Expansion concrete pile with bulk material core and construction method thereof

A technology of expansive concrete and bulk material piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low bearing capacity and stiffness, poor integrity of pile foundations, and high construction costs, so as to reduce construction costs and increase production costs. The pile effect is good and the construction speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment discloses a construction method of bulk material core expansion concrete pile, see Figure 4 , including the following steps:

[0034] 1) Hole forming: According to geological conditions, use a drilling rig to drill pile holes in the soil layer to the designed depth. Wherein, the pile hole is protected by mud.

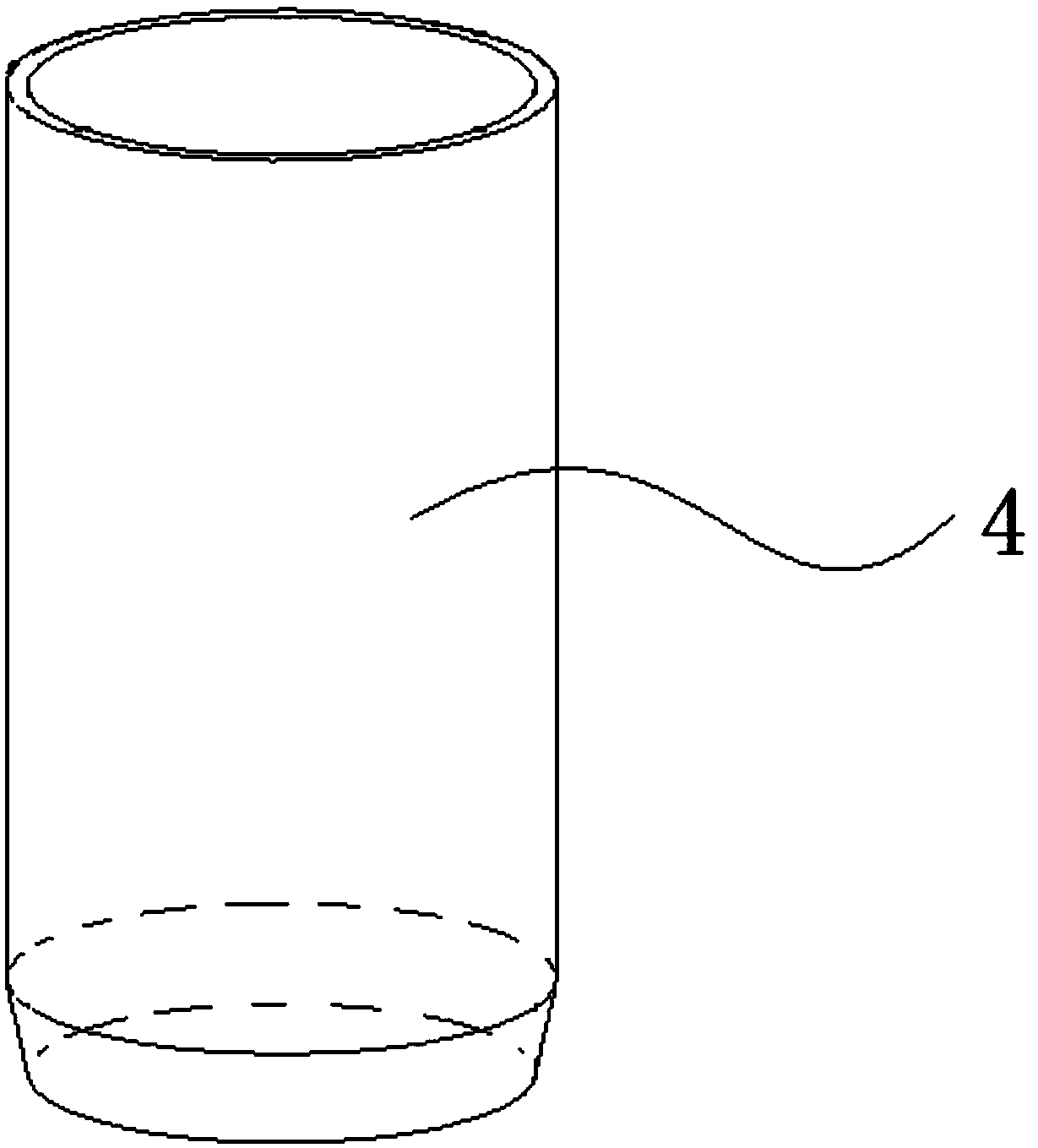

[0035] 2) Press down the steel pipe pile mold: inject mud into the pile hole to clear the hole. Lift the steel pipe pile form 4, align the pile position, and adjust the verticality of the steel pipe pile form 4. Then apply pressure to press the steel pipe pile form 4 into the soil layer to the design elevation. see image 3 , the steel pipe pile form 4 is a hollow cylinder whose upper and lower ends are open. The lower end opening of the steel pipe pile form 4 has a sharp cutting knife. The depth at which the cutter is inserted into the bottom of the hole is greater than or equal to 0.5 meters.

[0036] 3) Pouring expanded concrete around ...

Embodiment 2

[0042] An expanded concrete pile with a bulk material core made by the method described in Example 1, comprising a concrete semi-hollow pile 2 and a bulk material core 1 implanted in the soil layer.

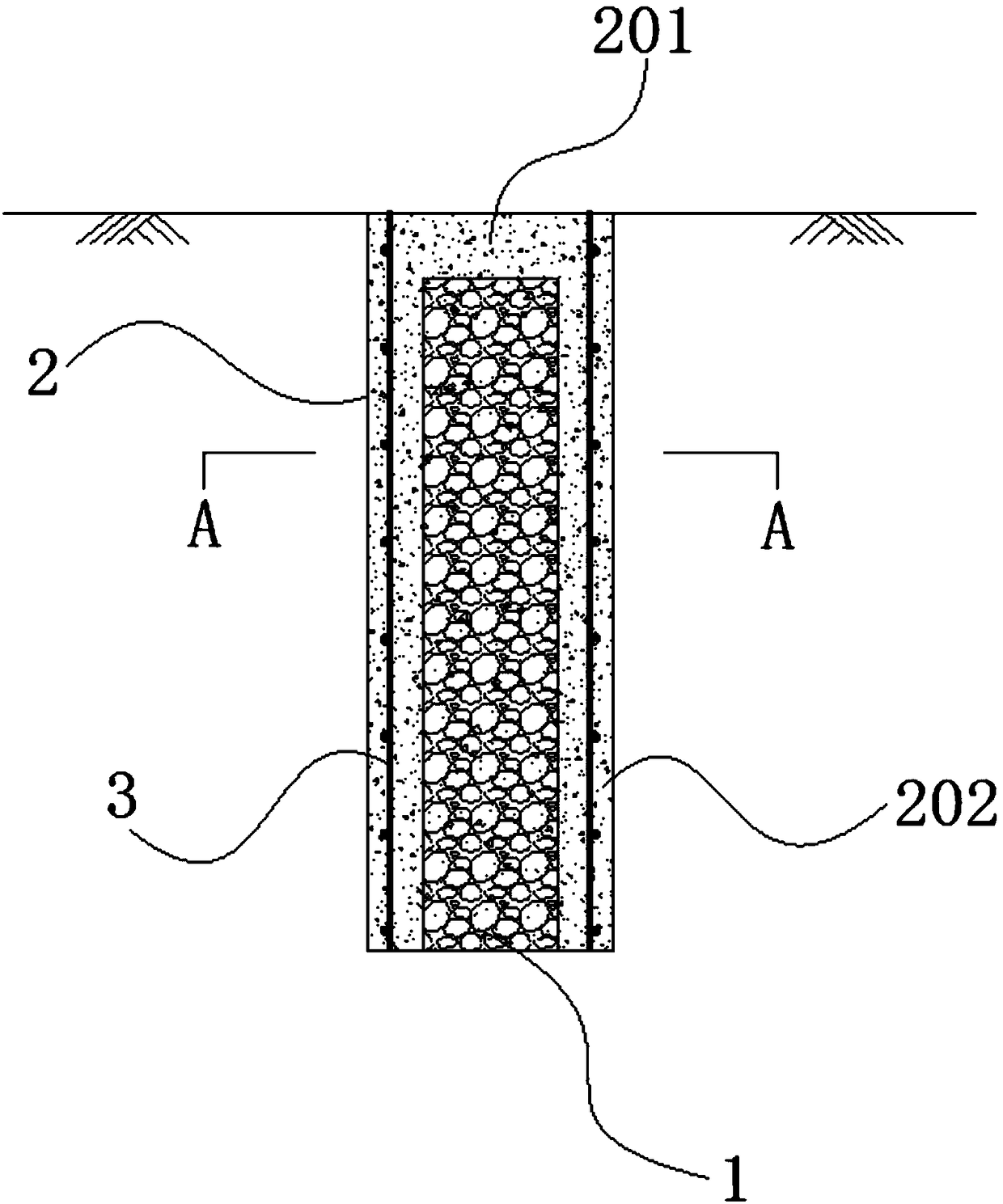

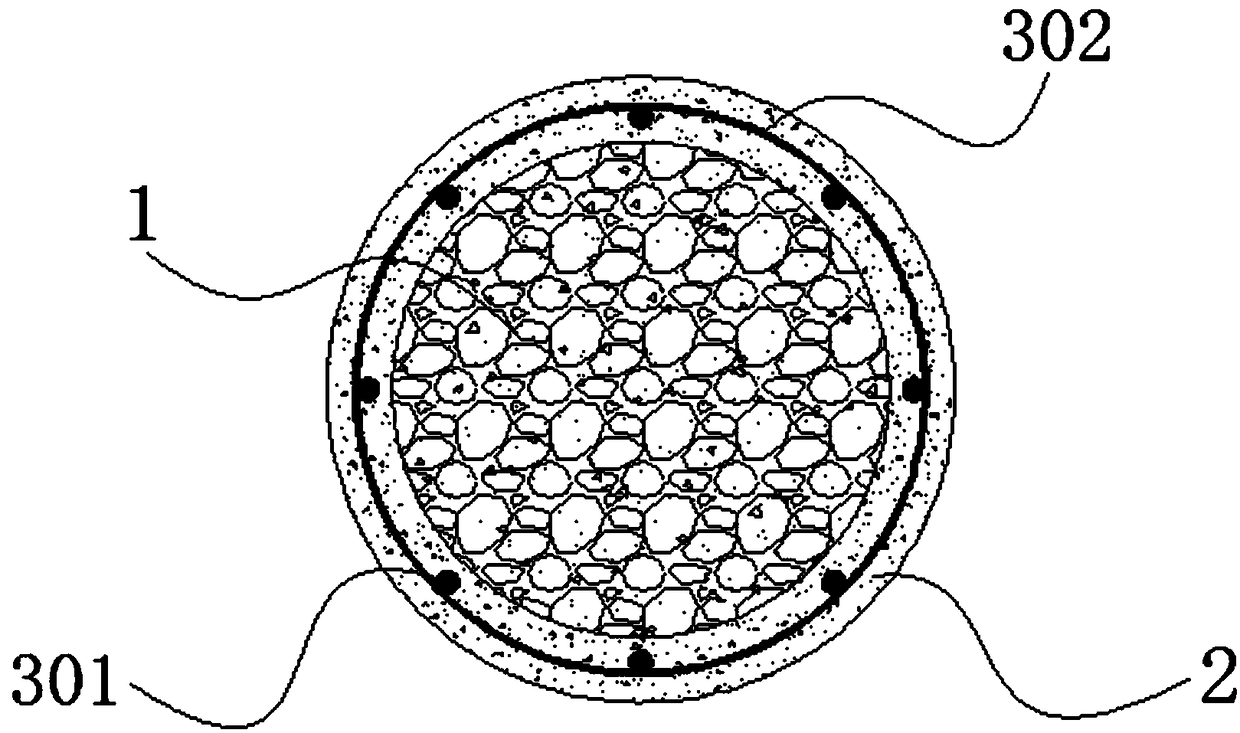

[0043] see figure 1 , the concrete semi-hollow pile 2 includes a solid cylindrical pile 201 and a hollow pipe pile 202 . The hollow pipe pile 202 is disposed at the bottom of the solid cylindrical pile 201 . The solid cylindrical pile 201 and the hollow pipe pile 202 are integrated. see figure 2 , the concrete semi-hollow pile 2 has the main reinforcement 301 of the pile body and the spiral stirrup 302 of the pile body. The main reinforcement 301 of the pile body and the spiral stirrup 302 of the pile body together constitute the reinforcement cage 3 . The reinforcement cage 3 is formed by splicing multiple sections of reinforcement cages. Each section of reinforcement cage is fixed by welding or riveting.

[0044] The inner cavity of the hollow pipe pile 202 is filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com