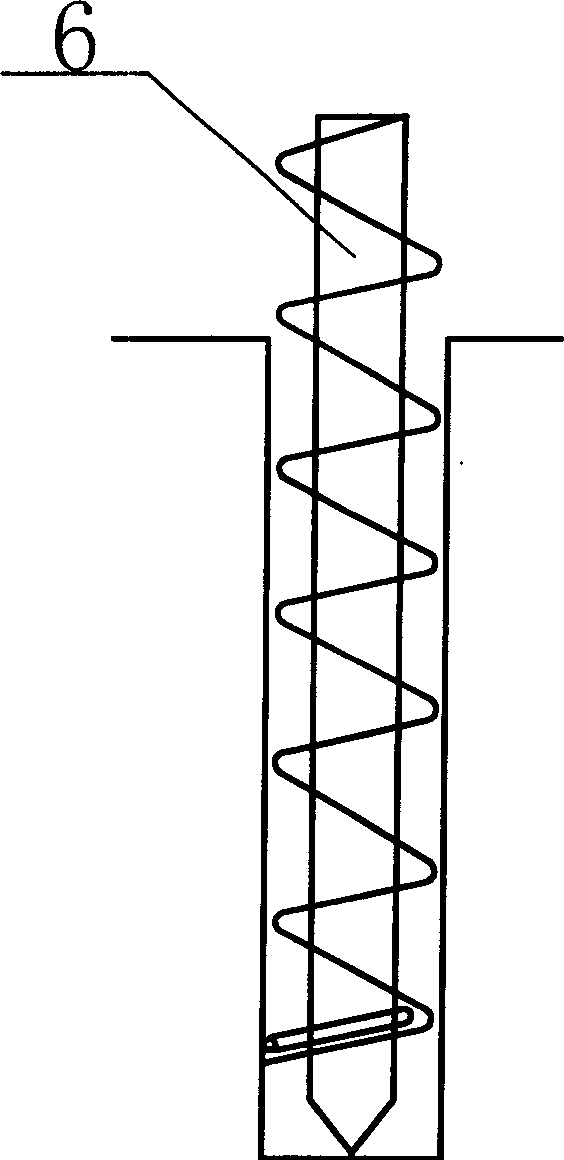

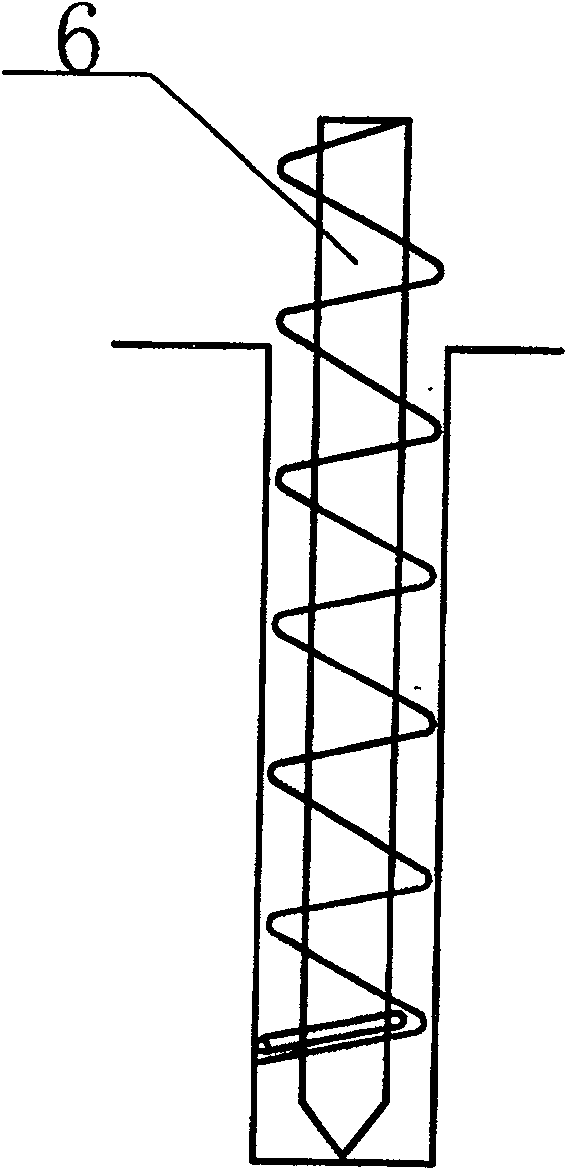

Construction method for spiral auger central pump injection superflowing concrete screw pile and device for fabricating screw thread of the pile

The invention relates to a method for constructing the concrete screw post of screw drilling rod central pump, and a relative screw producer, wherein it can solve the problems as high cost and hard synchronization; it comprises: first using the long screw driller to drill the hole to preset length; then the hydraulic jack extends out the screw producer to rotate reversely and lift the drilling rod, while filling over-flow concrete into the hollowing drilling rod; then drawing out the drilling rod to insert into the steel bar cage.

Owner:黑龙江省建工集团有限责任公司

Hollow stiffness-core slurry-solidified discrete material pile and construction method thereof

ActiveCN102505684BImprove carrying capacityIncrease side frictionBulkheads/pilesCement slurryPrecast concrete

The invention discloses a hollow stiffness-core slurry-solidified discrete material pile and a construction method thereof. The periphery of a pile body is a slurry-solidified discrete material pile. The center of the pile body is a small-diameter prefabricated concrete pipe pile. Slurry filling holes are left on the pile wall of the prefabricated concrete pipe pile at intervals. Slurry enters discrete materials through holes in the middle of the concrete pipe pile and the slurry filling holes. Peripheral discrete materials are integrally cemented and solidified through cement slurry. At the same time, under the effect of slurry filling pressure, the slurry seeps into pile periphery soil bodies and the strength of the pile periphery soil is improved; the slurry fills the holes in the middle of the concrete pipe pile; and a prefabricated pipe pile can be formed by multiple sections which can be connected through bolts. The construction method comprises technical steps of: forming holes, placing the pipe pile, installing a sealing cover and a slurry filling pump, washing the holes by using clean wash, putting the discrete materials, filling the slurry, solidifying, forming the pile and the like. The hollow stiffness-core slurry-solidified discrete material pile and the construction method have the advantages that the construction processes are clear, the construction speed is fast, the pile forming effect is good, the bearing capacity is high, the manufacturing cost is low, the resources are fully utilized, the environment is protected and the energy is saved.

Owner:HOHAI UNIV

Windproof and breathable garment material and processing method thereof

InactiveCN102080301AIncrease the number ofRemarkable windproof and breathable effectWarp knittingCivil engineeringTextile

Owner:CHANGSHU YINGCHUANG TEXTILE IMPORT & EXPORT

Pile planting construction device

PendingCN111945728AGuaranteed vertical drillingGuaranteed piling accuracyDerricks/mastsDirectional drillingAgricultural engineeringStructural engineering

The invention provides a pile planting construction device. The pile planting construction device comprises a pile frame, wherein a drill rod is arranged on the pile frame, and a power device is arranged at the top of the drill rod. The pile planting construction device is characterized in that a hollow stirring cage is arranged at the lower end of the drill rod; the part, provided with stirring blades, of a stirring shaft at the lower end of the drill rod is located in the stirring cage; fixed blades are arranged in the stirring cage; the fixed blades and the stirring blades on the stirring shaft are arranged in a staggered mode; the drill rod drives the stirring shaft to rotate to cut a stratum; and an outer-layer sleeve and the stirring cage are fixed together and do not rotate. According to the pile planting construction device, the stirring cage is arranged, so that the front end of the drill rod does not shake, and vertical downward drilling in the drilling process is guaranteed.The fixed blades and the stirring blades interact within the range of the stirring cage, cement slurry is fully stirred, and the pile forming effect is good.

Owner:SHANGHAI STRONG FOUND ENG

Windproof thermal clothes

The invention discloses windproof thermal clothes, comprising an external layer and an internal layer, wherein the external layer consists of a backer and piles which are distributed on the upper surface and the lower surface of the backer; the piles on the lower surface of the backer are connected with the internal layer; the internal layer is thermal fabric and is formed by blending 80-85 percent by mass of synthetic fiber and 15 to 20 percent by mass of composite alga carbon fiber; the composite alga carbon fiber comprises the following components, i.e. 60 to 75 parts by weight of alga carbon fiber, 15 to 20 parts by weight of aluminum oxide, 5 to 15 parts by weight of zirconium oxide, 5 to 10 parts by weight of tourmaline and 2 to 5 parts by weight of glass beads. According to the windproof thermal clothes provided by the invention, as the piles are erected upright on gauze, a good upright pile effect is generated; therefore, a good windproof performance is realized; the piles on the lower surface of the backer are woven together with the internal layer, so that a human body is kept warm; since the internal layer adopts the composite alga carbon fiber, not only is a good heat preservation function provided, but also the purposes of enhancing cell energy, enhancing cell function and vitality and the like can be realized.

Owner:KUNSHAN TIENIU SHIRT FACTORY

Expansion concrete pile with bulk material core and construction method thereof

ActiveCN107012861BImprove bearing capacityIncrease stiffnessBulkheads/pilesEngineeringUltimate tensile strength

The invention provides a discrete material core expansion concrete pile and a construction method thereof. The discrete material core expansion concrete pile comprises a concrete semi-hollow pile and a discrete material pile core. An inner cavity of the concrete semi-hollow pile is filled with the discrete material pile core. The construction method of the discrete material core expansion concrete pile comprises the steps of hole forming, steel pipe pile die downward pressing, pile body periphery concrete pouring, pile body center discrete material throwing, vibration pile die pulling, pulp supplementing and pile forming and the like. The discrete material of the center of a pile body of the discrete material core expansion concrete pile is good in integrity and high in strength. The pile body is high in overall bearing force and large in rigidity. The construction cost is low, and low carbon and environment friendliness are achieved. The discrete material core expansion concrete pile and the construction method thereof can be widely applied to the foundation project.

Owner:CHONGQING UNIV +1

Windproof thermal garment

InactiveCN102551223AIncreased amount of fluffGood windproof performanceProtective garmentSpecial outerwear garmentsWoolEngineering

The invention relates to a windproof thermal garment, which comprises an outer layer and an inner layer. The outer layer is composed of base cloth and piles distributed on the upper surface and the lower surface of the base cloth. The piles on the lower surface of the base cloth are connected with the inner layer which is a wool layer. The windproof thermal garment has the advantages that the piles on the upper surface of the base cloth contract with resilient retraction of the base cloth, the amount of the piles per unit area is increased, the piles can stand up on the cloth, the good erecting effect is achieved, and good wind proofing performance is achieved; and the lower piles are connected with the wool layer so that a wearer's body can feel warmer.

Owner:常熟市宏帅纺织服饰有限公司

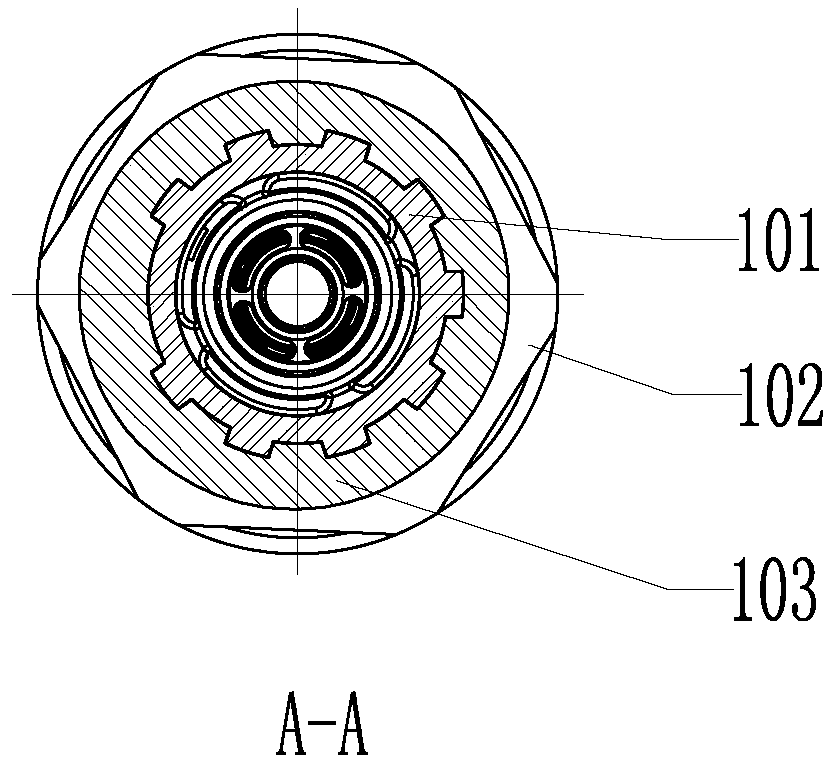

High-pressure rotary jet drilling machine capable of achieving directional swing jet at any azimuth angle and construction method

InactiveCN110805032AReliable deliveryEasy to set upBulkheads/pilesSoil preservationDrive shaftDrilling machines

The invention relates to a high-pressure rotary jet drilling machine capable of achieving directional swing jet at any azimuth angle and a construction method. The high-pressure rotary jet drilling machine comprises a power head and a drill rod, wherein a multi-circle absolute value encoder I is mounted on a driving shaft of a final driving stage of the drill rod on the power head; a sliding frameassembly is arranged on the drill rod; a multi-circle absolute value encoder II is arranged on the sliding frame assembly; the multi-circle absolute value encoder I and the multi-circle absolute value encoder II are connected with an industrial personal computer through CAN buses; and the drill rod is in a multi-section type, and all sections of the drill rod are connected through positioning connecting assemblies, so that the positions of all the sections of the drill rod are kept consistent. According to the high-pressure rotary jet drilling machine, parameter setting is convenient, the automation degree is high, a swing jet starting point and a swing jet returning point CAN be selected at will according to construction requirements, different modes such as continuous rotary jet, continuous swing jet, fixed-point rotary jet, fixed-point swing jet and continuous fixed jet are obtained, the swing jet direction and angle are still kept after the number of the drill rod is increased ordecreased, and swing jet motion is reliably transmitted.

Owner:南京同力建设集团股份有限公司

Multi-head mixing type cast-in-place large-diameter pipe pile device and its application

ActiveCN105239566BImprove carrying capacityIncrease contact areaBorehole drivesBulkheads/pilesWinchDrill

The invention discloses a multi-head stirring type large-diameter cast-in-situ pipe pile device. The multi-head stirring type large-diameter cast-in-situ pipe pile device comprises a main unit, a winch, a drill stem assembly, a positioning frame, a power device and a background concrete processing system. The main unit and the winch are sequentially arranged on a base. The drill stem assembly is fixed to the top of the positioning frame, and all drill stems work at the same time during one-time drilling. The end-to-end closed multi-head stirring type large-diameter cast-in-situ pipe pile device is formed through simultaneous pile sinking of the multiple annular drill stems during construction by adjusting the angles of the drill stems. By means of the device, the application range of a cement mixing pile is widened; in addition, the outer wall of a multi-head stirring type large-diameter cast-in-situ pipe pile is in a wavy stripe shape, in this way, the contact area between the pile and soil is greatly increased, and the side friction resistance of the pile can be improved. According to the multi-head stirring type large-diameter cast-in-situ pipe pile device, the construction technique is clear, the construction speed is high, the pile forming effect is good, the bearing capacity is high, and manufacturing cost is low.

Owner:HOHAI UNIV

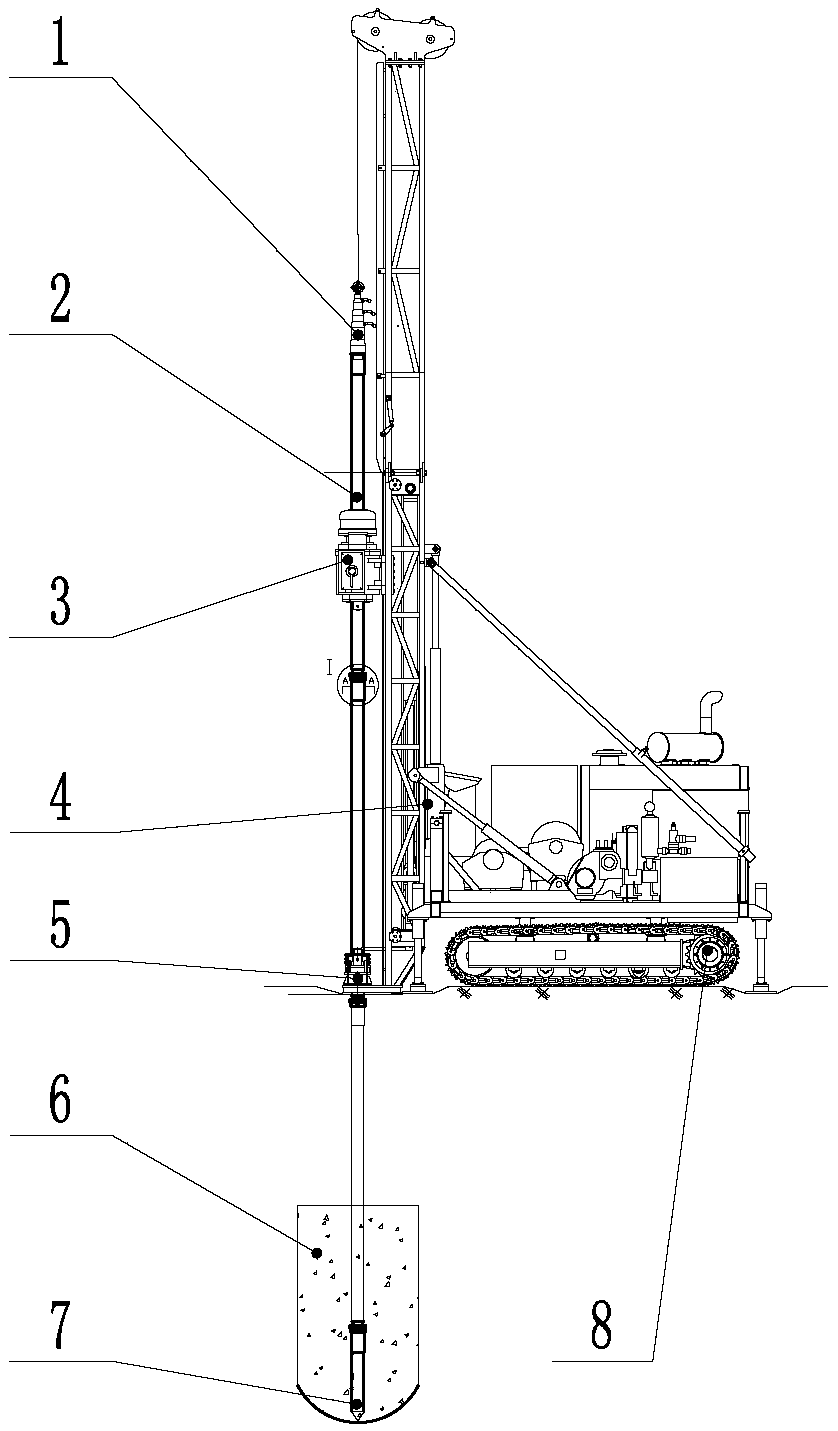

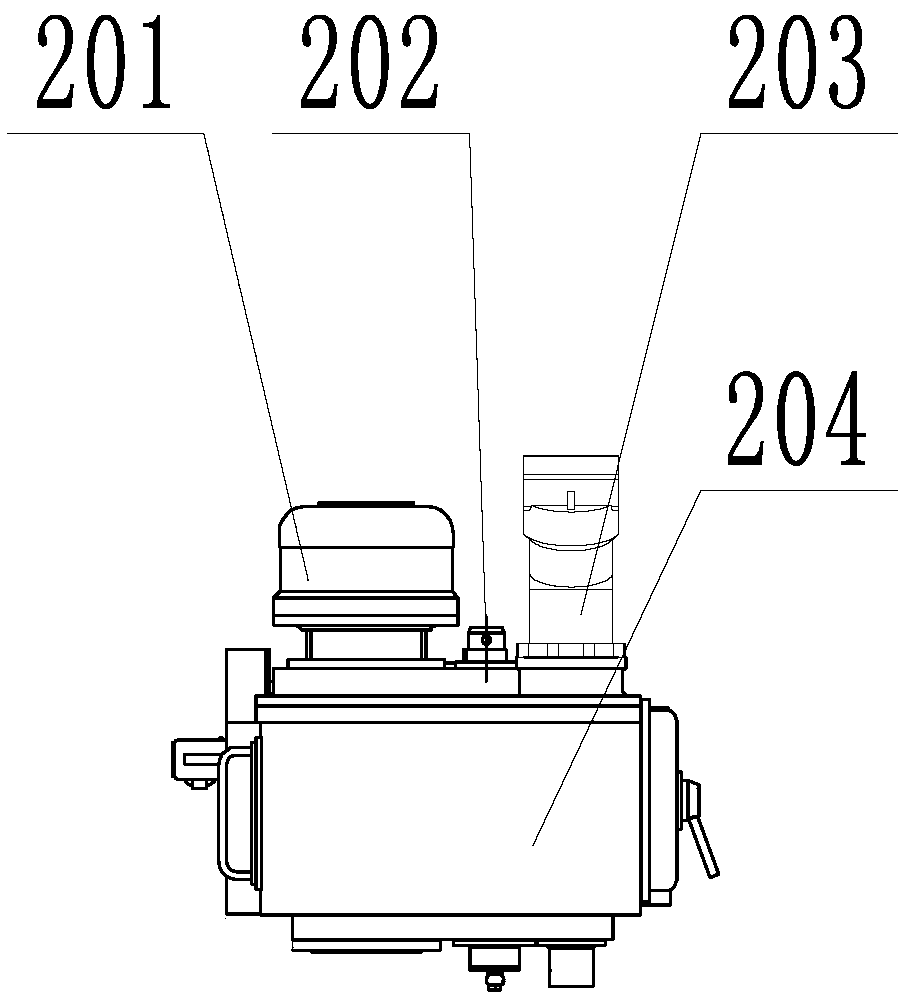

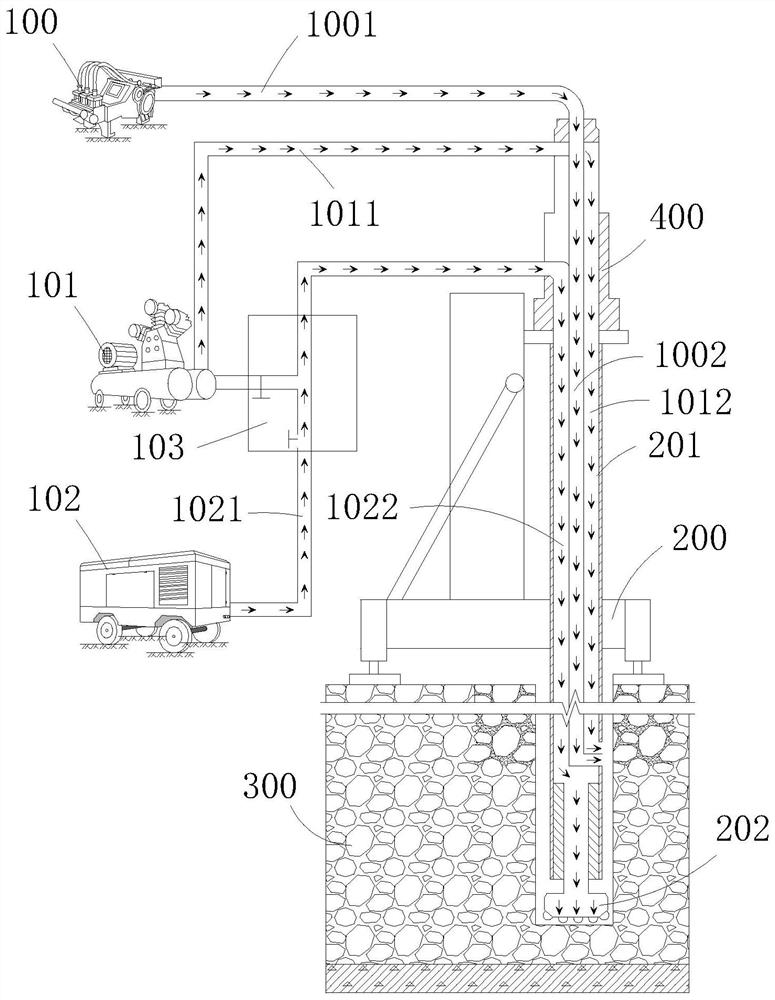

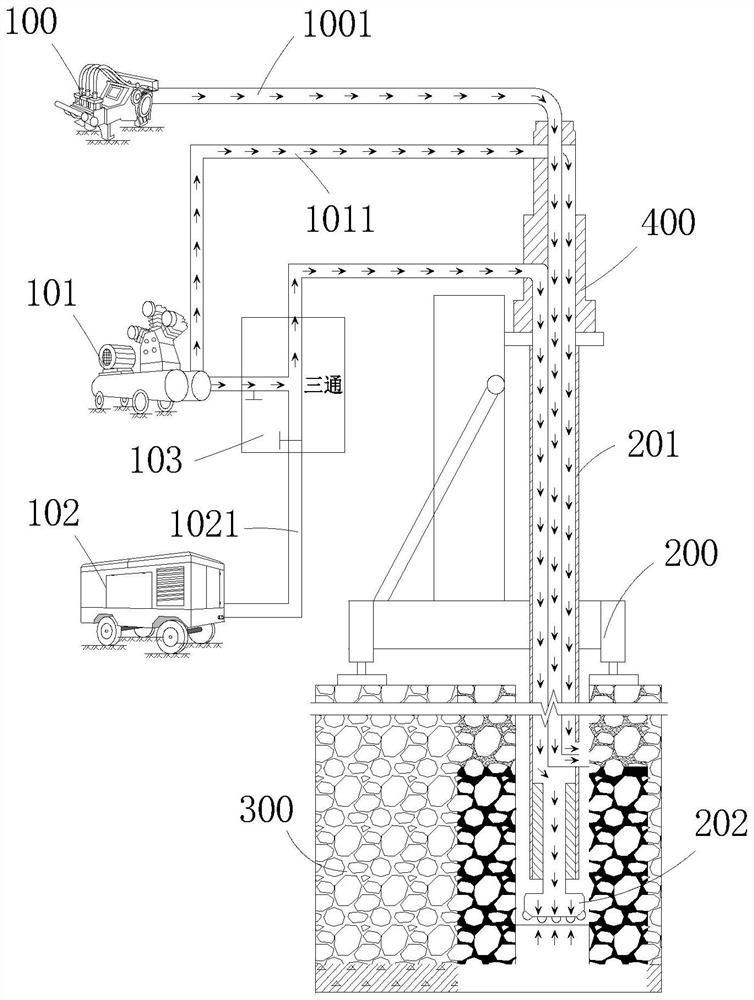

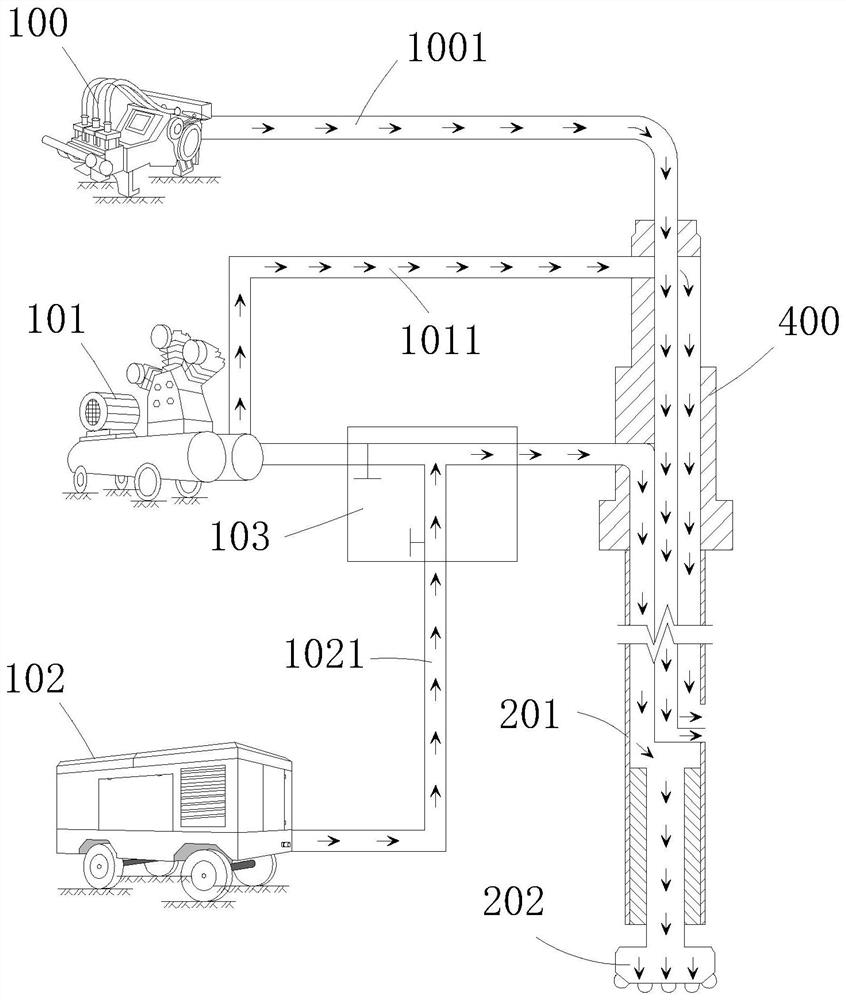

Deep and thick rockfill layer down-the-hole hammer hole guiding and rotary jet drilling and spraying integrated pile forming equipment

PendingCN114703840AHigh strengthHigh-strength high-strength cement-soil mixed pile, pile-forming effectBulkheads/pilesSoil preservationSlurryMachine

The invention relates to the technical field of pile forming construction, and discloses deep and thick rockfill layer down-the-hole hammer hole guiding and rotary jet drilling and spraying integrated pile forming equipment which comprises an all-in-one machine, the all-in-one machine comprises a rack, the rack is provided with a power head, an air slurry conveying connector and a drill rod, the lower portion of the drill rod is provided with a down-the-hole impact head, and the power head drives the drill rod to drill a hole guiding in a rockfill layer; the air slurry conveying connector is connected with a rotary spraying air compressor, a down-the-hole hammer air compressor and a high-pressure grouting pump, and a nozzle is arranged on the lower portion of the drill rod. In the process that the power head drives the drill rod to drill the guide hole to the designed elevation of the pile bottom, the down-the-hole hammer air compressor drives the down-the-hole impact head to impact and drill, the jet grouting air compressor jets high-pressure gas in the pile hole in a rotary mode through the nozzle, and the high-pressure grouting pump jets grout in the pile hole in a rotary mode through the nozzle; in the process that the power head drives the drill rod to be lifted in the pile hole, the jet grouting air compressor jets high-pressure gas in the pile hole in a jet mode through the nozzle, and the high-pressure grouting pump jets grout in the pile hole in a jet mode through the nozzle till the grout reaches the designed reinforcement height of the pile top.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

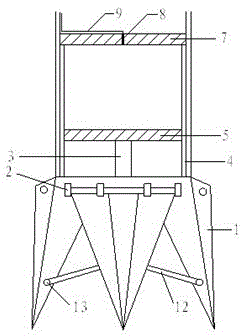

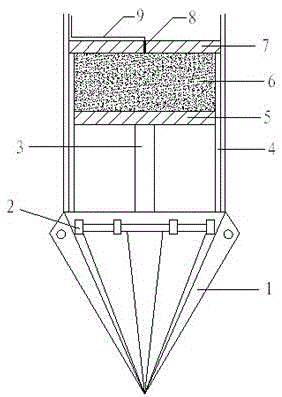

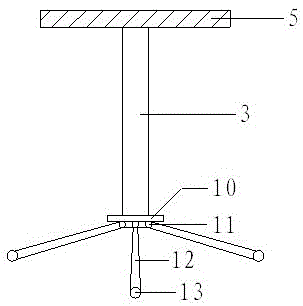

An explosive hollow picket

InactiveCN104047286BSimple structureReasonable structureBulkheads/pilesArchitectural engineeringDrill

The invention discloses an explosive hollow picket. Including the pile barrel 4; the bottom of the pile barrel 4 is hinged with a group of drill point valves through the hinge rod 2; each drill point valve 1 is evenly distributed along the bottom circumference of the pile barrel; each drill point valve 1 is provided with a hinge ball at the inner lower part 13; the hinge ball 13 is connected with the explosive propelling device arranged at the bottom of the stake barrel 4 . The invention has a simple structure and a reasonable structure; it can solve the problems of difficult pile drilling, unstable pile foundation and low bearing capacity under complex geological conditions; the pile forming effect is ideal, safe and reliable; the explosive hollow picket pile of the invention can be used The hard soil layer or stones under the pile barrel are first blown loose by the explosive bag, and then the top of the pile barrel is driven until the pile is formed, and finally the concrete is poured. The process of the invention is simple and feasible.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC

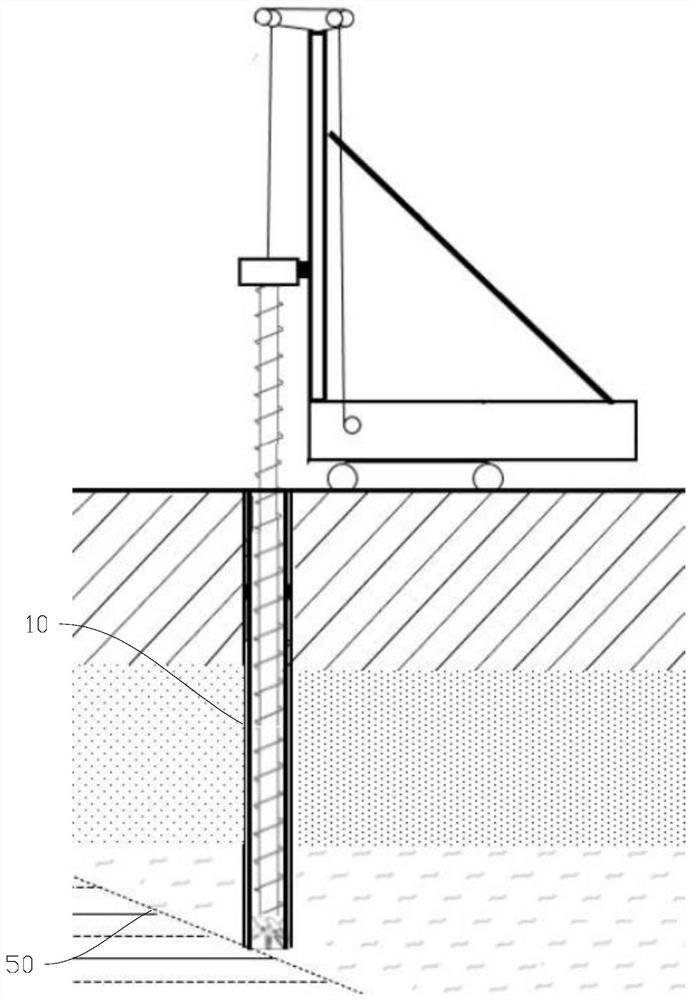

Pile foundation construction method for pre-drilling guide hole in inclined rock stratum

The invention discloses a pile foundation construction method for pre-drilling a guide hole in an inclined rock stratum. The method comprises the following steps of setting a first hole site on a cross section, and performing drilling by a drill rod from the first hole site to form a first guide hole; setting a second hole site group on the cross section, wherein the second hole site group comprises two second hole sites, and performing drilling by the drill rod from the second hole sites to form a second guide hole; drilling a pile site by a drill bit, transferring a reinforcement cage into the pile hole; and pouring concrete grout. The defects of a traditional inclined rock construction mode can be overcome; a good pile forming effect is achieved; a small-aperture drill rod is used for pre-drilling the guide hole; the possibility of drilling hole deflection is reduced; and the drilling speed is high. Due to the advanced drilling of the first guide hole and the second guide hole, when a pile machine drills or impacts the holes, the drill bit cannot deflect under the limiting effect of the guide holes, so that the inclination degree of pile bodies of pipe piles and cast-in-place piles is controlled within the allowable error range; the whole cross section can be enabled to be embedded into an inclined rock stratum; the error of the perpendicularity of pile holes is reduced; the pile forming quality and the pile bearing capacity are improved; and the construction cost is reduced.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

In-situ protection of pressure pipelines crossing deep foundation pits and retaining structures and construction methods

The invention provides a structure for in-situ protection of a pressure pipeline transversely penetrating through a deep foundation pit and surrounding soil-retaining and a construction method. The construction process of the soil-retaining structure comprises the steps that firstly, a first-stage underground continuous wall is constructed on the two sides of the pipeline to be protected in situ,the first-stage underground continuous wall is broken off at the position close to pipeline to be protected in situ, then a steel sheet pile supporting structure and a composite pile retaining wall are constructed on the outer side of the first-stage underground continuous wall, wherein the composite pile retaining wall is arranged on the outer side of the breaking region, is composed of MJS jet grouting pile reinforcing bodies composed of multiples mutually-occlusive MJS jet grouting piles and multiples micro steel pipe piles inserted into the MJS jet grouting pile reinforcing bodies, and isused for completely shielding the breaking region, and the steel sheet pile supporting structure is composed of two rows of steel sheet piles constructed on the two sides of the composite pile retaining wall. According to the structure and the construction method, the influence on the environment is greatly reduced, before the foundation pit is excavated, the effect of closing the surrounding structure is achieved, the possibility that water seepage, water leakage and collapse occur at a continuous wall reverse-constructing position when the foundation pit is excavated is effectively reduced,and the safety coefficient during foundation pit excavating and continuous wall reverse constructing is increased.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP +1

An unloading thin-walled box-shaped retaining wall supported by oblique and vertical composite steel pipe piles and its construction technology

ActiveCN111622234BAdaptableImprove playbackArtificial islandsExcavationsClassical mechanicsEngineering

The invention discloses an unloading thin-walled box-shaped retaining wall supported by oblique and vertical combined steel pipe piles. The wall module of the box type includes a rear exterior wall, an exterior wall of the front side, a left exterior wall, and a right exterior wall. The relative positions of the box-shaped wall modules are provided with multiple transverse inner partition walls. The relative positions of the box-shaped wall modules are There is a longitudinal inner partition wall, and an intermediate bearing plate is provided at the relative position inside the box-shaped wall module. Unloading plate, the bottom of the box-shaped wall module is provided with a horizontally arranged raft, the bottom of the raft is provided with a number of vertically arranged vertical steel pipe piles, and the left side of the raft is provided with a number of oblique steel pipe piles module. The beneficial effect of the invention is that it can be applied to the edges of various foundation pits with different complex terrains, and has good stability and convenient construction.

Owner:ZHONGYUN INTERNATIONAL ENGINEERING CO LTD

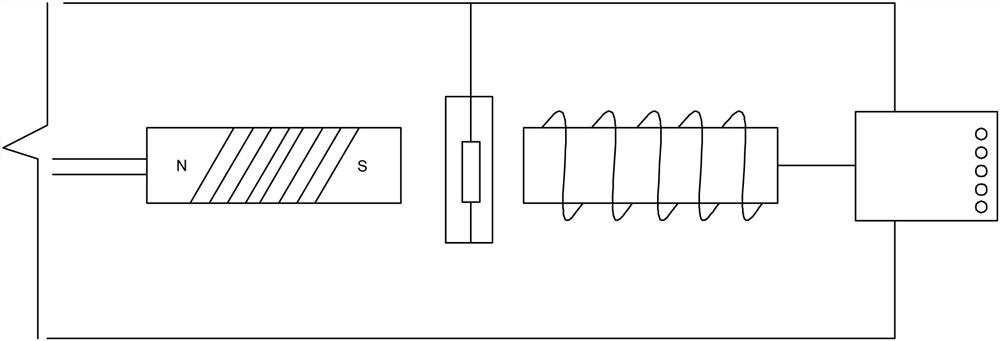

Coral sand foundation pile using expansion agent and construction method

ActiveCN113174925BImprove carrying capacityHigh strengthSoil preservationPore water pressureStructural engineering

The invention provides a novel coral sand foundation pile using an expansion agent and a construction method. Carrier piles are uniformly buried inside the coral sand foundation, and the pile bottom of the carrier pile is provided with a lower compacted filling material area; the lower part The expansion agent is filled inside the tamping filler area to form a bottom expansion head structure; the outer wall of the carrier pile is provided with a plurality of side wall extension expansion head branches, and the interior of the side wall extension expansion head branches is filled with expansion agent and Magnetic mortar, and an electromagnet device for controlling the fluidity of the magnetic mortar is arranged inside the branch of the side wall extension expansion head. In this method, expansion agent is added to the expansion area at the bottom of the carrier pile and the branch area of the extension head of the side wall to make it expand, extrude the coral sand around the pile, increase the density of the coral sand, reduce the pore water pressure of the coral sand, and the coral sand particles The effective pressure will increase.

Owner:CHINA THREE GORGES UNIV

Telescopic anti-drill-balling mixing pile drill bit

ActiveCN103758460ASolve the problem of easy to paste drillImprove adaptabilityDrill bitsConstructionsDrill bitPetroleum engineering

The invention discloses a telescopic anti-drill-balling drill mixing pile drill bit. The telescopic anti-drill-balling drill mixing pile drill bit comprises an upper mixing pile drill bit (1), a lower mixing pile drill bit (2) and a clamping ring (3) for connecting and sealing the upper and lower mixing pile drill bits. The telescopic anti-drill-balling drill has the advantages that by making substantial improvements on the thicknesses, the distance and structures of upper and lower blades (12) and (23) of the conventional mixing pile drill bit, the defects of poor adaptability of a cement mixing pile drill bit to stratums, non-uniform stirring and easiness in causing drill balling are overcome radically. The telescopic anti-drill-balling drill mixing pile drill bit has the advantages of reasonable and economical design, simple structure, convenience in installation and operation and good piling effect. By improving the conventional mixing pile drill bit, the telescopic anti-drill-balling drill mixing pile drill bit is reasonable in design, simple in structure, convenient to install and operate, reliable in tightness, good in pile-forming effect, economical and practical.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

A non-disturbance carbonized pile forming equipment and its construction method

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Construction method for spiral auger central pump injection superflowing concrete screw pile and device for fabricating screw thread of the pile

ActiveCN100558989CImprove bearing capacityReduce construction costsBulkheads/pilesEngineeringScrew thread

The construction method of threaded pile with superfluid concrete pumping in the center of the auger drill pipe and its thread making device. At present, there are many construction methods for concrete pouring piles in building construction. For example: superfluid concrete pouring into piles, which cannot form piles Screw threads have the disadvantages of wasting concrete and high cost. However, the existing threaded pile construction equipment is expensive, and the synchronization problem is difficult to solve. It is difficult to form threads and is difficult to succeed. The present invention can solve the above problems. The construction method of the spiral drill pipe central pump injection superfluid concrete threaded pile, first drills to the design depth with a long spiral drill with a thread making device, and then starts the hydraulic jack to extend the screw thread at the end. The fabricator reverses and lifts the drill pipe at the same time, pours superfluid concrete through the hollow part of the drill pipe while pulling out the drill pipe, and finally puts out the drill pipe and inserts it into a reinforcement cage. The invention is applicable to various building constructions.

Owner:黑龙江省建工集团有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com