Double-spraying bidirectional cement mixing pile drill and construction method thereof

A technology for cement mixing piles and construction methods, which is applied to drill bits, sheet pile walls, drilling equipment, etc., can solve the problems such as the inability to comprehensively and effectively solve the problems of anti-seepage in different soil layers, and achieves increased soil cutting times and good pile forming effect. , Improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

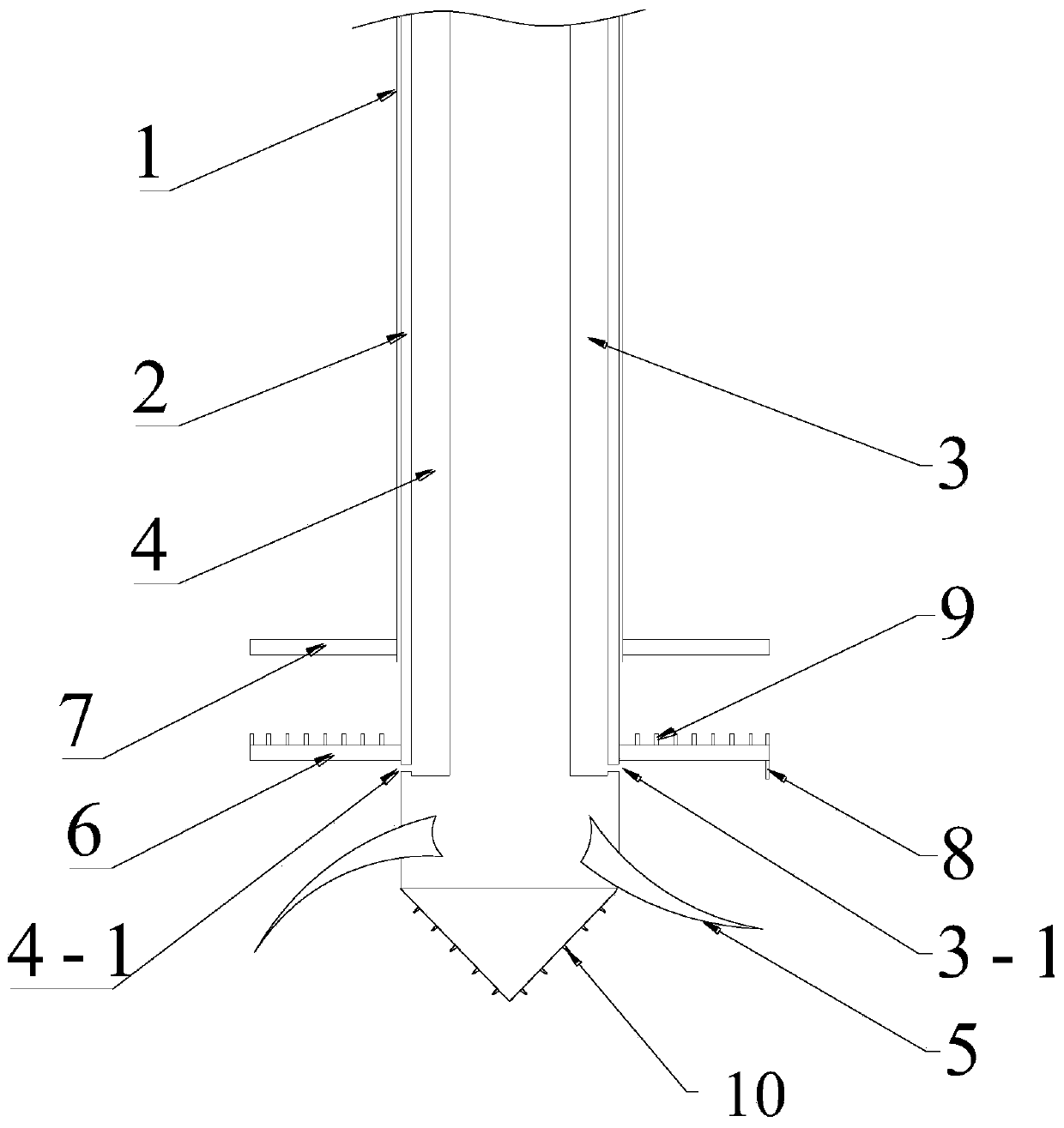

[0031] A double-spray two-way cement mixing pile drill bit, comprising: an outer main drill pipe 1, an inner main drill pipe 2, a high-pressure spraying pipe 3, a high-pressure powder spraying pipe 4, a first group of blades 5, a second group of blades 6, a third group of blades Set of blades 7, the main drill pipe is composed of an outer main drill pipe 1 and an inner main drill pipe 2, the outer main drill pipe is coaxially sleeved on the outer layer of the inner main drill pipe 2, and a high-pressure shotcrete pipe is installed inside the inner main drill pipe 2 at the same time. 3 and a high-pressure powder spraying pipe 4, the high-pressure spraying pipe 3 is connected to a computer-controlled high-pressure slurry pump and pulping equipment, and the high-pressure powder spraying pipe 4 is connected to a computer-controlled high-pressure air pump and a cement storage tank, spraying and powder spraying The whole process is controlled by computer, spraying or powder spraying ...

Embodiment 2

[0045]According to the geological survey data of a project, the upper soil layer is 0m-10m of silty clay, 10m-15m of soft soil, and 15m-22m of old clay. The design adopts cement mixing piles for foundation treatment. The diameter of cement mixing piles is 0.5m, the length of the piles is 15m, and the spacing between the piles is 1.0m. Cement slurry spray is used within the depth range of 0m-10m, the cement content is 18%, the water-cement ratio is 0.55, the drilling speed is 1.0m / min, the lifting speed is 0.5m / min, the rotation speed is 40r / min, and the shotcrete pressure during drilling 15MPa. Cement powder spraying is used within the depth range of 10m-15m, the cement content is 18%, the drilling speed is 1.0m / min, the lifting speed is 0.5m / min, the rotation speed is 40r / min, and the cement powder pressure during drilling is 0.6MPa. The depth of 15m-22m is old clay, and its index is relatively good, and it can meet the design requirements without reinforcement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com