Ventilated wind screen clothing material

A fabric and clothing technology, applied in the field of windproof clothing fabrics, can solve the problems of high cost, unsatisfactory fabric breathability, poor air permeability, etc., and achieve the effect of increasing quantity and good breathable windproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

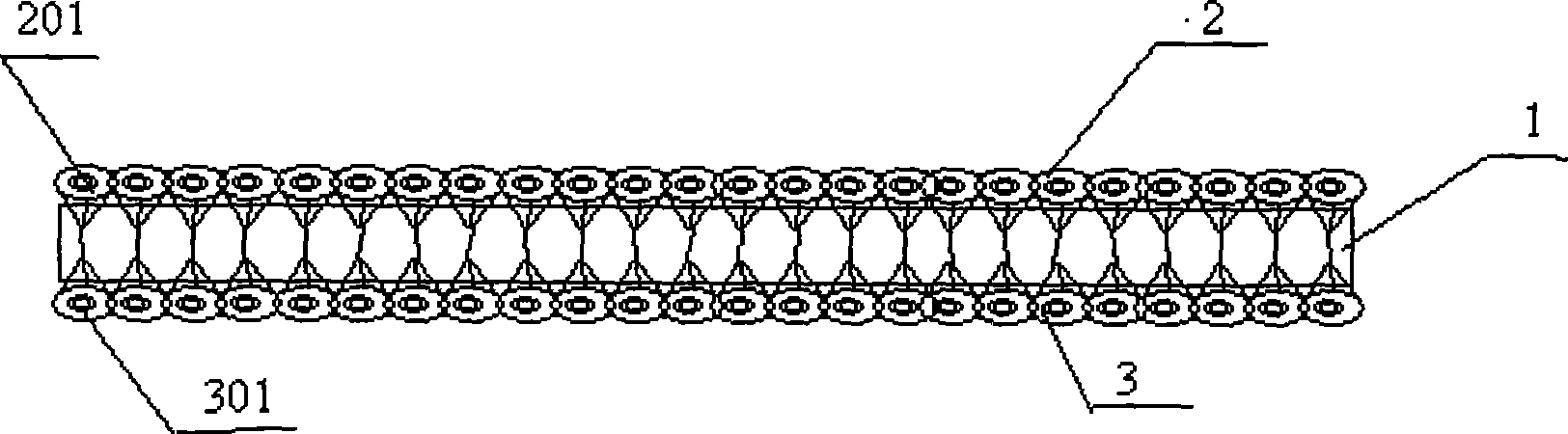

Image

Examples

preparation example Construction

[0014] The preparation method of the present invention comprises the steps of:

[0015] Knitting on a single-jersey circular knitting machine equipped with loop sinkers, the elastic spandex core-spun yarn and the loop yarn are lapped and formed into loops according to the plating process, and the spandex core-spun yarn forms a high-elasticity and high-density weft plain knitted middle base fabric, and the loop loop The sinker arc of the yarn loop is elongated by the sinker to form a loop. Adjust the pile height by adjusting the sinker height. When dosing spandex core-spun yarn and terry yarn guide position, ensure that the terry yarn is exposed on the front of the fabric, covering the loops of the spandex core-spun yarn, while the reverse side of the fabric is still the terry loops that elongate the sinker arc, after finishing In the process, part of the yarn of the pile is exposed on the front through napping, and the pile is processed to form a double-faced fleece fabric. T...

Embodiment 1

[0017] Knitting on a single-jersey circular knitting machine equipped with a terry sinker, the elastic spandex core-spun yarn and the terry yarn are lapped and looped according to the standard knitting process, but according to the special characteristics of the fabric, a special raw gram is selected , Spandex core-spun yarn forms a high-elasticity and high-density weft plain knitted intermediate base fabric, and the sinker arc of the terry yarn coil is elongated by the sinker to form a terry loop. Adjust the pile height by adjusting the sinker height. When dosing spandex core-spun yarn and terry yarn guide position, ensure that the terry yarn is exposed on the front of the fabric, covering the loops of the spandex core-spun yarn, while the reverse side of the fabric is still the terry loops that elongate the sinker arc, after finishing In the process, part of the yarn of the pile is exposed on the front through napping, and the pile is processed to form a double-faced fleece ...

Embodiment 2

[0030] The same materials and methods as in Example 1 are used, wherein the raw materials of the surface pile 201 and the bottom pile 301 are spun yarns, and the raw materials are 32S polyester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com