Semiconductor element processing method and forming process

A processing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, metal processing equipment, etc., can solve the problem of easy oxidation of the surface of semiconductor chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] see Figure 1-7 As shown, this embodiment is a method for processing a semiconductor element, the semiconductor element includes a semiconductor layer and a solder paste layer coated on the upper and lower surfaces of the semiconductor layer;

[0037] The semiconductor element is prepared by the following steps:

[0038] Step 1. Coating and forming: take the double-sided photolithographic semiconductor wafer as the processing object, put the semiconductor wafer into the fixed platform of the printing machine, use the printing machine to coat the solder paste on the upper surface of the semiconductor wafer, and then take it out Semiconductor wafer, and put it into the oven to dry, harden the solder paste layer on the upper surface of the semiconductor wafer, then turn over the semiconductor wafer, use a printing machine to coat the solder paste on the lower surface of the semiconductor wafer, and then semiconductor wafer, and Dry in an oven to harden the solder paste la...

Embodiment 2

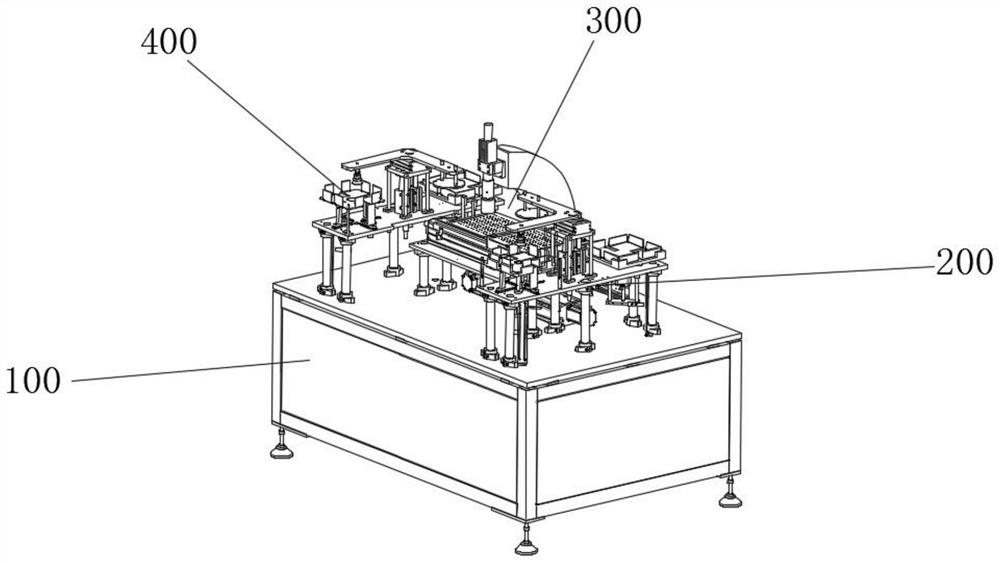

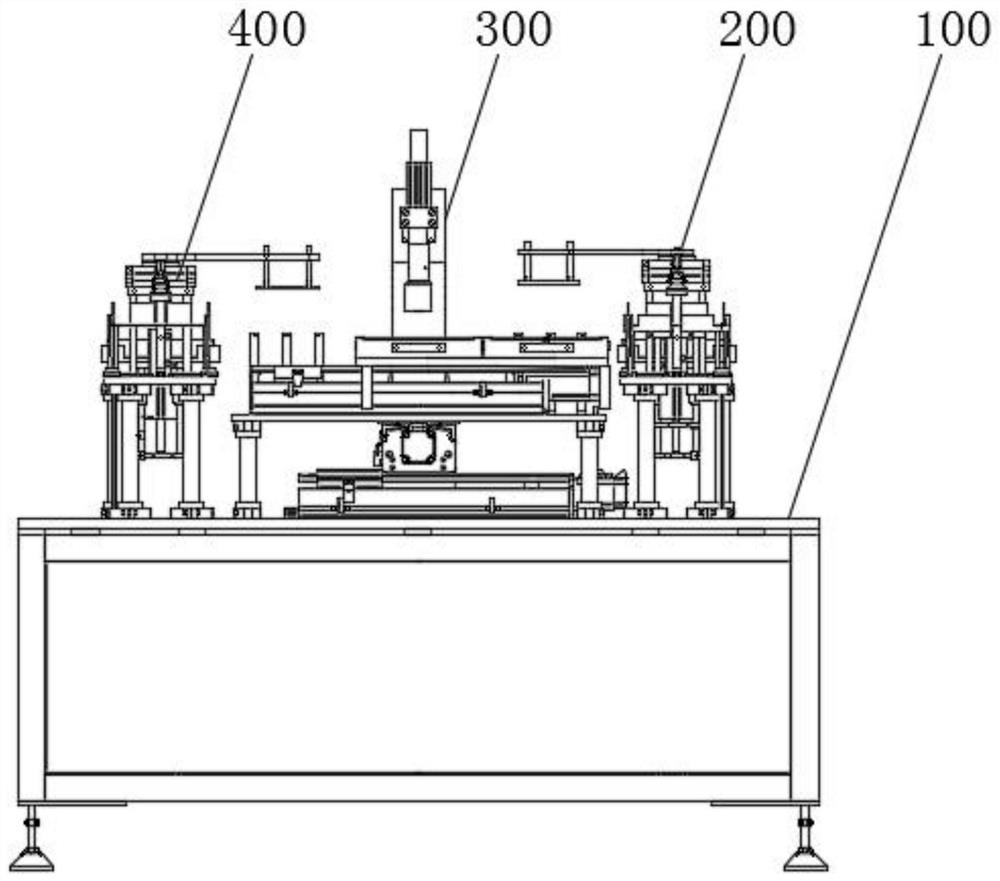

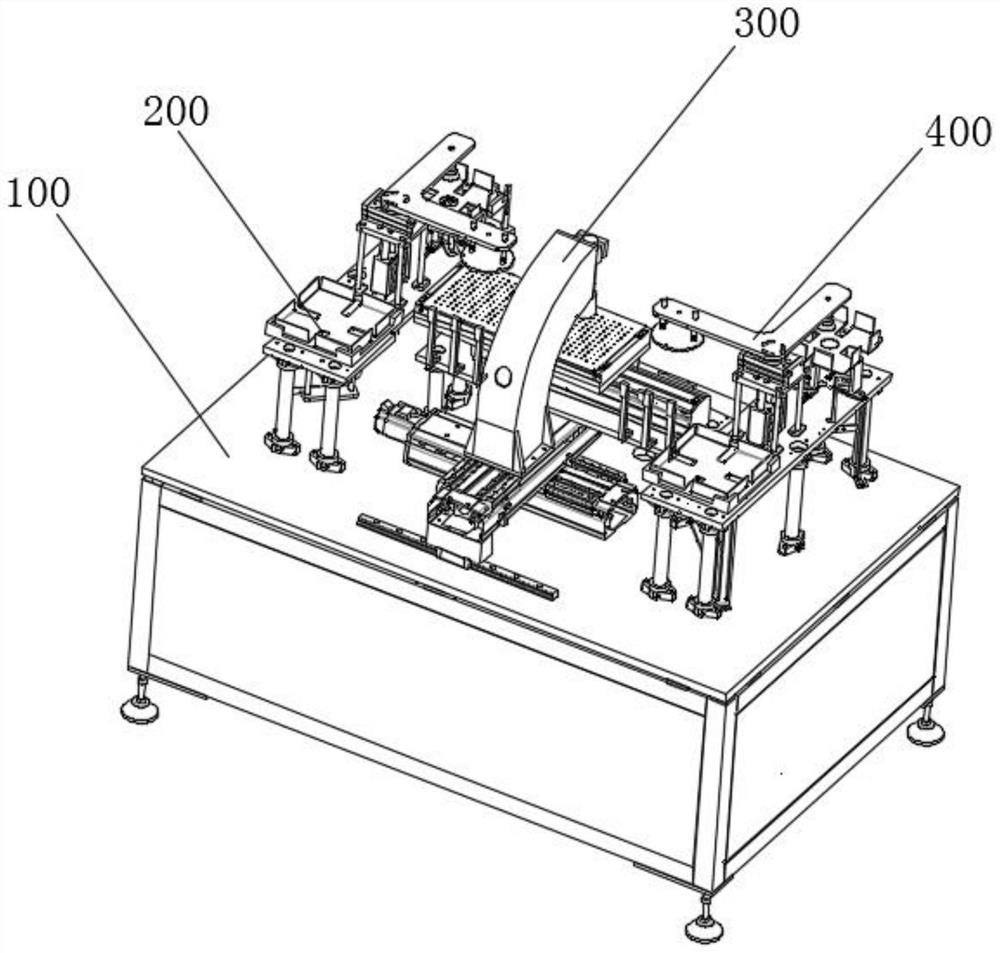

[0046] see Figure 1-7 As shown, the scribing equipment in this embodiment includes a load-bearing base 100, a first automatic loading and unloading mechanism 200, a scribing mechanism 300, and a second automatic loading and unloading mechanism 400. The top end of the load-bearing base 100 is equipped with a first automatic Loading and unloading mechanism 200, the end of the load-bearing base 100 away from the first automatic loading and unloading mechanism 200 is equipped with a second automatic loading and unloading mechanism 400, and the load-bearing base 100 is installed between the first automatic loading and unloading mechanism 200 and the second automatic loading and unloading mechanism 400 A scribing mechanism 300 is installed between them;

[0047] Wherein, the scribing mechanism 300 includes a high-energy laser generator 301, a C-shaped mounting frame 302, a first slide rail 305, a second slide rail 306, a third slide rail 311, and a dicing plate 312. The C-shaped mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com