Cutting method of blue glass, blue glass and application thereof

A cutting method and blue glass technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve problems such as undiscovered blue glass cutting methods, improve quality and stability, increase the number of cuts, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

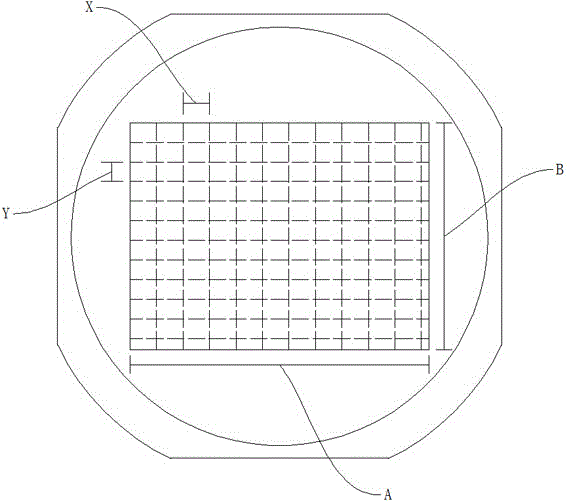

[0023] The length of a blue glass to be cut is A=66mm, the width B=66mm, the inherent width of the cutting head is a=0.2mm, the length of the blue glass with CMOS photosensitive area is Cx=4.73mm, and the width is Cy=3.51mm; The range of glass size length X, width Y is 6.13mm≤X≤6.73mm, 4.91mm≤Y≤5.51mm.

[0024] A kind of cutting method of blue glass, it comprises the following steps:

[0025] (1) According to Pmax=f([A / (X+0.2)]*[B / (Y+0.2)]), solve for Pmax in the range of 6.13mm≤X≤6.73mm, 4.91mm≤Y≤5.51mm Maximum value, obtain the maximum value of X and Y, as follows: X=6.4mm, Y=5.3mm;

[0026] (2) According to the X and Y obtained in step (1), and the inherent width of the cutting head of 0.2 mm, draw a cutting line and cut to obtain 120 small pieces of blue glass.

[0027] Under the same conditions, if the X and Y values are set to 6.13mm and 4.91mm respectively, the number of small pieces of blue glass obtained is the largest (120 pieces), but the size of the obtained sm...

Embodiment 2

[0029] The length of a blue glass to be cut is A=75mm, width B=40mm, the inherent width of the cutting head is a=0.2mm, and the length Cx=4.73mm and width Cy=3.51mm of the blue glass with CMOS photosensitive area; The range of glass size length X, width Y is 6.13mm≤X≤6.73mm, 4.91mm≤Y≤5.51mm.

[0030] A kind of cutting method of blue glass, it comprises the following steps:

[0031] (1) According to Pmax=f([A / (X+0.2)]*[B / (Y+0.2)]), solve for Pmax in the range of 6.13mm≤X≤6.73mm, 4.91mm≤Y≤5.51mm Maximum value, obtain the maximum value of X and Y, as follows: X=6.62mm, Y=5.51mm;

[0032] (2) According to the X and Y obtained in step (1), and the inherent width of the cutting head of 0.2mm, draw a cutting line and cut to obtain 77 small pieces of blue glass.

[0033] Under the same conditions, if the X and Y values are set to 6.13mm and 4.91mm respectively, the number of small pieces of blue glass obtained is the largest (77 pieces), but the size of the obtained small pieces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com