Unloading type thin-walled box dead walls borne by oblique vertical sectional steel tube piles and construction technology

A technology of combining steel pipes and steel pipe piles, which is applied in sheet pile walls, artificial islands, water conservancy projects, etc., can solve the problem of poor compaction of the backfill of the retaining wall, failure of the support structure to achieve the expected effect, and impact on the filling Friction with ribs and other problems, to achieve good flood control and earthquake resistance, reduce the thickness of the retaining wall and the consumption of building materials, and achieve good pile-forming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

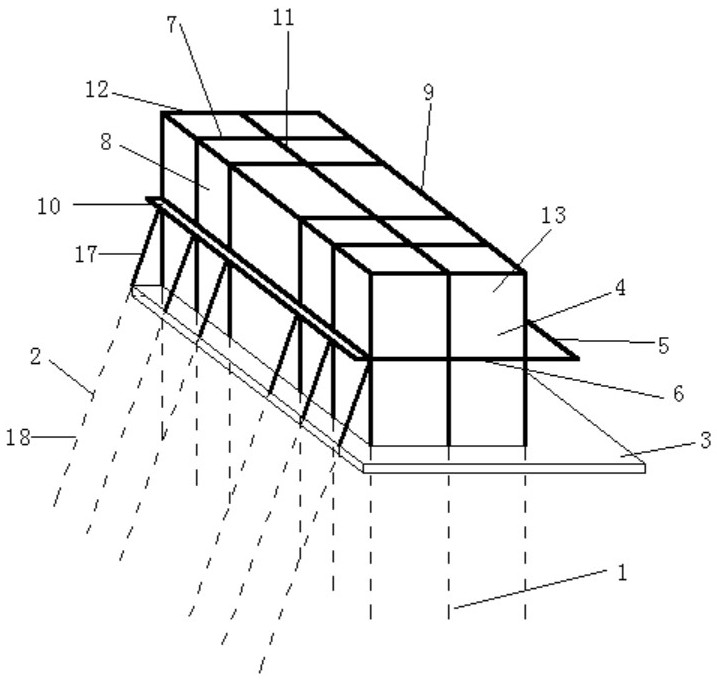

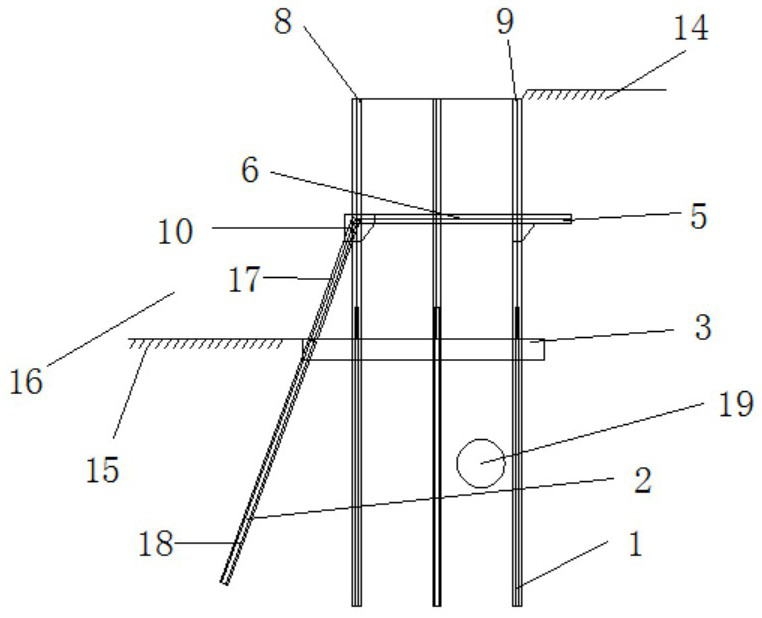

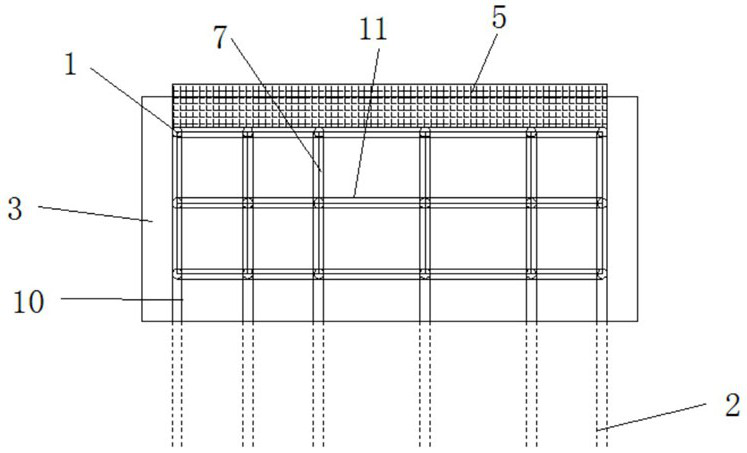

[0028] Example: such as figure 1 , figure 2 , image 3 As shown, including the foundation pit 16, the left side of the foundation pit 16 is provided with a low ground 15, the right side of the foundation pit 16 is provided with a high ground 14, the high ground 14 and the low ground 15 form a cliff-shaped structure, and the high ground 14 A box-shaped wall module 4 is provided relative to the lower ground 15. The box-shaped wall module 4 is a hollow structure. The box-shaped wall module 4 includes a rear outer wall 12, a front outer wall 13, and a left outer wall. The wall 8, the right exterior wall 9, the rear exterior wall 12, the front exterior wall 13, the left exterior wall 8, and the right exterior wall 9 are sequentially connected together to form a rectangular frame structure, and the internal relative positions of the box-shaped wall modules 4 A plurality of horizontal inner partition walls 7 are provided, a longitudinal inner partition wall 11 is provided at the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com