Windproof and breathable garment material and processing method thereof

A windproof, breathable and clothing technology, applied in the field of clothing fabrics, can solve the problems of unsatisfactory ventilation effect of fabrics, affecting the comfort of fabrics, poor ventilation effect, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

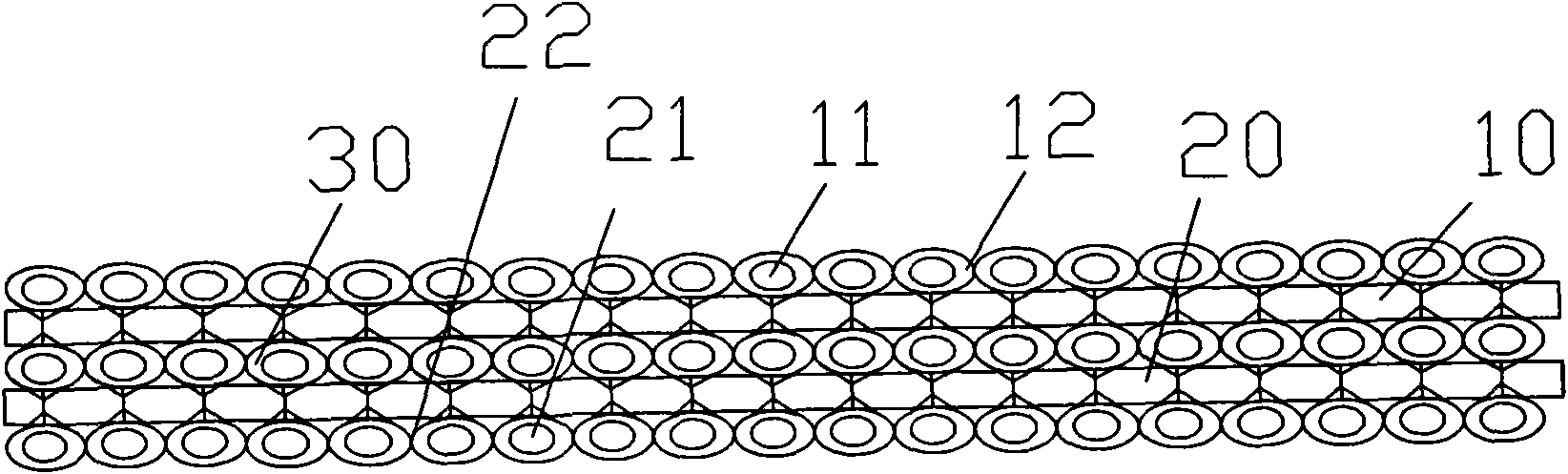

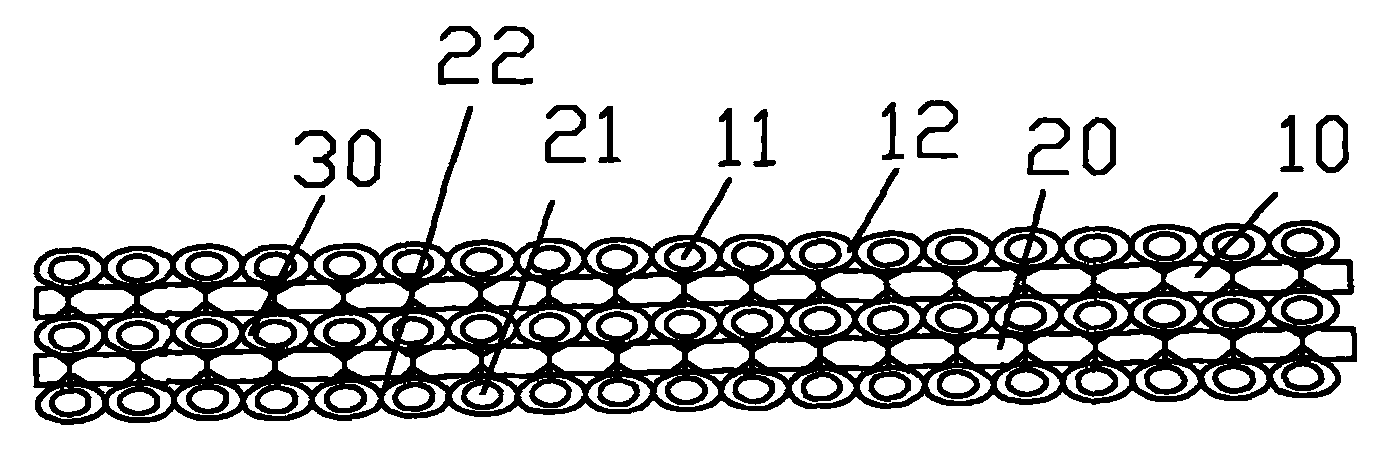

[0021] Knitted on a single jersey circular knitting machine equipped with loop sinkers, elastic spandex core-spun yarns and loop yarns are formed into loops according to the standard loop forming process of knitting. However, according to the special nature of the fabric, the spandex core-spun yarns form high The upper base fabric layer 10 and the lower base fabric layer 20 of elastic high-density weft jersey, the sinker arc of the loop of the pile yarn is elongated by the sinker to form a pile. Adjust the pile height by adjusting the height of the sinker. When dosing the spandex core-spun yarn and the terry yarn guide position, make sure that the terry yarn is exposed on the front of the fabric, and cover the spandex core-spun yarn loop, while the back of the fabric is still the terry that elongates the sinking arc. In the process, some of the yarns of the loops are exposed on the front through napping, and the napping process is performed to form a double-sided fleece fabric....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com