Screw pile lowering device applying force through ground, and pile lowering method

A technology of gravity device and screw, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of large volume of static press, large damage to pipe piles, and long time required to achieve high strength of pipe piles and all Small damage, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

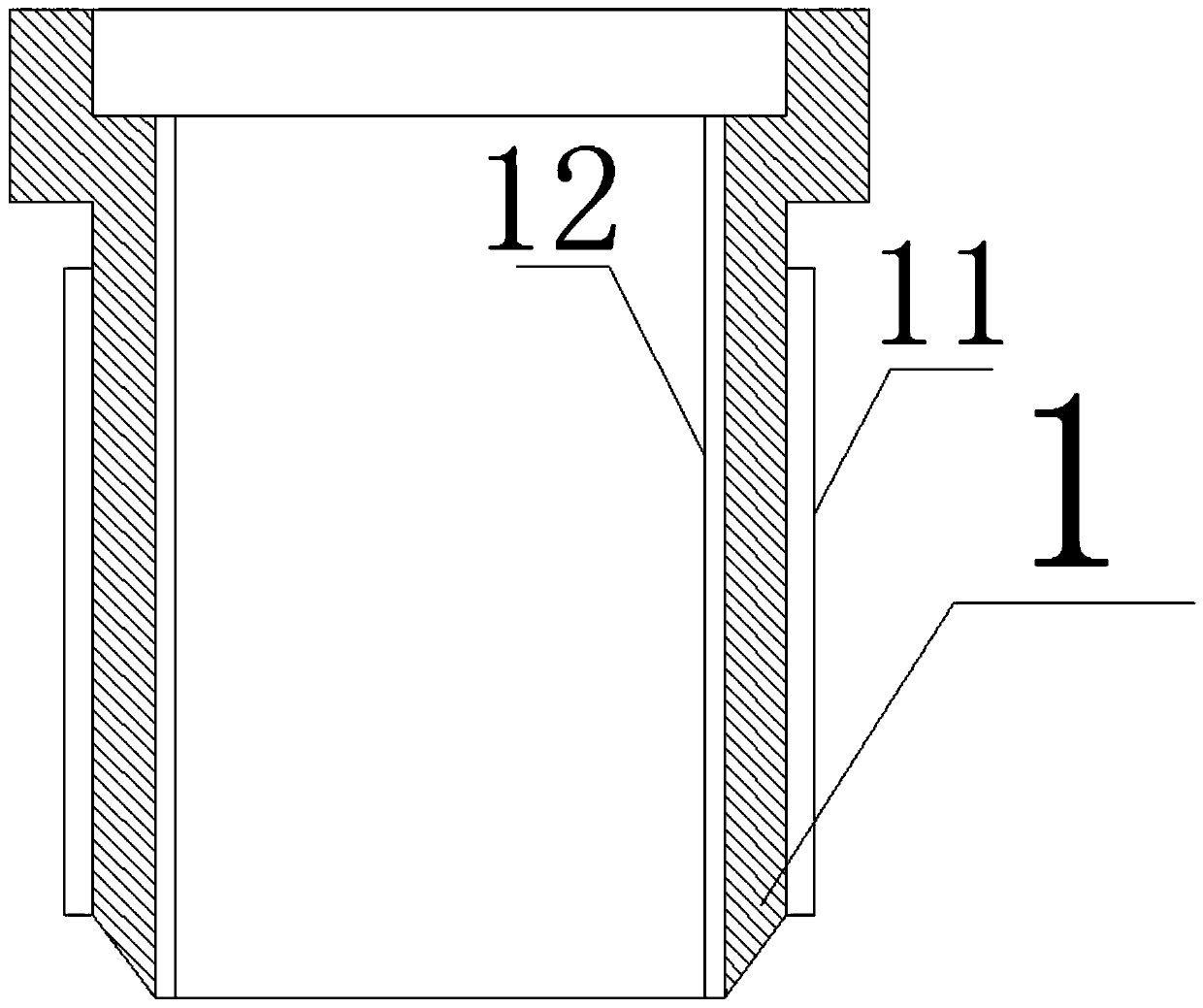

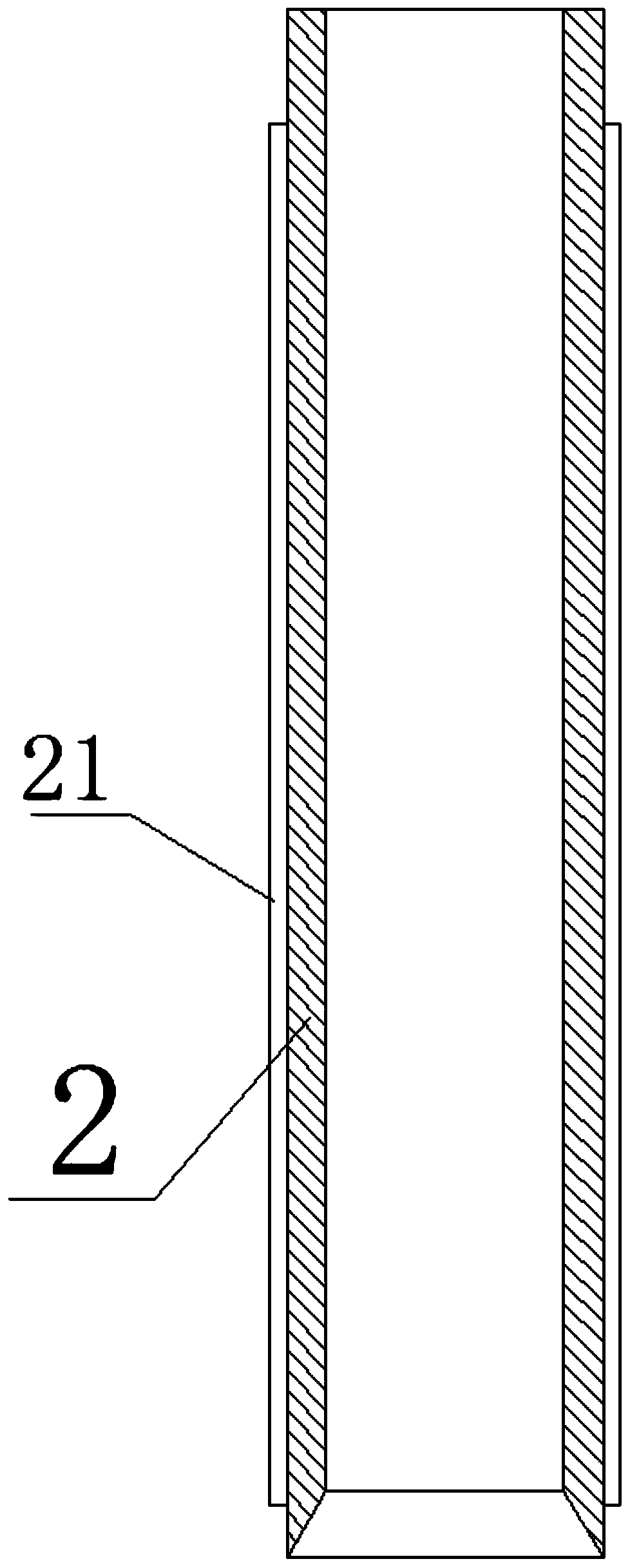

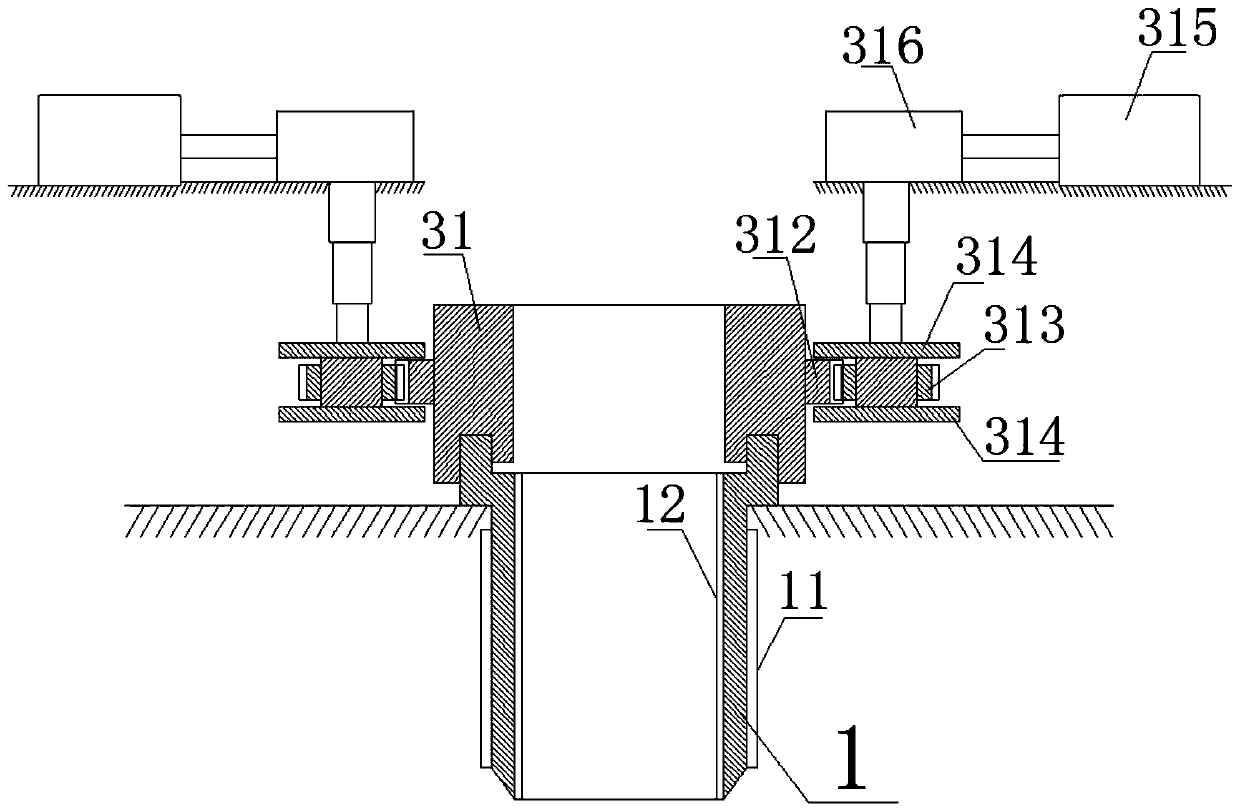

[0025] Such as Figures 1 to 4 As shown, the screw pile device for applying force on the ground includes a pile body and a force application mechanism; the pile body includes a steel outer cylinder 1 and a concrete pile body 2 with circular horizontal sections; the length of the steel outer cylinder 1 is less than the length of the concrete pile body 2; the outer circumferential surface of the steel outer cylinder 1 is provided with a first external thread 11 along its length direction, and the inner circumferential surface is provided with an internal thread 12 along its length direction; the external surface of the concrete pile body 2 The peripheral surface is provided with a second external thread 21 that cooperates with the internal thread 12; the lower end surfaces of the steel outer cylinder 1 and the concrete pile body 2 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com