Cutting device for luggage processing

A technology for cutting devices and bags, which is applied in metal processing, cleaning methods and tools, cleaning methods using liquids, etc., can solve the problems of low cutting efficiency, poor application, and low functionality of cutting machines, so as to improve Functional, improved cleaning effect, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

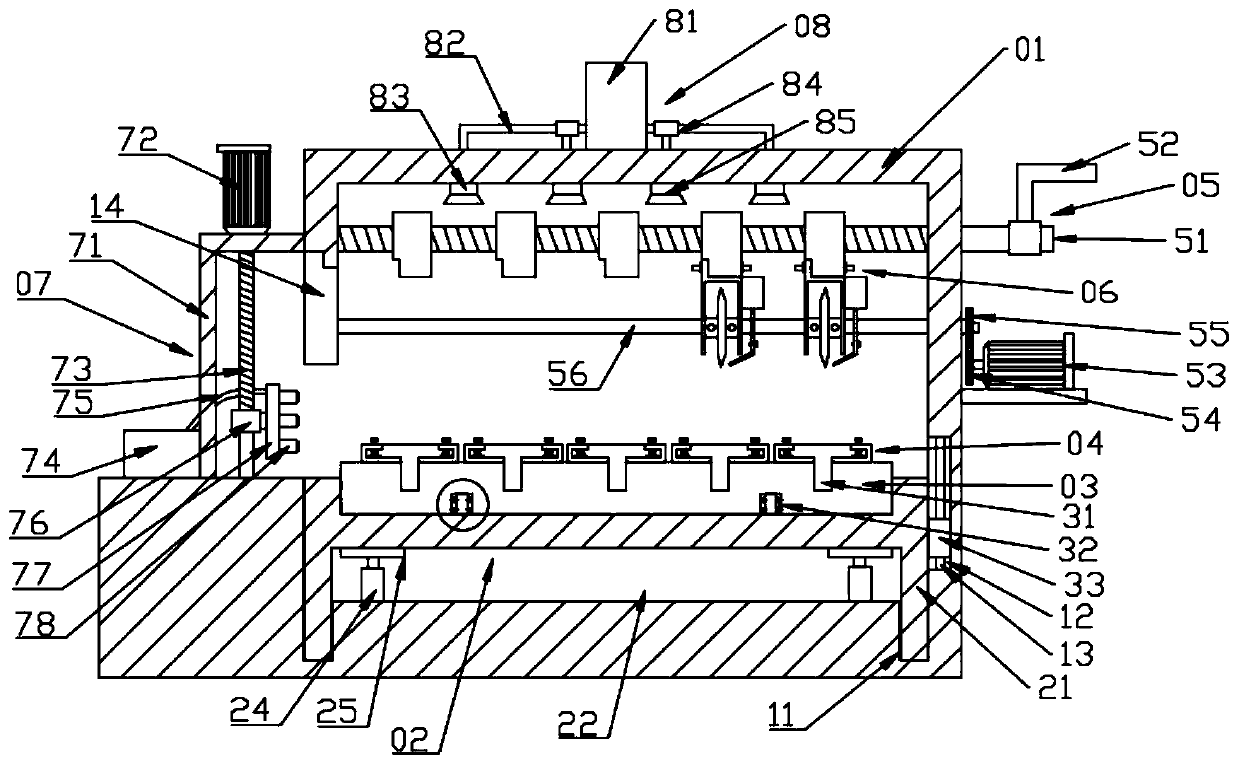

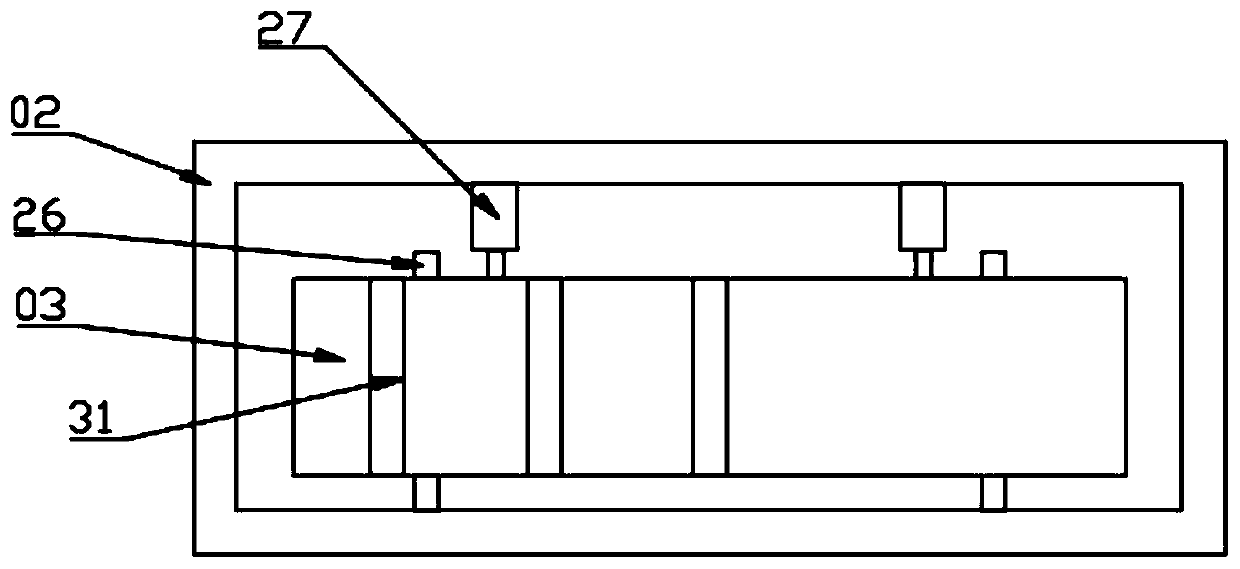

[0031] see Figure 1-7 , in an embodiment of the present invention, a cutting device for luggage processing includes a frame body 01, a support base 02 is slidably connected to the frame body 01, and a workbench 03 is slidably connected to the support base 02, and the workbench 03 is convenient for processing The raw material is cut, and the fixing jig 04 is fixed on the workbench 03, and the raw material is fixed by the fixing jig 04, which is convenient for cutting and can improve the cutting efficiency. An adjustment assembly 05 is arranged above the workbench 03, and a cutting assembly 05 is provided on the adjustment assembly 05. Assembly 06, the position of cutting assembly 06 can be adjusted by adjusting assembly 05, and then it is convenient to cut raw materials in different positions. The number of said cutting assembly 06 is multiple, which can be selected according to needs; There is a cleaning component 07, through which the workbench 03 can be sprayed and cleaned,...

Embodiment 2

[0042] The dust blowing assembly 08 is also provided on the top of the frame body 01, and the debris on the workbench 03 can be blown away by the dust blowing assembly 08; the dust blowing assembly 08 includes a fan 81 fixed on the frame body 01. The air duct 82 communicates with the first dust removal nozzle 83, and then blows air through the first dust removal nozzle 83; the air duct 82 is also provided with a shunt pipe 84, and the shunt pipe 84 communicates with the second dust removal nozzle 85 in the frame body 01 , thereby improving the effect of dust removal, and has very good practicability.

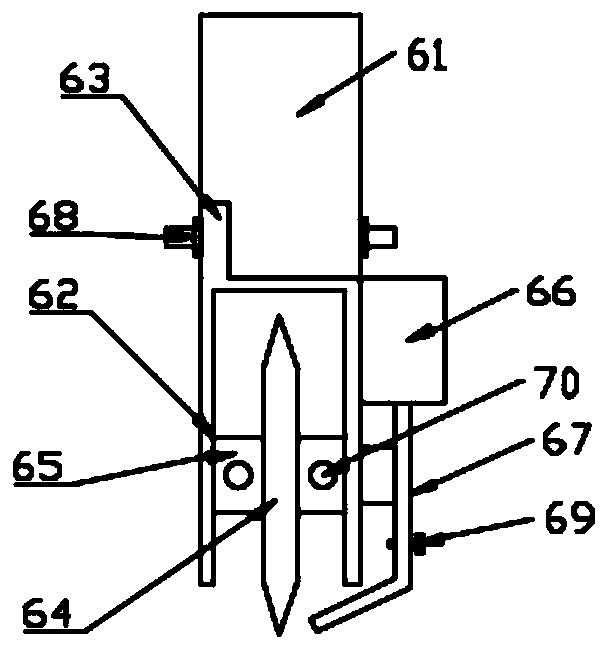

[0043] The working principle of the present invention is: the raw material is placed in the installation cavity 42, clamped by the pressing plate 44, and then the first hydraulic cylinder 24 is opened to drive the support base 02 to move in the vertical direction. The first motor 53 drives the second sliding rod 56 to rotate, and then drives the cutting knife 64 to rotate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com