Multi-head stirring type large-diameter cast-in-situ pipe pile device and application thereof

A large-diameter pipe and agitation technology, which is used in drilling driving devices, sheet pile walls, drilling equipment and other directions in the wellbore, can solve the problems of significant soil squeeze effect and difficult construction of immersed tubes, and achieve clear construction technology, The effect of good piling effect and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

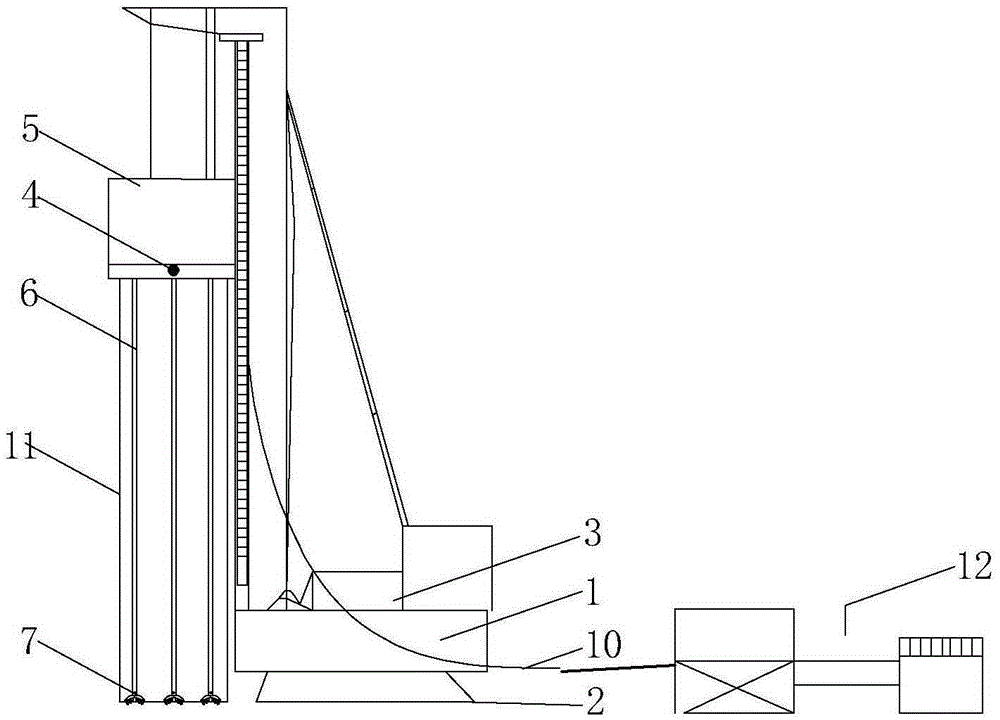

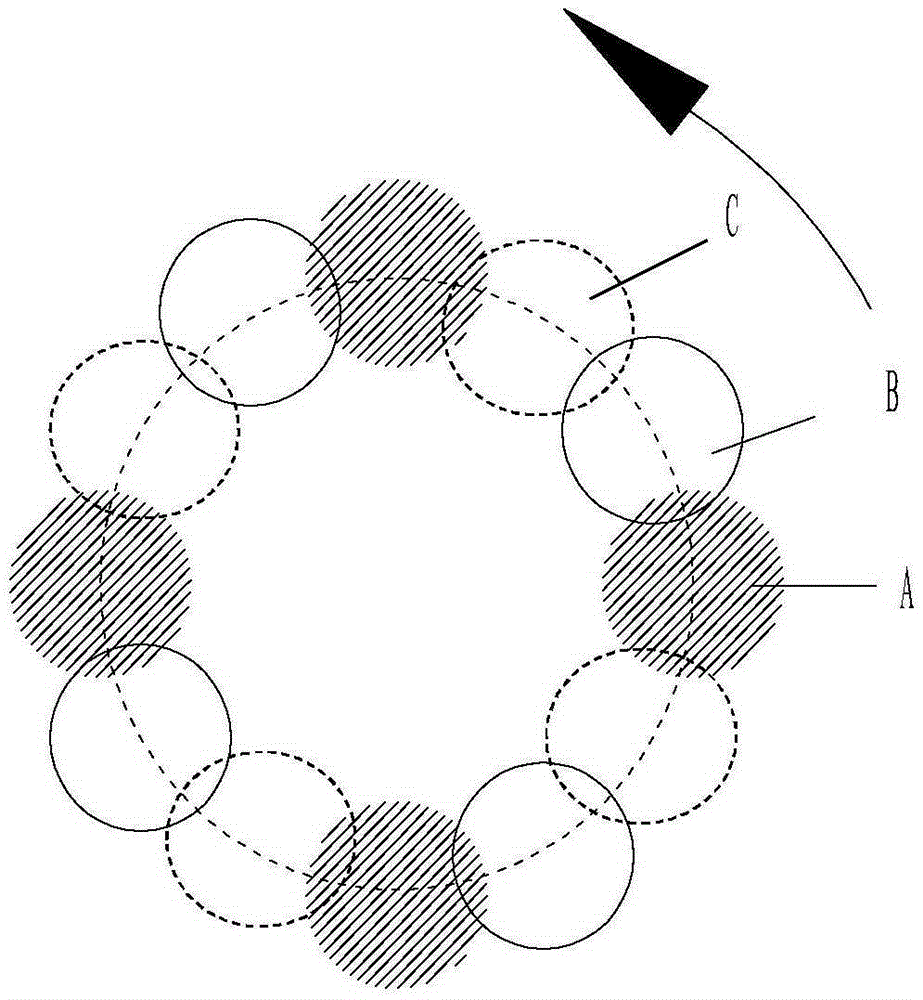

[0034] This implementation provides a method for preparing cast-in-situ large-diameter pipe piles with an outer diameter of 1200mm, a wall thickness of 300mm, and a depth of 20m.

[0035] First set out the stake, release the actual sample according to the construction drawings; excavate the trench, remove the ground and underground debris; then set the guide positioning line; determine the center position of the cast-in-place large-diameter pipe pile, and at the same time determine the annular combined drill pipe 6 s position.

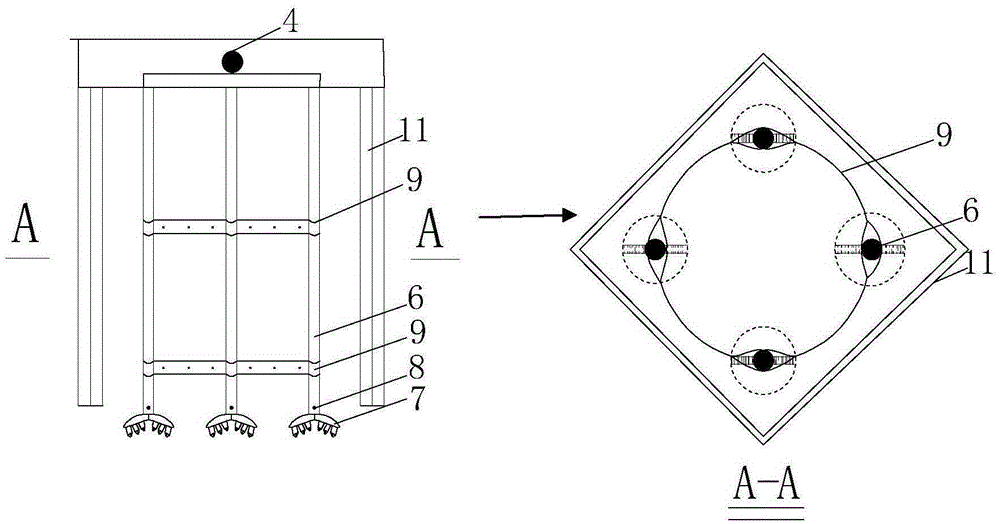

[0036]The multi-head mixing type cast-in-place large-diameter pipe pile device is in place and the cement slurry is prepared: check the length of the annular combined drill pipe 6, the diameter of the drill bit, connect the delivery pipeline, and move the multi-head stirring type cast-in-place large-diameter pipe pile device to the designated position The center of the annular composite drill pipe 6 is aligned with the design center of the pipe pile, a...

Embodiment 2

[0041] This implementation provides a method for preparing cast-in-situ large-diameter pipe piles with an outer diameter of 1500mm, a wall thickness of 350mm, and a depth of 25m.

[0042] First set out the stake, release the actual sample according to the construction drawings; excavate the trench, remove the ground and underground debris; then set the guide positioning line; determine the center position of the cast-in-place large-diameter pipe pile, and at the same time determine the annular combined drill pipe 6 s position.

[0043] Pile driver in place and cement slurry preparation: check the length of the annular composite drill pipe 6, the diameter of the drill bit, connect the delivery pipeline, move the pile driver to the designated position, and align the center of the annular composite drill pipe 6 with the design center of the pipe pile. The rods are aligned with each mixing point; the cement slurry is mixed, and the pipeline is connected to the grouting port 8, tha...

Embodiment 3

[0048] This implementation provides a method for preparing cast-in-situ large-diameter pipe piles with an outer diameter of 2000mm, a wall thickness of 400mm, and a depth of 30m.

[0049] First set out the stake, release the actual sample according to the construction drawings; excavate the trench, clear the ground and underground debris; Combined drill pipe 6 position.

[0050] Pile driver in place and cement slurry preparation: check the length of the annular composite drill pipe 6, the diameter of the drill bit, connect the delivery pipeline, move the pile driver to the designated position, and align the center of the annular composite drill pipe 6 with the design center of the pipe pile. The rods are aligned with each mixing point; the cement slurry is mixed, and the pipeline is connected to the grouting port 8, that is, after the mixer sinks to a certain depth, the cement slurry is configured according to the design mix ratio and delivered to the drill bit.

[0051] Stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com