Patents

Literature

36results about How to "Increase the number of cuts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

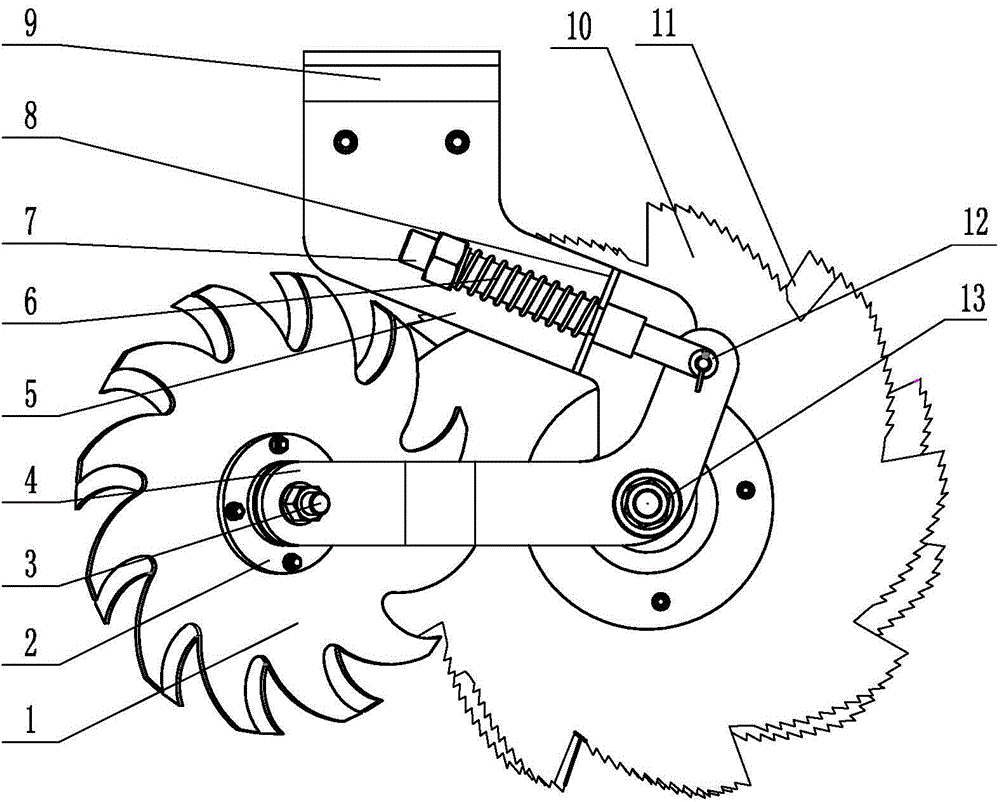

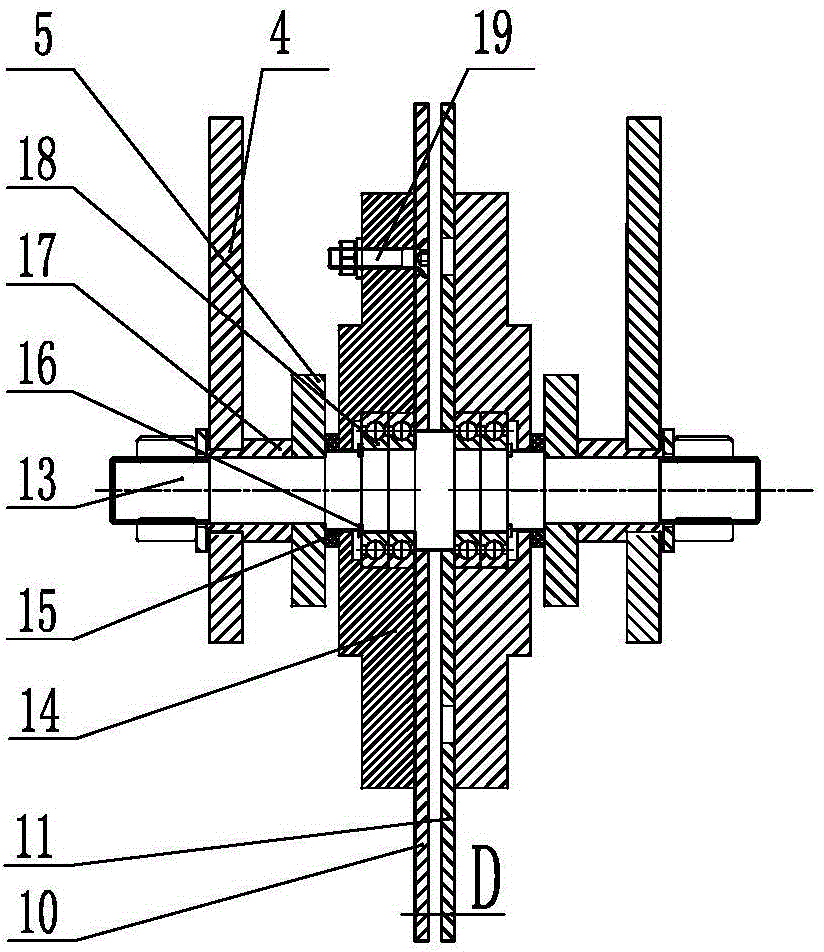

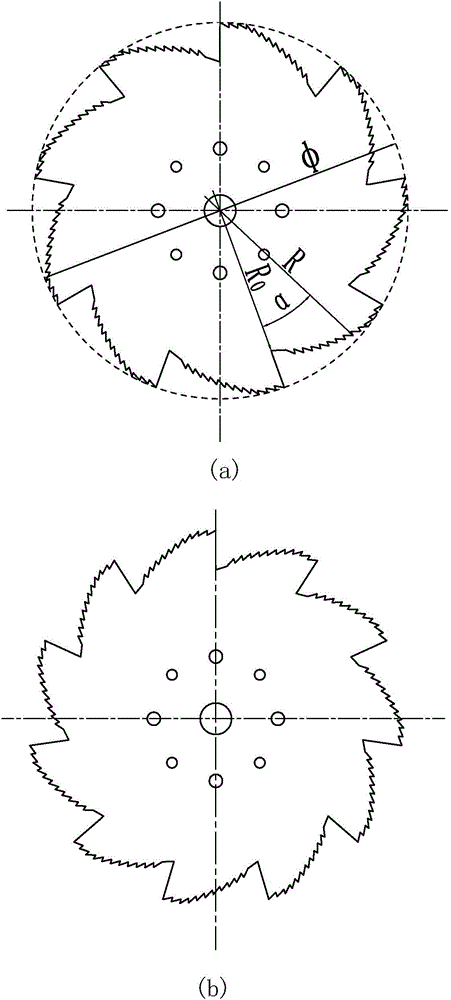

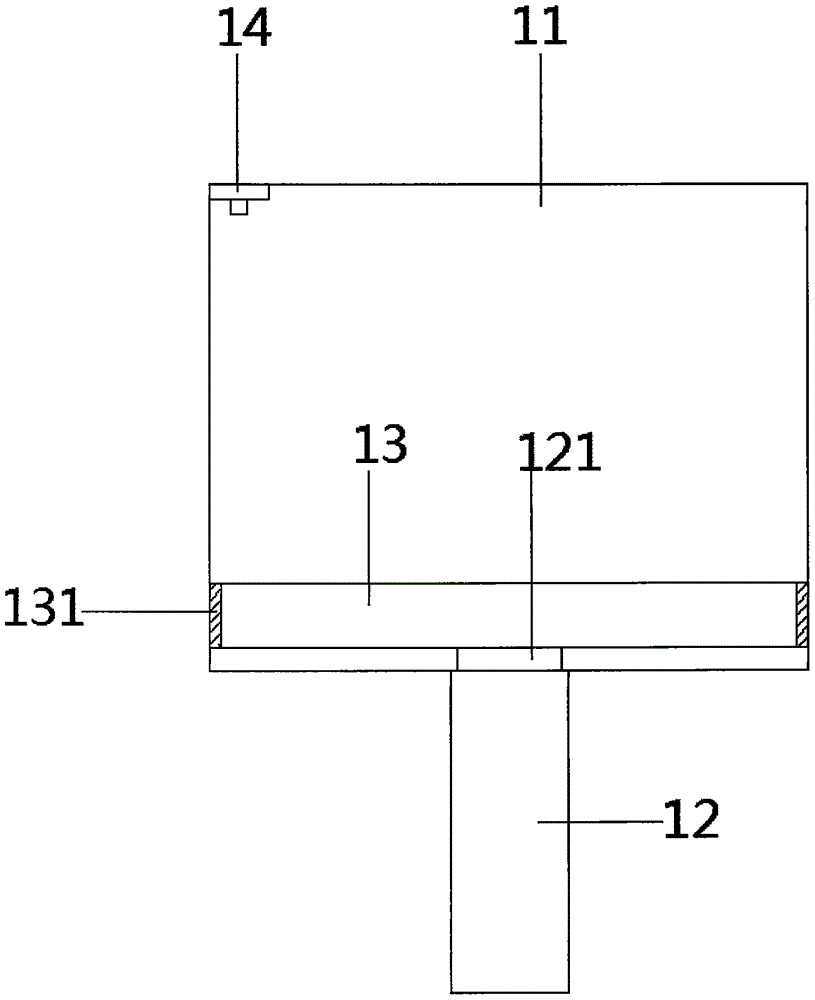

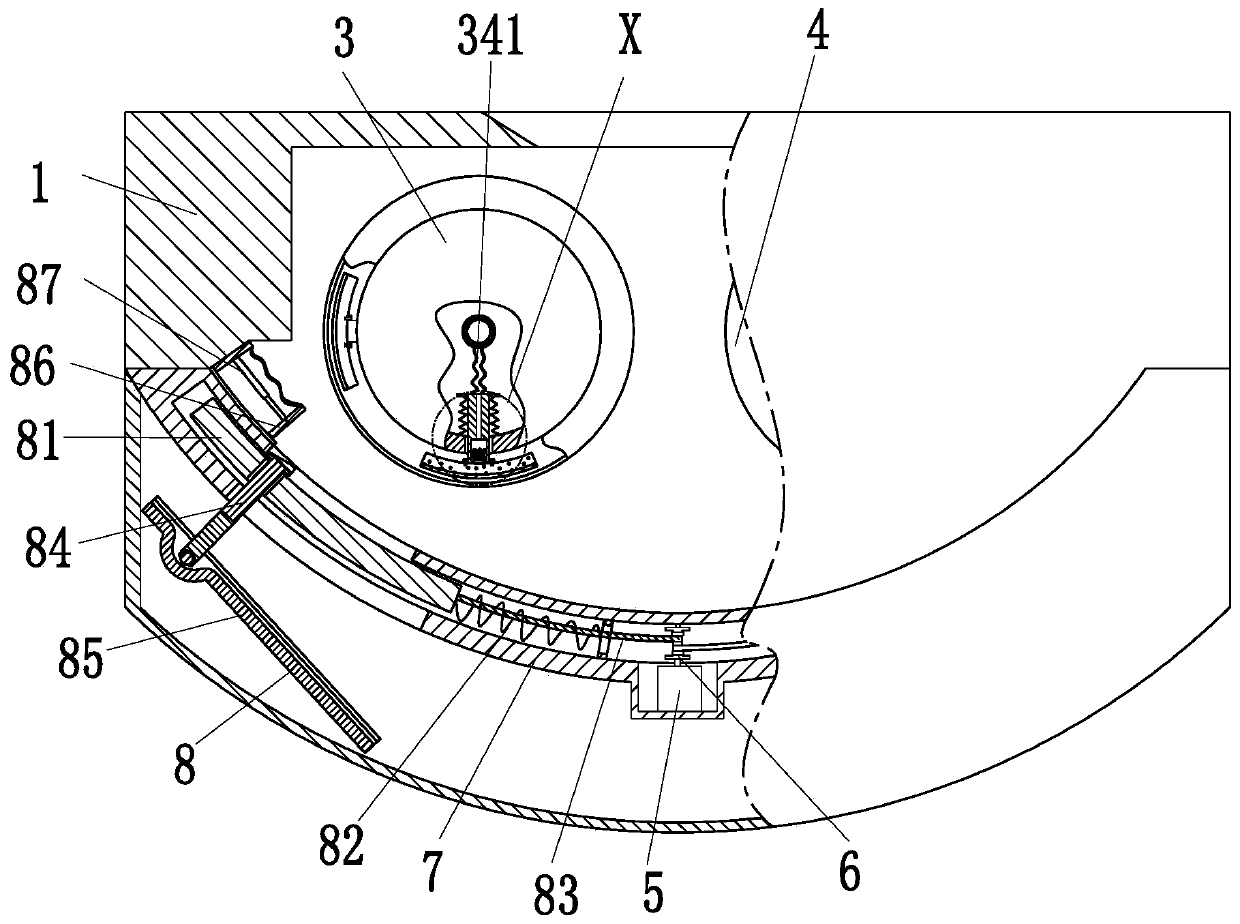

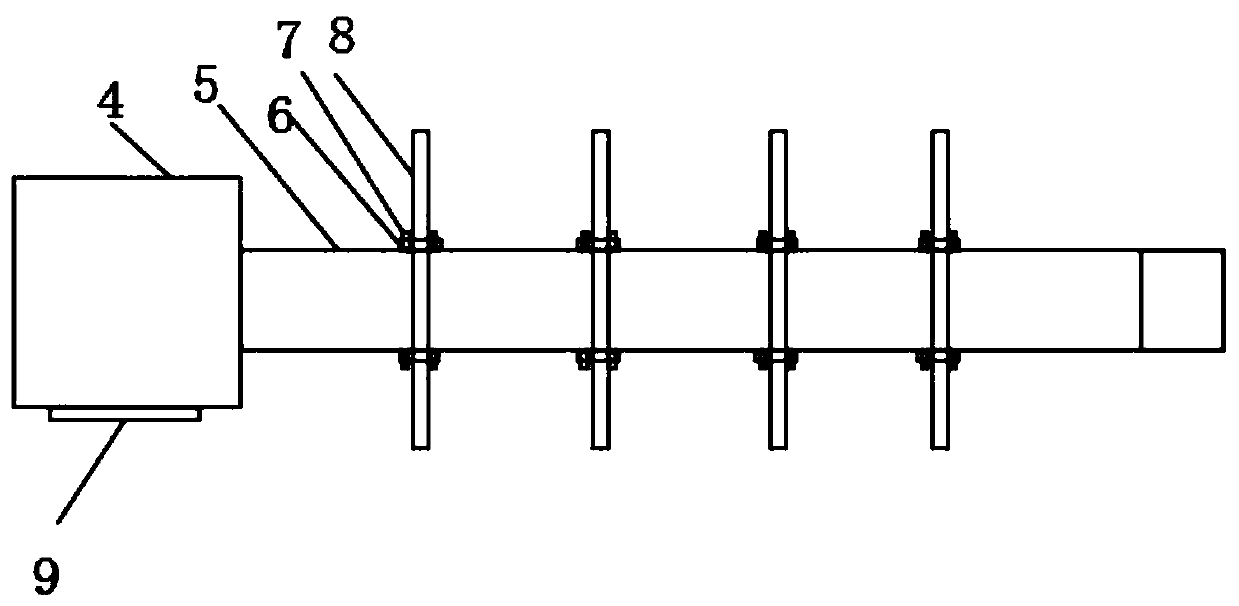

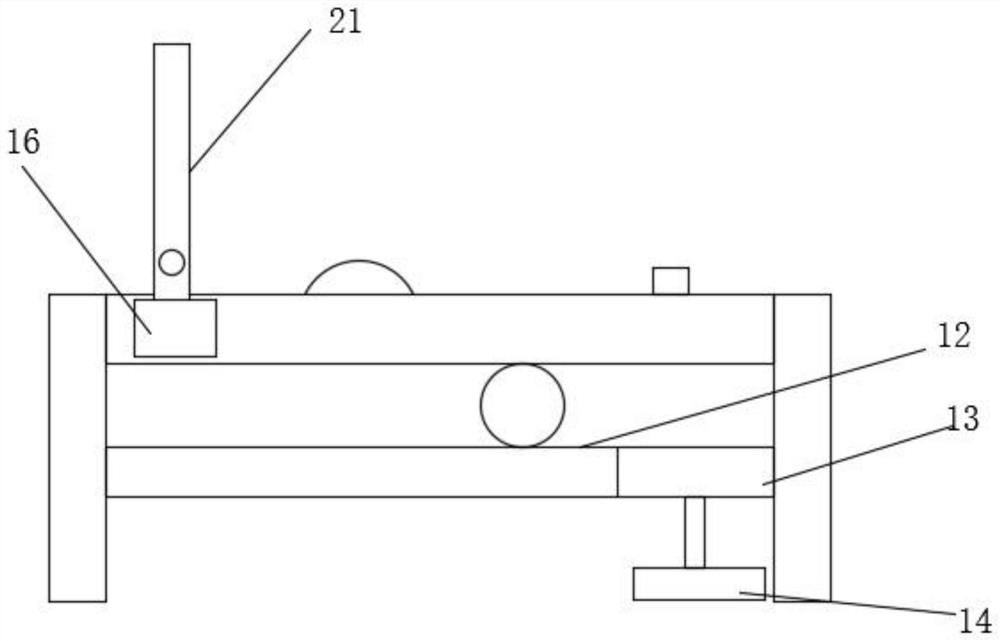

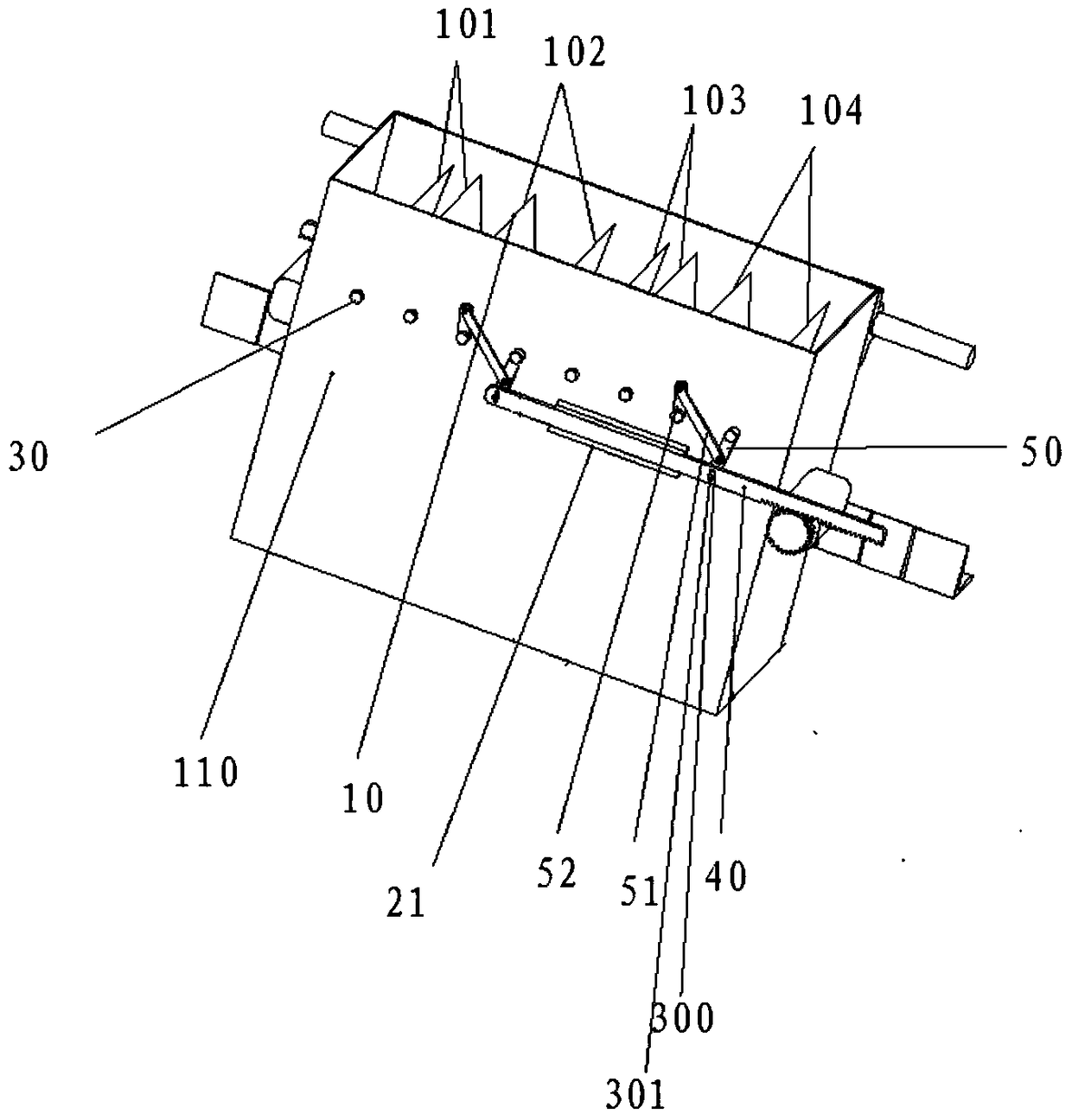

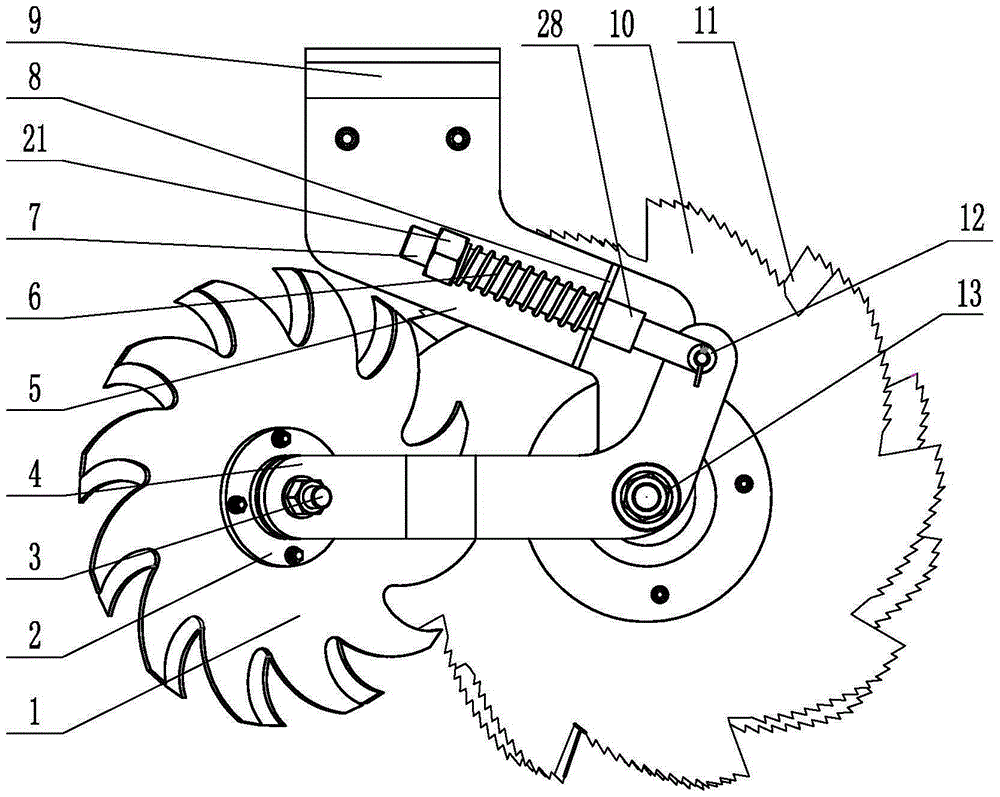

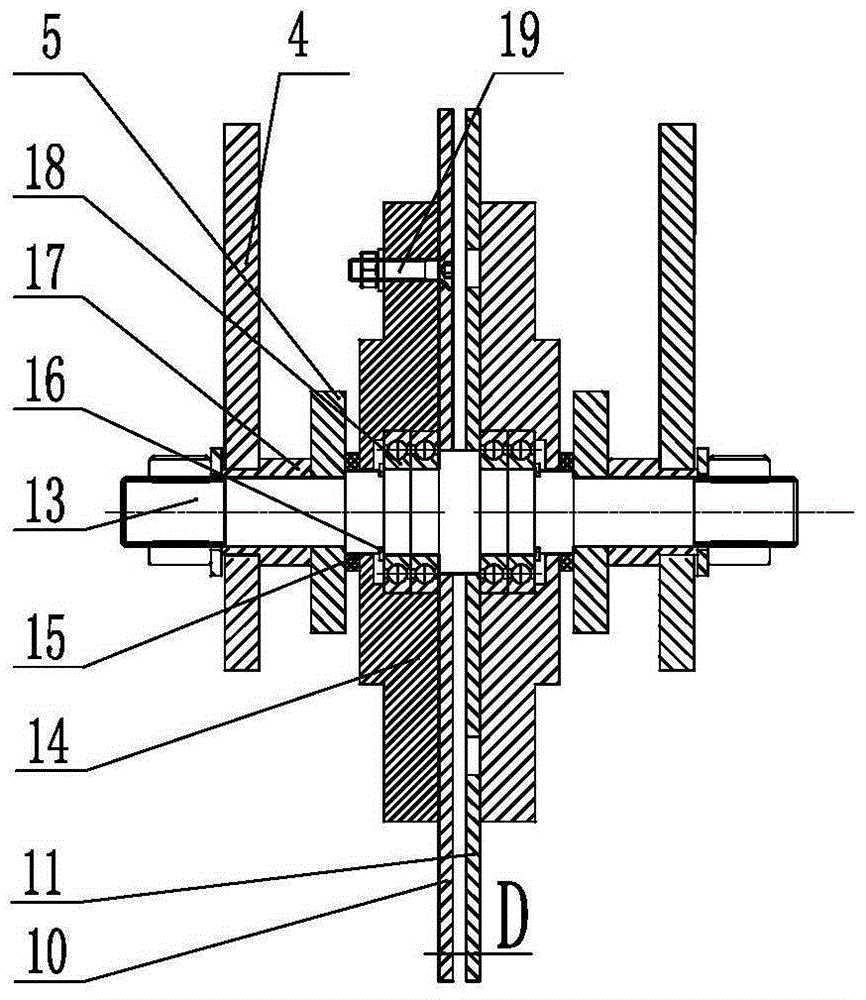

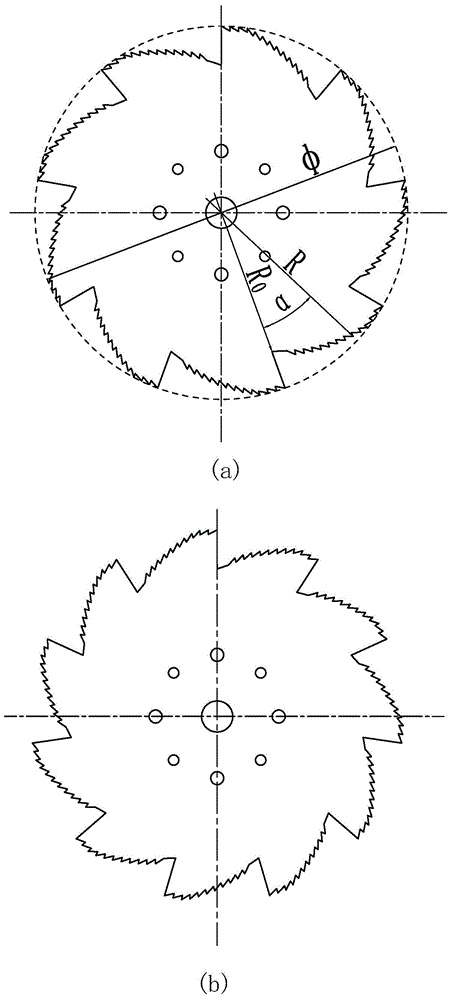

Cutting, shifting and blocking preventing device

InactiveCN104081898AAvoid missed cutsWork resistance is smallSpadesPloughsDevice formAgricultural machinery

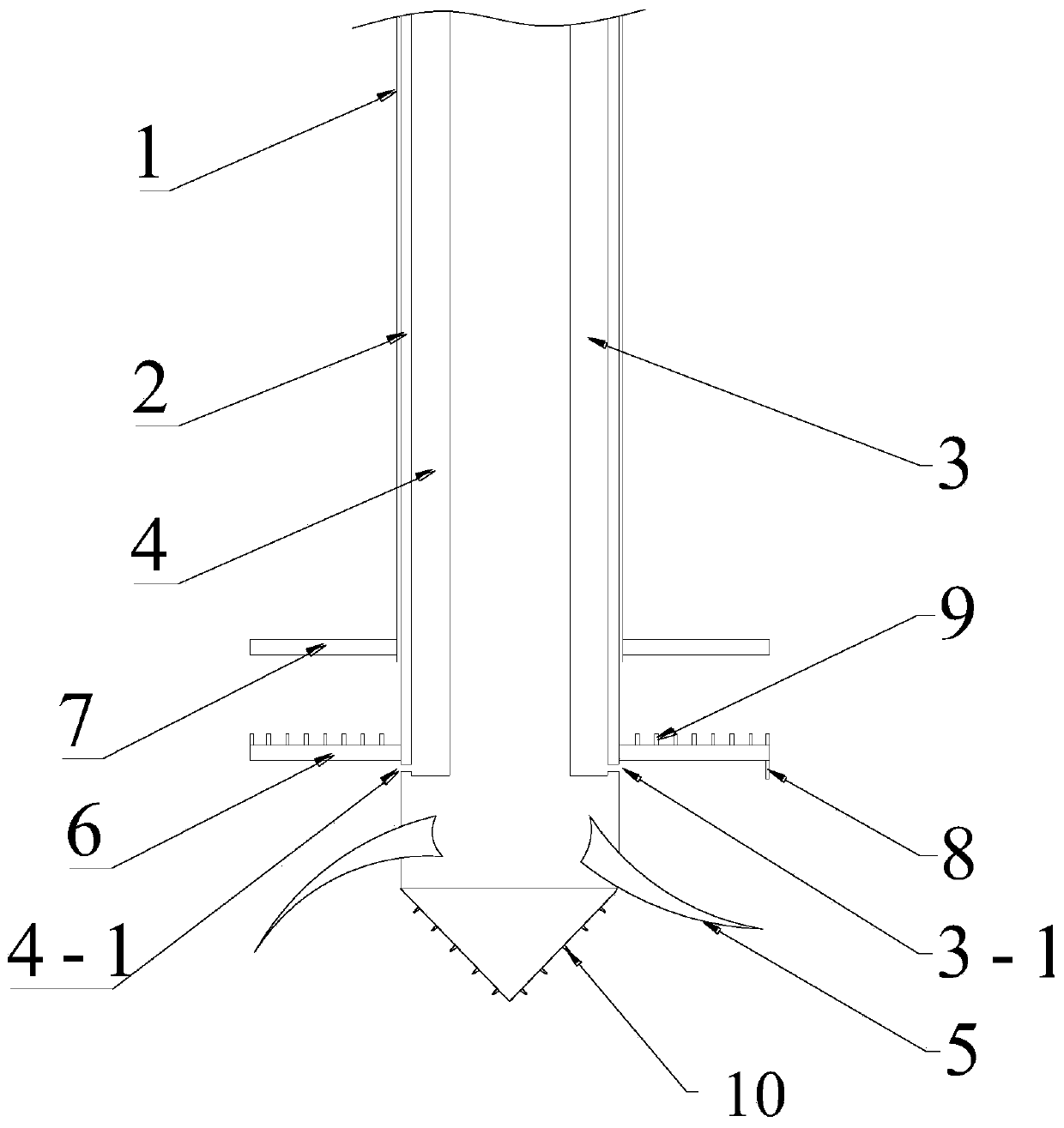

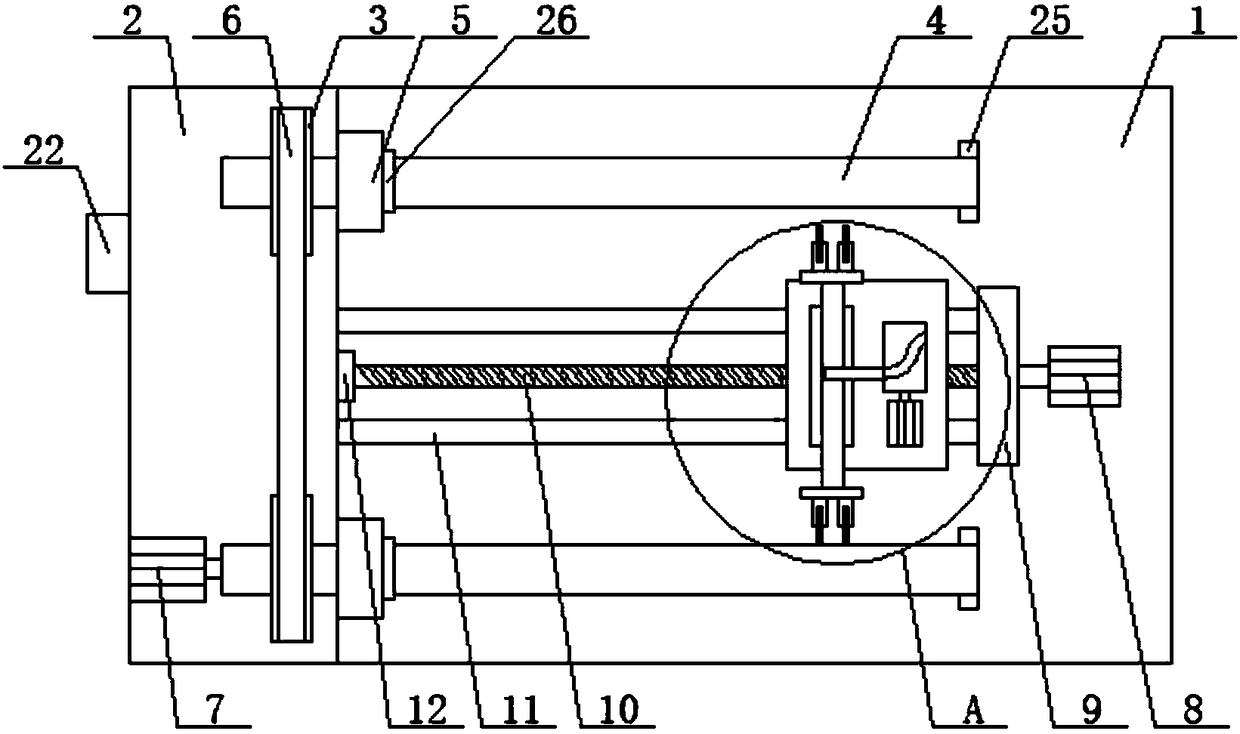

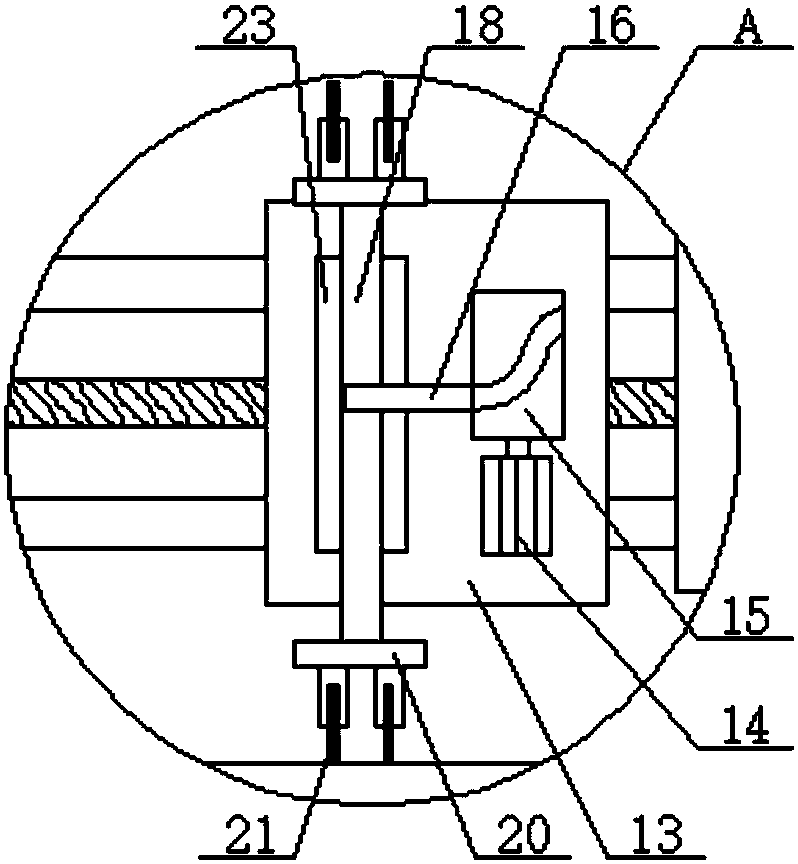

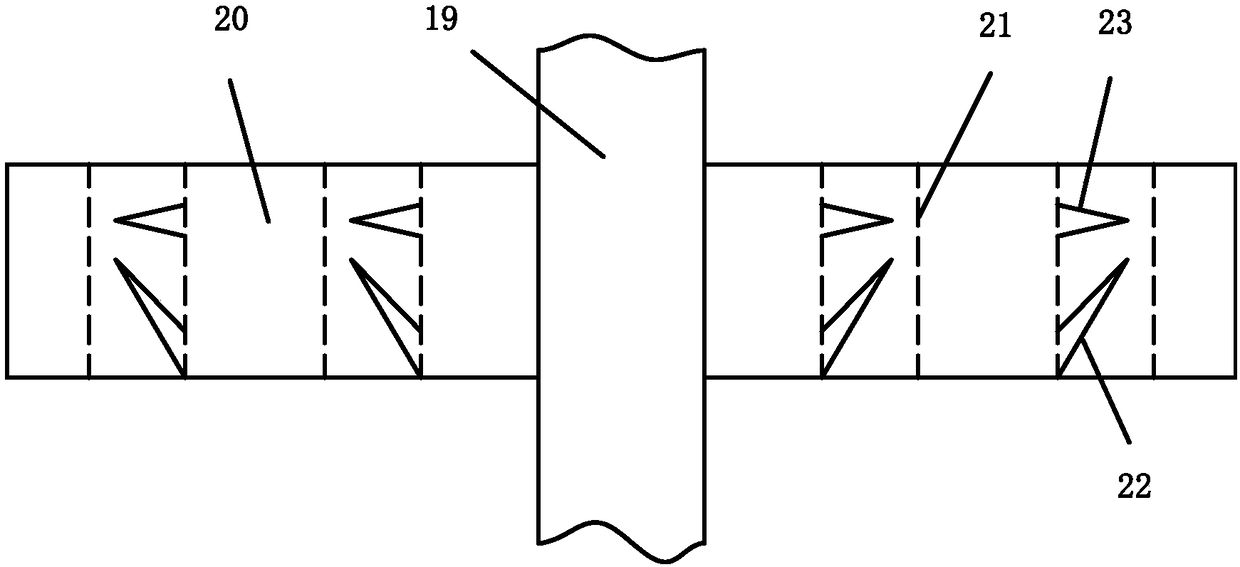

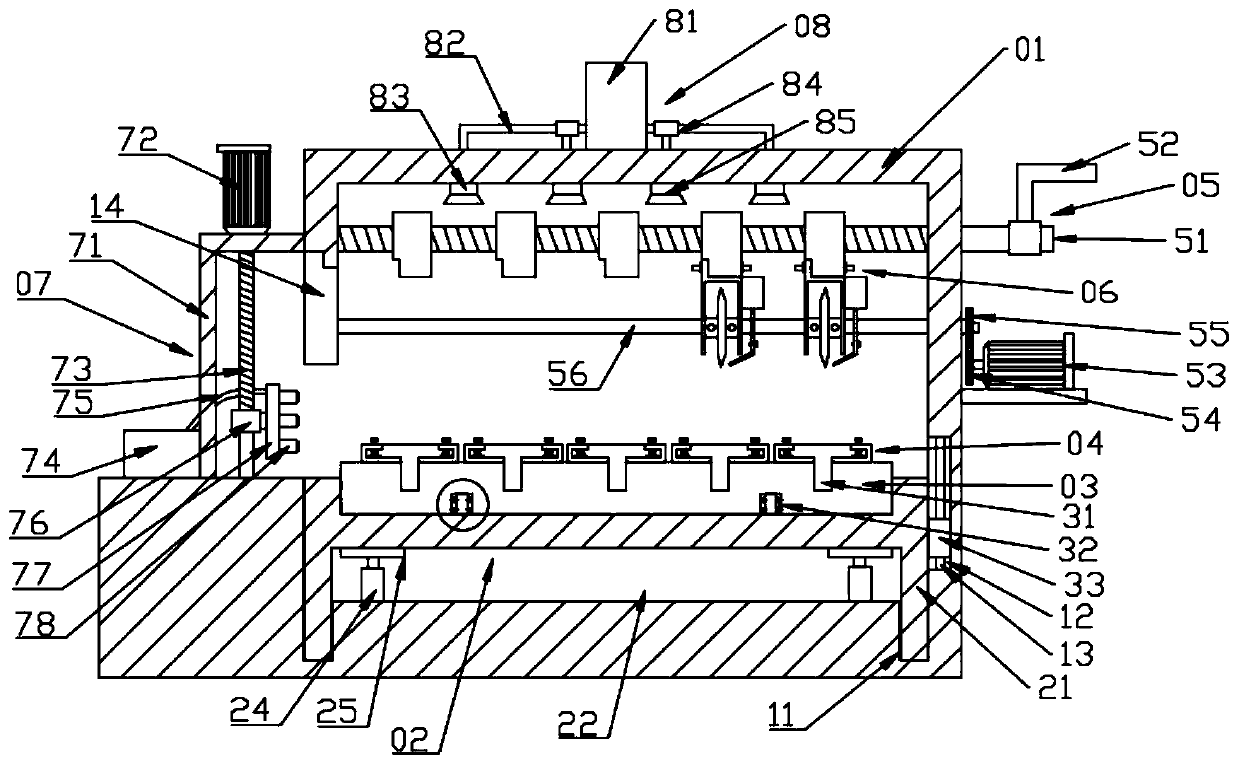

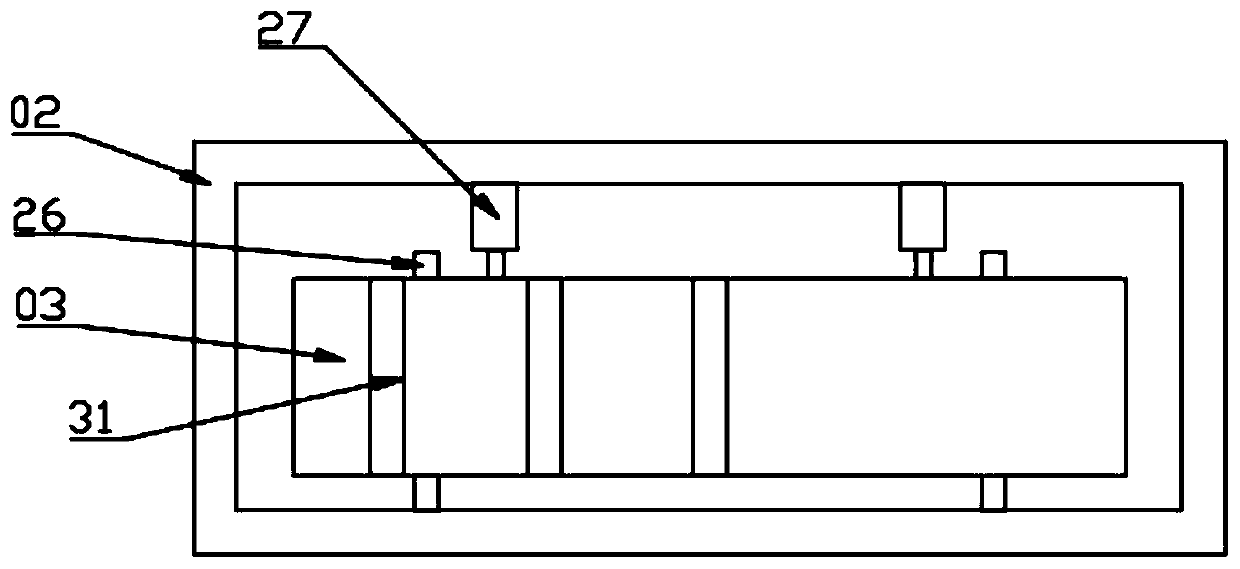

The invention discloses a cutting, shifting and blocking preventing device, and belongs to the technical field of agricultural machinery. The cutting, shifting and blocking preventing device comprises a spindle, connecting sleeve plates, inclined plates, a breaking and cutting device and stubble shifting and blocking preventing devices, wherein the breaking and cutting device is mounted in the middle of the spindle, two groups of stubble shifting and blocking preventing devices are symmetrical about the breaking and cutting device and connected to two ends of the spindle, stubble shifting wheels of the stubble shifting and blocking preventing devices and breaking and cutting discs of the breaking and cutting device form deflection angles, and accordingly, the two symmetrical stubble shifting wheels are mounted on two sides of the end part of the breaking and breaking and cutting device in a splayed manner and simultaneously backwards shift stubble and laterally push stubble, straw and weeds; the connecting sleeve plates are symmetrically connected between the breaking and cutting device and the stubble shifting and blocking preventing devices on the spindle and are simultaneously connected with the stubble shifting and blocking preventing devices respectively; and during working, the two connecting sleeve plates are connected with a no-tillage planter for corn ridge culture respectively. The device can cut the stubble, straw and weeds, can shift the stubble, can throw the straw, the stubble and the weeds to the rear side and can push the straw, the stubble and the weeds to furrows on two sides, a clean seed bed is formed on a ridge, blocking is reduced, and the breaking and cutting quality is guaranteed.

Owner:SHENYANG AGRI UNIV

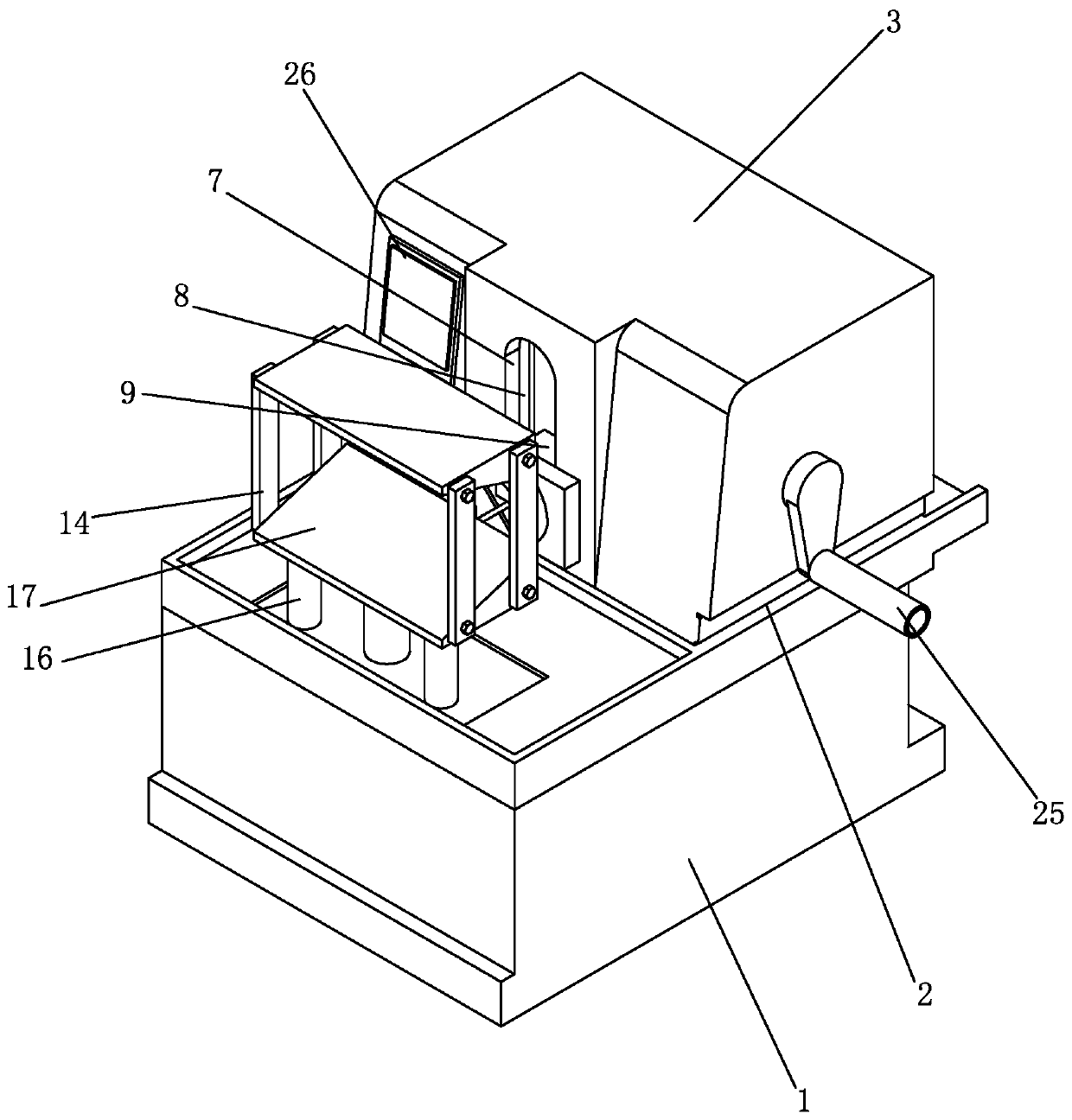

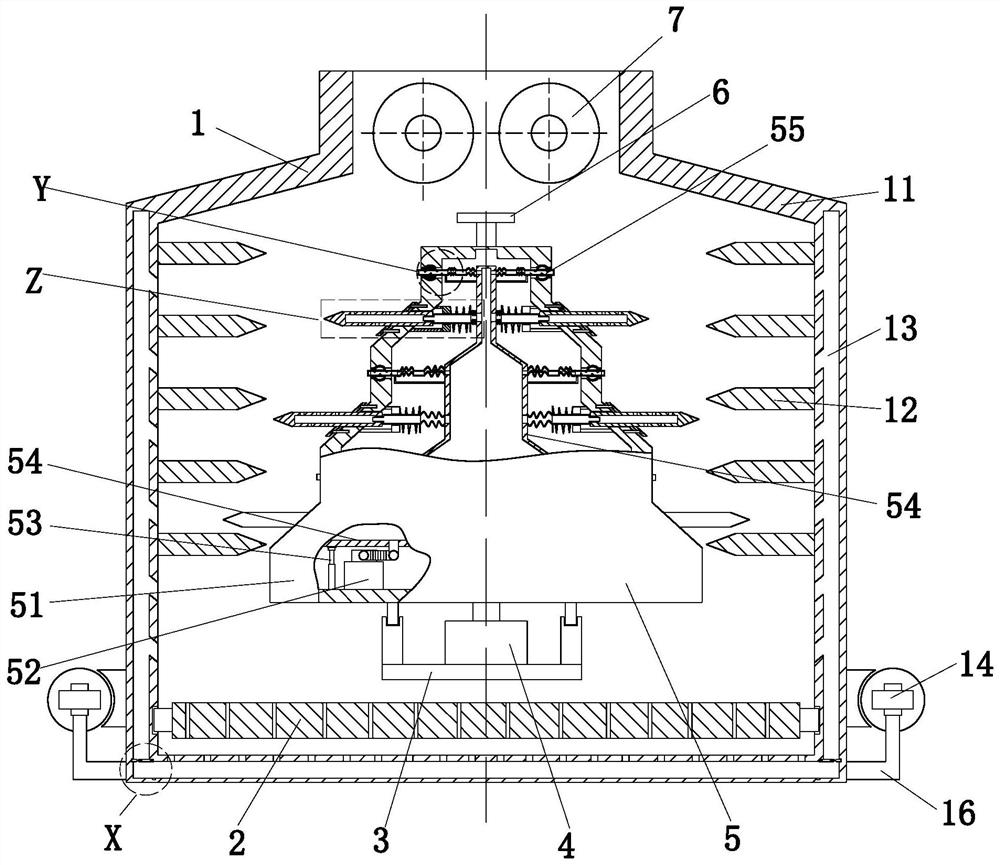

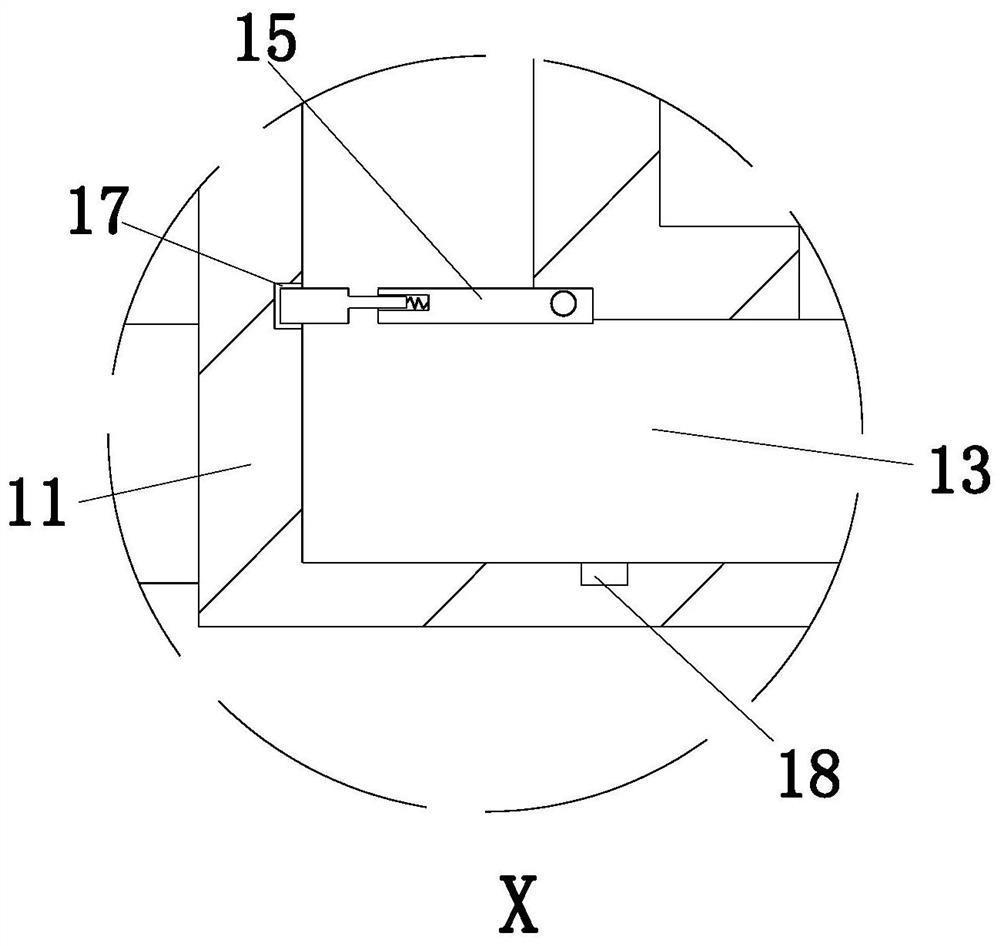

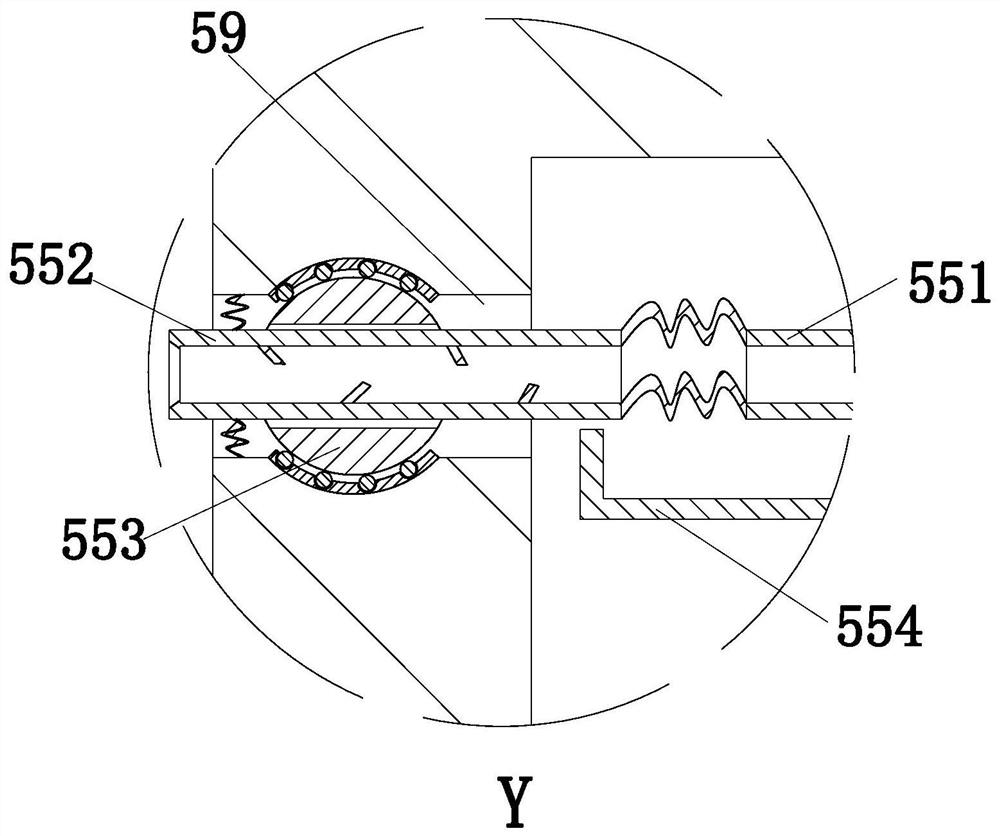

Vertical environment-friendly smashing machine for building construction

InactiveCN105817303AImprove work efficiencyIncrease the number of cutsDispersed particle filtrationGrain treatmentsArchitectural engineeringRaw material

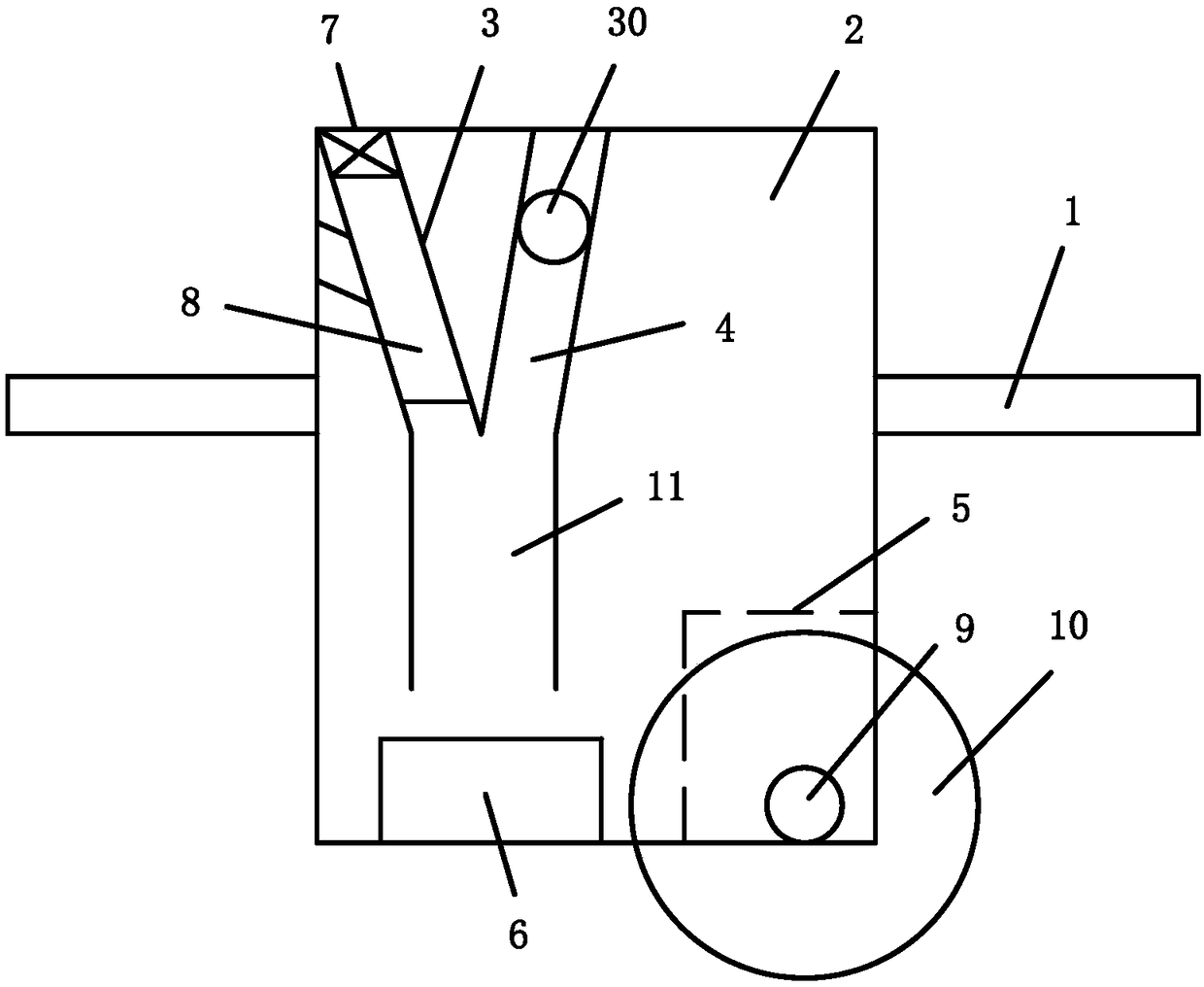

The invention discloses a vertical environment-friendly smashing machine for building construction. The vertical environment-friendly smashing machine for building construction comprises a machine body. A feeding hopper is arranged at the left end of the upper side of the machine body. A machine frame is arranged on the left side of the machine body. Telescopic columns are connected to the periphery of the bottom of the machine frame, and a sliding rail is arranged on the upper sides of the telescopic columns. The sliding rail comprises an obliquely arranged ascending section and a bent section arranged at the top end of the ascending section, and a transmission chain is arranged on the sliding rail. The two ends of the sliding rail are each provided with a driving chain wheel and a plurality of driven chain wheels. By means of the vertical environment-friendly smashing machine for building construction, automatic feeding can be achieved, feeding is sufficient and thorough, manual operation is not needed, and the working efficiency of the smashing machine is effectively improved; the smashing effect is effectively improved through two V-shaped smashing rods which are arranged with one below the other; materials are further smashed by smashing blades, so that the smashing quality is ensured; and meanwhile, fragments generated in the operating and discharging processes of the smashing machine can be recycled, so that dust pollution is avoided, environmental protection is achieved, and waste of raw materials is reduced.

Owner:姚旺东

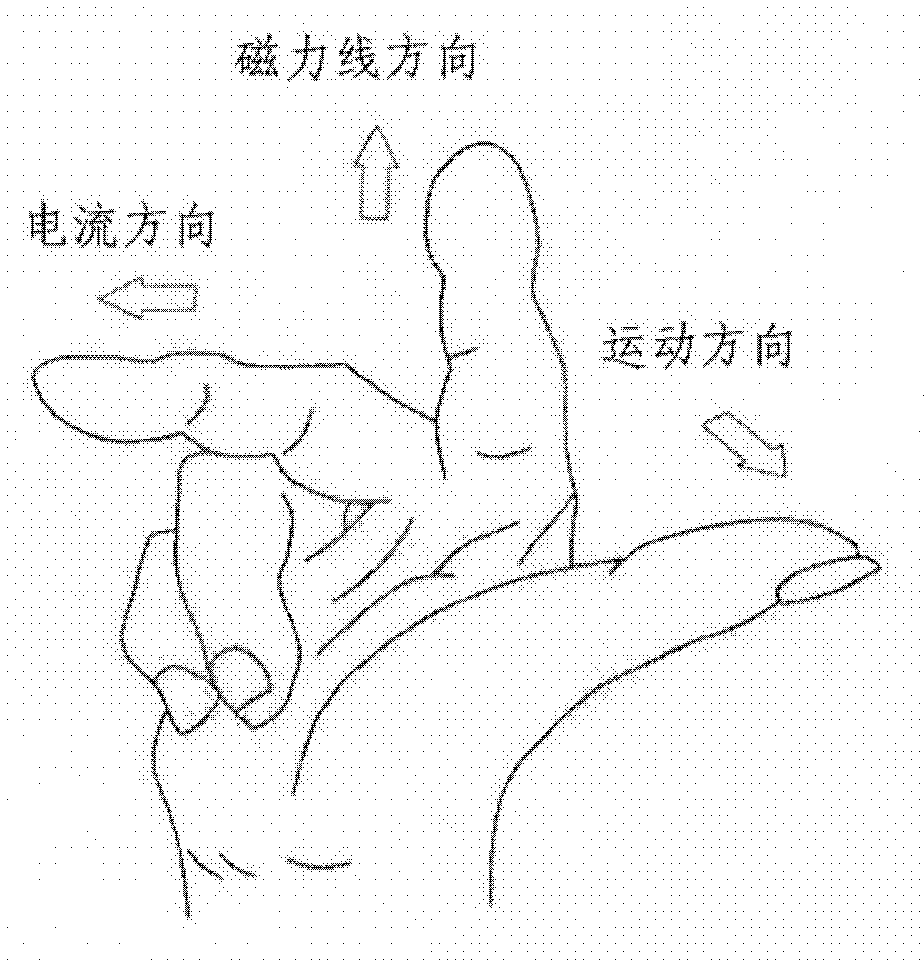

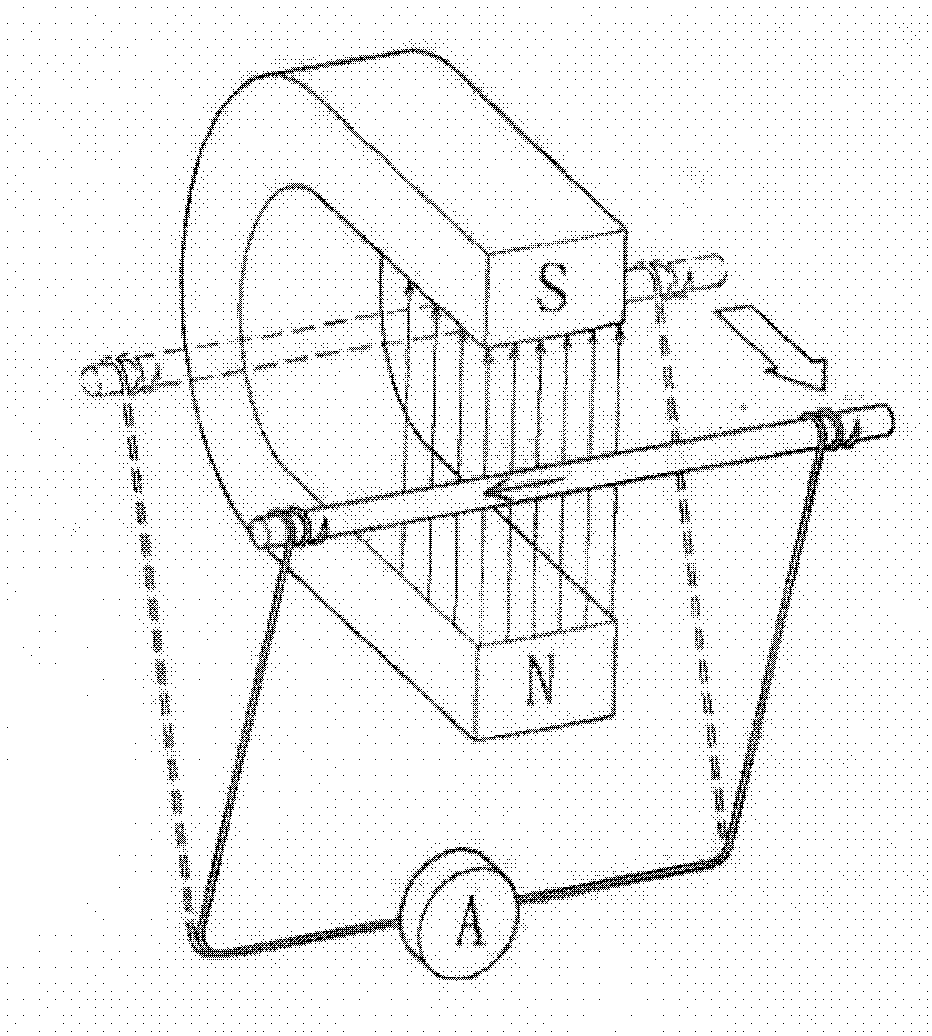

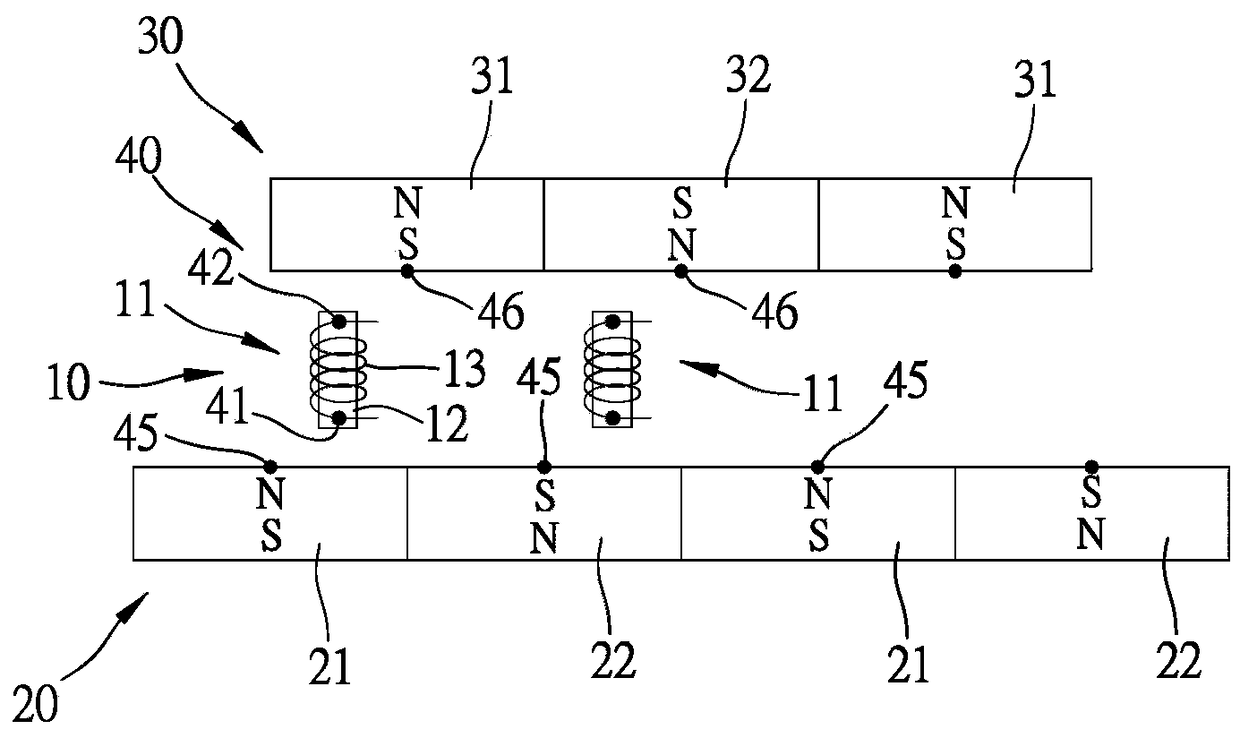

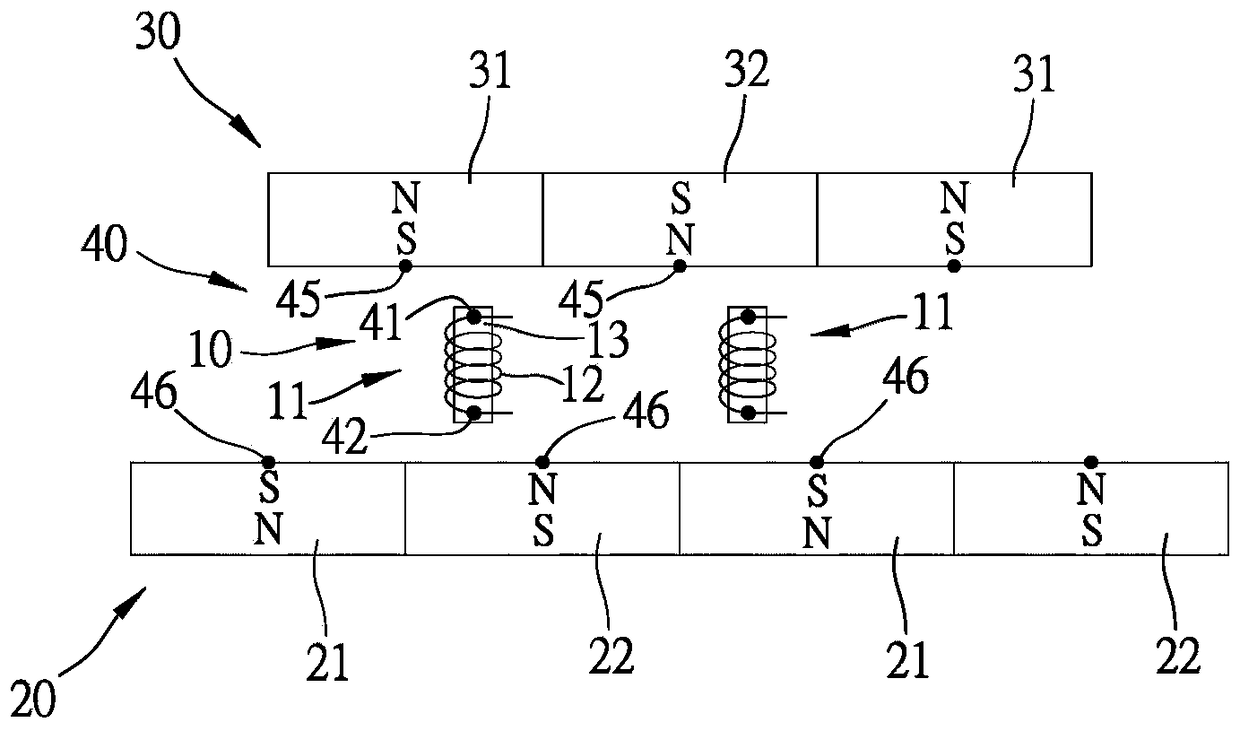

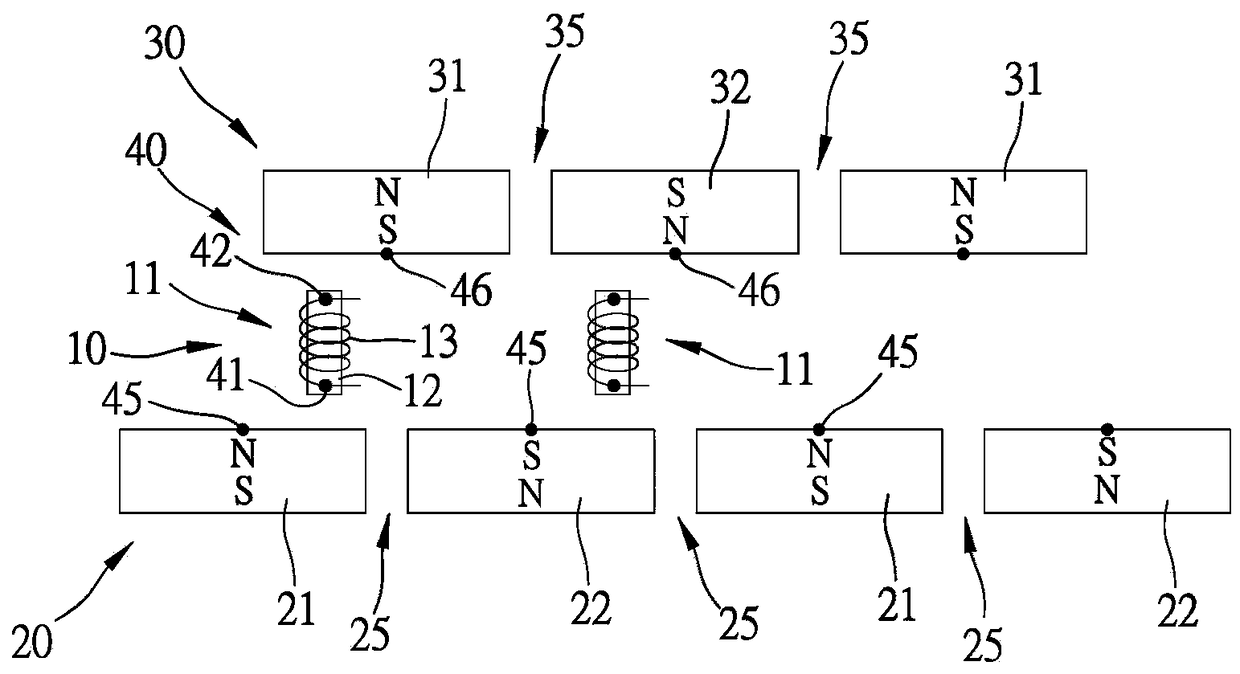

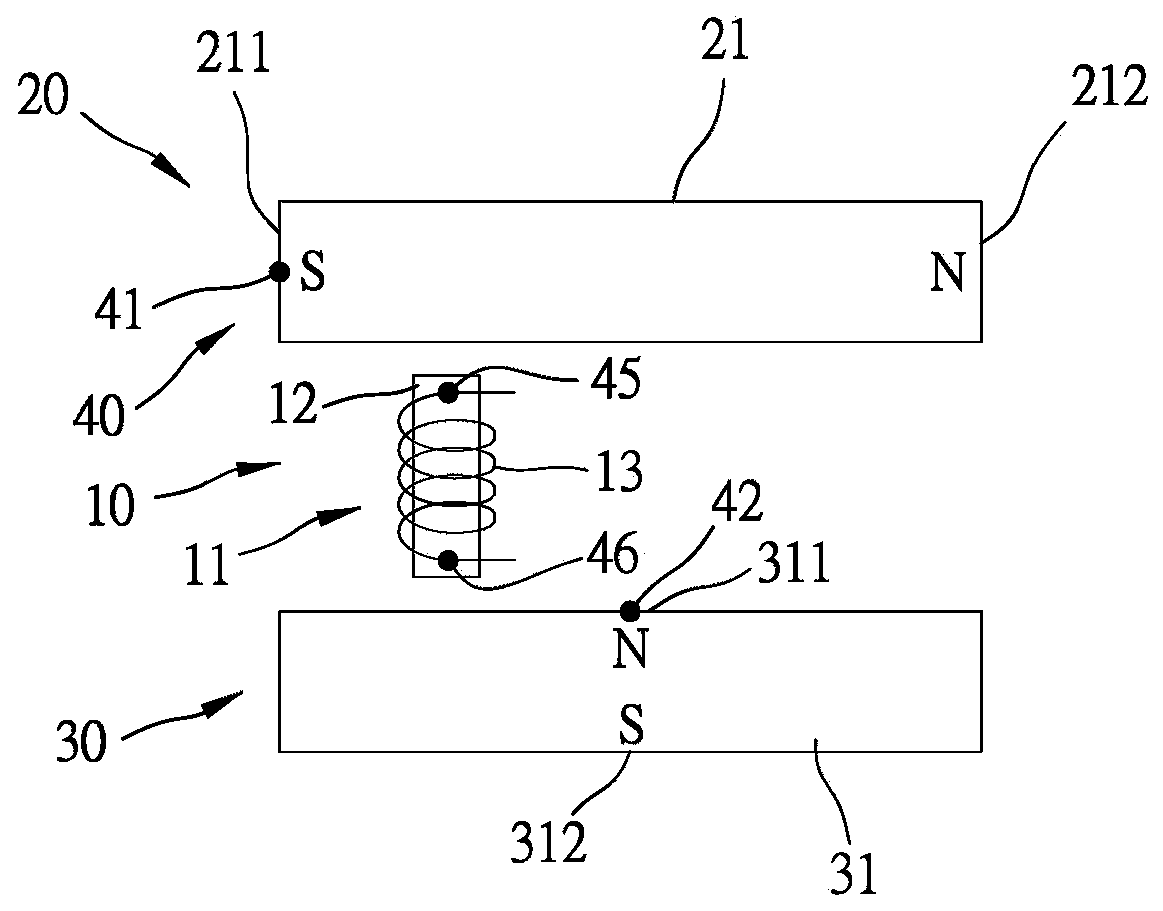

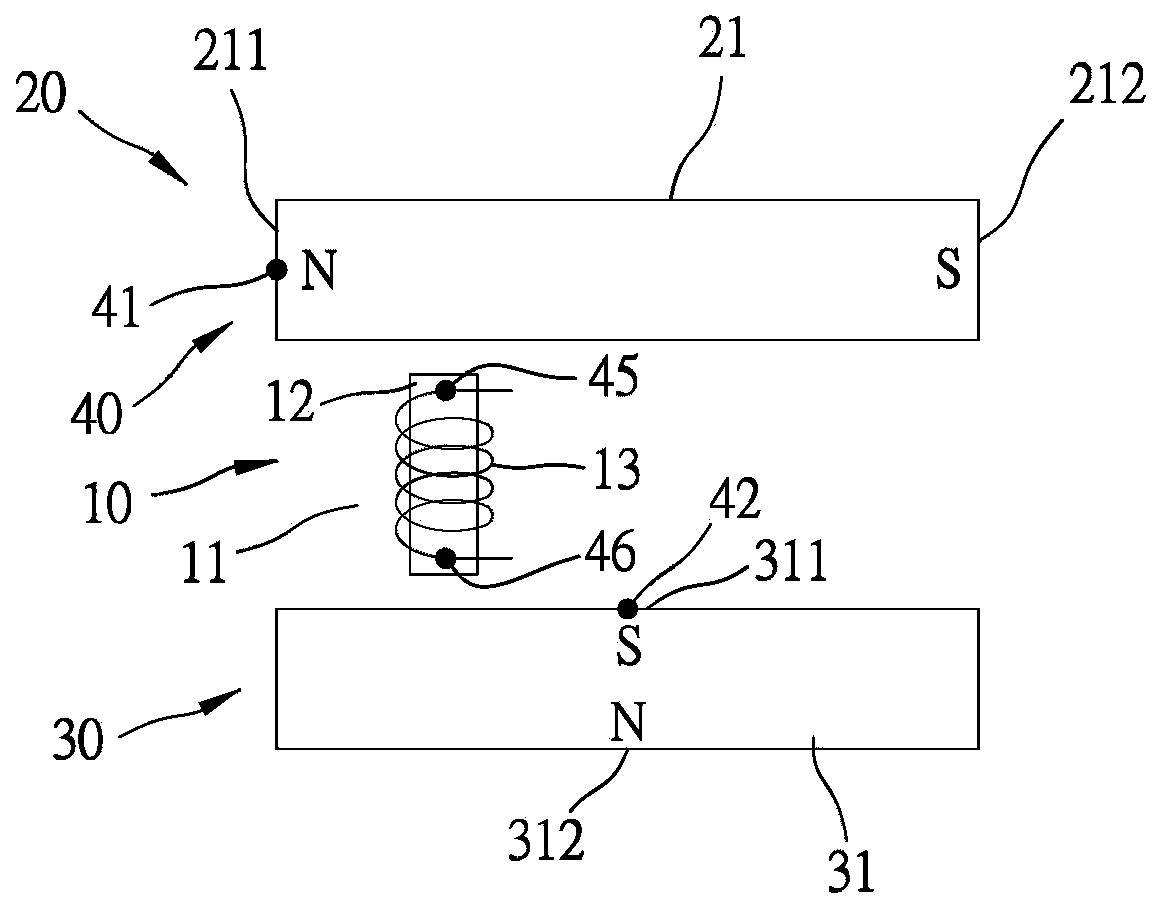

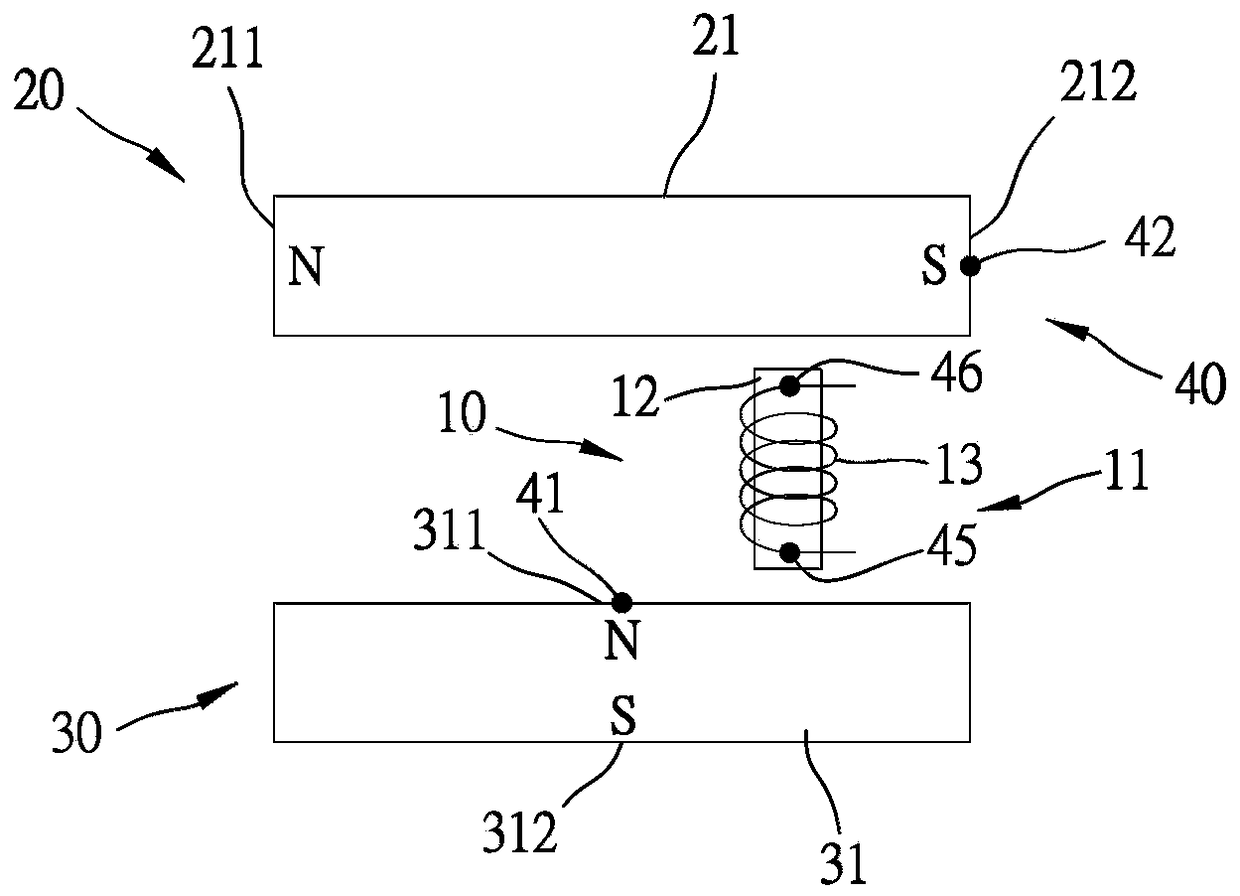

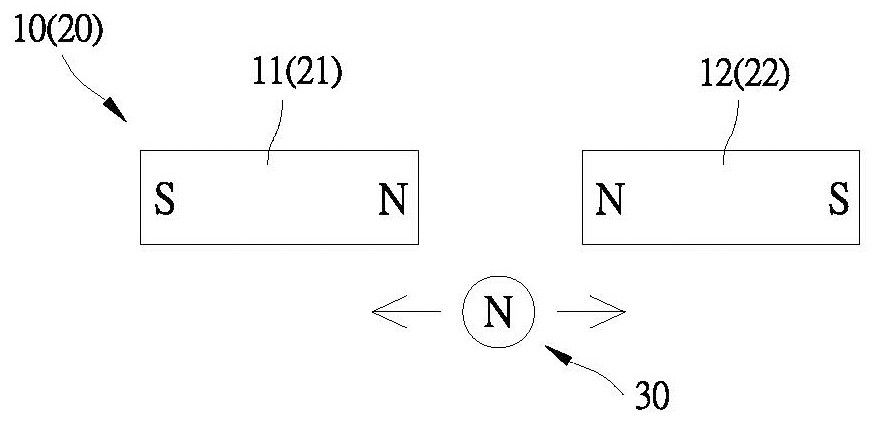

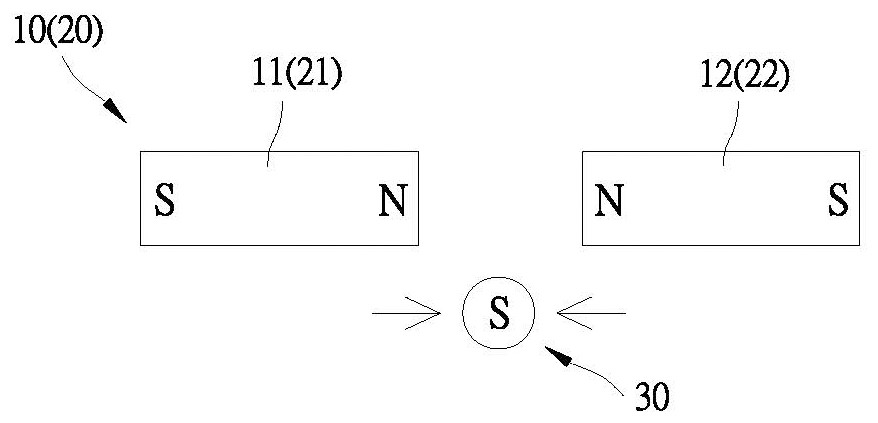

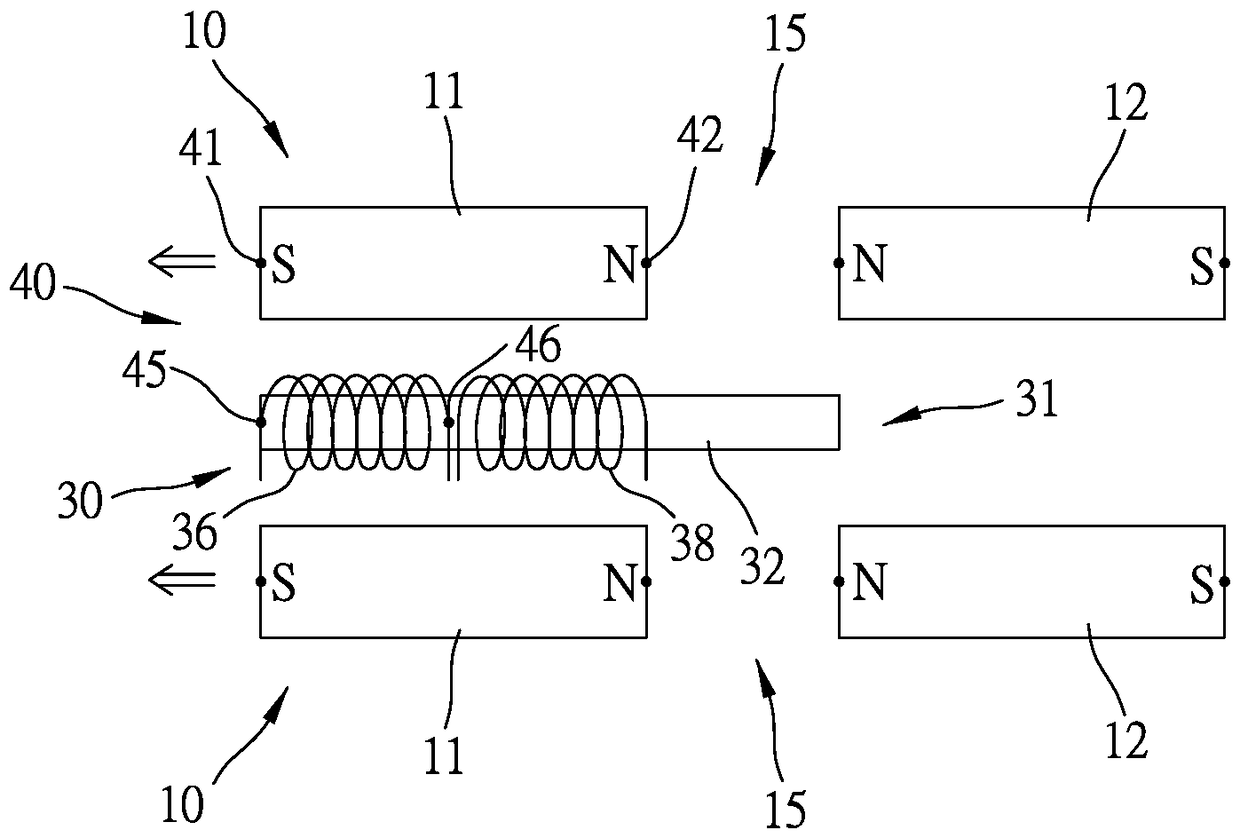

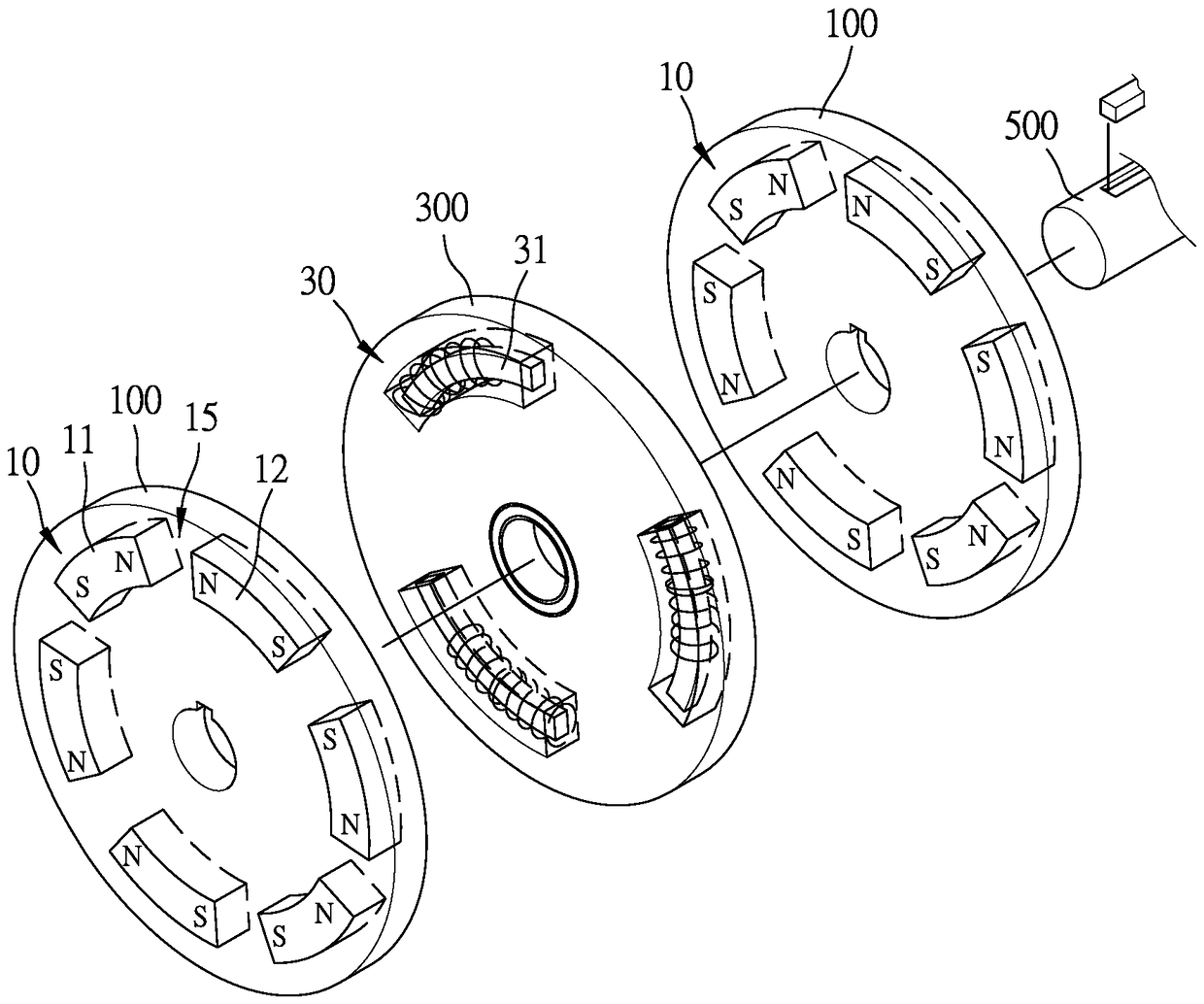

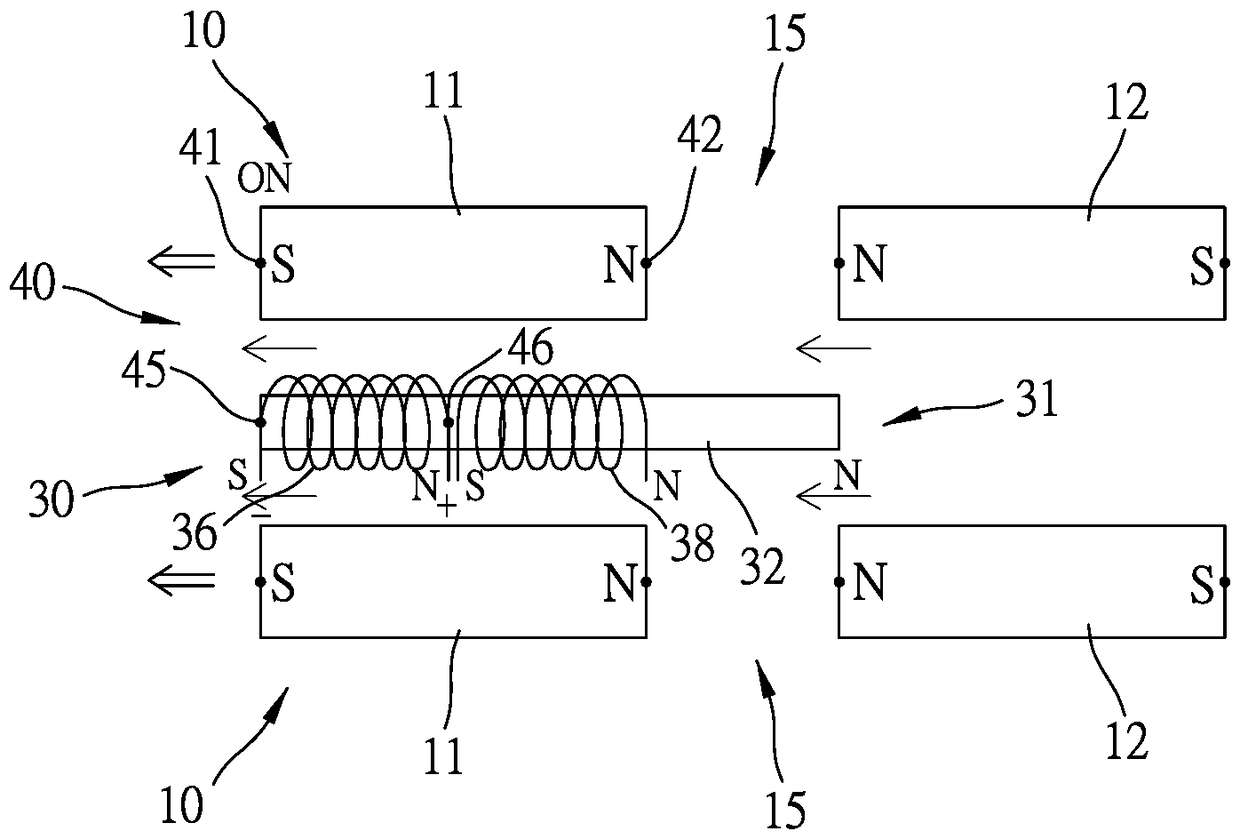

Electromagnetic device employing homopolar opposite magnetic set

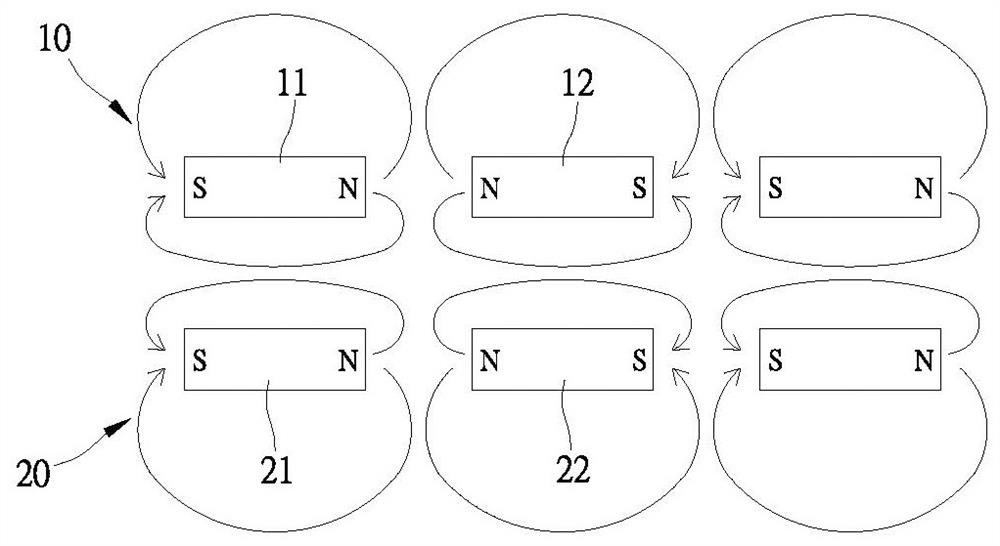

Provided is an electromagnetic device employing homopolar opposite magnetic sets, comprising one or more magnetic sets, with the magnetic sets being formed by every two oppositely fixed magnets. The two opposite magnets of the magnetic set are arranged in homopolar opposite manner and the magnetic field of two opposite magnets of the magnetic set can be passed by one or more coils. The opposite magnets of the magnet set are arranged in the manner of Pole N to N or S to S. The magnetic set can be defined as rotor while the coils can be defined as stator. The magnetic set can also be defined as stator while the coils can be defined as rotor. The magnetic set and coil of the electromagnetic device are selected from disk type or wheel type arranging manner. The electromagnetic apparatus can be as the generator or motor. The generating efficiency of the electromagnetic device emphasizes cutting number rather than the rotating speed. With the increase of the cutting number, the output of heavy current and voltage can be realized, thereby substantially raising the generating efficiency and the revolving efficiency of the motor.

Owner:许光智 +3

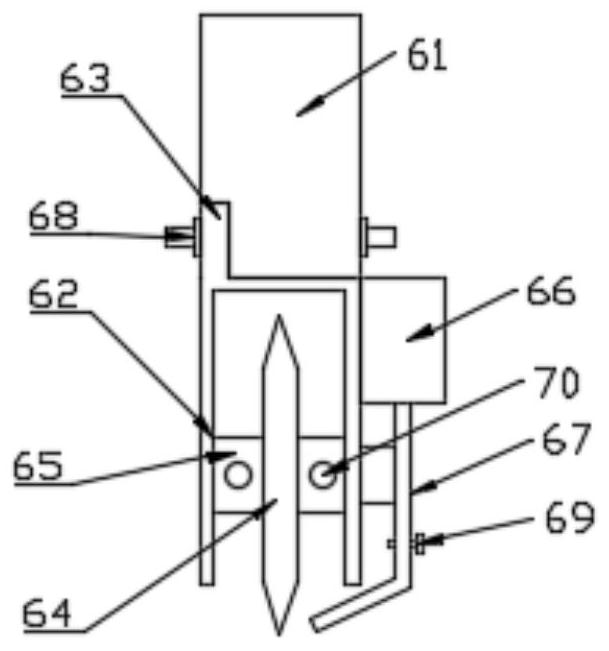

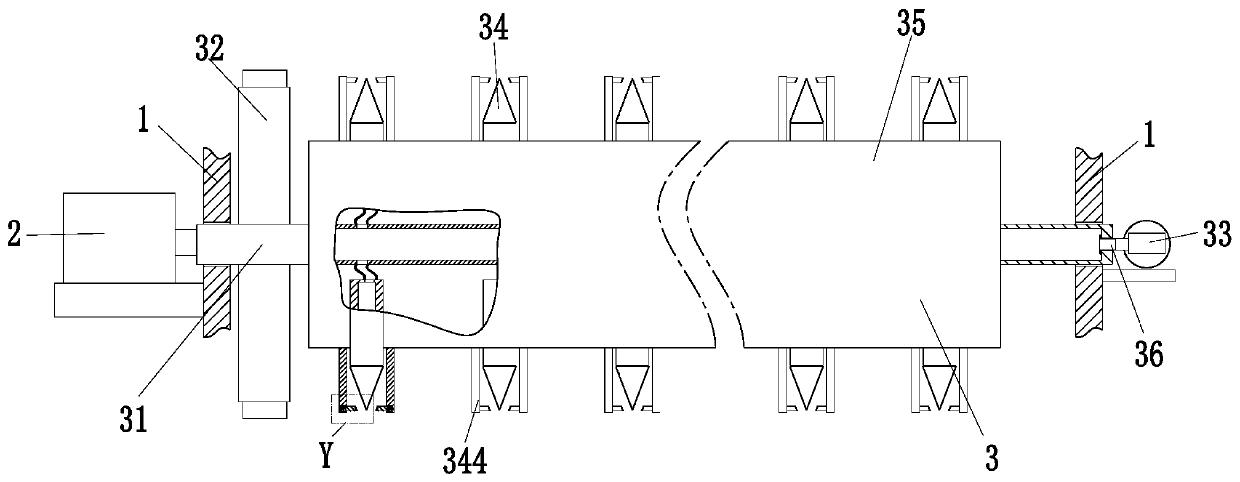

Double-spraying bidirectional cement mixing pile drill and construction method thereof

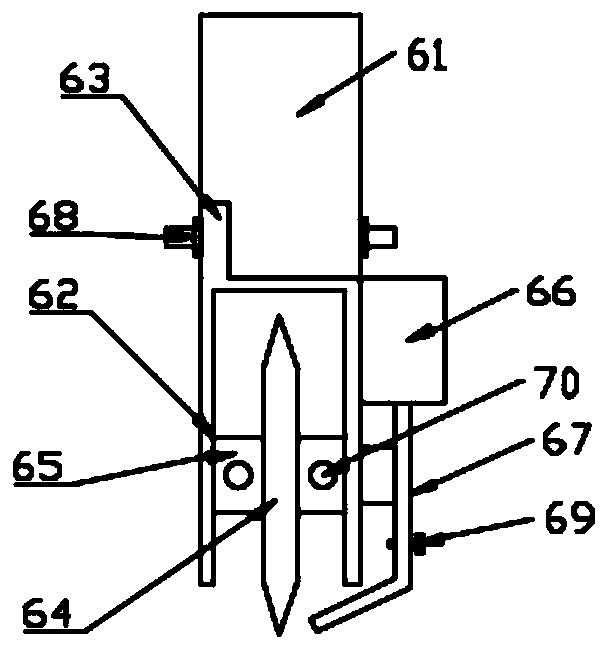

PendingCN110952522ASolve processing problemsGood processing effectDrill bitsBulkheads/pilesAir pumpHigh pressure water

The invention discloses a double-spraying bidirectional cement mixing pile drill and a construction method thereof. A main drill pipe comprises an outer main drill pipe and an inner main drill pipe; ahigh-pressure grout spraying tube and a high-pressure powder spraying tube are simultaneously arranged in the inner main drill pipe; the high-pressure grout spraying tube is connected with a high-pressure grout pump and grout manufacture equipment, which are controlled through a computer; the high-pressure powder spraying tube is connected with a high-pressure air pump and a cement storage tank,which are controlled through the computer; a first group of vanes and a second group of vanes are arranged on the inner main drill tube; the first group of vanes is positioned below the second groupof vanes; the first group of vanes adopts spiral alloy vanes; the grout spraying hole of the high-pressure grout spraying tube and the powder spraying hole of the high-pressure powder spraying tube are arranged on the lower part of the second group of vanes; and the outer end of the vane above the grout spraying hole is provided with a vertical baffle plate for blocking high-pressure cement grout.A high-pressure cement grout tube and a high-pressure cement powder tube are simultaneously arranged for effectively selecting cement under different states according to different soil layers, and working efficiency is reasonably improved to achieve an optimal foundation processing effect.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

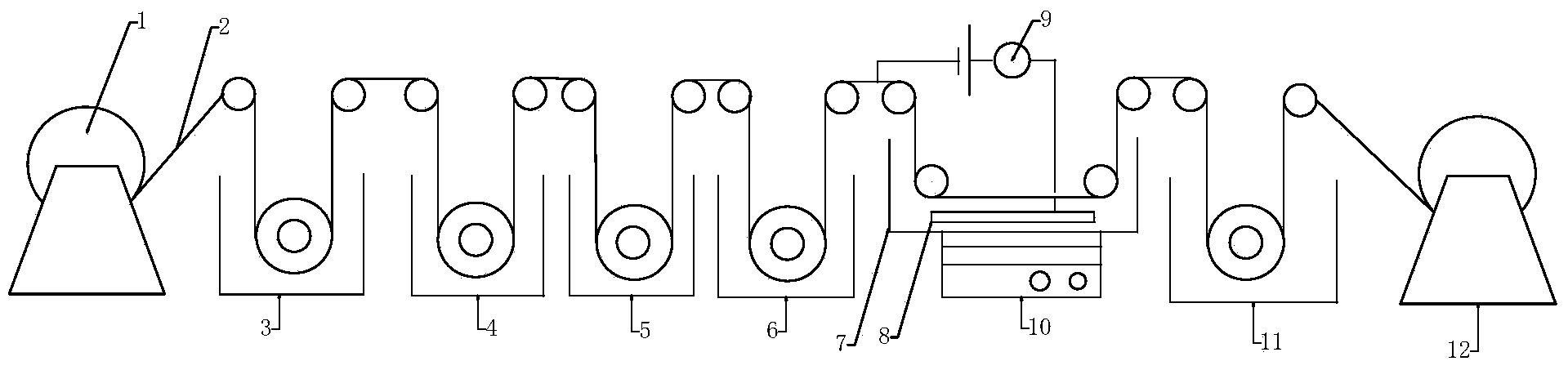

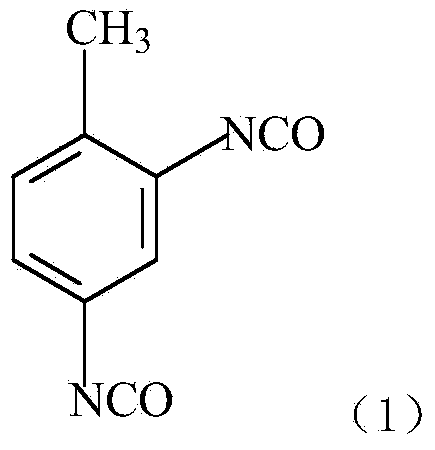

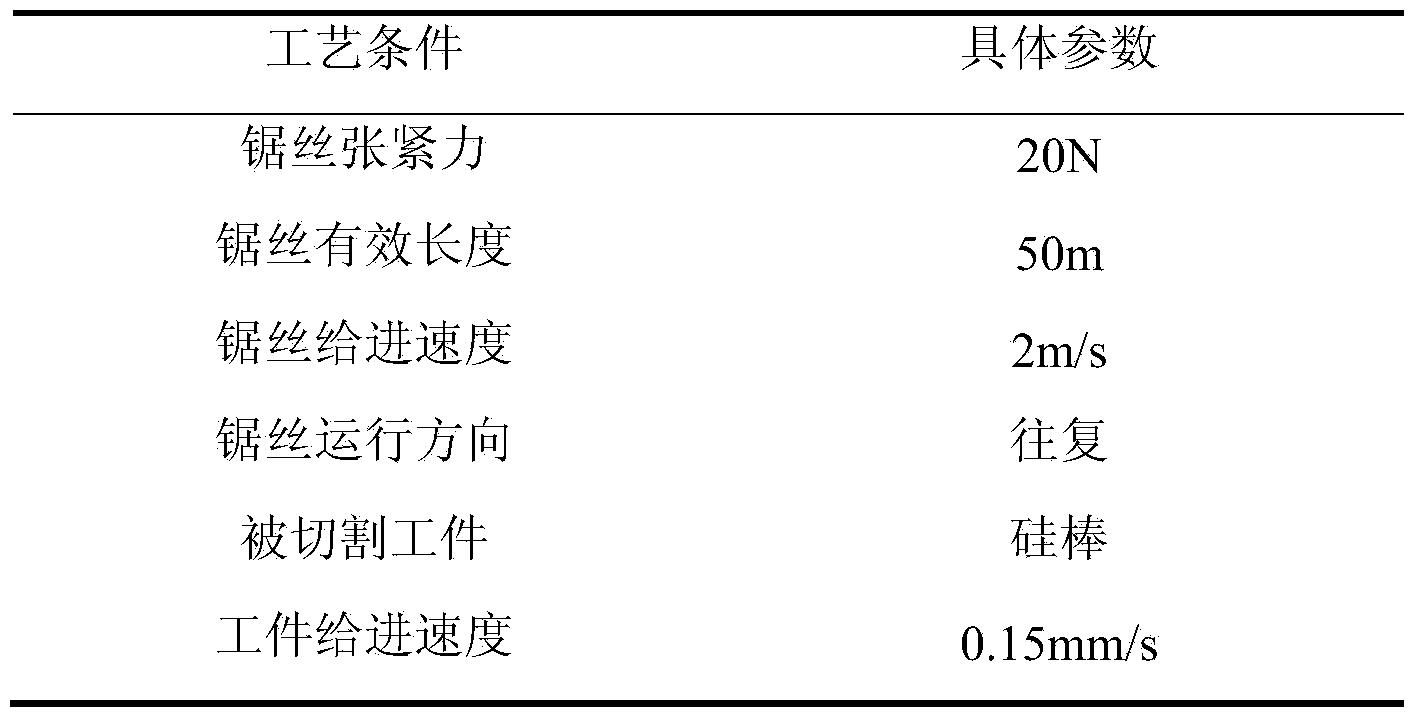

Preparation and superhigh-pressure processing method for cathode-electrophoresis-resin diamond scroll saw

ActiveCN104018207ALow unsealing temperatureHigh reactivityElectrolytic coatingsEmulsionPolymer science

The invention discloses preparation and a superhigh-pressure processing method for a cathode-electrophoresis-resin diamond scroll saw, and belongs to the field of preparation of diamond scroll saws. The diamond scroll saw is prepared by employing an electrophoresis method. The preparation method comprises: firstly preparing an emulsion of cathode electrophoresis resin, then adding diamond into the prepared emulsion, and employing an intermittent stirring manner to enable diamond to be uniformed suspended in the emulsion; and enabling a pretreated saw filament to pass through the diamond-containing emulsion in an electrophoresis way, and then performing pre-solidification, deep solidification, superhigh-pressure processing and the like, so as to finally prepare the diamond scroll saw. According to the prepared diamond scroll saw, the diamond usage amount is less, applied sand is uniform, the thickness of a resin layer is easily controllable, the resin layer is uniform, retention capability on wear debris, wear resistance and other aspects are better than those of diamond scroll saw coated with a resin binder.

Owner:SHANDONG UNIV OF SCI & TECH

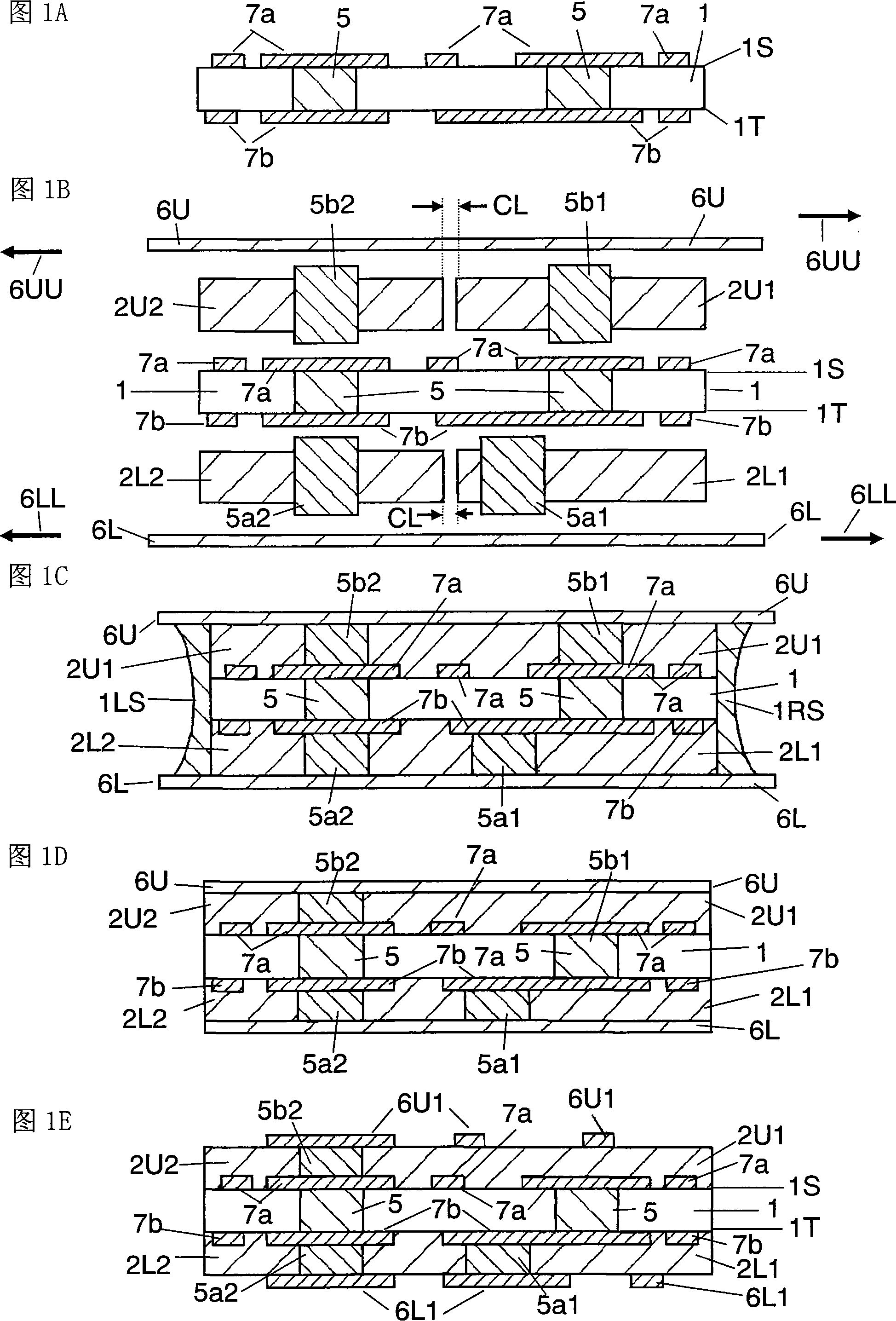

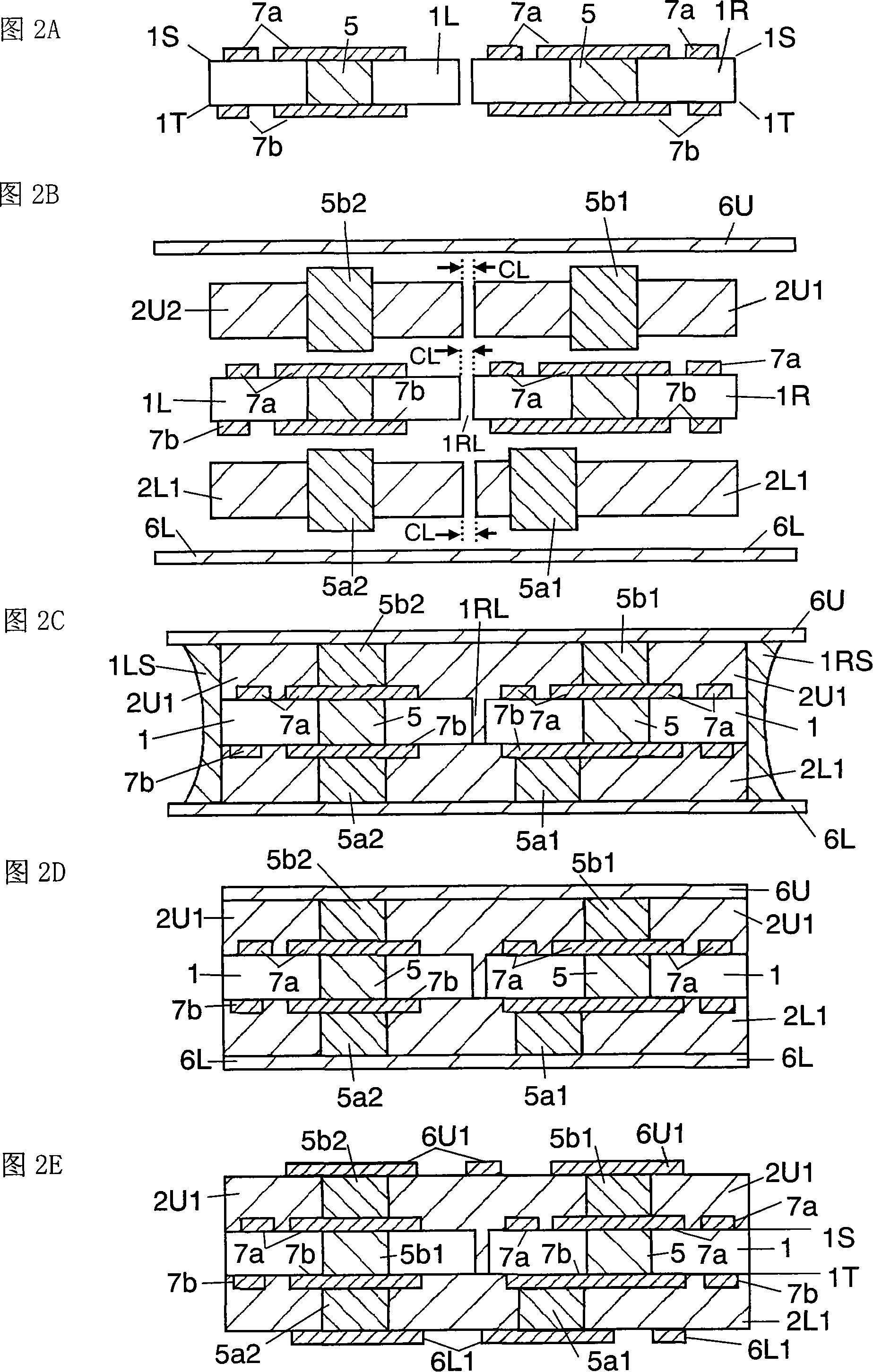

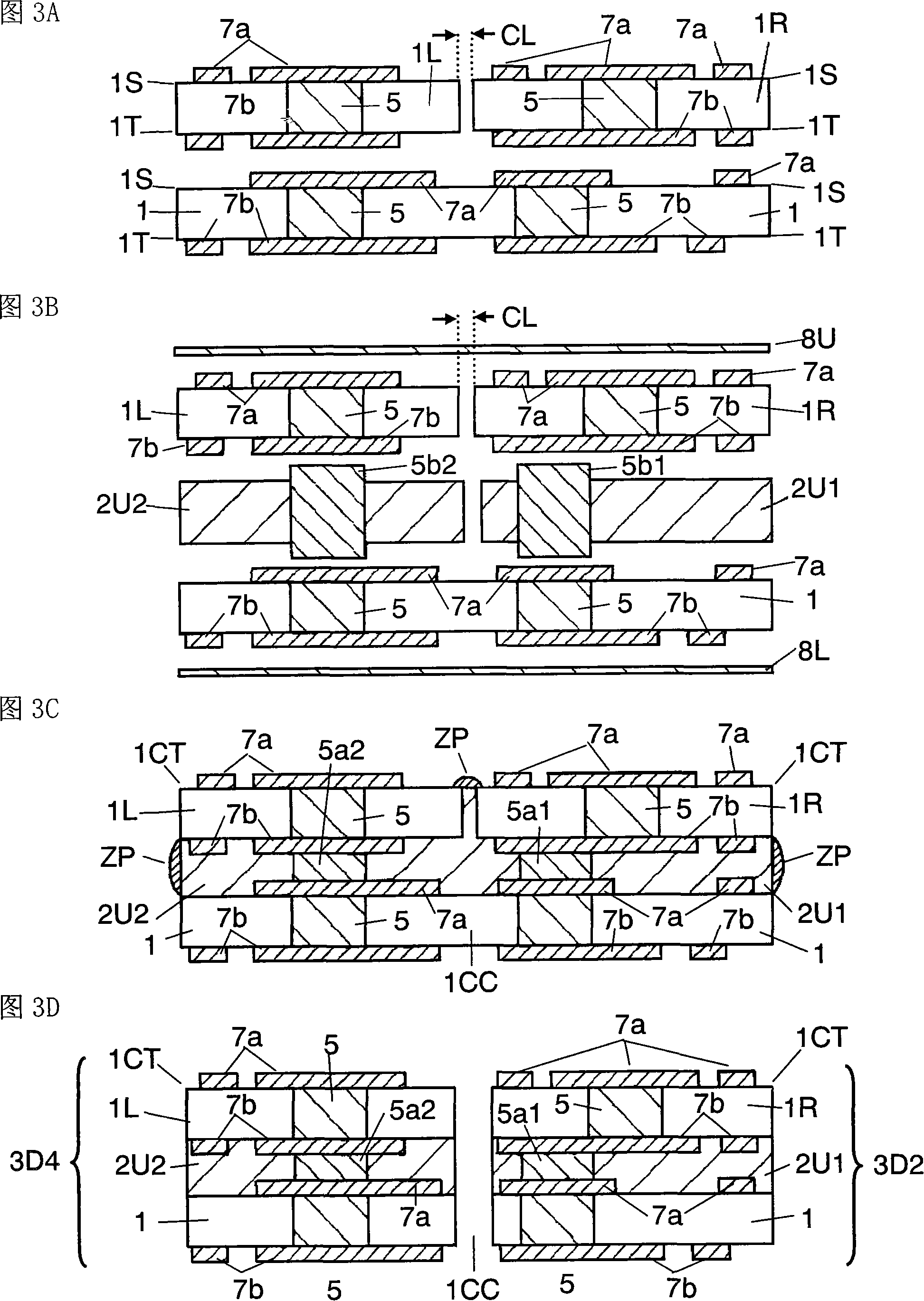

Method for manufacturing circuit forming board

InactiveCN101142863AStabilizationExert dimensional stabilityPrinted circuit aspectsInsulating layers/substrates workingMetal foilMetal

A stable and high quality circuit forming board is provided even when a work size is increased. Prepreg sheets (2L1, 2L2), which are board material for stage (B), are arranged on a first metal foil (6L) in a stacking process, and are stacked on the first metal foil (6L). A board material (1) for a stage (C) is stacked on the board material (2L1, 2L2). Two or more prepreg sheets (2U1, 2U2), which are the board material for the stage (B), are stacked on the board material (1), and a second metal foil (6U) is stacked thereon.

Owner:PANASONIC CORP

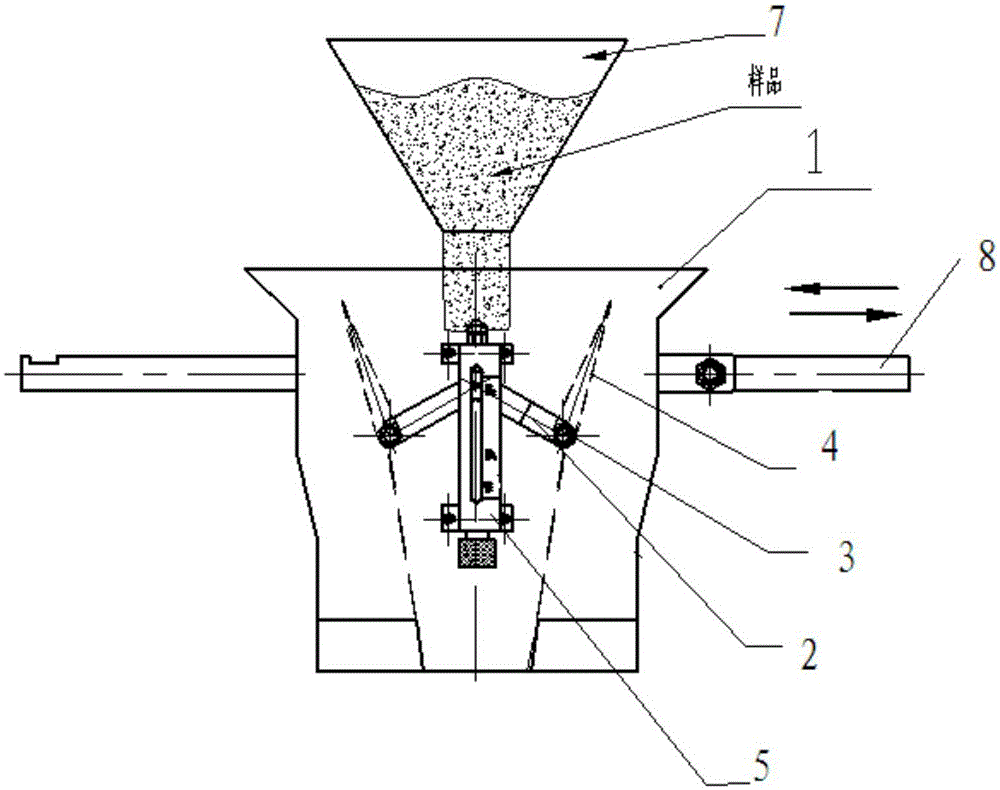

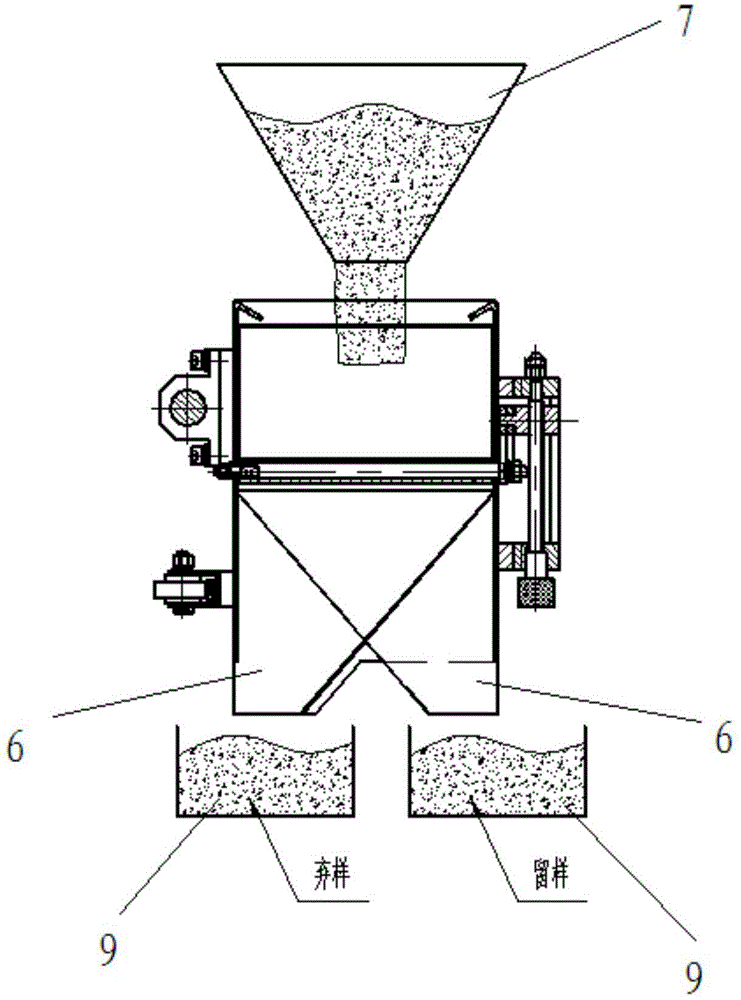

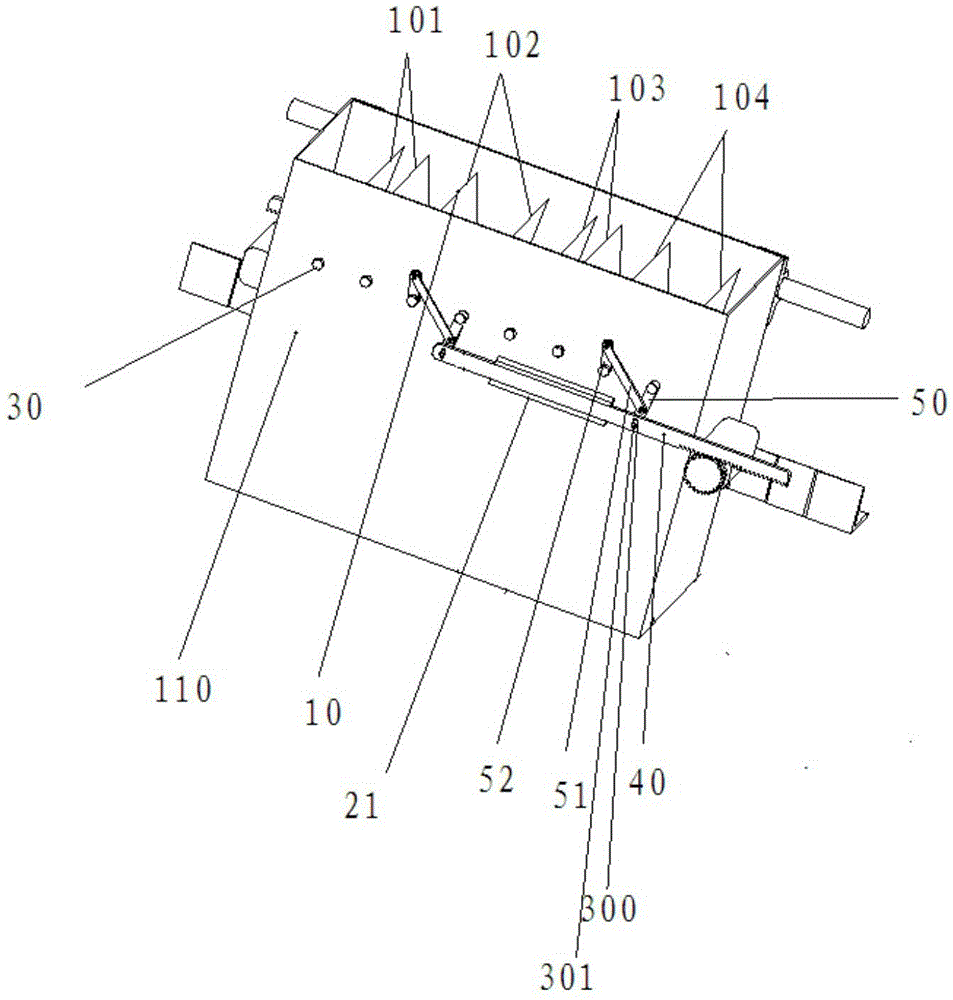

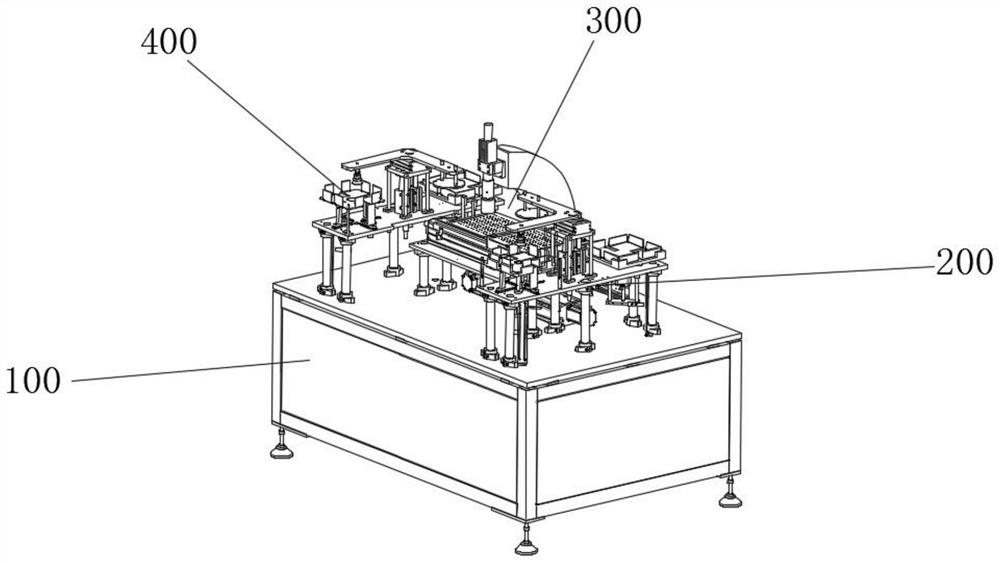

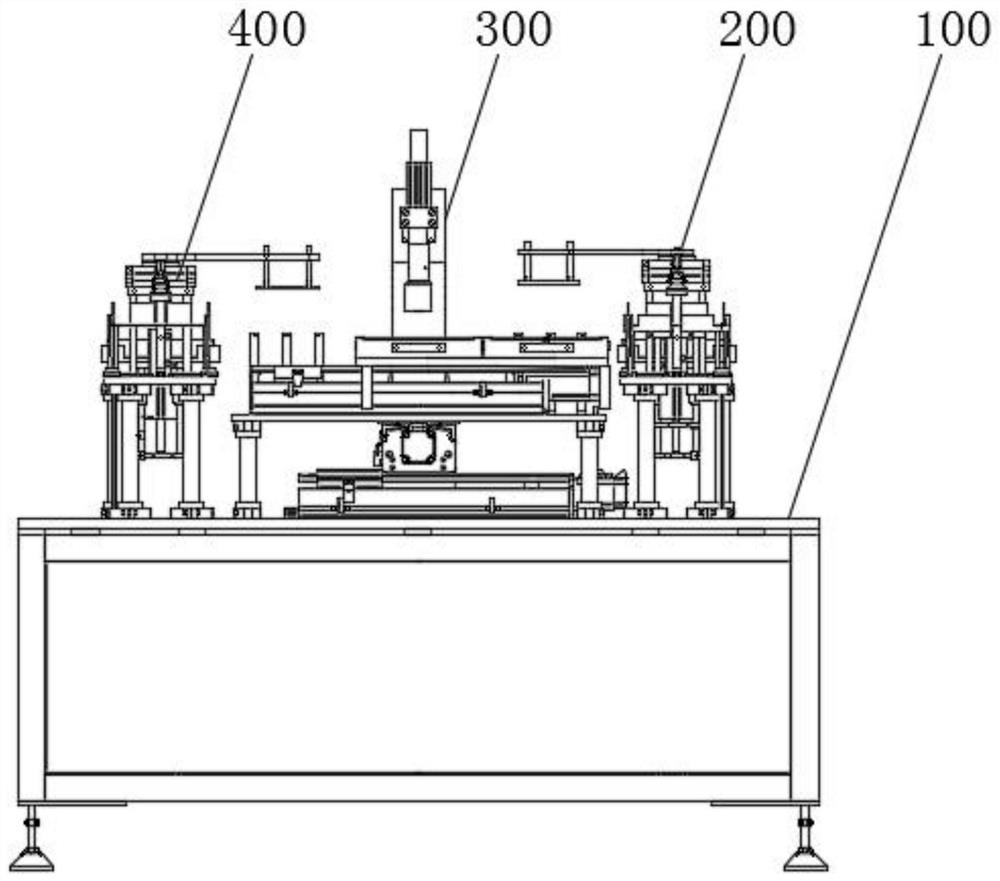

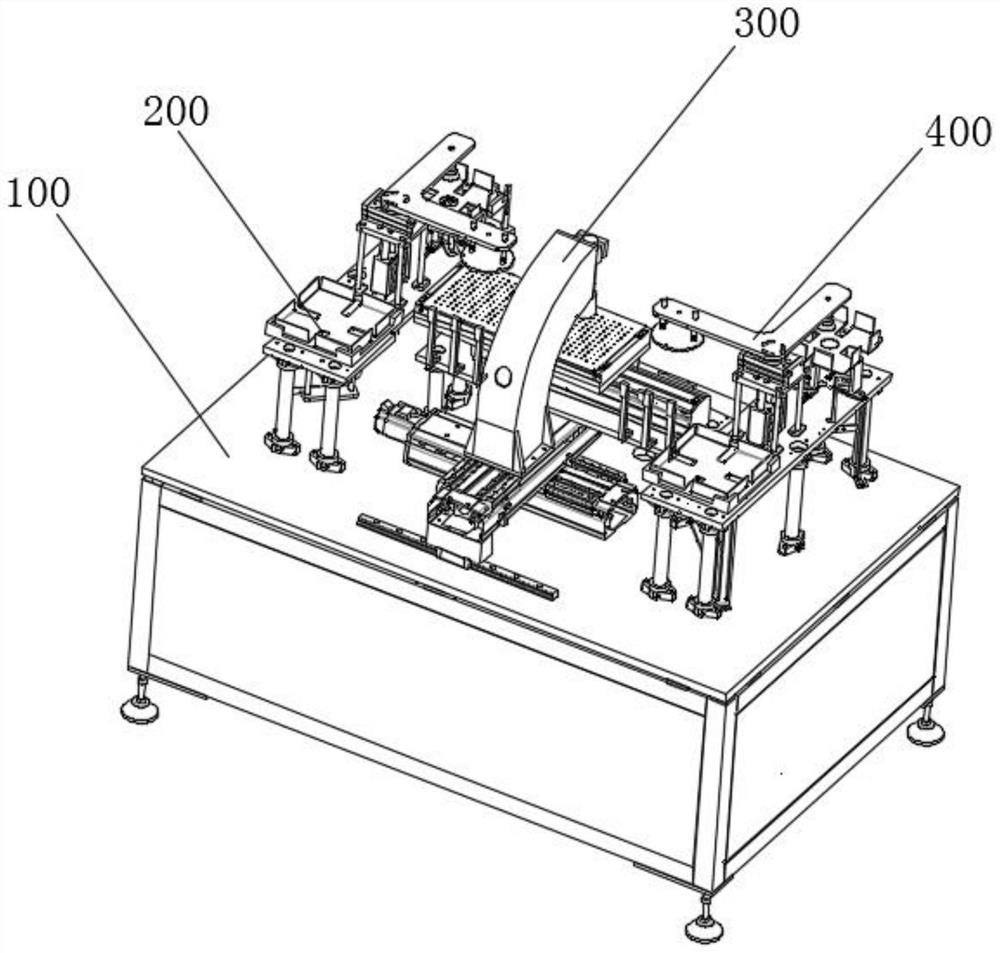

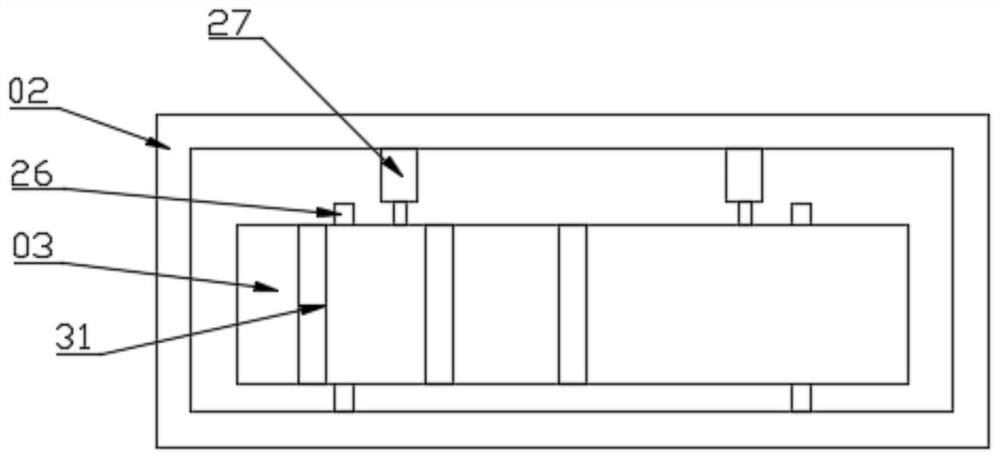

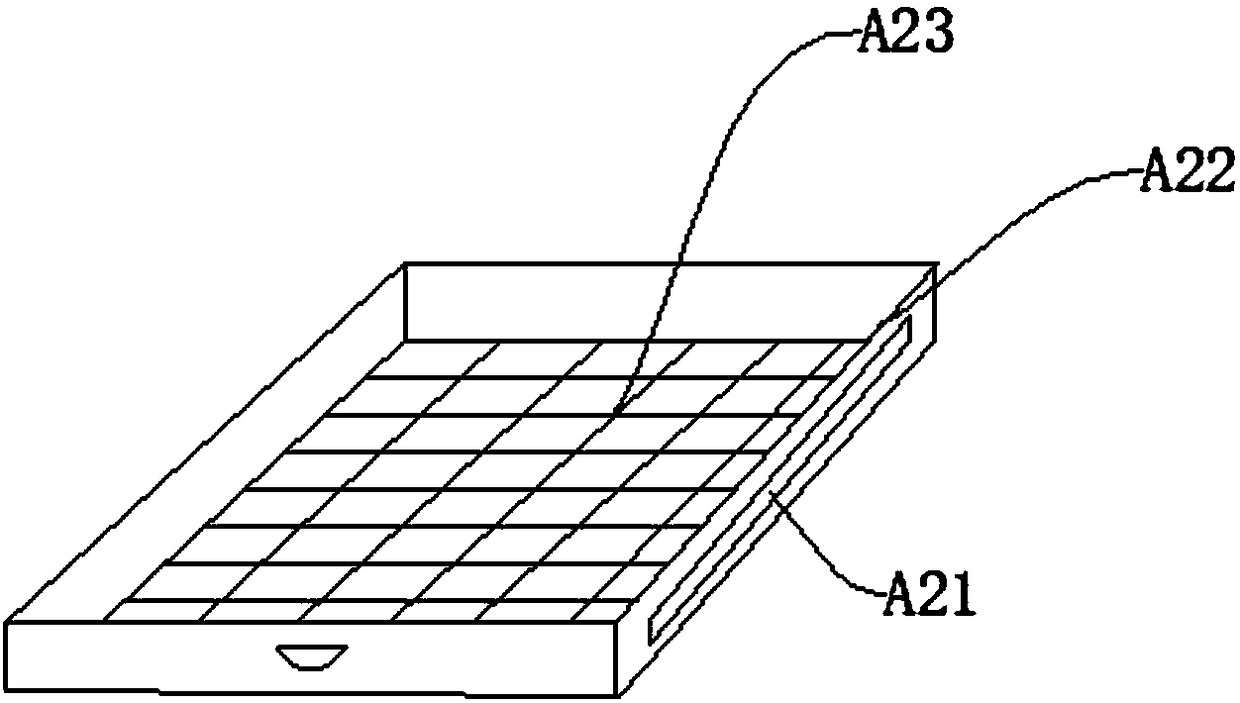

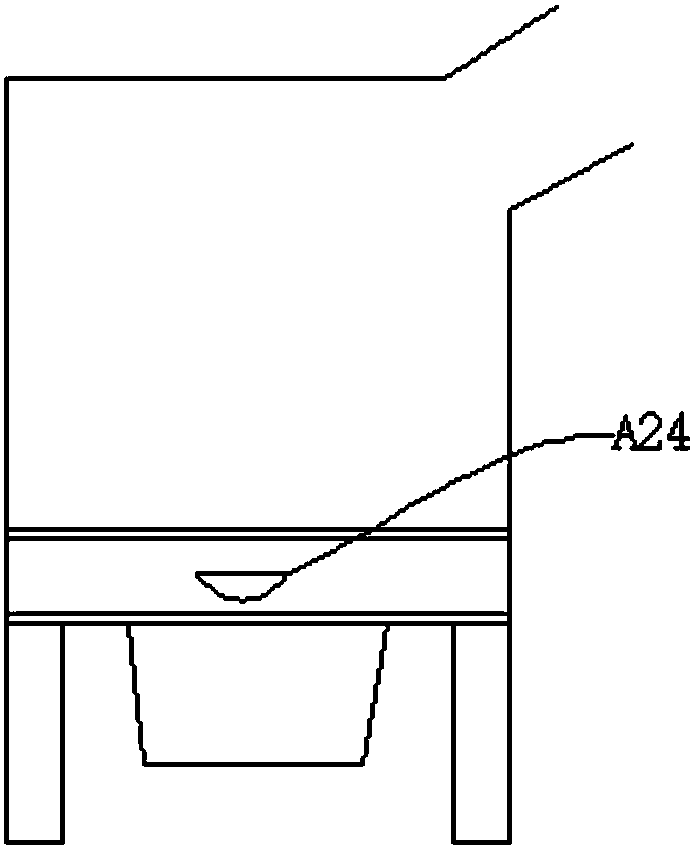

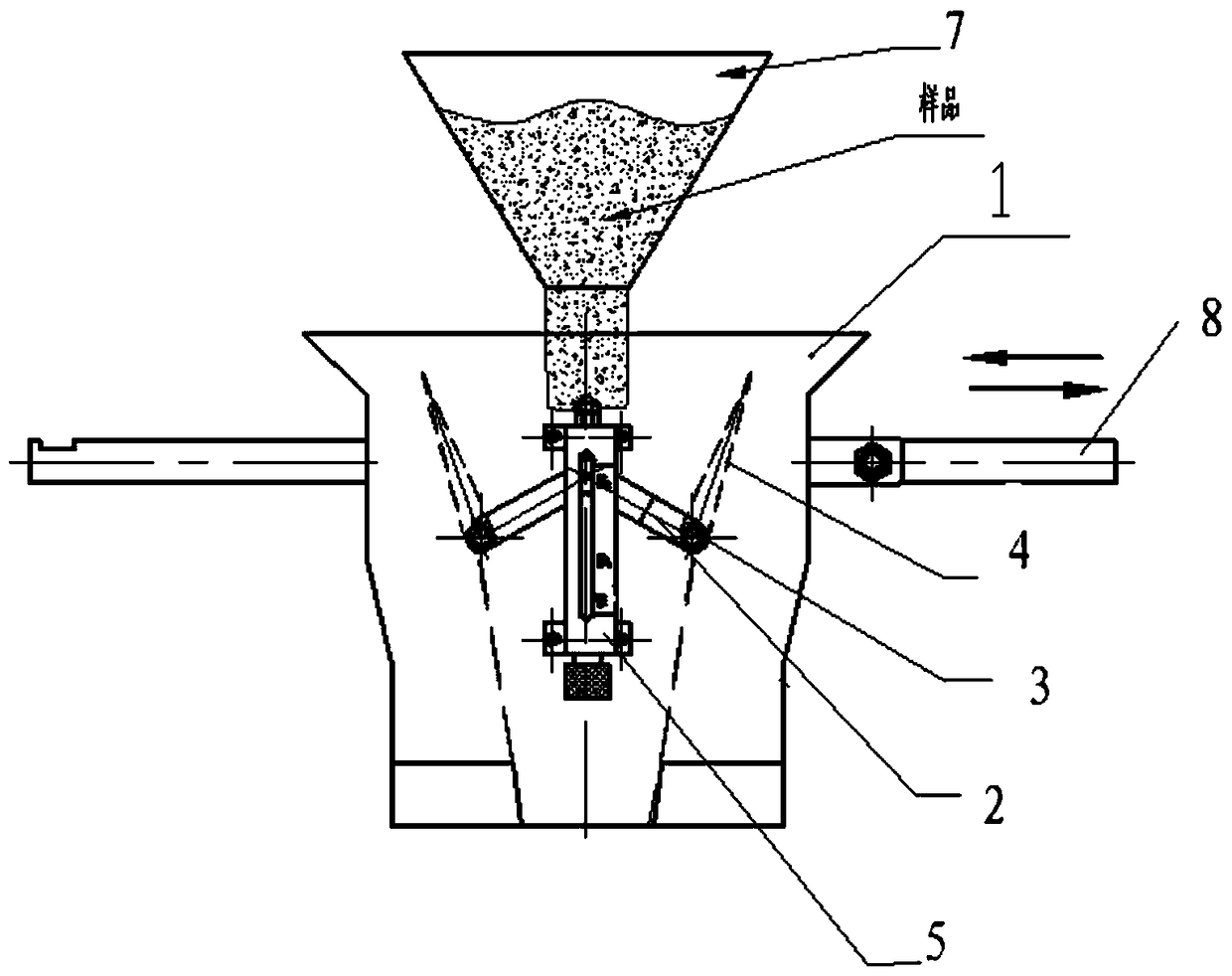

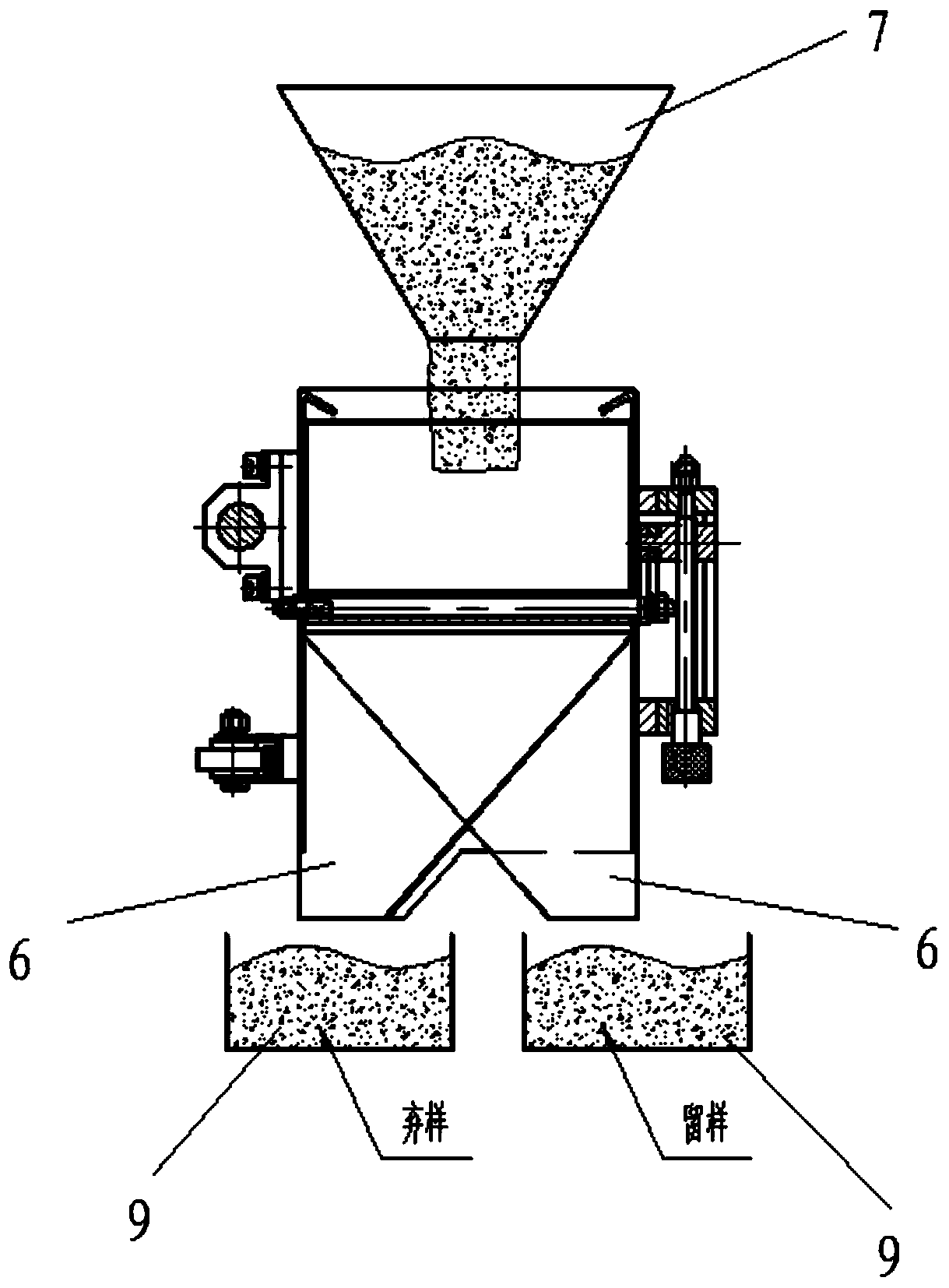

Multi-separation groove reduction device

ActiveCN105136535AIncrease the number of cutsHigh precisionPreparing sample for investigationEngineeringMaterial distribution

The present invention relates to a multi-separation groove reduction device, which comprises a box, baffles, a connection rod mechanism, a long connection rod, a horizontal movement mechanism, material receiving grooves, a material falling hopper and a drive mechanism, wherein the horizontal movement mechanism is connected with the box and is used for driving the box to drive, the box is arranged below the material falling hopper, the upper end of the box is the opening, more than three sequentially-aligned material distribution separation grooves are arranged inside the box, the material receiving grooves are arranged below the box, the number of the material receiving grooves is more, a plurality of the material receiving grooves are aligned along the direction perpendicular to the aligning direction of the material distribution separation grooves, the outlets are arranged below each material distribution separation groove, the directions of the outlets of each material distribution separation groove are not exactly the same, the outlets are respectively corresponding to the one material receiving groove, the baffle is arranged above the position above any two adjacent material distribution grooves, each baffle is rotatably arranged on the box through a rotation shaft, and the adjusting device is connected with the rotation shaft and is used for controlling the size of the opening between the any two adjacent baffles.

Owner:长沙开元仪器有限公司

Environment-friendly smashing device for building construction

InactiveCN107185674AImprove work efficiencyIncrease the number of cutsGrain treatmentsEngineeringDust pollution

Owner:金柯楠

Green grass crushing device for livestock breeding

InactiveCN110547101AMinimize the unreachableAvoid Passivation SituationsFeeding-stuffCuttersLivestock breedingEngineering

The invention relates to a green grass crushing device for livestock breeding. The device comprises an outer frame, a driving motor, a first roller cutter, a second roller cutter, a rotating motor, arotating column, a chopping platform and two collecting devices. The left side of the upper end of the outer frame is provided with the first roller cutter through a bearing, the rear end of the firstroller cutter is connected with an output shaft of the driving motor, and the driving motor is mounted on the side wall of the outer frame; the right side of the upper end of the outer frame is provided with the second roller cutter through a bearing, the middle of the outer frame is provided with the chopping platform, the middle of the chopping platform is provided with the rotating motor, theoutput shaft of the rotating motor is provided with the rotating column, and the left and right ends of the rotating column are connected with the two collecting devices. The green grass crushing device can solve the problems that when existing grass crushing machines are used for processing green grass, the green grass is often adhered to the surfaces of cutter heads, the cutter heads are often passivated after the green grass which is not cleaned away in time is heated and adhered to the cutter heads, and the green grass is easily splashed to the periphery under driving of the cutter heads in the cutting process.

Owner:柴磊

Automatic biological tissue rapid slicing machine

PendingCN111458200AFix slow issuesReduced Fixture TravelPreparing sample for investigationElectric machinerySurgery

The invention discloses an automatic biological tissue rapid slicing machine. The machine comprises a base. An advancing slide rail and a push rod motor for driving the advancing slide rail to move are arranged on the base. An equipment seat body is arranged on the advancing slide rail, a clamping mechanism capable of clamping an embedded biological tissue is arranged on the equipment seat body, and an up-down driving mechanism capable of driving the clamping mechanism to move up and down is arranged in the equipment seat body. A longitudinal straight notch is formed in the bottom of a movableblade bearing, and a transverse sliding block is arranged in the longitudinal straight notch to move front and back and drive the longitudinal straight notch to move up and down at the same time. Theclamp stroke can be reduced, the number of walking cutting times each time is increased, and the structure is reasonable.

Owner:广东安顺达供应链管理有限公司

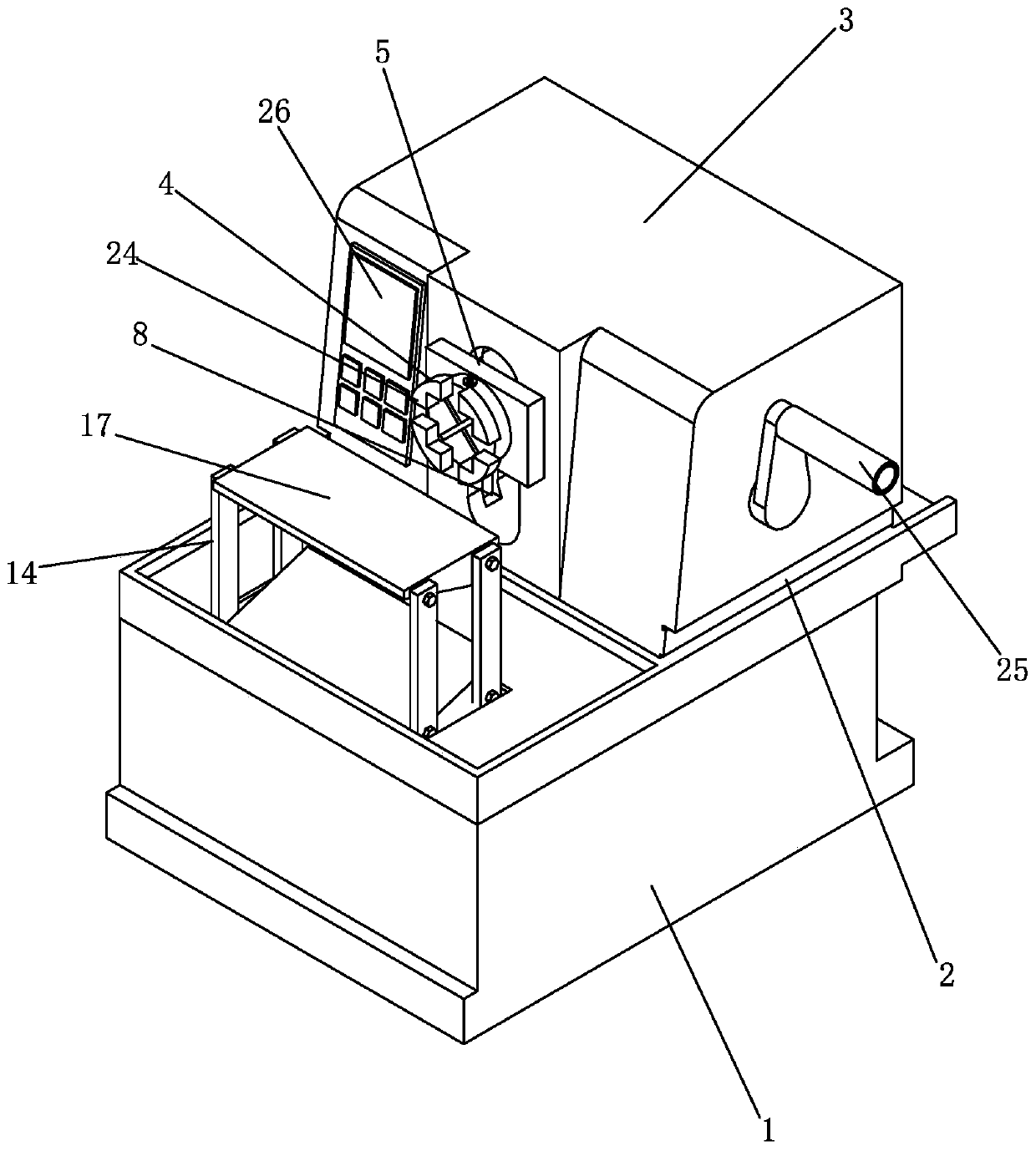

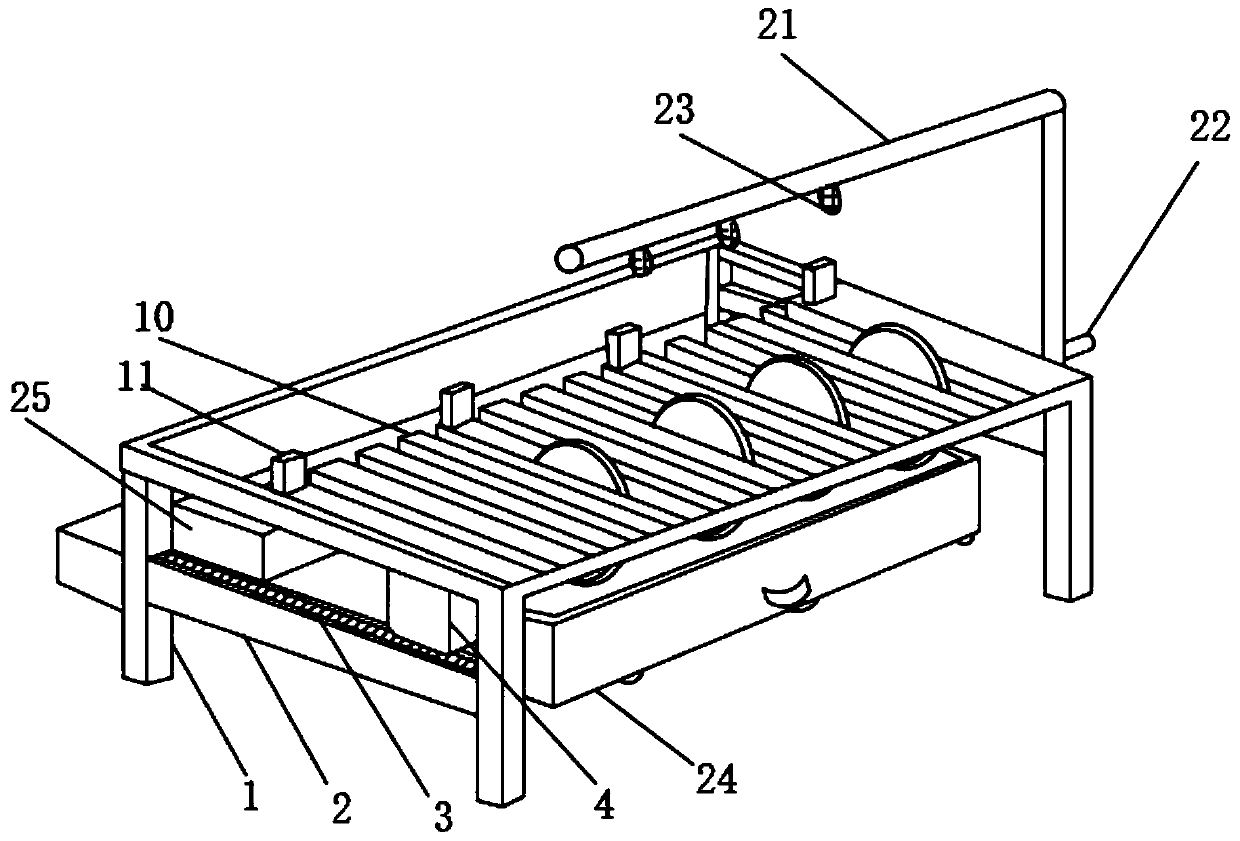

Cutting treatment device for aluminum plate finish machining

ActiveCN111299682AAchieve multi-segment cutting effectEasy to operateTube shearing machinesMaintainance and safety accessoriesDrive shaftElectric machinery

The invention discloses a cutting treatment device for aluminum plate finish machining. A supporting frame is included, and a first cross beam is fixedly installed on one side of the supporting frame;the surface of the first cross beam is provided with a part groove in which a hydraulic push rod is arranged; a motor is installed on the surface of the hydraulic push rod in an engaging manner, anda driving shaft is rotationally connected to the motor; a cutting mechanism is fixedly installed on the surface of the driving shaft; the cutting mechanism comprises cutting blades, positioning piecesand fastening bolts; each cutting blade is in a shape of a circle, and the position of the circle center of each cutting blade is provided with a through hole; the driving shaft penetrates through the through holes of the cutting blades, and the cutting blades are fixedly installed on the driving shaft through the fastening bolts in the positioning pieces; and a workbench is fixedly connected tothe upper end of the supporting frame. The cutting treatment device for aluminum plate finish machining solves the problems that a cutting device can only cut one position at a time, the cutting efficiency is low, it is needed that a user manually pushes a plate to move during cutting, the labor force is increased, and position adjusting and number adjusting cannot be performed according to the specific using requirement.

Owner:河南鑫瑞佳新材料有限公司

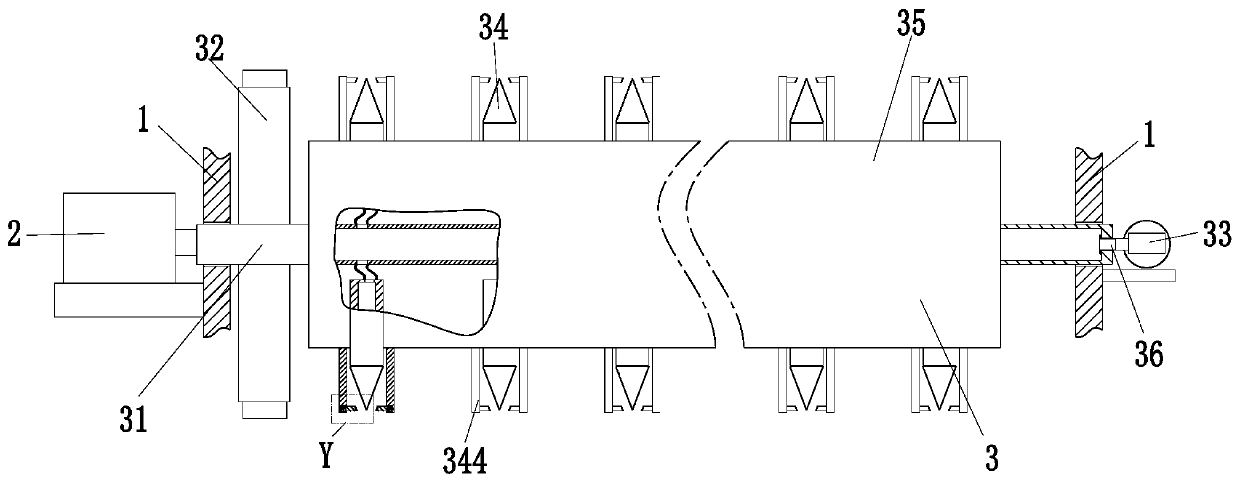

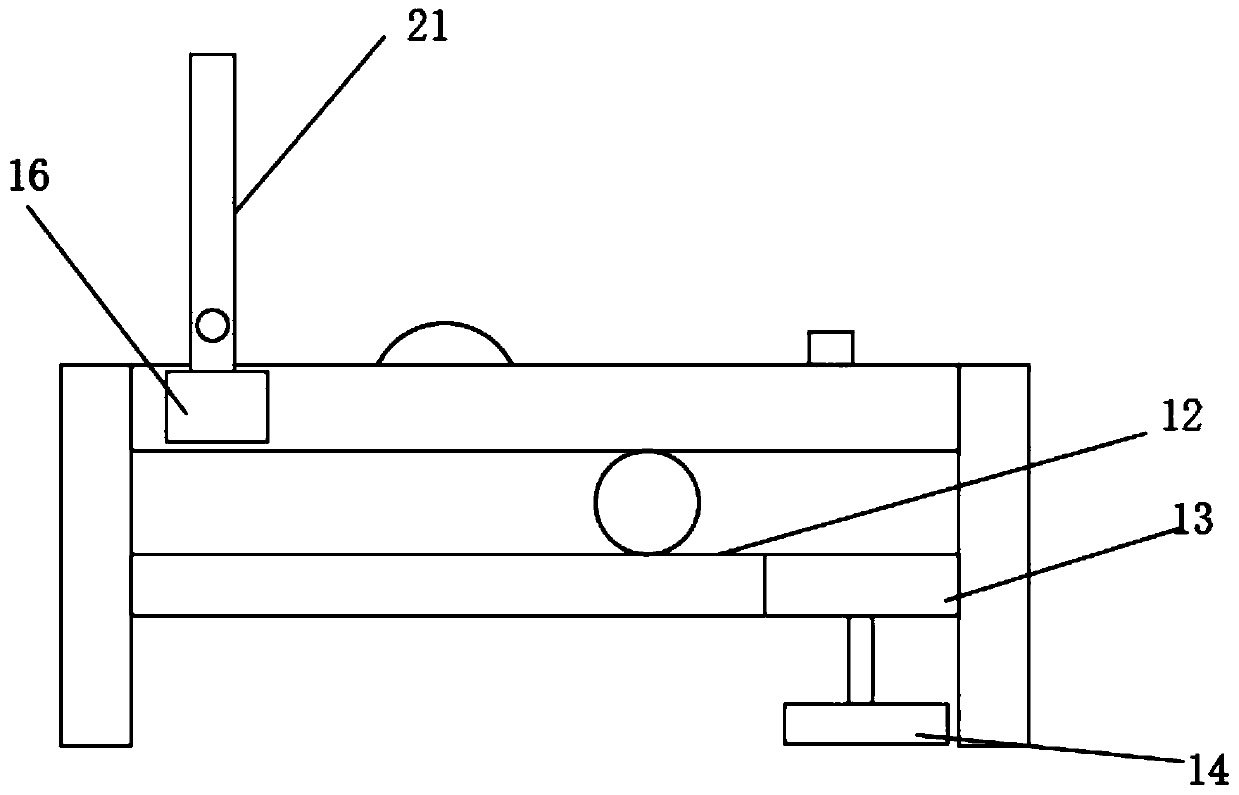

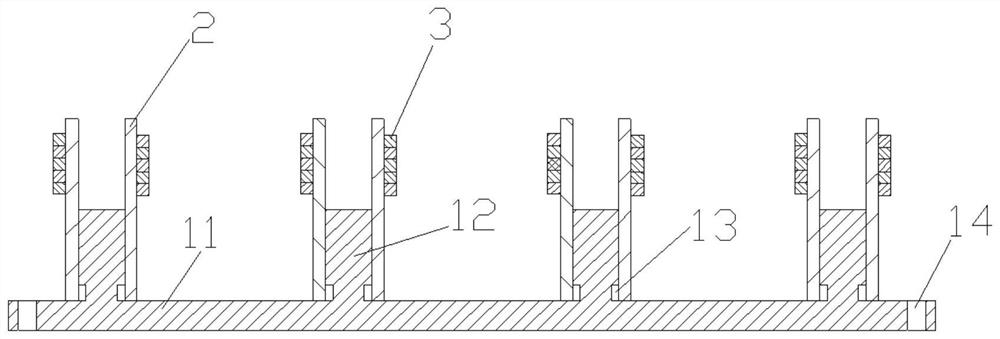

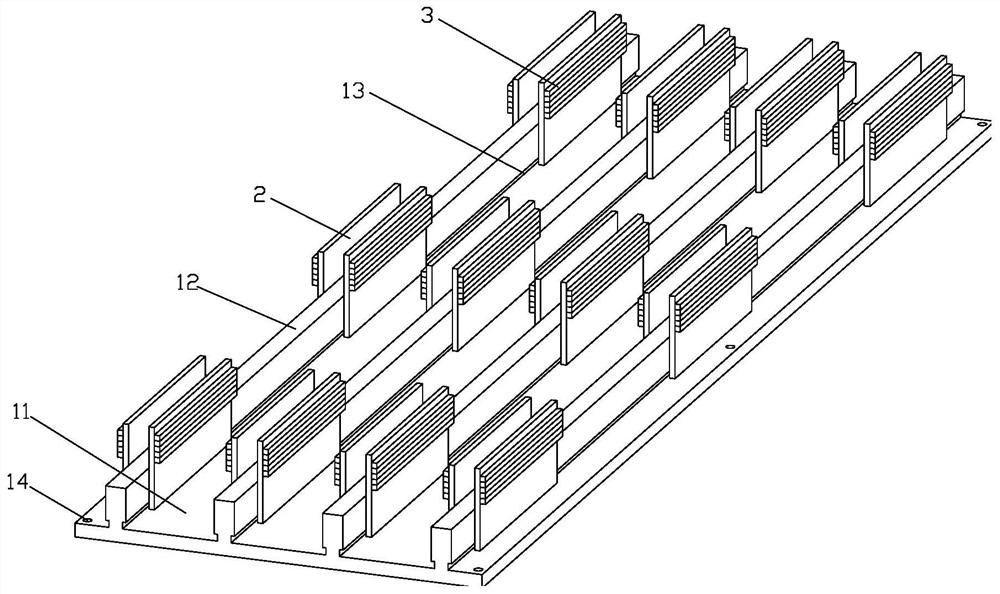

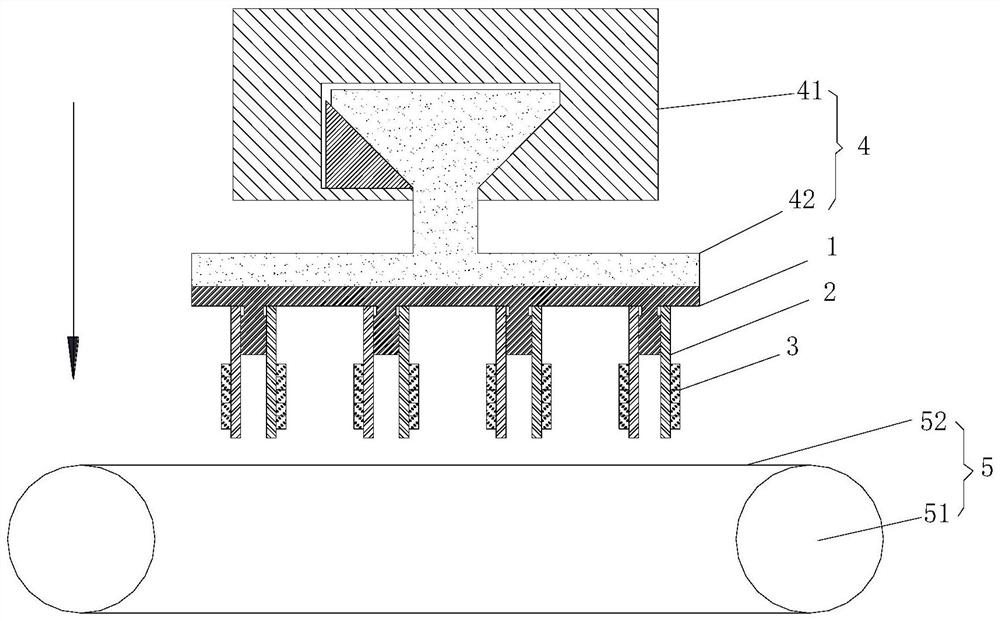

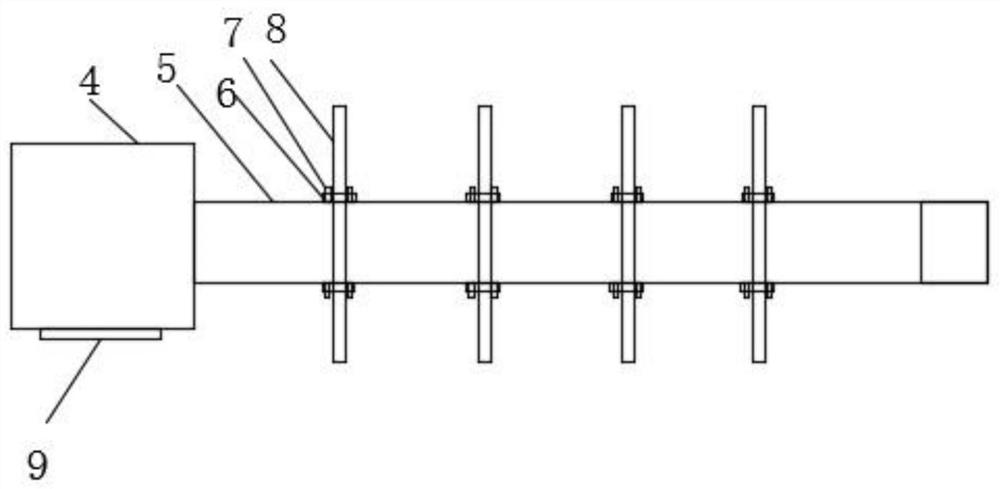

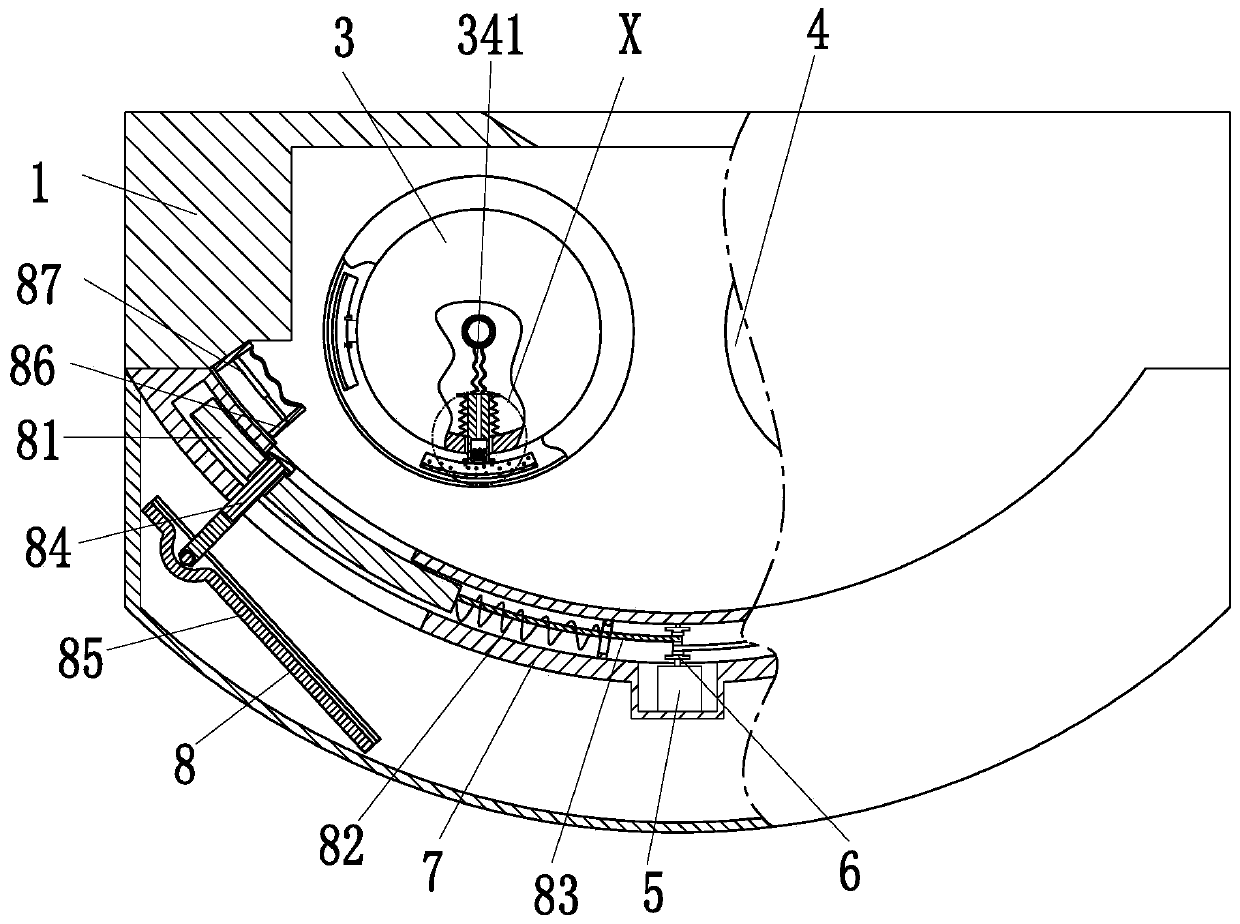

Small-size lens product multi-line cutting fixing device, cutting system and cutting method

ActiveCN113814866AIncrease profitImprove yieldWorking accessoriesGrinding machinesWire cuttingStructural engineering

The invention relates to the technical field of optical part machining, in particular to a small-size lens product multi-line cutting fixing device, a cutting system and a cutting method. The cutting fixing device comprises a tool plate connected with a multi-wire cutting machine and leaning bodies used for fixing strip-shaped products to be cut; the tool plate comprises a bottom plate and stand columns fixedly arranged on the same side plate face of the bottom plate at intervals; the surface of one side of each leaning body is fixedly connected with the side wall of one transverse side of each stand column, the surfaces of the other sides of the leaning bodies are used for fixing the to-be-cut products, the bottom edge of each leaning body is parallel to and fixedly connected with the plate face of the bottom plate, and the top edge of each leaning body is higher than the top edge of each stand column; and the fixed connection positions of the to-be-cut products and the leaning bodies are located between the top edges of the leaning bodies and the top edges of the stand columns. According to the small-size lens product multi-wire cutting fixing device and the cutting method, multi-wire cutting can be carried out on small-size semi-finished products which are high in smoothness requirement and have coating appearance, and the product utilization rate and the yield are improved.

Owner:FOCTEK PHOTONICS LNC

Control method for food processor

The invention provides a controlling method for a food processor. The food processor comprises a motor which is a brushless electric machine, the brushless electric machine is provided with a smashingcutter blade, and in the pulping process, the food processor smashes materials in two stages, namely the initial smashing stage and the smashing stage. In the initial smashing stage, the revolving speed M of the brushless electric machine is smaller than 8000 revolutions / minute, forward rotation and reverse rotation of the brushless electric machine are continuously alternately conducted, and thepreset waiting time duration T between the forward rotation and the reverse rotation is longer than 0.5 second and shorter than 10 seconds. In the control method, through the work mode that restrictive forward-reverse rotation of the motor is conducted through initial smashing, noise can be effectively reduced, the smashing time can be greatly shortened, and the smashing efficiency is improved.

Owner:JOYOUNG CO LTD

Semiconductor element processing method and forming process

InactiveCN111640678ASimple processGood coating fixation effectSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesSemiconductor chipLead frame

The invention discloses a semiconductor element processing method and a forming process. The method comprises the steps of taking a semiconductor wafer subjected to double-sided photoetching as a processing object; coating the upper surface and the lower surface of the semiconductor wafer with soldering paste, completing double-sided coating of the soldering paste to obtain a semi-finished productof the semiconductor element, feeding the semi-finished product of the semiconductor element into scribing equipment, cutting the semi-finished product of the semiconductor element into a plurality of small blocks, moving the cut small blocks to a lead frame for packaging, and performing finished product testing on the packaged small blocks to obtain the semiconductor element. The semiconductor element processing method is simple and feasible in process, good in solder paste layer coating and fixing effect, capable of effectively preventing the surface of the semiconductor chip from being oxidized, capable of improving the compactness of the surface of the semiconductor chip and high in reliability. According to the forming process, the scribing equipment is used for preparing the semiconductor element, the scribing equipment is high in automation degree and high in feeding and discharging speed, and the production efficiency of the semiconductor element is effectively improved.

Owner:安徽富信半导体科技有限公司

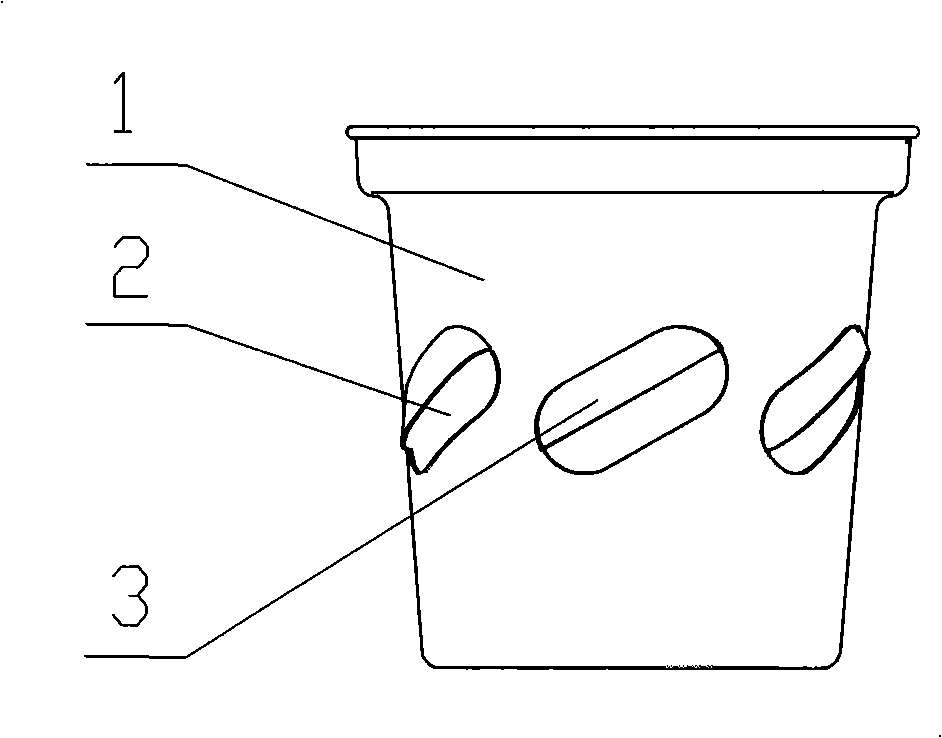

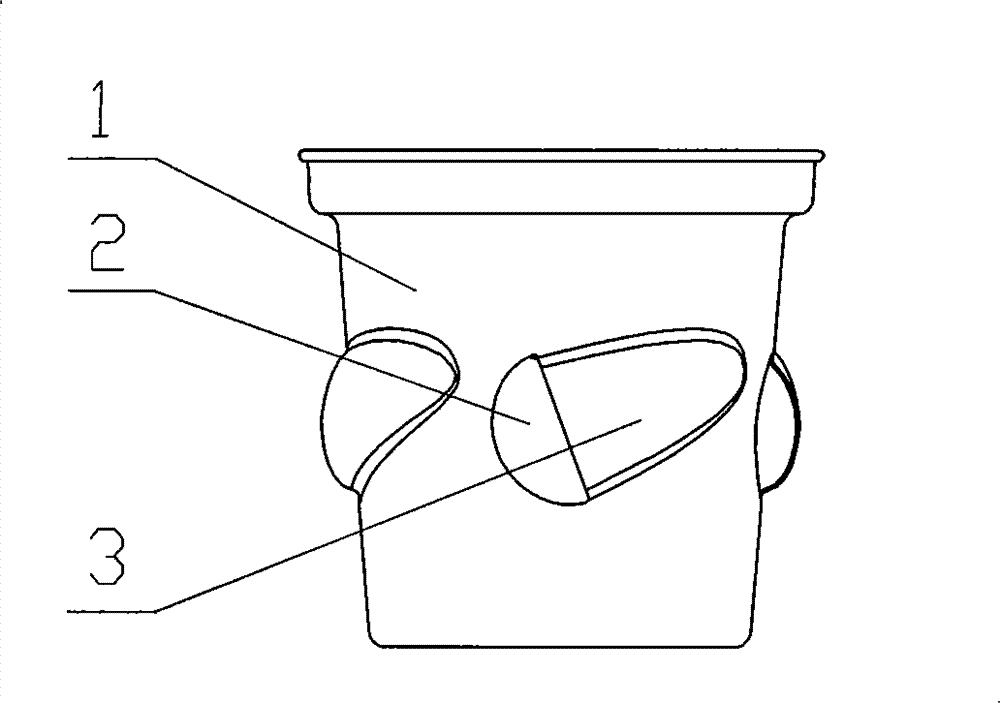

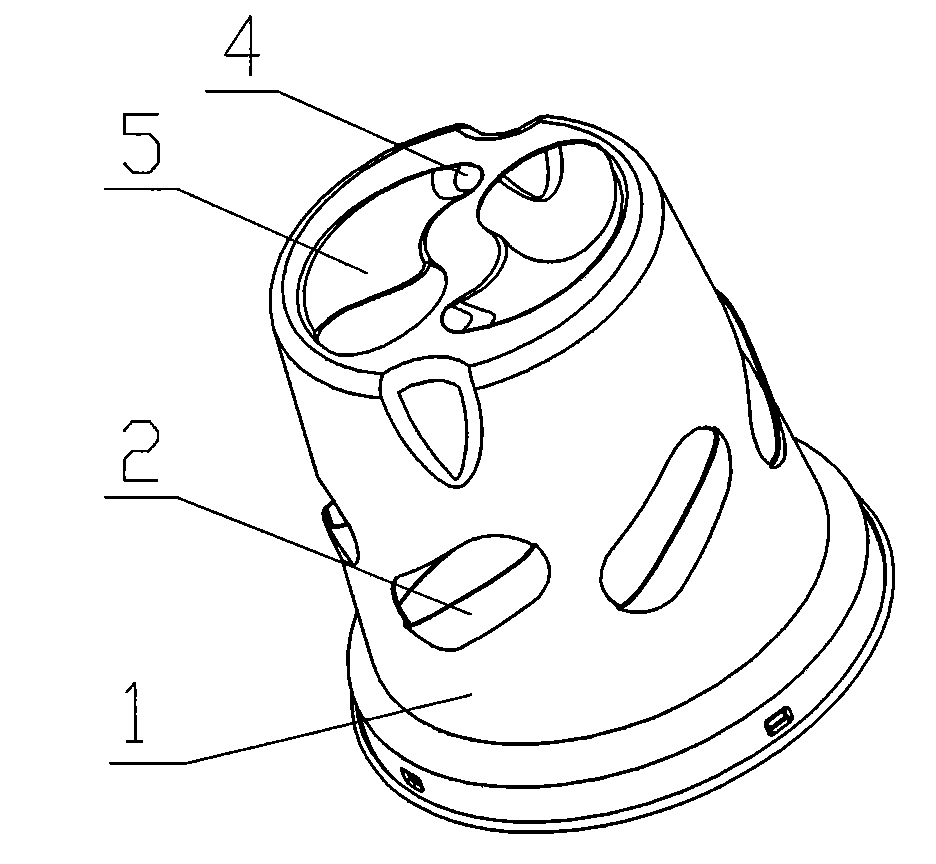

Air guide sleeve and soybean milk machine using the air guide sleeve

ActiveCN101485421BPracticalReduce generationBeverage vesselsFood preparationRefluxPulp and paper industry

The invention provides a diversion cover and a soybean milk machine using the same. The diversion cover comprises a cover body, the side wall of the cover body is provided with a pulp outlet, the bottom of the cover body is provided with a pulp inlet, and the pulp inlet is connected with a spiral guiding slot; and the pulp inlet can be also provided with a cut-off surface. The spiral guiding slot can greatly improve the guiding effect, and the materials for preparing the soybean milk can be quickly and effectively guided to a fluid director so as to shorten the circulation time. The cut-off surface can effectively lower the pulp-ejection height while discharging the pulp, make the reflux more effective and shorten the pulping circulation time; moreover, under the conditions of the same rotary speed, the cut-off surface can increase frequency of cutting the materials for preparing the pulp, so on the one hand, the pulp-ejection height is prevented to be so high that an overflow prevention switch is triggered for action; because the pulp-ejection height is effectively lowered, the foam generated in large quantity in the pulping process is effectively reduced, the problem that the capacity of the prior soybean milk machine cannot be too large is solved; and the soybean milk machine is more convenient for a consumer to use; and on the other hand, the problem that the upper wall of the cup body is hard to clean because a great deal of pulp is collected on the upper wall is solved.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

A kind of cutting processing device for aluminum sheet finishing

ActiveCN111299682BAchieve multi-segment cutting effectEasy to operateTube shearing machinesMaintainance and safety accessoriesDrive shaftElectric machine

The invention discloses a cutting processing device for aluminum plate finishing, which includes a support frame, a first beam is fixedly installed on one side of the support frame, and a component groove is opened on the surface of the first beam, and a hydraulic push rod is arranged in the component groove. The surface of the hydraulic push rod is engaged with a motor, and the motor is connected with a drive shaft. The surface of the drive shaft is fixed with a cutting mechanism. The cutting mechanism includes a cutting piece, a positioning piece, and a fastening bolt. The cutting piece is circular and cuts A through hole is provided at the center of the sheet, the drive shaft passes through the through hole of the cutting sheet, and the cutting sheet is fixedly installed with the drive shaft through the fastening bolts in the positioning sheet, and the upper end of the support frame is fixedly connected with a workbench; the invention solves the problem of The cutting device can only cut one position at a time, and the cutting efficiency is low. When cutting, the user needs to manually push the plate to move, which increases the labor force, and cannot adjust the position and quantity according to the specific use requirements.

Owner:河南鑫瑞佳新材料有限公司

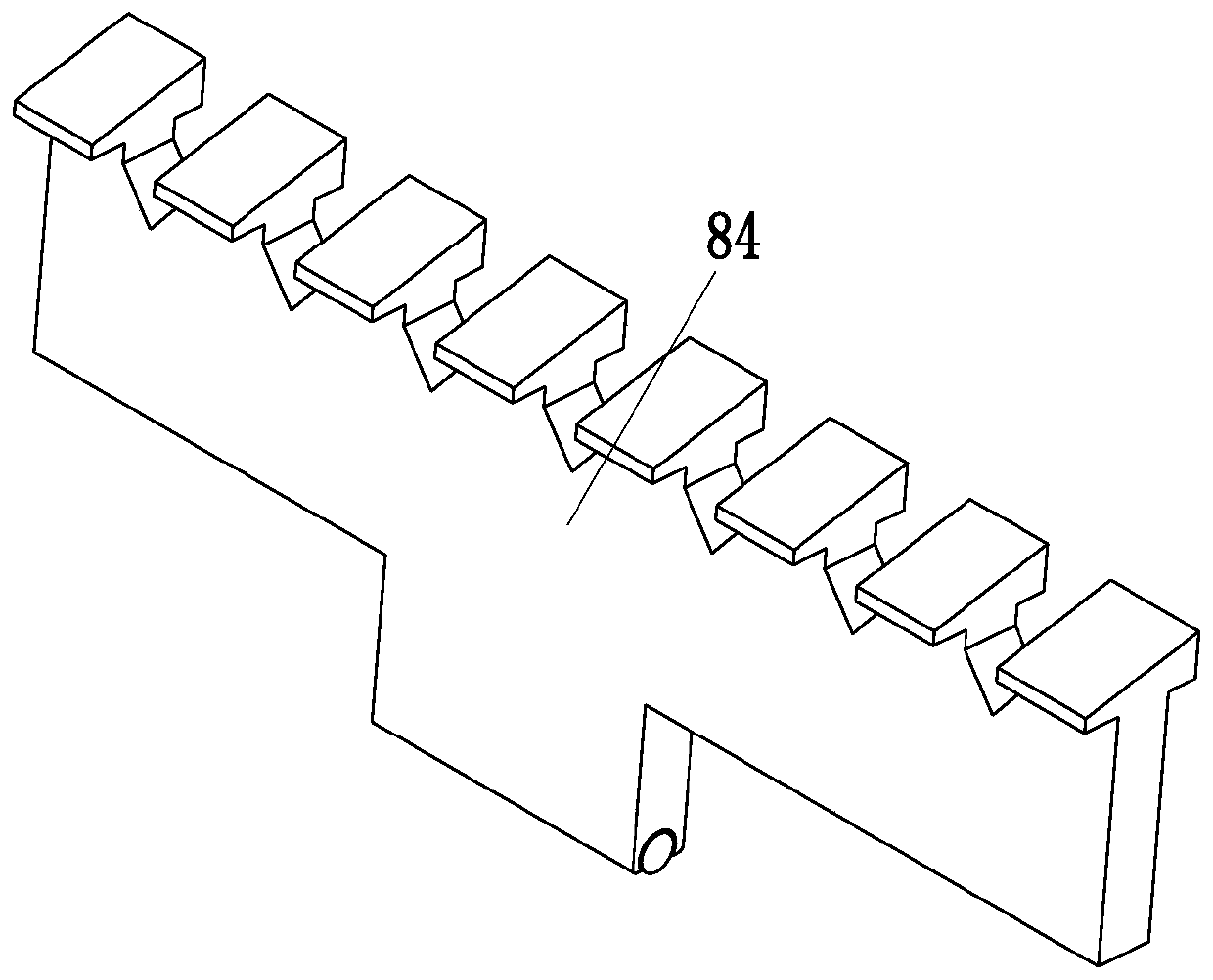

A cutting device for bag processing

ActiveCN111037629BIncrease the number of cutsImprove practicalityCleaning using gasesCleaning using liquidsEngineeringScrew thread

The invention discloses a cutting device for luggage processing, which comprises a frame body, a support base is slidably connected to the frame body, a workbench is slidably connected to the support base, a fixing fixture is fixed on the workbench, and an adjustment assembly is arranged above the workbench. The assembly is provided with a cutting assembly, the number of the cutting assembly is multiple, the frame body is also provided with a cleaning assembly and a dust blowing assembly, and the adjustment assembly includes a first threaded rod that is rotatably connected to the frame body. The assembly includes a first moving block that is threadedly connected with the first lead screw. The number of the first moving block is the same as that of the cutting cavity. There is a fixed sleeve rod connected in rotation between them, the fixed sleeve rod is fixedly connected with the cutting knife, and the fixed sleeve rod is fixedly connected with the second sliding rod through a screw, which can cut multiple raw materials at the same time, improves the cutting effect, and has better functionality at the same time.

Owner:浙江铂仁旅游用品有限公司

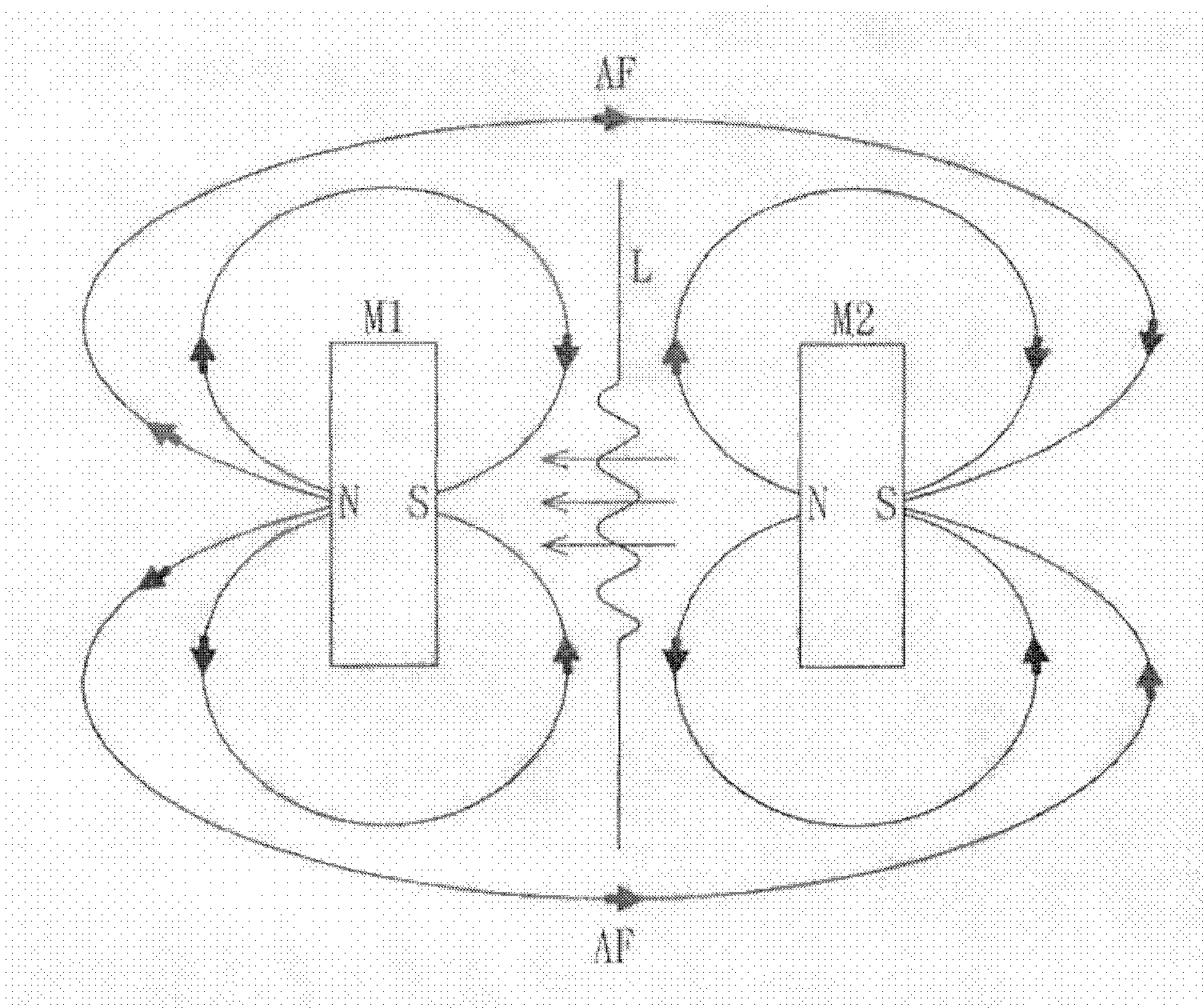

Magnetic pole staggered power generation device

InactiveCN108880173AReduce lossImprove conversion efficiencyDynamo-electric machinesMagnetic polesEnergy conversion efficiency

The invention discloses a magnetic pole staggered power generation device. The magnetic pole staggered power generation device is provided with an induction coil group; a first magnetic group and a second magnetic group which can synchronously move relative to each other are arranged on the two sides of the induction coil group respectively; the first magnetic group is formed by at least one firstmagnetic piece and second magnetic piece which are magnetized in the movement direction and are connected at equal intervals in series in a different-pole arrangement mode; the second magnetic groupis formed by a third magnetic piece and a fourth magnetic piece which are magnetized in the movement direction and are connected at equal intervals in series in a different-pole arrangement mode; thethird and fourth magnetic pieces and the first and second magnetic pieces are arranged in a staggered mode relatively; a load switch group for selectively performing power-on on the induction coil group or not is arranged between the induction coil group and the first magnetic group and between the induction coil group and the second magnetic group separately; therefore, the magnetic stress, relative to the induction coil group, of the first magnetic group and the second magnetic group can be mutually eliminated, so that the kinetic energy loss is reduced, and the cutting frequency is effectively increased; and in addition, most of the magnetic lines of force flows through the coil part, so that the cutting quantity can be greatly increased, and the energy conversion efficiency can be effectively improved.

Owner:YUZEN SUSTAINABLE ENERGY PTE LTD +1

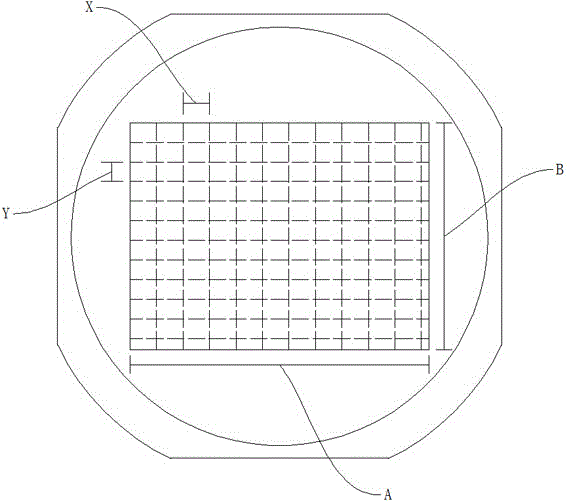

Cutting method of blue glass, blue glass and application thereof

InactiveCN105645750AQuality improvementImprove stabilityTelevision system detailsColor television detailsGlass sheetChemistry

The invention discloses a cutting method of blue glass. The method comprises the following steps: (1) according to the formula Pmax=f([A / (X+a)]*[B / (Y+a)]), solving the Pmaxmaximum value within the ranges of Cx+1.4mm<=X<=Cx+2mm and Cy+1.4mm<=Y<=Cy+2mm, thereby obtaining X and Y of the maximum value, wherein A and B are respectively the length and width of the blue glass to be cut, a is the natural width of the cutting head, Cx and Cy are respectively the length and width of a chip photosensitive region, X and Y are respectively the length and width of the cut blue glass sheets, and P is the total number of the obtained blue glass sheets; and (2) drawing cutting lines and carrying out cutting according to X and Y obtained in the step (1) and the natural width a of the cutting head, thereby obtaining a plurality of blue glass sheets. The invention also discloses blue glass obtained by the cutting method and application thereof. The cutting method optimizes the blue glass cutting design to obtain the optimum cutting size and achieve the maximum cutting quantity, thereby enhancing the production efficiency, lowering the cost and further enhancing the quality and stability of the blue glass finished product.

Owner:TRULY OPTO ELECTRONICS

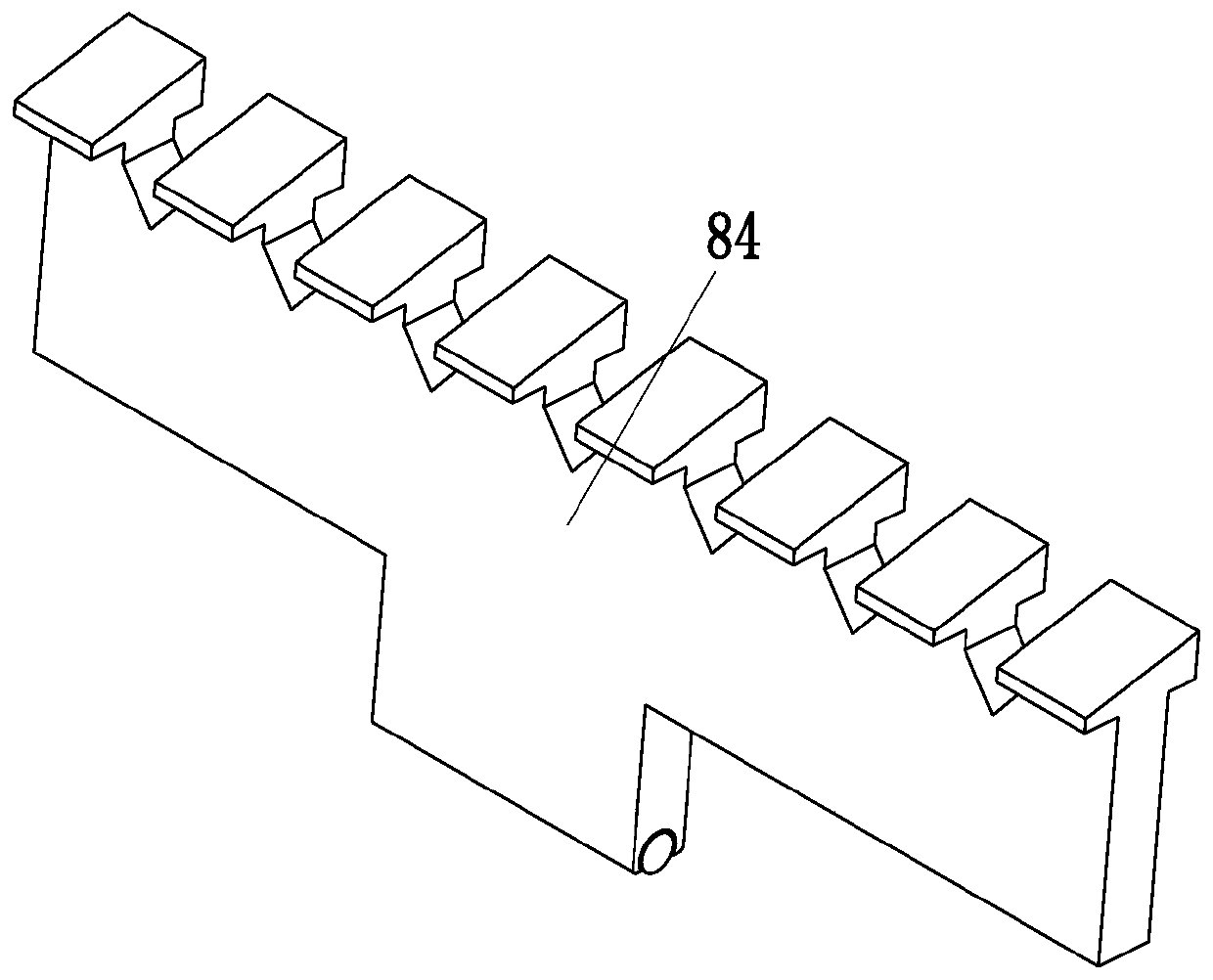

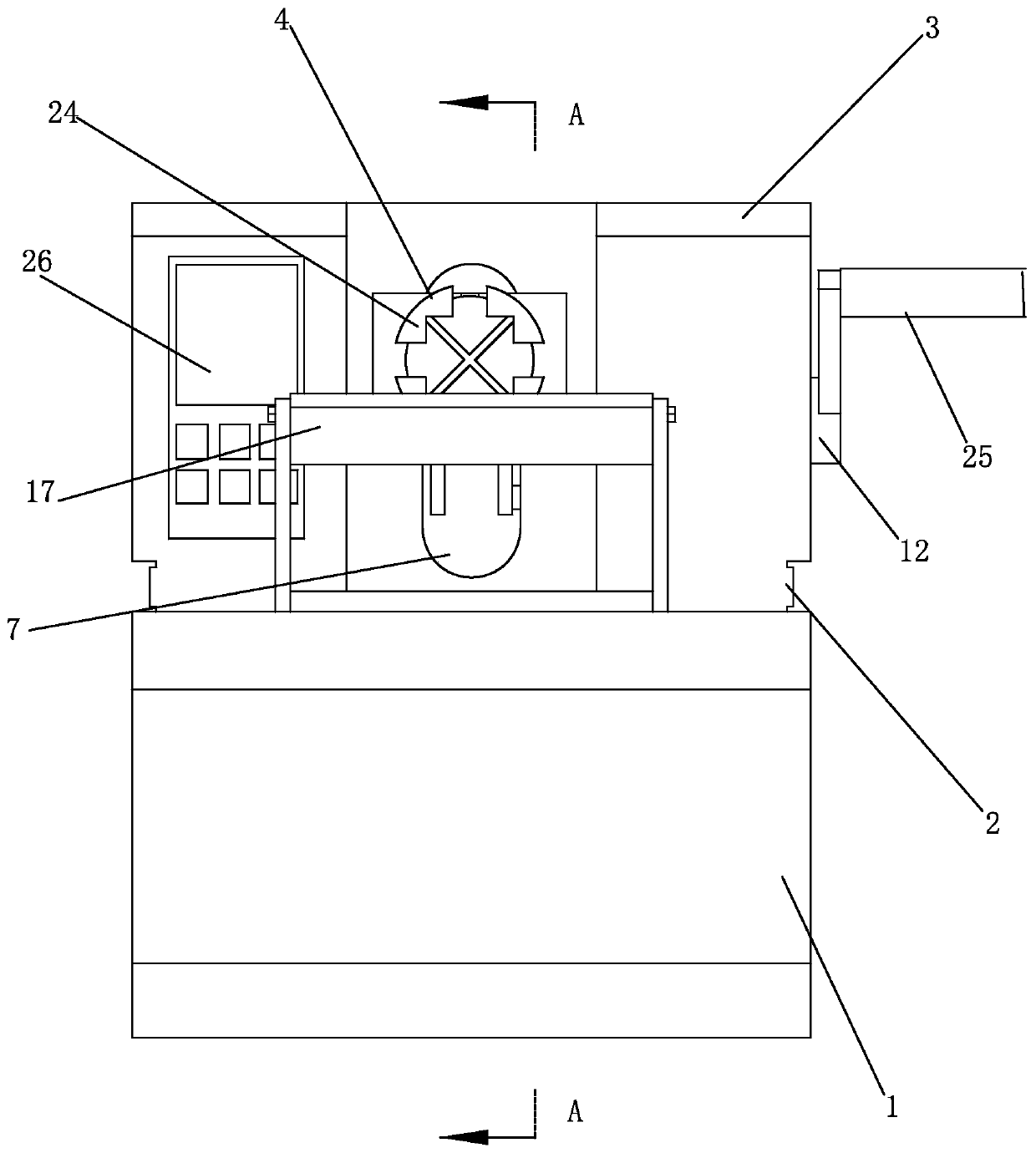

A Paper Cutting Tube Machine with Improved Cutting Efficiency

ActiveCN106737991BImprove cutting efficiencyIncrease the number of cutsMetal working apparatusReciprocating motionPulp and paper industry

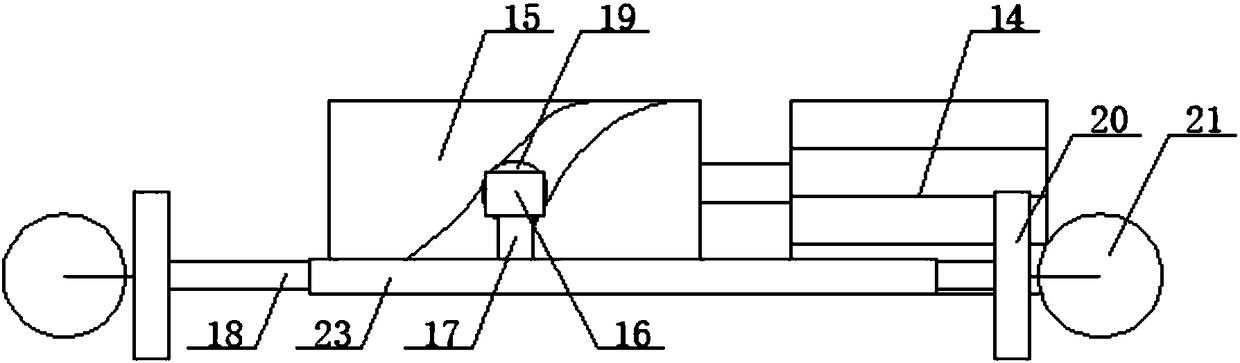

The invention relates to a paper tube cutting machine for improving cutting efficiency. The paper tube cutting machine for improving the cutting efficiency comprises a machine base, a power chamber, a rotating mechanism, a sliding mechanism and a cutting mechanism. The rotating mechanism comprises two rotating assemblies. Each rotating assembly comprises a belt wheel, a paper tube roller and a first bearing. The sliding mechanism comprises a second motor, a fixing block, a lead screw, a limiting rod, a second bearing and a sliding table. The cutting mechanism comprises a third motor, a sleeve, a connecting rod, a supporting rod, a sliding rod, a cutting assembly and a guiding assembly. According to the paper tube cutting machine for improving the cutting efficiency, the two parallel paper tube rollers are arranged and correspond to blades, the blades are located between the two paper tube rollers, the paper tube rollers rotate to drive paper tubes to rotate, and the blades are driven by the cutting mechanism to reciprocate so as to cut the paper tubes on the two paper tube rollers; and in addition, the blades are driven by the sliding mechanism to slide in the axial direction of the paper tubes while cutting the paper tubes, so that the number of cutting times in unit time is increased, and the cutting efficiency is improved accordingly.

Owner:TONGXIANG HENGTAI PAPER TUBE

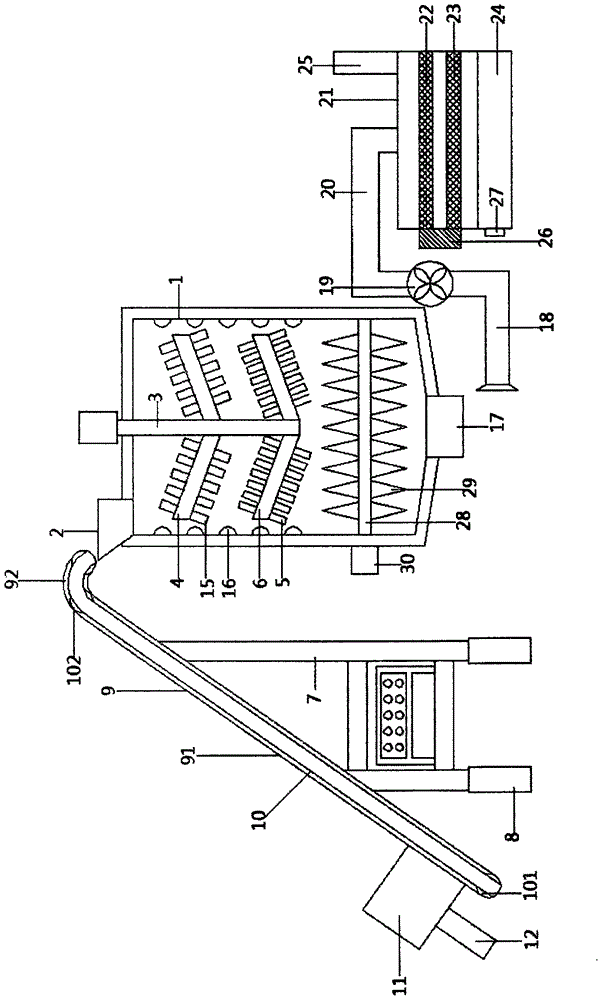

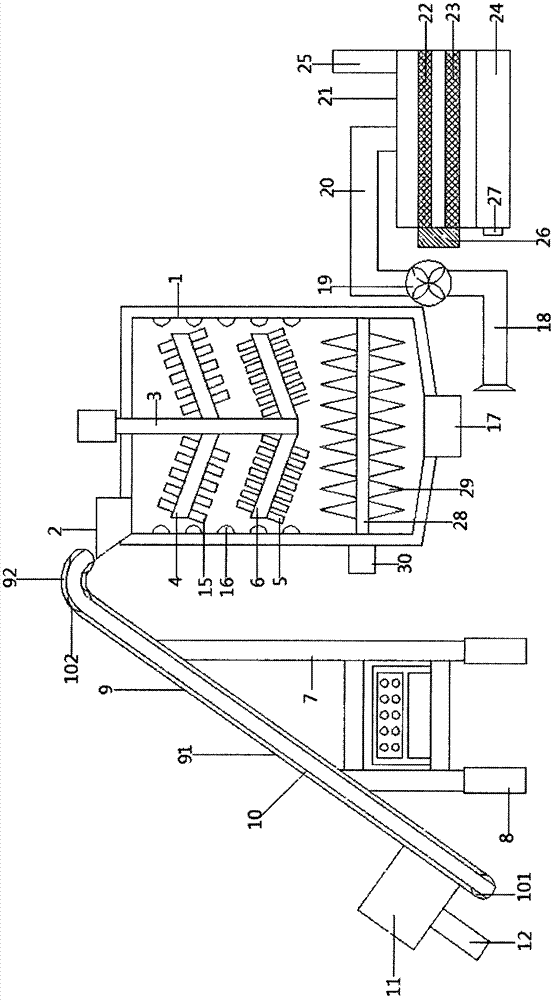

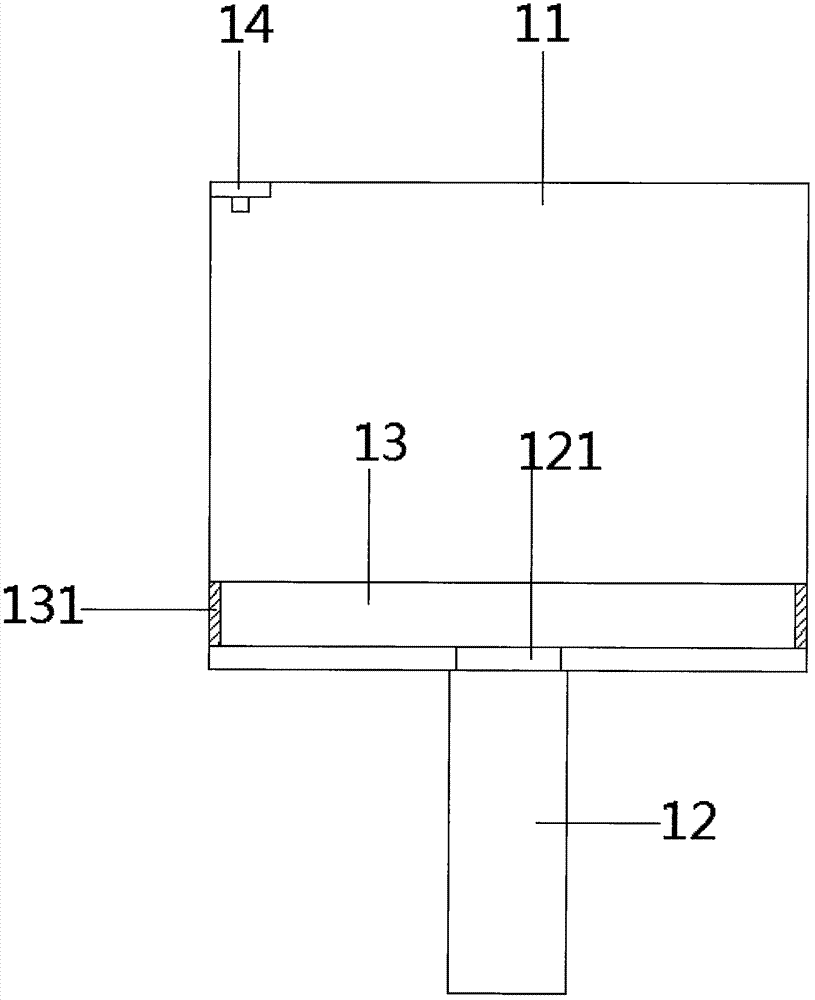

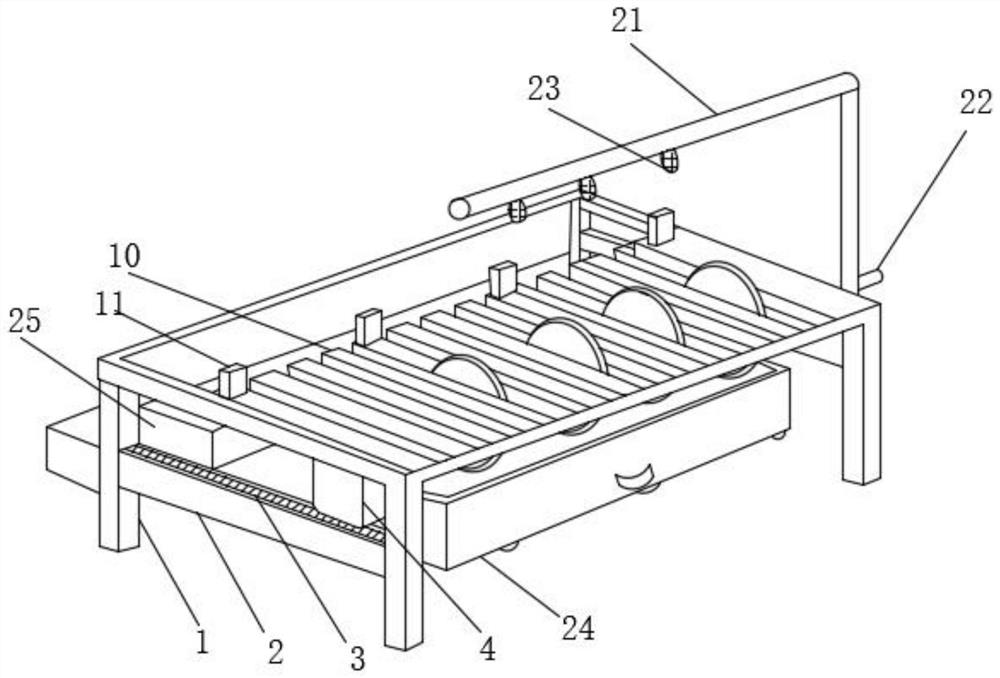

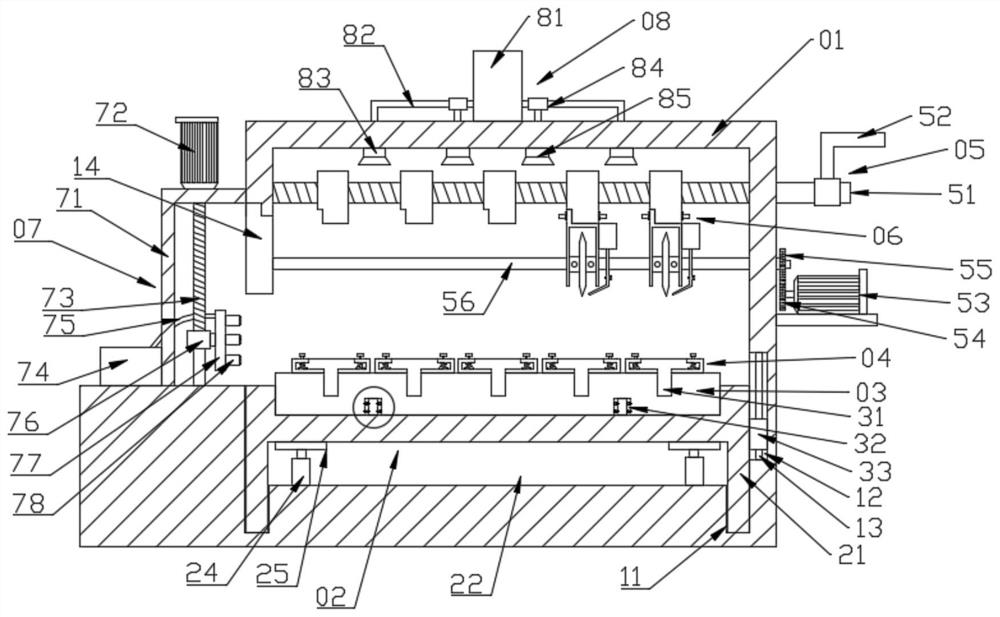

Multifunctional corn straw smashing and fertilizing rotary tillage machine

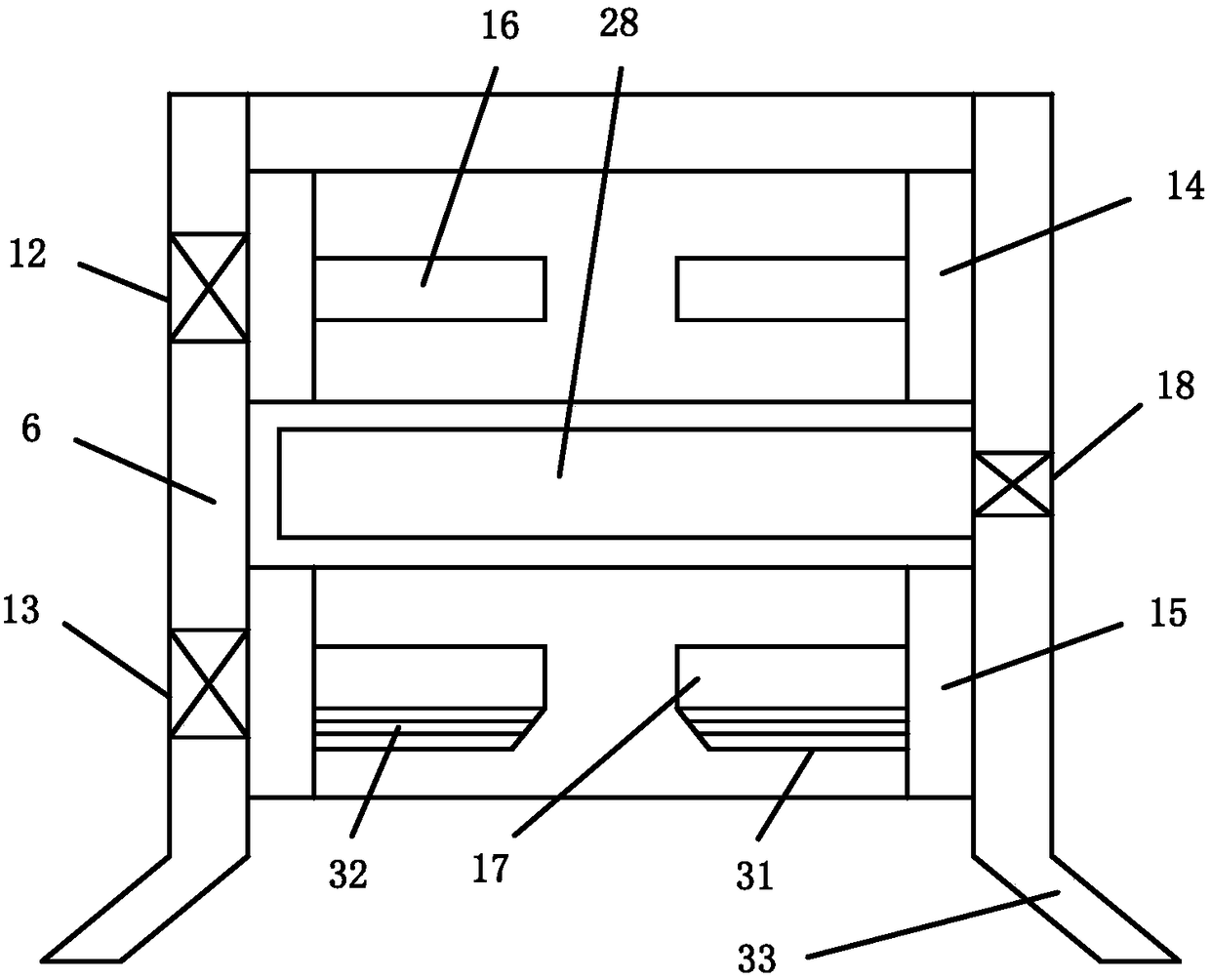

PendingCN108235837AIncrease the number of cutsImprove the mixing effectSpadesMowersAgricultural engineeringMixing effect

The invention discloses a multifunctional corn straw smashing and fertilizing rotary tillage machine which comprises a rack, wherein a shell is fixedly arranged on the rack, a straw feeding pipe and abase fertilizer feeding pipe are respectively arranged at the top of the shell, a soil inlet and a soil outlet are respectively arranged at the bottom of the shell; a smashing cutting head is connected into the straw feeding pipe by a first motor, a rotary tillage wheel is connected into the soil inlet by a second motor, the tail ends of the straw feeding pipe and the base fertilizer feeding pipeare jointly connected to a mixed pipe, the top and the bottom of the soil outlet are respectively connected with a first rotating cylinder and a second rotating cylinder by a third motor and a fourthmotor, a first vane is fixed in the first rotating cylinder, a second vane is fixed in the second rotating cylinder, a mixing roller is arranged between the first rotating cylinder and the second rotating cylinder, and the mixing roller is connected to a fifth motor. According to the machine, deficiencies in the prior art can be improved, the tillage efficiency can be improved, and the mixing effect of the soil with the straw and the base fertilizer can be improved.

Owner:HEBEI AGRICULTURAL UNIV. +1

Power generation device with opposite magnetic groups and different magnetic poles

InactiveCN108880172AReduce lossImprove conversion efficiencyDynamo-electric machinesMagnetic polesEngineering

The invention discloses a power generation device with opposite magnetic groups and different magnetic poles. The power generation device is provided with an induction coil group; a horizontal magnetic group and a vertical magnetic group which can synchronously move relative to each other are arranged on the two sides of the induction coil group respectively, wherein the horizontal magnetic groupis composed of at least one first magnetic piece which is magnetized in the movement direction; the vertical magnetic group is composed of at least one second magnetic piece, wherein the magnetizing direction of the second magnetic piece is perpendicular to the movement direction; the first magnetic piece and the second magnetic piece are arranged oppositely; a power switch group for selectively performing power-on on the induction coil group or not is arranged between the induction coil group and the horizontal magnetic group and between the induction coil group and the vertical magnetic group separately; therefore, the magnetic resistance can be eliminated by virtue of the relative arrangement of the magnetic pieces so as to reduce the loss of kinetic energy, so that the rotating speed can be improved, and the cutting frequency can be increased; and most of the magnetic fluid flows through the coil part, and high magnetic flux which flows smoothly via a magnetizer is achieved, so that magnetic lines can be effectively cut, the cutting quantity is increased, the power generation amount is greatly increased, and therefore, the energy conversion efficiency can be effectively improved.

Owner:YUZEN SUSTAINABLE ENERGY PTE LTD +1

A green grass crushing device for animal husbandry

InactiveCN110547101BMinimize the unreachableAvoid Passivation SituationsFeeding-stuffCuttersAnimal scienceCrop livestock

The invention relates to a green grass crushing device for livestock breeding. The device comprises an outer frame, a driving motor, a first roller cutter, a second roller cutter, a rotating motor, arotating column, a chopping platform and two collecting devices. The left side of the upper end of the outer frame is provided with the first roller cutter through a bearing, the rear end of the firstroller cutter is connected with an output shaft of the driving motor, and the driving motor is mounted on the side wall of the outer frame; the right side of the upper end of the outer frame is provided with the second roller cutter through a bearing, the middle of the outer frame is provided with the chopping platform, the middle of the chopping platform is provided with the rotating motor, theoutput shaft of the rotating motor is provided with the rotating column, and the left and right ends of the rotating column are connected with the two collecting devices. The green grass crushing device can solve the problems that when existing grass crushing machines are used for processing green grass, the green grass is often adhered to the surfaces of cutter heads, the cutter heads are often passivated after the green grass which is not cleaned away in time is heated and adhered to the cutter heads, and the green grass is easily splashed to the periphery under driving of the cutter heads in the cutting process.

Owner:柴磊

Cutting device for luggage processing

ActiveCN111037629AIncrease the number of cutsImprove practicalityCleaning using gasesCleaning using liquidsScrew threadWorkbench

The invention discloses a cutting device for luggage processing. The cutting device comprises a frame body, wherein a supporting base is slidably connected into the frame body, a workbench is slidablyconnected with the supporting base, a fixing clamp is fixed to the workbench, an adjusting assembly is arranged above the workbench, and a plurality of cutting assemblies are arranged on the adjusting assembly; a cleaning assembly and a dust blowing assembly are further arranged on the frame body, and the adjusting assembly comprises a first lead screw rotationally connected with the frame body;each cutting assembly comprises a first moving block in threaded connection with the first lead screw, and the number of the first moving blocks is the same as that of cutting cavities; and the firstmoving blocks are fixedly connected with assembling folded edges on assembling plates at the lower part through fixing bolts, fixing sleeve rods are rotationally connected between the assembling plates, the fixing sleeve rods are fixedly connected with cutters, and the fixing sleeve rods are fixedly connected with a second sliding rod through screws. Multiple pieces of raw material can be cut at the same time, the cutting effect is improved, and meanwhile the better functionality is achieved.

Owner:浙江铂仁旅游用品有限公司

High flux magnetic group device

ActiveCN109104063BEfficient poolingEffective guidanceDynamo-electric machinesMagnetic effectHigh flux

A high flux magnetic assembly device is disclosed. The device is at least composed of a first side magnetic column group and a second side magnetic column group, while the first and second magnetic row groups are formed by serially connecting magnetic members magnetized along the moving direction at intervals, and the same magnetic poles of the adjacent magnetic members are adjacent to each other,and a magnetic gap is respectively arranged between adjacent magnetic members, and each magnetic gap is provided with a perpendicular moving direction magnetized flow conductive magnetic member, theflow conductive magnetic member the adjacent magnetic member are arranged in a heteropolar manner. Thus, the magnetic line of force can be effectively managed, the magnetic flux utilization rate canbe improved, the double magnetic effect can be overcome, the magnetic resistance can be reduced, and the kinetic energy los can be reduced. Thus, when the magnetic force is used for an electric motor,the output power can be improved, and when the magnetic force is use for an electric generator, the cutting frequency and the cutting quantity can be increased, and the purpose of improving the energy conversion efficiency can be achieved.

Owner:DONGGUAN CITY JIADA MAGNETOELECTRICITY PROD CO LTD

Concentric common-battery magnetic electricity device

InactiveCN109428405AIncrease the number of cutsIncrease the angleMagnetic circuit shape/form/constructionElectricityEnergy conversion efficiency

The invention discloses a concentric common-battery magnetic electricity device, which consists of at least two magnetic column groups, at least one parallel coil column group arranged between opposite magnetic column groups, and at least one inductive switch group, wherein each magnetic column group consists of a first magnetic element and a second magnetic element, and the first magnetic elementand the second magnetic element are magnetized in a motion direction and have a magnetic gap; the coil column group consists of at least one coil, wherein each coil element is provided with a magnetizer, and the length of the magnetizer is length obtained by adding one magnetic element and one magnetic gap; the magnetizer is independently provided with an electricity supply coil connected with apower supply, and an inductance coil connected with a load on one side corresponding to a motion direction leaving end; and the inductive switch group can control whether the electricity supply coil of the coil column group supplies electricity or not. Therefore, a purpose that rotation speed is increased in a whole process can be realized, output power and emitted electric power can be further improved so as to improve the energy conversion efficiency of the device, and the structure is fully utilized.

Owner:YUZEN SUSTAINABLE ENERGY PTE LTD +1

A woven bag recycling and reuse processing system

ActiveCN110497561BExtend passivation timeReduce the amount of windingPlastic recyclingMechanical material recoveryElectric machineryStructural engineering

The invention relates to a system for recycling and reusing woven bags, which includes a frame body, a collection frame, a fixed frame, a motor, a cutting frame, a connecting plate and two rotary knives. The frame is connected, the fixed frame is installed in the frame, the motor is installed on the fixed frame, the cutting frame is installed on the output shaft of the motor, the upper end of the cutting frame is connected with the connecting plate through the pin shaft, the connecting plate is installed inside the frame, and the frame Two rotary knives are installed on the inner upper end, and the two rotary knives are arranged left and right. When the present invention can be shredded, there will be more woven bag shreds wrapped around the shredding roller, and long-term winding may cause damage to the cutting knife on the shredding roller, thereby causing passivation. The existing shredding roller only The passing woven bags can be shredded once, and there are still problems such as large pieces of woven bags after shredding.

Owner:铜陵天润包装有限责任公司

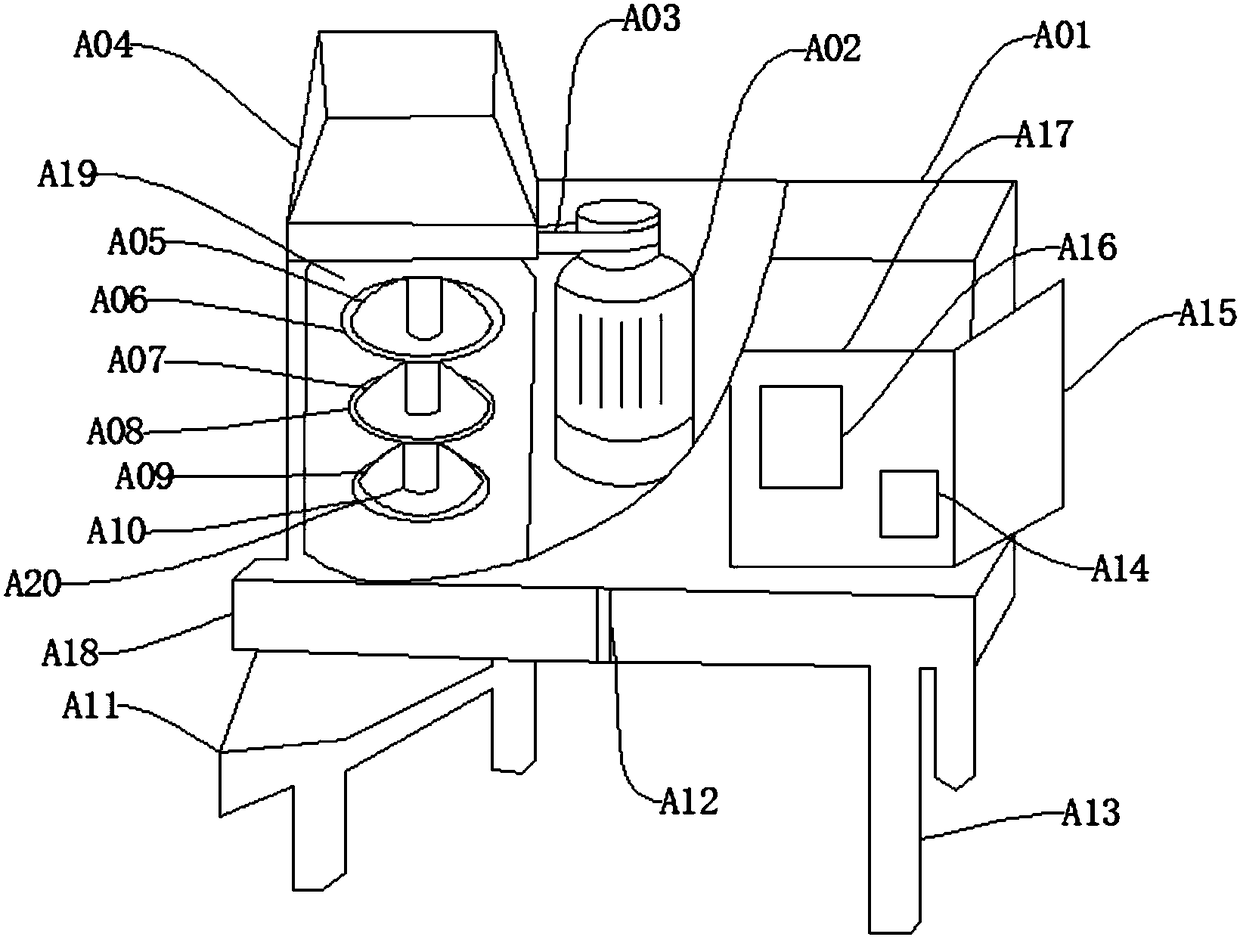

Pulverizing device for agricultural pulverizer and use method of pulverizing device

PendingCN108235869AImprove crushing efficiencyIncrease the number of cutsFeeding-stuffCuttersPulverizerEngineering

The invention provides a pulverizing device for an agricultural pulverizer and a use method of the pulverizing device. The pulverizing device comprises a machine body, a pulverizing chamber, a drawerand a discharging channel, wherein support legs are arranged at the lower end of the machine body, a feeding funnel is arranged at the upper end of the machine body, and the pulverizing chamber is formed in the lower end of the feeding funnel; and a funnel disc I is arranged in the pulverizing chamber, a cutter disc I is arranged at the lower end of the funnel disc I, a funnel disc II is arrangedat the lower end of the cutter disc I and a cutter disc II is arranged at the lower end of the funnel disc II. The pulverizing device is of a three-layer cutter disc design, corn straws are put into the pulverizing device through the feeding funnel, collides with the funnel disc I to slide to the cutter disc I, are cut by the cutter disc I, collide with the inner wall of the pulverizing chamber, are flipped to the funnel disc II, are cut by the cutter disc II, are repeated processed, are cut by a cutter disc III and are cut by three layers of the cutter discs in total, so that the pulverization is relatively thorough.

Owner:浙江开创智库科技有限公司

A multi-compartment shrink divider

ActiveCN105136535BIncrease the number of cutsHigh precisionPreparing sample for investigationMaterial distributionMulti channel

The present invention relates to a multi-separation groove reduction device, which comprises a box, baffles, a connection rod mechanism, a long connection rod, a horizontal movement mechanism, material receiving grooves, a material falling hopper and a drive mechanism, wherein the horizontal movement mechanism is connected with the box and is used for driving the box to drive, the box is arranged below the material falling hopper, the upper end of the box is the opening, more than three sequentially-aligned material distribution separation grooves are arranged inside the box, the material receiving grooves are arranged below the box, the number of the material receiving grooves is more, a plurality of the material receiving grooves are aligned along the direction perpendicular to the aligning direction of the material distribution separation grooves, the outlets are arranged below each material distribution separation groove, the directions of the outlets of each material distribution separation groove are not exactly the same, the outlets are respectively corresponding to the one material receiving groove, the baffle is arranged above the position above any two adjacent material distribution grooves, each baffle is rotatably arranged on the box through a rotation shaft, and the adjusting device is connected with the rotation shaft and is used for controlling the size of the opening between the any two adjacent baffles.

Owner:长沙开元仪器有限公司

Cutting anti-blocking device

The invention discloses a cutting, shifting and blocking preventing device, and belongs to the technical field of agricultural machinery. The cutting, shifting and blocking preventing device comprises a spindle, connecting sleeve plates, inclined plates, a breaking and cutting device and stubble shifting and blocking preventing devices, wherein the breaking and cutting device is mounted in the middle of the spindle, two groups of stubble shifting and blocking preventing devices are symmetrical about the breaking and cutting device and connected to two ends of the spindle, stubble shifting wheels of the stubble shifting and blocking preventing devices and breaking and cutting discs of the breaking and cutting device form deflection angles, and accordingly, the two symmetrical stubble shifting wheels are mounted on two sides of the end part of the breaking and breaking and cutting device in a splayed manner and simultaneously backwards shift stubble and laterally push stubble, straw and weeds; the connecting sleeve plates are symmetrically connected between the breaking and cutting device and the stubble shifting and blocking preventing devices on the spindle and are simultaneously connected with the stubble shifting and blocking preventing devices respectively; and during working, the two connecting sleeve plates are connected with a no-tillage planter for corn ridge culture respectively. The device can cut the stubble, straw and weeds, can shift the stubble, can throw the straw, the stubble and the weeds to the rear side and can push the straw, the stubble and the weeds to furrows on two sides, a clean seed bed is formed on a ridge, blocking is reduced, and the breaking and cutting quality is guaranteed.

Owner:SHENYANG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com