Rotating extrusion concrete filling pile construction method and equipment

A construction method and concrete technology, applied in drilling equipment, earthwork drilling, sheet pile walls, etc., can solve the problems of high construction cost, low construction efficiency, large waste of concrete, etc., to achieve easy popularization, reduce construction cost, cost-effective pile effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

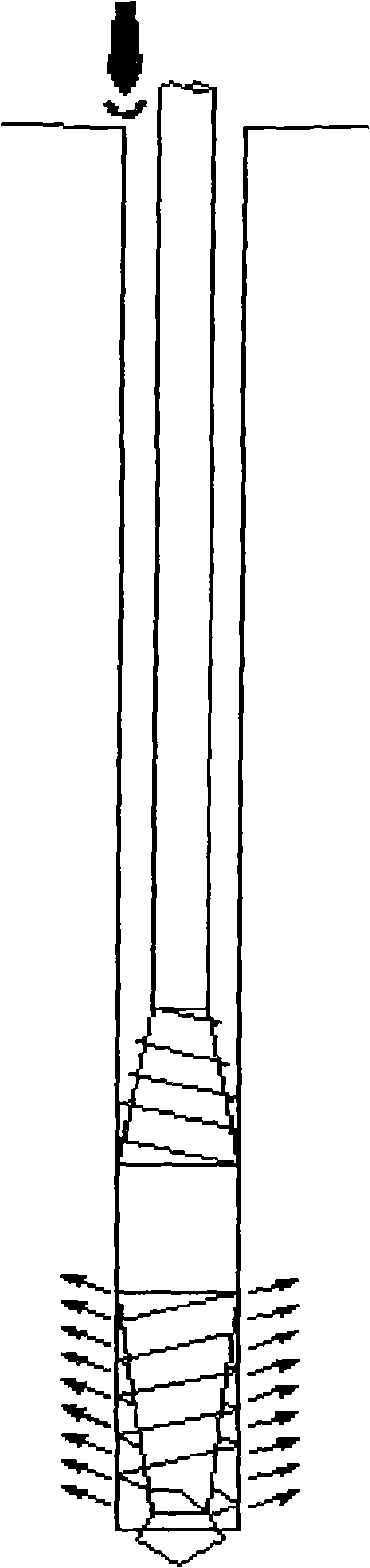

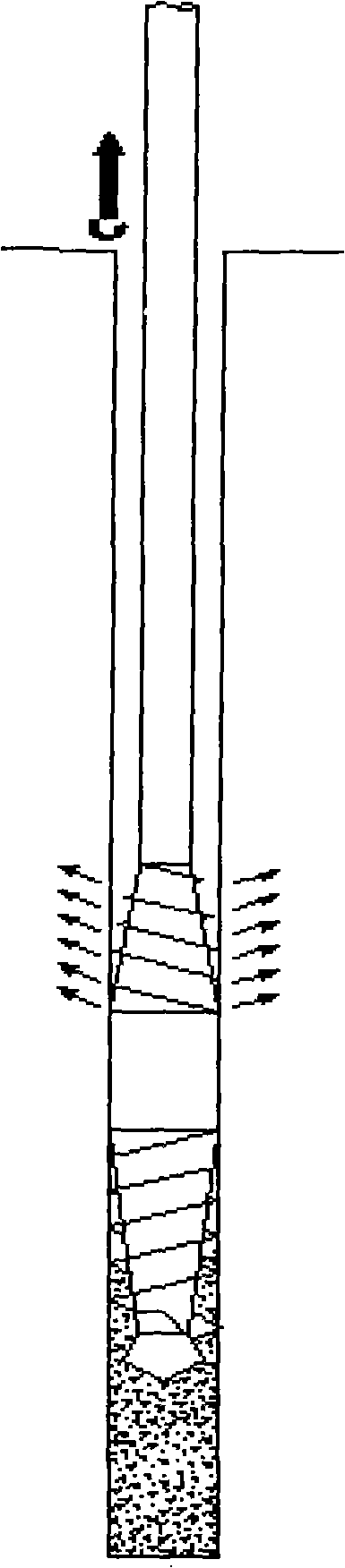

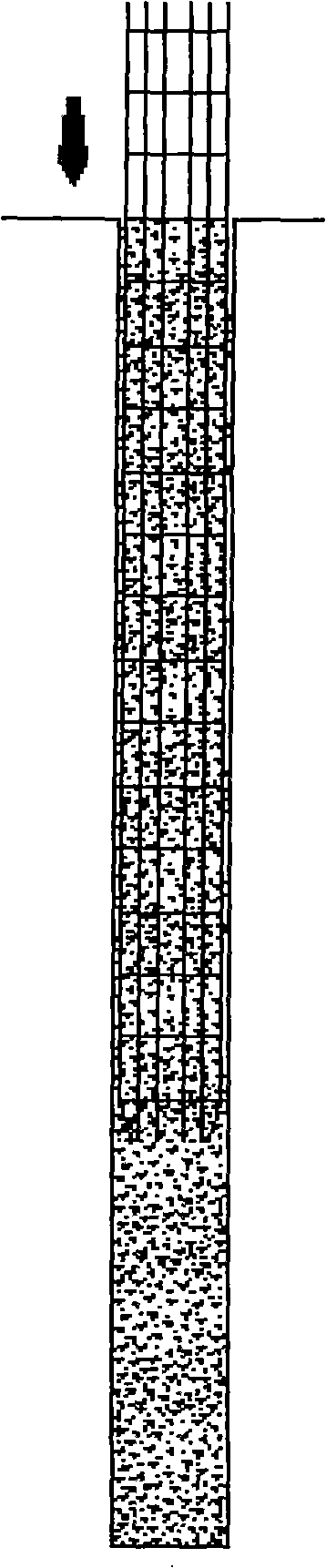

[0015] The rotary extrusion concrete pouring pile construction method uses a drilling tool with an olive-type drill bit to drill holes. Through the rotary extrusion of the drill bit on the soil, a drill hole with the surrounding soil compacted to the design depth is formed, and then reversed to lift Drill pipe, while lifting the drill pipe, pump superfluid concrete into the hollow drill pipe. After the drill pipe is raised, it vibrates and inserts into the reinforcement cage. In the construction method of the above rotary extrusion concrete pouring pile, the concrete is concrete with a slump of 22-25cm. The borehole is formed by the rotary extrusion of the olive drill bit on the soil, which does not need to take soil and has a good compaction effect on the surrounding soil. After the concrete pouring pile is drilled, concrete is pumped into the center of the drill pipe. Realize the used equipment of rotary extruding concrete cast-in-situ pile construction method of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com