Air guide sleeve and soybean milk machine using the air guide sleeve

The technology of a deflector cover and a soymilk maker is applied in the field of small kitchen appliances, which can solve the problems of difficult cleaning of the filter screen cover, poor flow deflector and cutting effect, and low pulp yield, etc., and achieves easy disassembly and cleaning, The effect of shortening the beating cycle time and reducing the shot height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

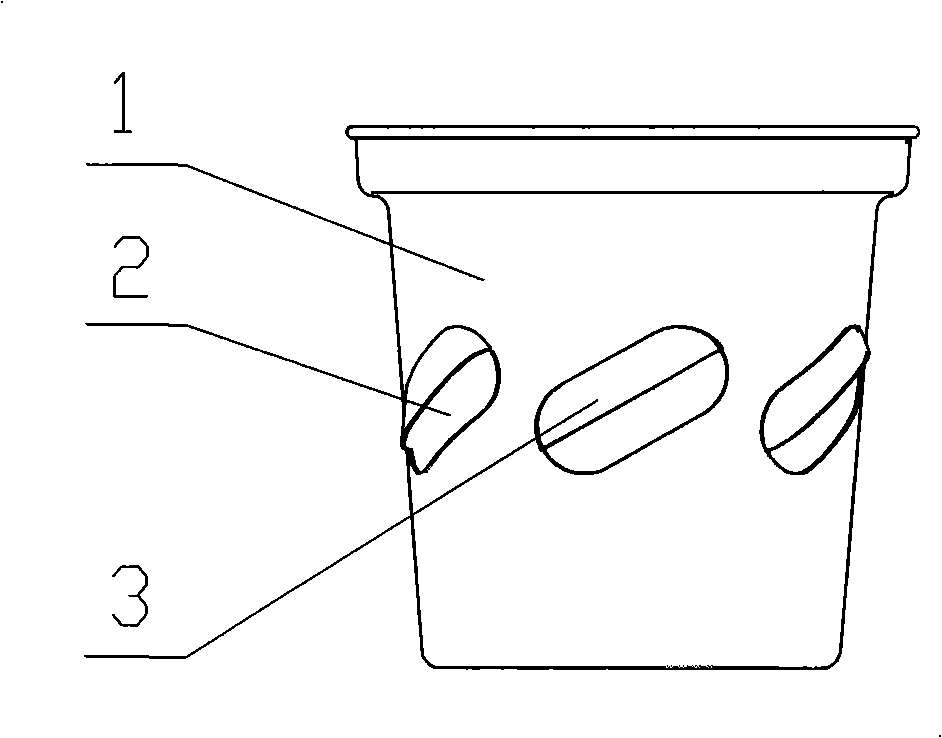

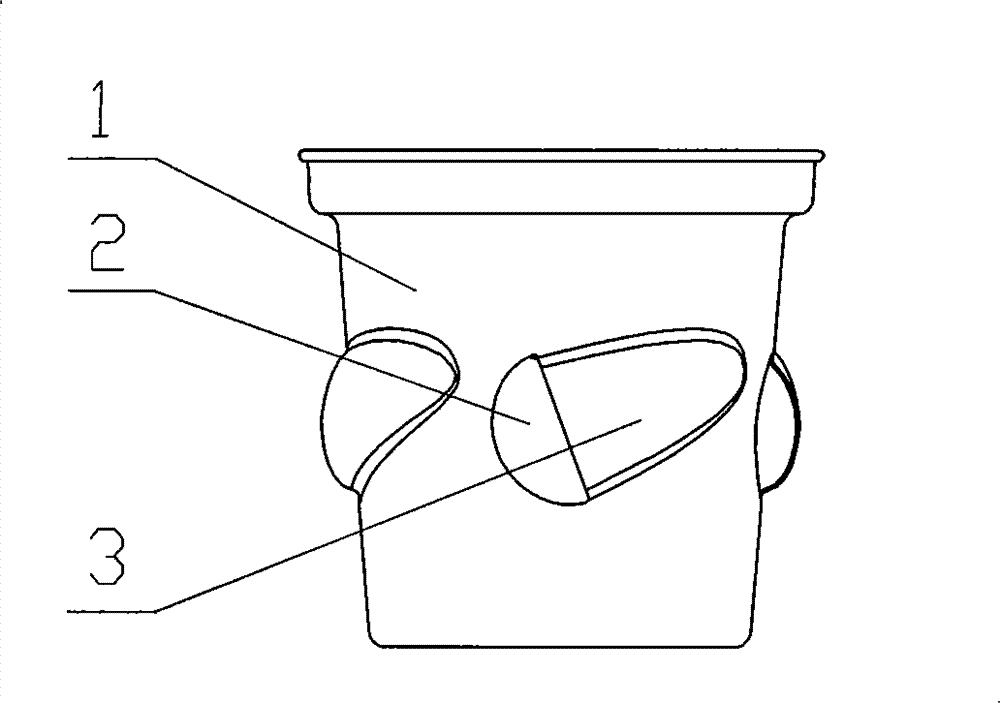

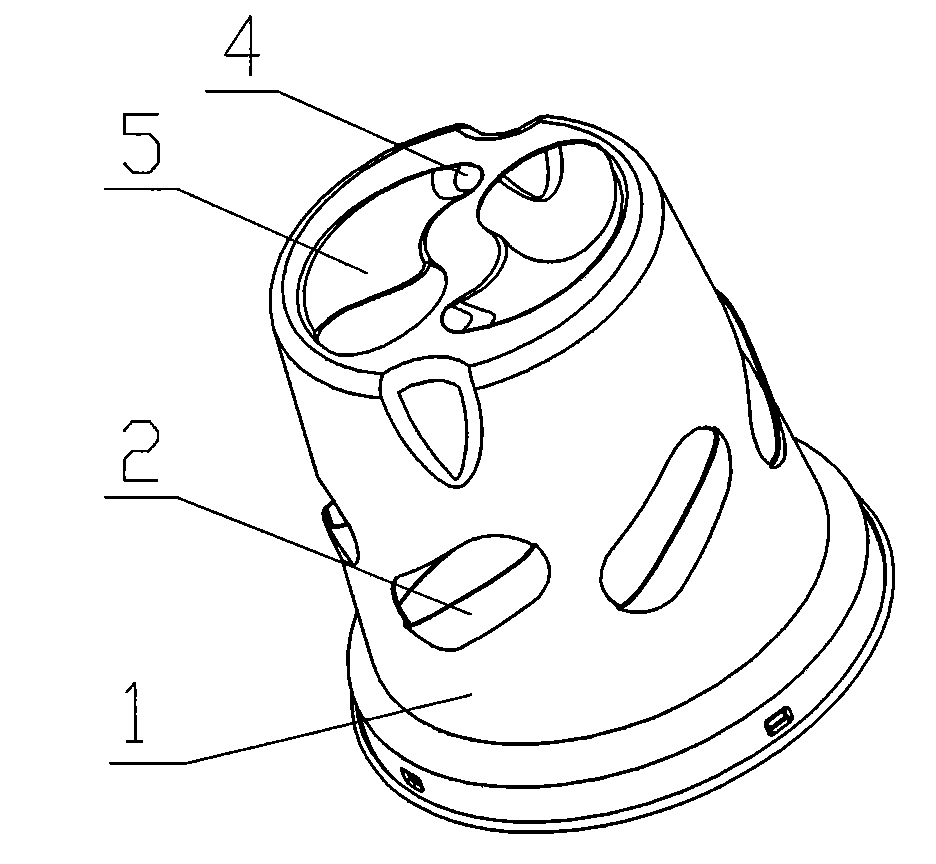

[0022] like Figure 1-Figure 4 As shown, such a guide cover includes a cover body 1 , and a slurry outlet 2 is provided on the upper side wall of the cover body 1 . The bottom of the cover body 1 is semi-open, and is provided with a slurry inlet 4, and the slurry inlet 4 is connected with a helical drainage groove 5. The quantity of its helical drainage groove 5 and slurry outlet 2 can be more than one. A cut-off surface 3 is provided at the pulp outlet 2 .

[0023] like image 3 As shown, the drainage groove 5 may be a helical groove directly opened on the bottom wall of the cover body 1 . like Figure 4 As shown, the drainage groove 5 can also be surrounded by the groove wall 6 arranged on the bottom wall of the cover body 1 . image 3 The spiral drainage groove 5 in the center is mainly located at the bottom of the cover body 1 . and Figure 4 The shown spiral dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com