Patents

Literature

42results about How to "Good warmth function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions

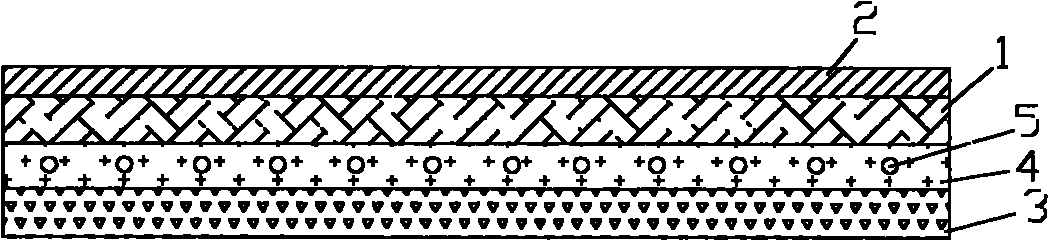

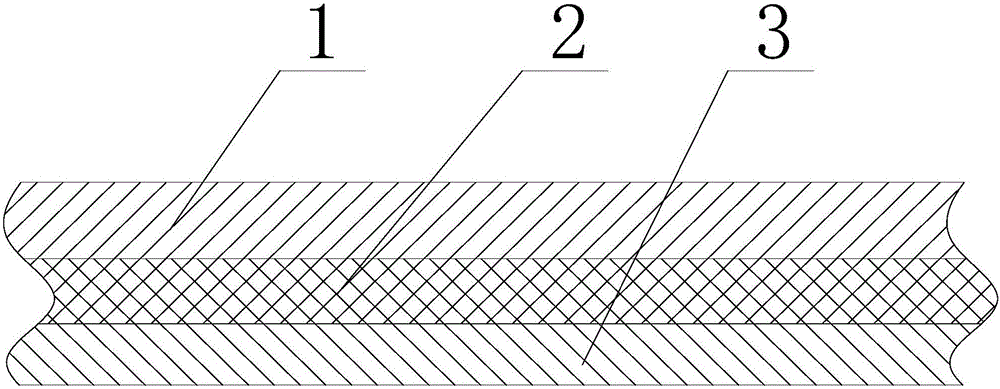

InactiveCN104413965AGood warmth functionGood warmth retentionProtective garmentSpecial outerwear garmentsFiberSurface layer

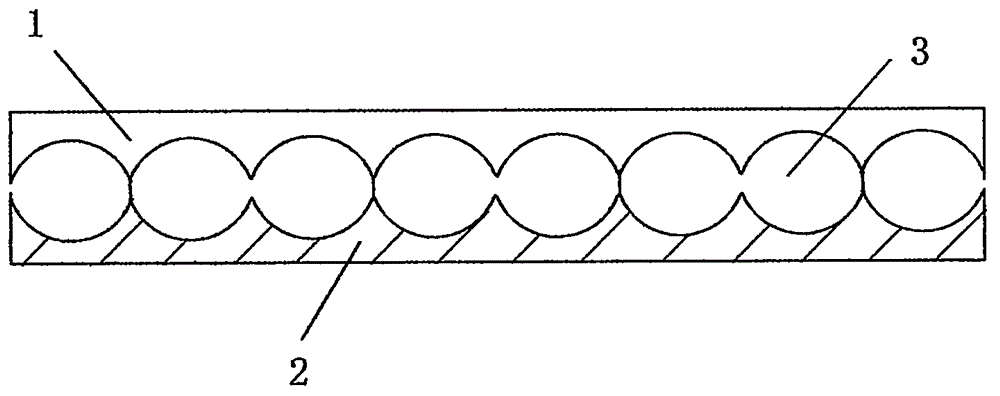

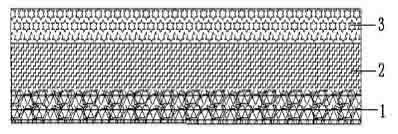

The invention discloses light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions. The light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions has a double-layer structure, the inner layer is composed of hollow far infrared warm keeping fiber, hydrophilic moisture absorbing and perspiring fiber and cotton or viscose in a blending mode, and the inner layer has warm keeping, moisture guiding and perspiring functions; the surface layer is composed of elastic fiber and cotton or viscose in a blending mode, and the surface layer has durable elasticity and moisture absorbing and quick drying functions; a regular air heat insulation cavity is formed between the surface layer and inner layer after being connected, and the heat storage and warm keeping performances are reinforced. The fabric is light and thin and has warm keeping, moisture guiding and quick drying effects, durable size stability and good hand feel; the light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions is especially suitable for underwear, warm clothing and the like.

Owner:毛志富

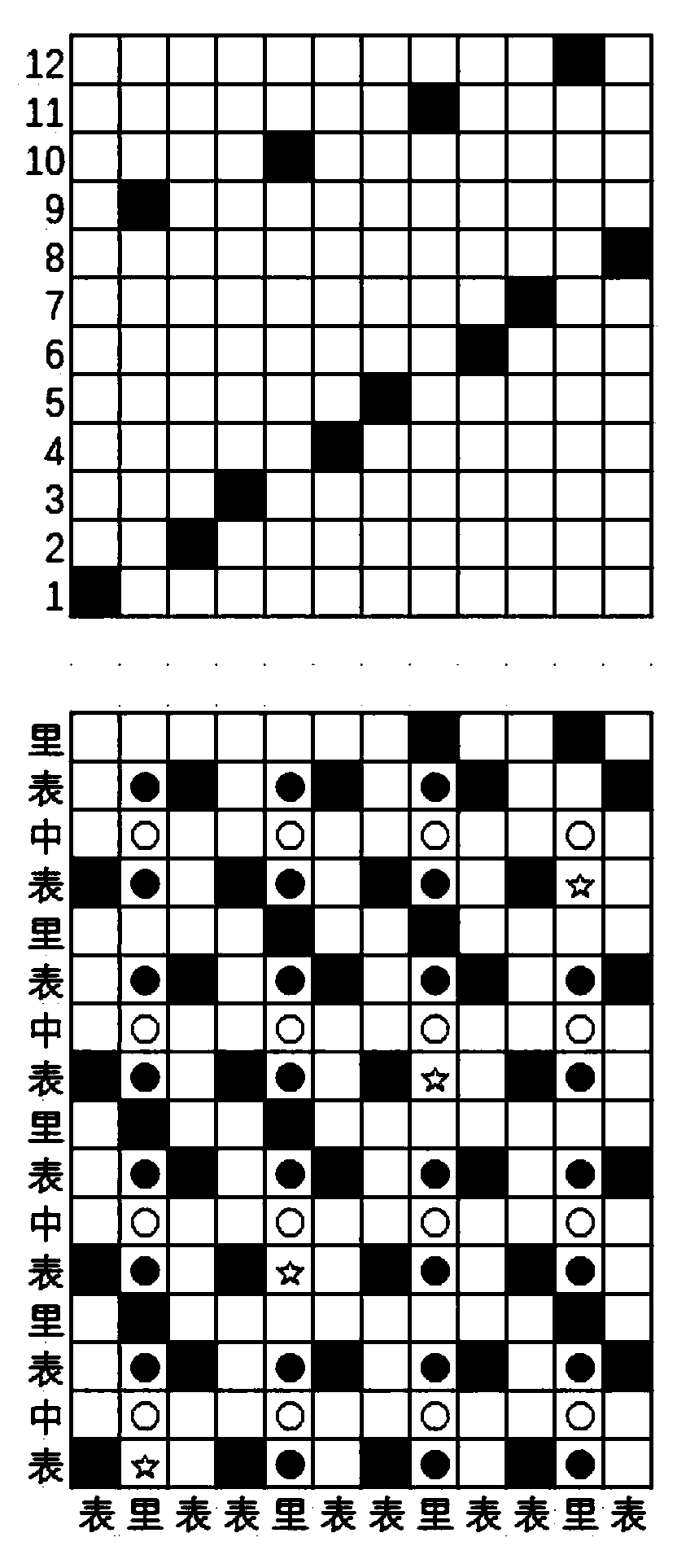

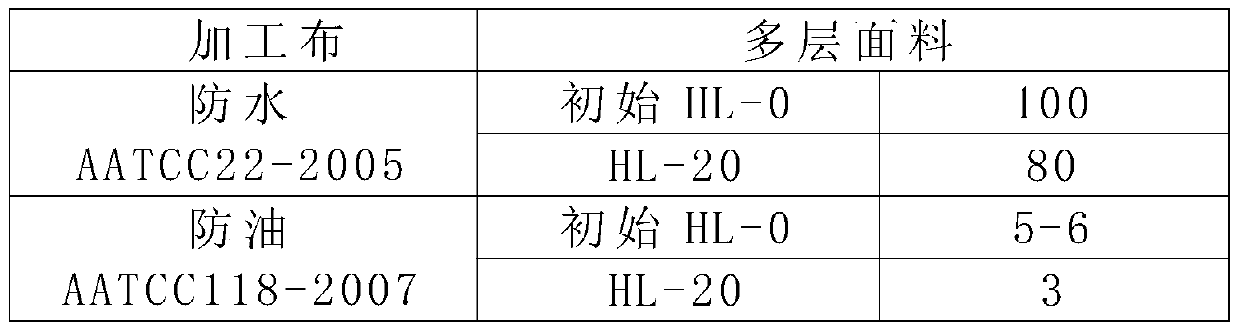

Design method and production process of double-layer quick-drying three-proofing fabric

The invention discloses a design method and a production process of double-layer quick-drying three-proofing fabric. Quick-drying fiber is selected as the inner layer of the fabric, and warm-keeping fiber is selected as the outer layer of the fabric, so that the fabric has excellent moisture permeation and warm keeping functions; in order to improve comfort of the fabric, modal and coolmax blendedyarn is used in the inner layer; after three-proofing finishing, the quick-drying performance of the fabric is slightly reduced, but water-proof, oil-proof and anti-fouling functions are greatly enhanced. The produced double-layer quick-drying three-proofing fabric is most suitable for infant clothing, infants are lively and active and can produce a lot of sweat during playing, the fabric can quickly absorb sweat produced by the human body, keep the human body dry and clean, when infants have rests quietly, the fabric has the excellent warm keeping function and can effectively prevent loss ofheat of the human body and protect infants against wind cold attack, after three-proofing treatment, clothing is easy to wash clean, and the fabric is excellent functional fabric.

Owner:IANGSU COLLEGE OF ENG & TECH

Warm underwear fabric

InactiveCN102845843AGood warmth retentionIncreased durabilityUndergarmentsProtective garmentFiberHuman body

The invention discloses warm underwear fabric which is formed by blending, by weight percent, 55-65% of cotton fiber, 20-30% of soybean fiber, and 15-20% of composite seaweed carbon fiber. The composite seaweed carbon fiber comprises, by weight, 60-75 parts of seaweed carbon fiber, 10-15 parts of titanium dioxide, 10-20 parts of magnesium oxide, 10-15 parts of medical stone, and 2-5 parts of zinc oxide. The warm underwear fabric is highly skin-friendly, has various amino acids necessary to human bodies and has fine health functions. The composite seaweed carbon fiber has the function of absorbing far infrared which functions in well preserving warmth, enhancing cell energy, enhancing cell function and activity and the like. The warm underwear fabric can be made into various warm undergarments and underpants which are fine in warmth retention and highly durable and are still fine in warmth retention after multiple wash.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

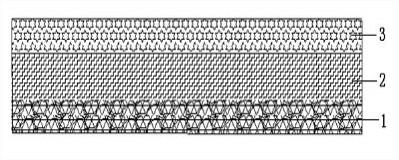

Method for manufacturing warm-keeping warp lace fabric

ActiveCN106367823AAchieve preparationAchieve recyclingOrnamental textile articlesHollow filament manufactureFiberHollow fibre

The invention relates to a method for manufacturing a warm-keeping warp lace fabric. The fabric has a three-layer structure including a surface layer, a warm-keeping layer and a hollow fiber bottom layer, wherein the surface layer is made of conventional polyester fibers, the warm-keeping layer is made of warm-keeping fibers, and the hollow fiber bottom layer is made of hollow polyester fibers having a hollowness degree of 30 percent. According to the manufacturing method, the warm-keeping fibers, the conventional polyester fibers and the hollow polyester fibers serving as raw materials are subjected to a three-dimensional warp lace process, wherein the warm-keeping fibers and the conventional polyester fibers are subjected to warp interlacing to connect the surface layer and the warm-keeping layer; and the warm-keeping fibers and the hollow polyester fibers are subjected to warp interlacing to connect the hollow fiber layer and the warm-keeping layer. Due to the design of three-dimensional warp lacing layers, the fibers having a hollow structure are used as the raw material to improve the warm-keeping structure of the fabric, and the warm-keeping fibers with a far infrared absorption function are used as an intermediate warm-keeping layer to prepare the warm-keeping warp lace fabric by the three-dimensional warp lace structure. The warm-keeping warp lace fabric has excellent warm-keeping effect and structure strength.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Woolen sweater

InactiveCN102845849ADoes not generate static electricityHigh affinityGarmentsArtifical filament manufactureFiberHuman body

The invention discloses a woolen sweater. The woolen sweater is manufactured by blending the following components in parts by weight: 60-70 parts of wool, 5-10 parts of cashmere, 10-20 parts of artificial cotton, 10-20 parts of soybean protein fiber and 5-10 parts of composite seaweed carbon fibers. The woolen sweater is manufactured by blending the soybean protein fibers and the composite seaweed carbon fibers, is of friendliness with the skin of a human body, contains various amino acids required by the human body, and has excellent healthcare functions; and the composite seaweed carbon fiber has a function of absorbing far infrared ray, and the far infrared ray not only has an excellent heating function, but also can activate cells to discharge old or dead cells or to apply regeneration capability to old or dead cells so as to be capable of reinforcing energy of the cells, functions of the cells, activities of the cells and the like. The woolen sweater disclosed by the invention utilizes the artificial cotton so as to be smooth relative to fluffs and to be unlikely to pill, and the artificial cotton has excellent heat and electricity conductivity and does not generate static electricity so that the whole woolen sweater is unlikely to generate static electricity.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

Fabric of body shaping thermal underwear

InactiveCN102851840AIncrease elasticityFull display of linesWoven fabricsProtective garmentFiberBody shape

The invention discloses a fabric of a body shaping thermal underwear. The fabric comprises wraps and wefts, wherein the cross sections of both the wraps and wefts are in the shape of reversed I; the warps and the wefts are high-elastic fibers; and hollow fibers and composite seaweed carbon fibers are hybrid to be woven on the wraps and the wefts based on the ratio of 1: 1 to 3; and wearable layers are sewed inside the wraps and the wefts. According to the fabric of the body shaping thermal underwear provided by the invention, the warps and the wefts are high-elastic fibers so that the fabric has relatively high elasticity, and the line of the body can be fully shown, and the stretching amplitude of the body in moving can be greatly improved; the hollow fibers have higher function of water absorbing, which are beneficial for draining sweat on the skin, and the purpose of weighting losing is achieved; the composite seaweed carbon fibers have an excellent thermal function by which the cells can be activated, and the functions and activities of the cells can be improved.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

Manufacturing method of machine washable western-style clothes and western-style clothes surface fabric

InactiveCN103431558AEasy to cleanWash thoroughlySynthetic resin layered productsAnimal fibresYarnBreaking strength

The invention discloses a piece of machine washable western-style clothes. The piece of the machine washable western-style clothes comprises a surface layer, a middle layer and an inner layer, wherein the middle layer is used for connecting the surface layer with the inner layer, the middle layer is woven through middle layer yarns, the inner layer is woven through inner layer yarns, a plurality of holes are formed in the inner layer and in the middle layer, and a fabric of the surface layer comprises, by weight, 40-60% of Australian wool, 20-30% of Thermolite hollow fabric, 20-30% of aramid fiber and 0.5-1% of aramid-base conductive fiber. The invention further discloses a manufacturing method of the fabric of the surface layer of the piece of the machine washable western-style clothes. The piece of the machine washable western-style clothes can be conveniently and thoroughly washed, and is good in air permeability and comfortable to wear. On the other hand, the surface layer of the piece of the machine washable western-style clothes is woven through multiple kinds of fabrics in a blended mode, the fabric has a good warm-keeping function and an anti-static function and is strong in breaking strength and tearing strength. Besides, after being post-processed, the fabric has good anti-microbial and deodorizing functions, and has excellent waterproof, oil-repellent and dirt-resistant functions.

Owner:JIANGSU AOYANG TEXTILE IND

Wind-shield warm garment

InactiveCN102871232AHigh affinityIncrease health functionLayered productsOvergarmentsSoybean ProteinsCell function

The invention discloses a wind-shield warm garment which comprises an outer layer and an inner layer. The outer layer is composed of base cloth and fluff. The fluff is distributed on upper and lower surfaces of the base cloth. The fluff on the lower surface of the base cloth is connected with the inner layer. The inner layer is made of warm fabric made by blending, by weight percent, 55-65% of cotton fiber, 20-30% of soybean protein fiber, and 15-20% of composite carbon fiber. The fluff on the wind-shield warm garment is upright on the gauze, the fine effect of upright pile is generated, and fine wind-shielding performance is achieved. The fluff on the lower surface of the base cloth is woven together with the inner layer, so that warmth retention for bodies is achieved. The inner layer is made of the composite seaweed carbon fiber, is well skin-friendly and has functions of health caring, warmth retaining, cell energy enhancing, cell function and activity enhancing, and the like.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

Production method of warming shirts

The invention discloses a production method of warming shirts. The production method comprises the following steps of: carrying out liquid ammonia treatment on full-cotton spinning fabrics, carrying out pre-shirking treatment on the fabrics by a pre-shrinking machine, padding the fabrics in impregnation liquid containing a warming finishing agent, carrying out drying, tailoring and clothes making on the treated fabrics, and carrying out pressing shaping on the fabrics by a drying shaping machine, wherein the warming finishing agent comprises the following components in parts by weight: 60-75 parts of seaweed carbon fibers, 10-15 parts of titanium dioxide, 10-20 parts of magnesium oxide, 10-15 parts of medical stones, 2-5 parts of zinc oxide, 2-5 parts of silane coupling agents and 0.5-1.0 part of sodium polyacrylate dispersing agent, and water is added in the warming finishing agent to prepare the impregnation liquid with the mass ratio of 15%-40%. The warming shirt disclosed by the invention has an excellent warming function, has the effects of enhancing cell energy, enhancing functions and activity of cells and the like, is strong in durability, and can still maintain original performance basically after being washed for multiple times.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

Method for producing clothing fabric with waterproof, breathable and health-care functions

InactiveCN103469583AWaterproofLittle impact on weightSynthetic fibresCarbon fibresElastomerCarbon fibers

The invention discloses a method for producing a clothing fabric with waterproof, breathable and health-care functions. The method comprises the following steps: performing rotary screen printing and waterproof finish on one side of a fabric; applying a hydrophobic agent on one side of the fabric, wherein the hydrophobic agent comprises the following components: 80-100 g / kg of polyether ester elastomer, 20-30 g / kg of stearic acid propylene glycol ester, 5-10 g / kg of dimethyl hydrogen-contained polysiloxane, and 1-3 g / kg of an aluminum zirconic acid ester coupling agent; performing hydrophilic finish on the other side of the fabric by using a padding method, wherein the fabric is prepared from the following components in percentage by weight in a blending manner: 80-85% of synthetic fiber and 15-20% of compound seaweed carbon fiber, and the compound seaweed carbon fiber comprises the following components in parts by weight: 60-75 parts of seaweed carbon fiber, 15-20 parts of aluminum oxide, 5-15 parts of zirconia, 5-10 parts of tourmaline and 2-5 parts of glass beads. The clothing fabric has waterproof, breathable and excellent health-care and warm-keeping functions, and can be improved in flexibility.

Owner:KUNSHAN TIENIU SHIRT FACTORY

Design method and weaving process of three-layer warmth-keeping fabric

ActiveCN109898211AIncrease warmthIncrease contentMulti-ply fabricsRougheningEngineeringAcrylic fibre

The invention discloses a design method and weaving process of a three-layer warmth-keeping fabric. The produced woven three-layer warmth-keeping fabric is in a three-layer structure including an inner layer, a middle layer and an outer layer, wherein the inner layer is woven from moisture absorbing thermal fiber and can avoid cold and wet feeling and achieve high comfort when being worn; the middle layer is a thermal insulating layer woven from hollow acrylic fiber and accordingly is soft and light and can bring convenience to limb movement; the outer layer is interwoven from Tencel fiber andpolyester fiber and is tidy, attractive in appearance and high in durability; the three layers are connected in a bottom-to-top jointed manner, jointed textures can form mountain-like patterns on thesurface layer, and through processes such as napping as well as an appropriate fiber blending ratio, the warmth-keeping performance of the three-layer warmth-keeping fabric can be further enhanced.

Owner:IANGSU COLLEGE OF ENG & TECH

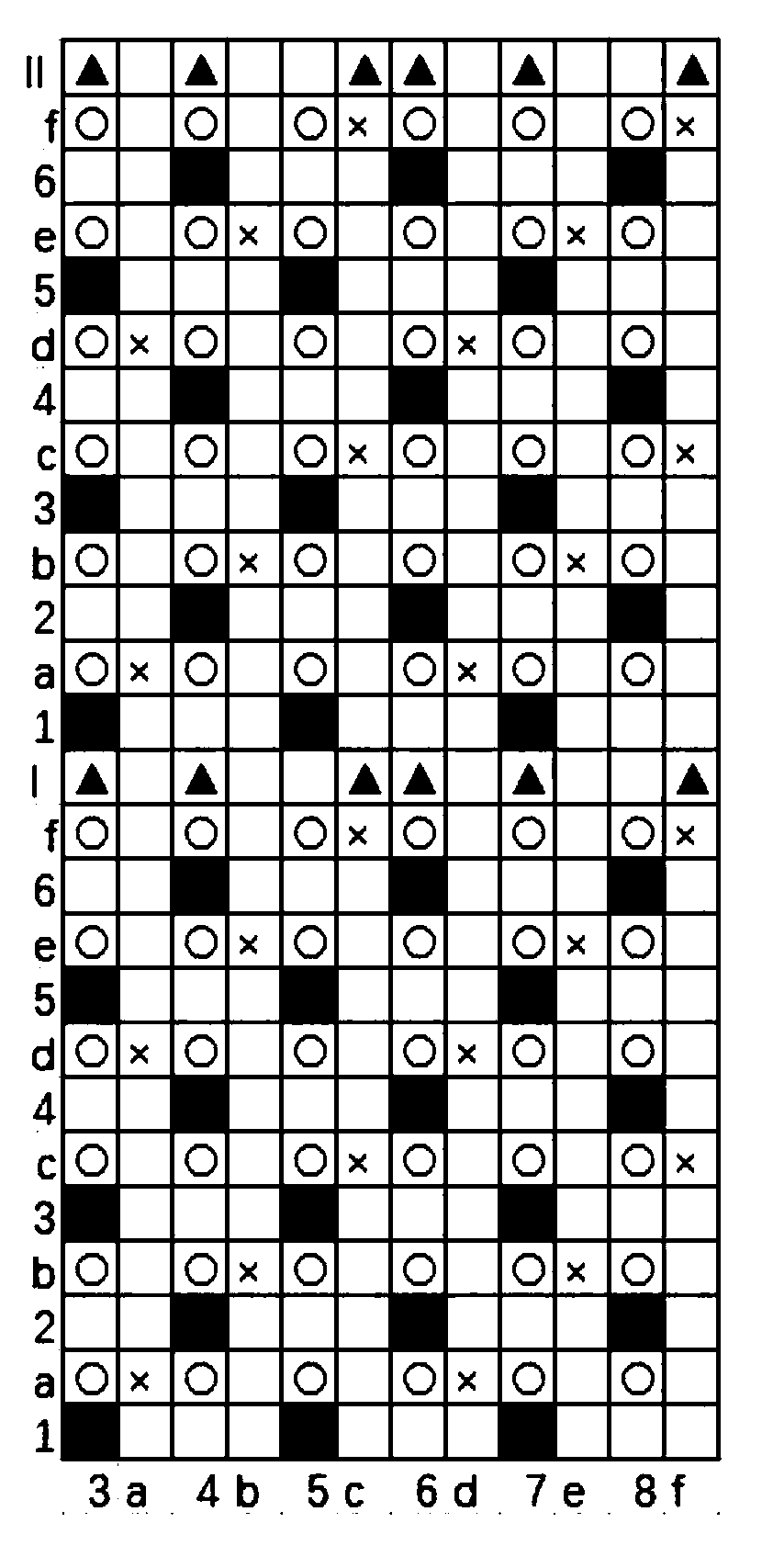

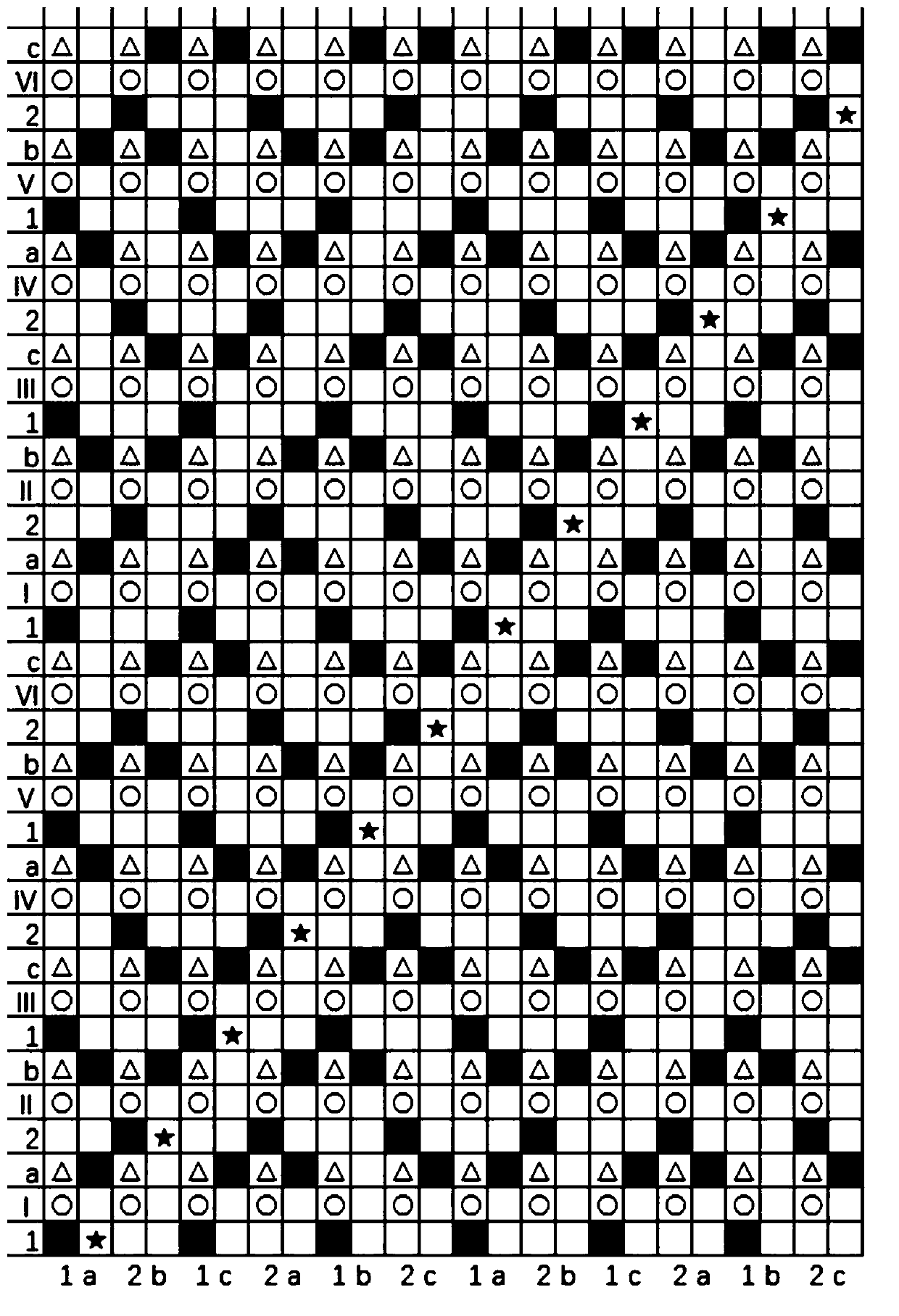

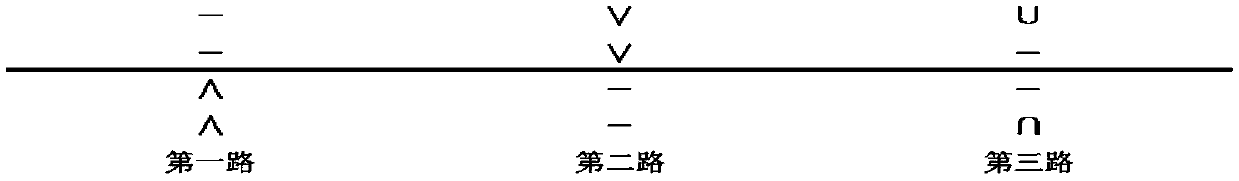

Weaving method of water-absorbing quick-drying heat-preserving suede fabric

The invention discloses a weaving method of a water-absorbing quick-drying heat-preserving suede fabric. The method comprises the steps that a two-faced machine is provided to arrange cams and knitting needles according to requirements; yarns are provided, wherein the yarns comprise sea-island draw textured yarns, polyester fiber draw textured yarns and polyurethane fiber yarns; weaving procedurescomprise the steps that weaving is conducted in a manner that weaving repeating is conducted in three rows: in a first row, the sea-island draw textured yarns are adopted, and the inner layer of a polyurethane fiber weaving fabric is lined with the sea-island draw textured yarns; in a second row, the polyester fiber draw textured yarns are adopted, and the outer layer of the polyurethane fiber weaving fabric is lined with the polyester fiber draw textured yarns to form a weft plain structure at the outer layer; in a third row, the polyester fiber draw textured yarns are connecting yarns and used for connecting the inner layer and outer layer of the fabric. According to the method, the woven fabric has a better heat preservation function, and damp-heat balance of a human body can be effectively controlled.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

Anti-static thermal insulation fabric

The invention relates to an anti-static thermal insulation fabric, comprising basic cloth wove by warp and weft, wherein the basic cloth is provided with an anti-static layer. The inner surface of the basic cloth is provided with a thermal insulation layer. An activated carbon adsorbing layer is arranged between the basic cloth and the thermal insulation layer, mints are added into the inside of the activated carbon adsorbing layer, the anti-static layer is anti-static wires, and the thermal insulation layer is thermal insulation cotton. The invention integrates advantages of simpleness and convenience for manufacture, low cost, favorable antistatic function, and thermal insulation. The anti-static thermal insulation fabric has environmental protection function of resisting bacteria and deodorizing, which can prevent bacteria and fungi from multiplying, eliminate smell and efficiently protect skins of human bodies from being damaged by harmful substances.

Owner:WUJIANG FEIXIANG WARP KNITTING TEXTILE

Heat insulation wind coat

InactiveCN103462245AGood warmth retentionIncreased durabilityOvergarmentsProtective garmentCarbon fibersEngineering

The invention discloses a heat insulation wind coat, which comprises an inner layer and an outer layer, wherein the inner layer is knitted by adopting mercerizing cloth in a mixed way, the outer layer is knitted by cotton and hemp in a mixed way, a heat insulation sandwich layer is arranged between the inner layer and the outer layer, and is made of far infrared heat insulation plus materials, the inner layer, the outer layer and the sandwich layer are closed by adopting zippers, the far infrared heat insulation plus materials are blended by 80 to 85 mass percent of synthetic fiber and 15 to 20 mass percent of composite seaweed carbon fiber, and the composite seaweed carbon fiber comprises the following ingredients in parts by weight: 60 to 75 parts of seaweed carbon fiber, 15 to 20 parts of aluminum oxide, 5 to 15 parts of zirconium oxide, 5 to 10 parts of tourmaline and 2 to 5 parts of glass micro beads. The heat insulation wind coat has good heat insulation functions, and also has the effects of activating cells, enhancing the cell energy, enhancing the cell functions and vitality and the like. In addition, the durability is high, and good heat insulation performance can still be realized after washing for many times.

Owner:KUNSHAN TIENIU SHIRT FACTORY

Soft light thin and breathable pure cotton linter fabric

PendingCN111270391AReduce stiffnessQuality improvementSucessive textile treatmentsWeft knittingPolymer scienceSpinning

The present invention provides a soft light thin and breathable pure cotton linter fabric, and relates to the technical field of fabric preparation. The soft light thin and breathable pure cotton linter fabric is formed by weaving 40s combed cotton, 20D lycra spandex and 40s siro spinning yarns. The fabric is prepared by the following steps of S1, weaving, wherein the 40s combed cotton, the 20D lycra spandex and the 40s siro spinning yarns are prepared, and a circular knitting machine is used to perform weaving forming; S2, pretreatment, wherein a woven fabric in the step 1 is put into a treatment tank, a softening agent is added into the treatment tank and the fabric is soaked for a period of time; and S3, bleaching, wherein the pretreated fabric is put into bleaching liquid for bleachingtreatment. Compared with an existing warm-keeping garment, the pure cotton linter fabric has high strength, soft hand feeling, relatively good sweat-absorbing property and air permeability and excellent comfort, has a relatively good warm-keeping function, and can make the human body sensing temperature rise, so that all the performances of the pure cotton linter fabric are obviously improved andthe production process is also obviously optimized.

Owner:无锡红博供应链管理有限公司

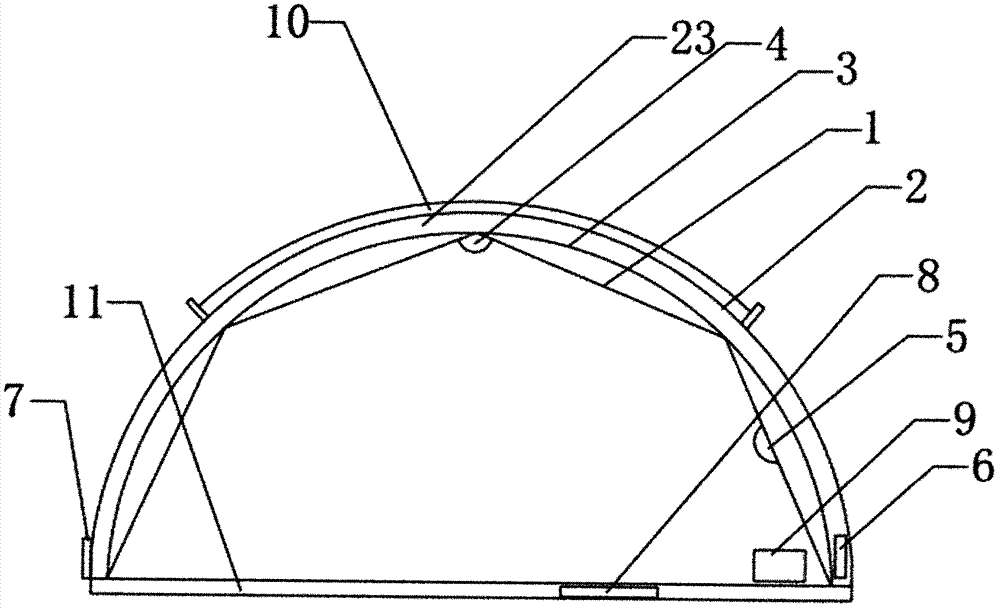

Field tent with alarm function

The invention discloses a field tent with an alarm function, which comprises a solar electric panel, a tent cloth, a tent frame and a tent mattress, an LED light is provided on the top of the tent frame, a power supply is provided inside the tent, and an infrared lamp is provided on the outer surface of the tent cloth. sensors and photosensitive sensors, a microprocessor is also arranged in the tent cloth, and an alarm is arranged on the tent frame, and the infrared sensor and the photosensitive sensor are respectively connected with the input terminals of the microprocessor, and the alarm and the LED light are connected with the microprocessor. The output terminal is connected, and the power supply supplies power to each component. The tent senses approaching objects and sounds an alarm to let people know when an object is approaching; the tent is made of double layers for warmth and protection from rain.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

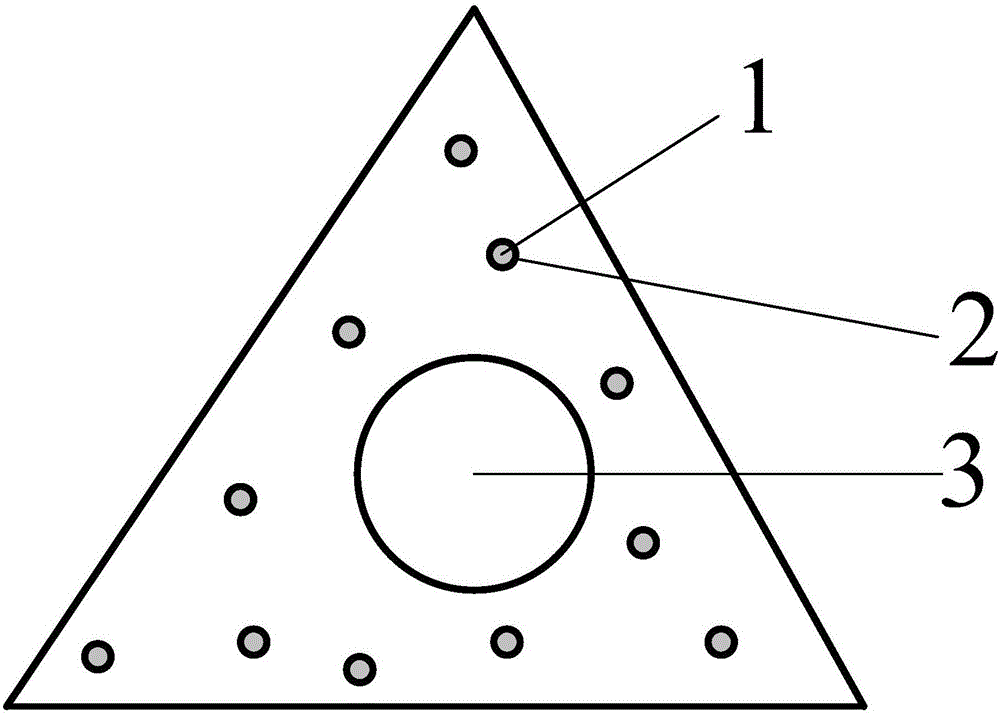

A printed upper

InactiveCN102283470AReasonable structural designGood warmth functionUpperBootlegsTextile printerEngineering

The invention discloses a printed shoe upper, which comprises a cotton fabric layer (1), a bamboo charcoal fiber layer (2) sewn on the cotton fabric layer (1), and leather shoes bonded to the bamboo charcoal fiber layer (2). surface (3), and its printed film (4) adhered to the leather upper (3). The printed vamp provided by the invention has a reasonable structural design, a printing effect, good aesthetics, good sweat-absorbing and deodorizing functions, can meet the requirements of high-standard vamps, and has a wide range of applications.

Owner:SUZHOU CHAOSHENG PRINTING & PLATEMAKING IND

Woolen sweater fabric

InactiveCN106617416ADoes not generate static electricityHigh affinityProtective garmentSpecial outerwear garmentsYarnFiber

The invention discloses a woolen sweater fabric. The formula of the fabric consists of the following components: wool, cashmere, artificial cotton, soybean protein fibers, algae carbon fibers, nylon, silk yarns and modal fibers. The woolen sweater fabric, which is prepared in accordance with the formula and is woven by blending the soybean protein fibers and the composite algae carbon fibers, is skin-friendly to human body; in addition, the fabric, which contains various amino acids required by human body, has a good health care function; the composite algae carbon fibers have a function of absorbing far infrared ray, and the far infrared ray not only has an excellent warm-keeping function but also is capable of activating cells, so that the excretion of old and dead cells is promoted or a regenerating capacity is guaranteed, the quantity of cells is increased and effects of enhancing function, activity and the like of the cells are achieved. The fabric, which adopts the artificial cotton, is smoother than nap and the fabric is not easy for piling; and the artificial cotton is good in heat conductivity and electrical conductivity and is free from the generation of static electricity, so that the entire woolen sweater cannot cause the static electricity easily.

Owner:RUGAO LIFU WEAVING CO LTD

Windproof thermal clothes

The invention discloses windproof thermal clothes, comprising an external layer and an internal layer, wherein the external layer consists of a backer and piles which are distributed on the upper surface and the lower surface of the backer; the piles on the lower surface of the backer are connected with the internal layer; the internal layer is thermal fabric and is formed by blending 80-85 percent by mass of synthetic fiber and 15 to 20 percent by mass of composite alga carbon fiber; the composite alga carbon fiber comprises the following components, i.e. 60 to 75 parts by weight of alga carbon fiber, 15 to 20 parts by weight of aluminum oxide, 5 to 15 parts by weight of zirconium oxide, 5 to 10 parts by weight of tourmaline and 2 to 5 parts by weight of glass beads. According to the windproof thermal clothes provided by the invention, as the piles are erected upright on gauze, a good upright pile effect is generated; therefore, a good windproof performance is realized; the piles on the lower surface of the backer are woven together with the internal layer, so that a human body is kept warm; since the internal layer adopts the composite alga carbon fiber, not only is a good heat preservation function provided, but also the purposes of enhancing cell energy, enhancing cell function and vitality and the like can be realized.

Owner:KUNSHAN TIENIU SHIRT FACTORY

A kind of manufacturing method of special-shaped hollow thermal insulation polyester low elastic yarn

ActiveCN105908269BFully calcinedFully activeHollow filament manufactureFilament/thread formingYarnFiber

Owner:福建百宏聚纤科技实业有限公司

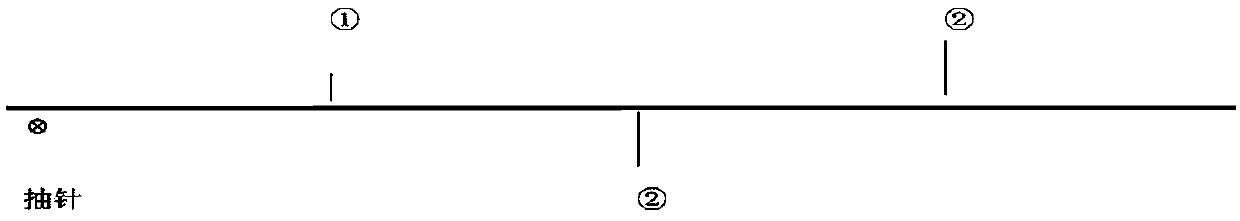

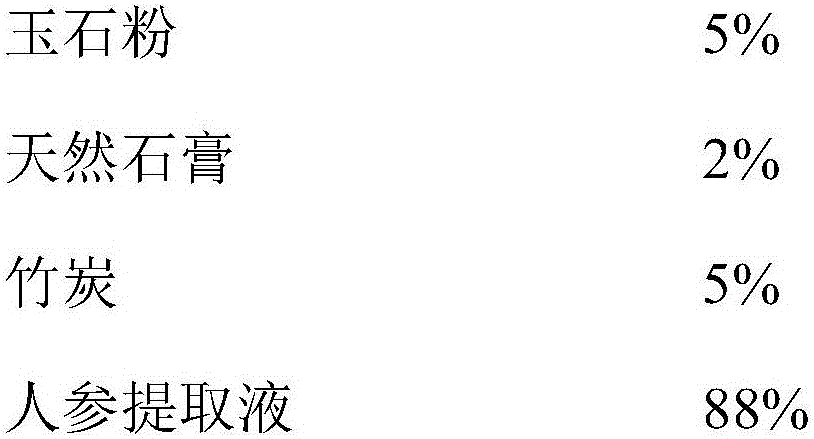

A multifunctional fabric that provides lightweight warmth and moisture wicking

InactiveCN104413965BGood warmth functionGood warmth retentionProtective garmentSpecial outerwear garmentsFiberSurface layer

The invention discloses light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions. The light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions has a double-layer structure, the inner layer is composed of hollow far infrared warm keeping fiber, hydrophilic moisture absorbing and perspiring fiber and cotton or viscose in a blending mode, and the inner layer has warm keeping, moisture guiding and perspiring functions; the surface layer is composed of elastic fiber and cotton or viscose in a blending mode, and the surface layer has durable elasticity and moisture absorbing and quick drying functions; a regular air heat insulation cavity is formed between the surface layer and inner layer after being connected, and the heat storage and warm keeping performances are reinforced. The fabric is light and thin and has warm keeping, moisture guiding and quick drying effects, durable size stability and good hand feel; the light and thin multi-functional fabric with warm keeping, moisture absorbing and perspiring functions is especially suitable for underwear, warm clothing and the like.

Owner:毛志富

A kind of multifunctional wool worsted suit fabric

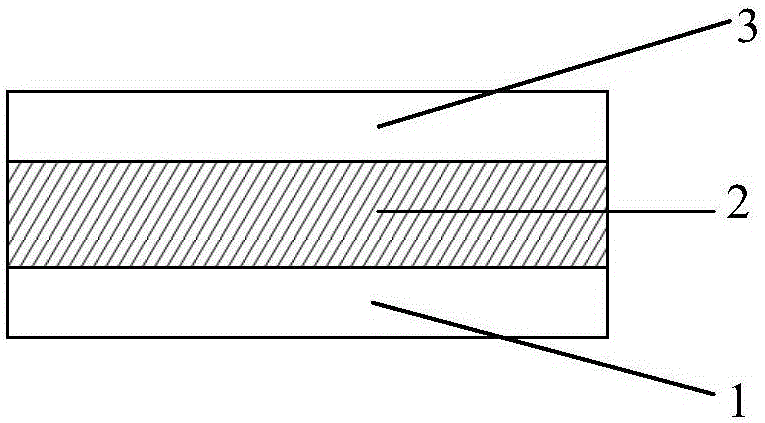

ActiveCN103431559BImprove waterproof performanceExcellent oil repellencyWoven fabricsProtective garmentHollow fibreYarn

The invention discloses a multi-functional wool worsted suit fabric, which includes a surface layer, a middle layer and an inner layer, and is characterized in that: the middle layer is used as a basis to connect the surface layer and the inner layer; the surface layer is a surface layer woven from surface yarns, The surface yarn is a surface yarn woven from aramid-based conductive fibers with a length of 20-45mm; the middle layer is a middle layer woven from a middle yarn, and the middle yarn is made of a Thermolite hollow fiber and an aromatic The inner layer is woven from the inner layer yarn, and the inner layer yarn is woven from Australian wool with a length of 50-80mm. The present invention has good warming function and antistatic effect, and super strong breaking strength and tearing strength. In addition, the present invention has good antibacterial and deodorizing functions, and has excellent waterproof, oil repelling and dirt repelling functions.

Owner:JIANGSU AOYANG TEXTILE IND

Manufacturing method for leather capable of preventing and treating tinea pedis

ActiveCN105316439AGood warmth functionGood sweat wicking abilityAntimycoticsTanning treatmentPharmaceutical SubstancesFoot ringworm

The invention relates to a manufacturing method for leather, and discloses a manufacturing method for the leather capable of preventing and treating tinea pedis. The manufacturing method comprises the following steps that a, medicine is proportioned and milled into powder for standby application; b, medicine powder is added into water to form a mixed solution, and the mixed solution is stirred intermittently; and c, an animal hide is subjected to water squeezing, and then is naturally air-dried and dried by baking in sequence. According to the manufacturing method for the leather capable of preventing and treating the tinea pedis, a wet-salted bovine hide is immerged into the medicine, and then the wet-salted bovine hide is manufactured into leather shoes or shoe pads; the sizes of the leather shoes or shoe pads cannot be increased, and the wearing comfort cannot be influenced; the medicine has a preventive effect; when the leather shoes or the shoe pads are wore by people, the tinea pedis is prevented and treated; the treatment method is simple, effective, convenient and economical; meanwhile, the medicine effect is lasting, effect starting is fast, and irritation and side-effects are avoided. Components of the medicine are easy to get, high in quality and low in cost.

Owner:QUANZHOU GONGJIN LEATHER CO LTD

Printed warm keeping cloth

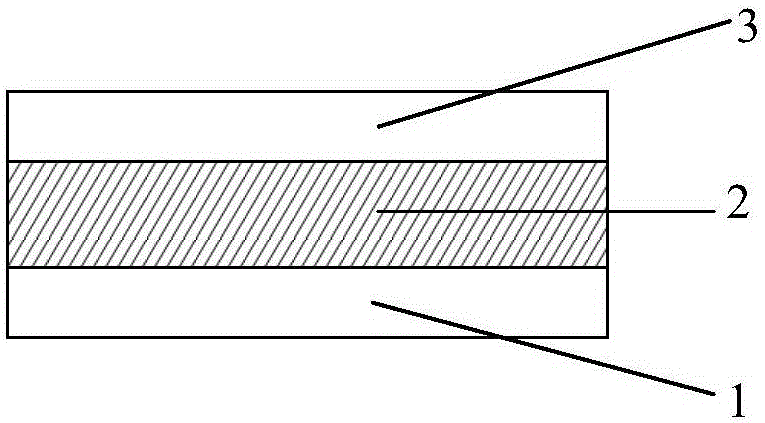

InactiveCN102416719AReasonable structural designColor adjustableDecorative surface effectsLayered productsTextile printerPolymer science

The invention discloses printed warm keeping cloth which comprises a cotton cloth layer (1), a fuzz warm keeping layer (2) sewn on the inner surface of the cotton cloth layer (1) and a coating layer (3) arranged on the outer surface of the cotton cloth layer (1) by dyeing and finishing. The printed warm keeping cloth provided by the invention has a reasonably designed structure; a coating layer (3) with different colors and patterns is printed on the outer surface of the cotton cloth layer (1) in a dyeing and finishing mode; and the printed warm keeping cloth is very beautiful, has a good warm keeping function, can meet the requirements on high-standard cloth and has a wide application range.

Owner:SUZHOU CHAOSHENG PRINTING & PLATEMAKING IND

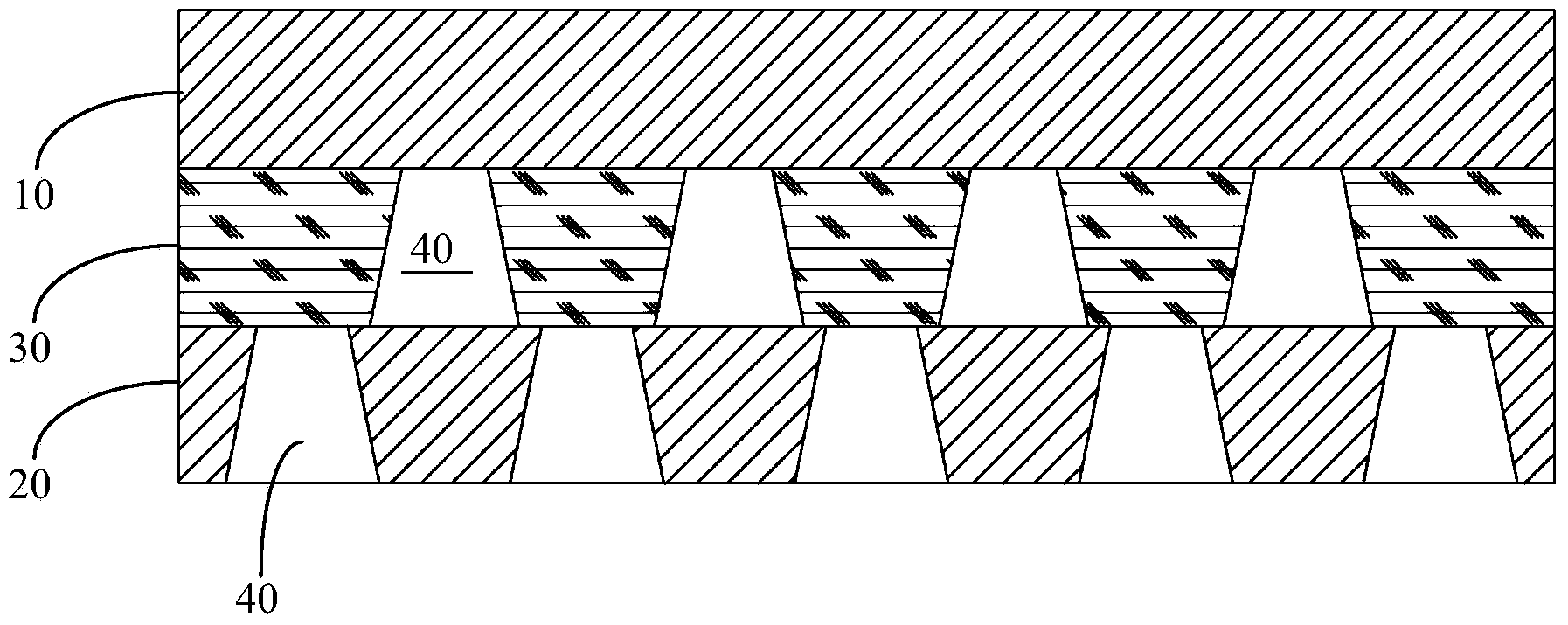

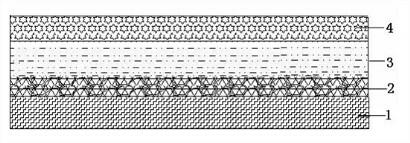

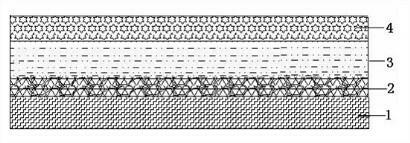

Manufacturing method of thermal warp knitted lace fabric

ActiveCN106367823BGood warmth functionGood warmth retentionOrnamental textile articlesHollow filament manufacturePolyesterHollow fibre

The invention relates to a method for manufacturing a warm-keeping warp lace fabric. The fabric has a three-layer structure including a surface layer, a warm-keeping layer and a hollow fiber bottom layer, wherein the surface layer is made of conventional polyester fibers, the warm-keeping layer is made of warm-keeping fibers, and the hollow fiber bottom layer is made of hollow polyester fibers having a hollowness degree of 30 percent. According to the manufacturing method, the warm-keeping fibers, the conventional polyester fibers and the hollow polyester fibers serving as raw materials are subjected to a three-dimensional warp lace process, wherein the warm-keeping fibers and the conventional polyester fibers are subjected to warp interlacing to connect the surface layer and the warm-keeping layer; and the warm-keeping fibers and the hollow polyester fibers are subjected to warp interlacing to connect the hollow fiber layer and the warm-keeping layer. Due to the design of three-dimensional warp lacing layers, the fibers having a hollow structure are used as the raw material to improve the warm-keeping structure of the fabric, and the warm-keeping fibers with a far infrared absorption function are used as an intermediate warm-keeping layer to prepare the warm-keeping warp lace fabric by the three-dimensional warp lace structure. The warm-keeping warp lace fabric has excellent warm-keeping effect and structure strength.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Design method and production process of multifunctional three-proofing antibacterial warm-keeping and itching-relieving fabric

InactiveCN110983560AWith health functionHas antibacterial and antipruritic propertiesArtificial filaments from viscoseMulti-ply fabricsPolyesterYarn

The invention discloses a design method and a production process of a multifunctional three-proofing antibacterial warm-keeping and itching-relieving fabric. According to the design method and the production process, a health-care function and an antibacterial and itching-relieving function are applied to a lining layer of the fabric, so that the lining fabric has health-care, itching-relieving and antibacterial functions; hollow filament fibers are used as a filling layer of the fabric, and the fabric is fluffy and soft, so that the fabric has excellent warm-keeping function; and the outer layer of the fabric adopts high-count polyester / cotton yarns, so that the fabric has excellent appearance quality. A plurality of different functional fibers are utilized, and through combination, warm-keeping and health-care antibacterial itching-relieving functional fabric integrating multiple functions can be developed.

Owner:NEWSEGA TEXTILE NANTONG CO LTD

Anti-static warming fabric

InactiveCN109203613AEasy to manufactureGood antistatic functionSynthetic resin layered productsClothingsPolyesterFiber

The invention discloses an anti-static warming fabric which comprises a woven layer, a natural rubber layer and a heat insulating layer. The woven layer is located on the outer layer, the natural rubber layer is connected between the woven layer and the heat insulating layer, and the woven layer is an interwoven layer of polyester, nylon, antistatic fiber and bamboo fiber, and the antistatic fiberis carbon fiber. The anti-static warming fabric has the following advantages: the fabric is simple in manufacture, integrates good anti-static and warm-keeping functions, has an environmental protection function of inhibiting bacteria and deodorizing, can prevent the proliferation of bacteria and fungi, and eliminate odor, and effectively protects the human body from harmful substances to the skin. Through combination of the bamboo fiber and the carbon fiber, the anti-static warming fabric can provide outstanding antistatic antibacterial and health care properties, and has good gas permeability.

Owner:东莞市虎门服装创新服务中心有限公司 +2

Wool keratin/water-based polyurethane composite emulsion coating agent with warming function and preparation method thereof

ActiveCN110685170BGood warmth functionImprove performanceTextiles and paperPolymer scienceThermal insulation

The invention relates to a wool keratin / water-based polyurethane composite emulsion coating agent with a function of keeping warm and a preparation method thereof. The coating agent can be prepared by the following preparation method: use waste wool as raw material, extract wool keratin therefrom; then prepare keratin into O / W type wool keratin emulsion; prepare aqueous polyurethane emulsion, and extract wool keratin emulsion It is compounded and mixed with water-based polyurethane emulsion to prepare a wool keratin / water-based polyurethane composite emulsion coating agent with a function of keeping warm. After the wool keratin / water-based polyurethane composite emulsion coating agent prepared by the invention is used for the coating and finishing of cotton fabrics, the heat retention rate of the cotton fabrics rises from 24.7% to over 66%, indicating that the coating agent has a good heat preservation function. The preparation process of the invention is simple, the production process has no pollution to the environment, and is beneficial to further popularization and application.

Owner:WUHAN TEXTILE UNIV

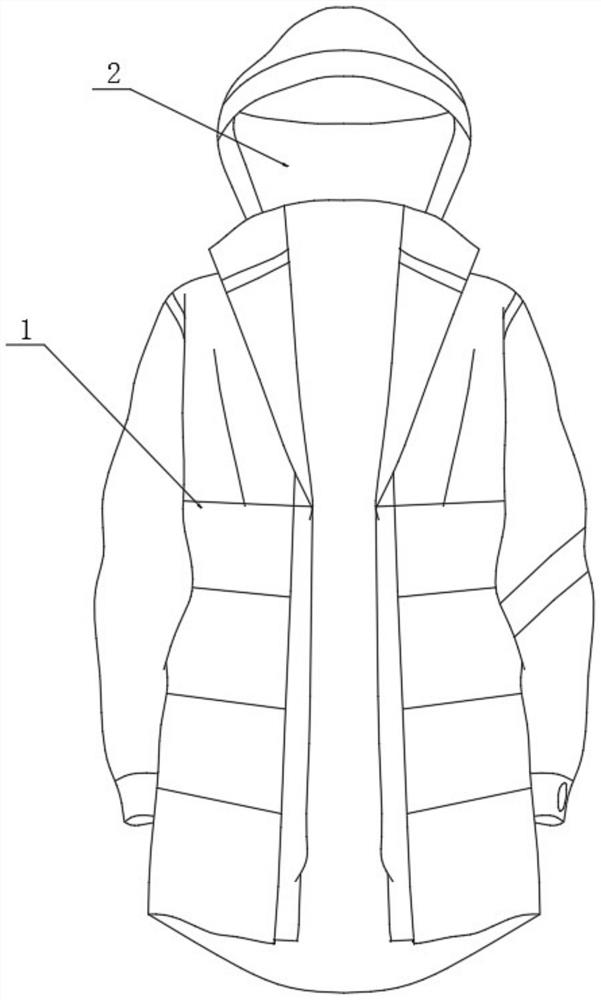

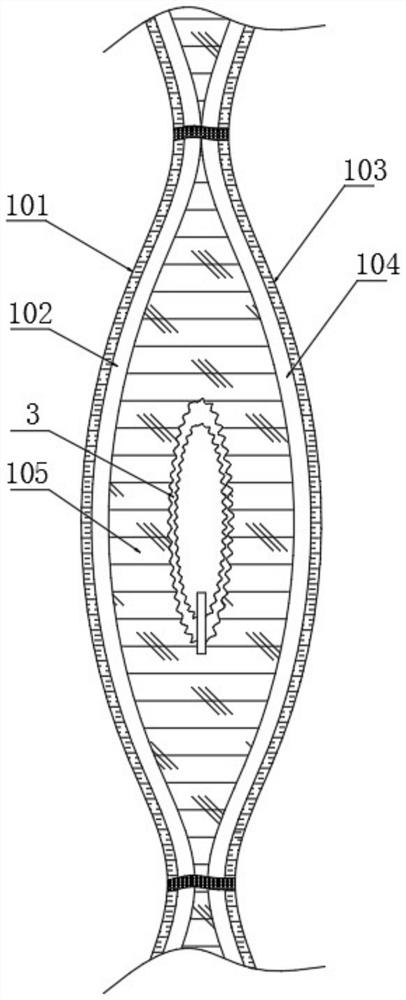

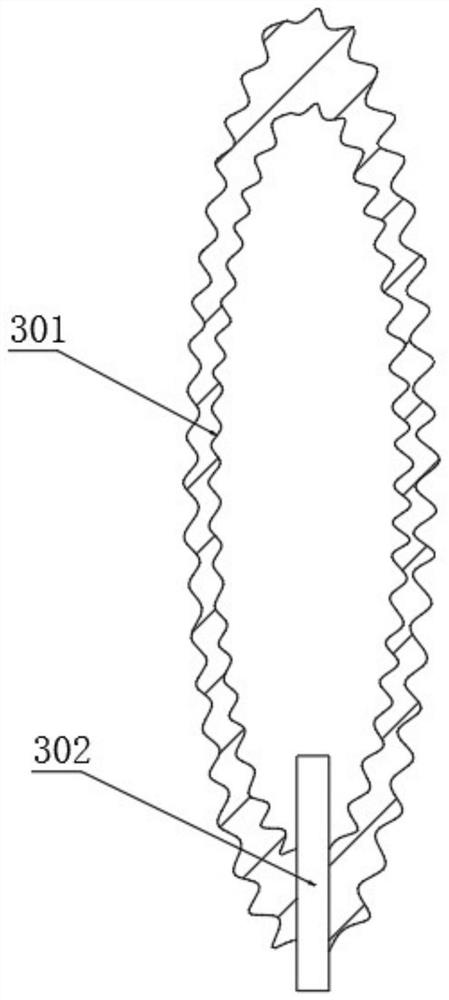

Dual-purpose convenient down jacket and processing technology

InactiveCN111955809AImprove securityWith waterproof functionLife-savingOvergarmentsEngineeringMechanical engineering

The invention relates to a dual-purpose convenient down jacket and a processing technology. The down jacket comprises a down jacket main body and a down jacket cap body detachably connected to the down jacket main body, wherein the down jacket body comprises an outer surface layer, a waterproof breathable layer attached to the inner surface of the outer surface layer, an inner surface layer, a breathable layer attached to the inner surface of the inner surface layer, down feathers arranged between the breathable layer and the waterproof breathable layer and a plurality of protection mechanisms, wherein the down feathers are evenly distributed on the peripheries of the protection mechanisms; and the protection mechanism comprises an air bag and an inductor connected to the air bag, one endof the inductor is located in the air bag, and the other end of the inductor is located outside the air bag. According to the dual-purpose convenient down jacket and the processing technology, the protection mechanisms are additionally arranged in the down jacket, when a wearer falls into water accidentally, the air bags in the protection mechanisms can be inflated and expanded, and large buoyancyis provided for the wearer, so that the wearer can float on the water surface, the safety is high, and the dual-purpose convenient down jacket can be used as a life jacket.

Owner:ANHUI GUIGU E COMMERCE

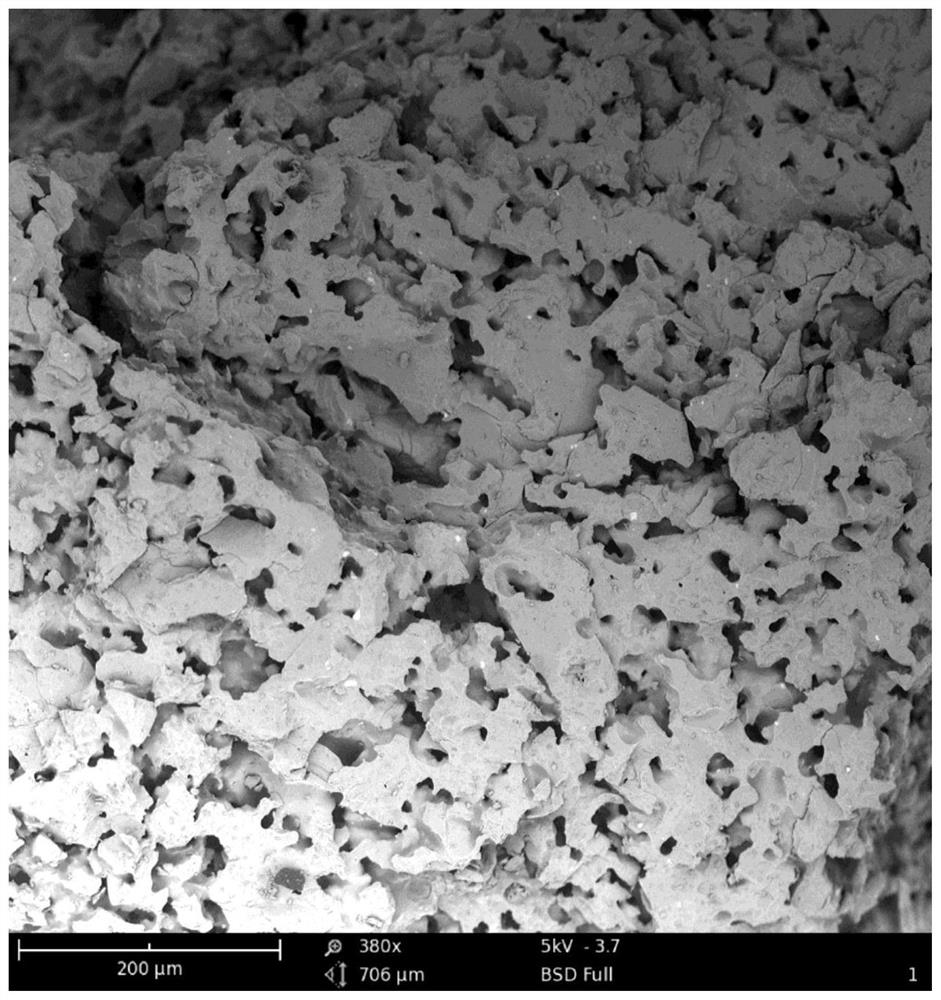

Warm-keeping fabric taking polyurethane aerogel as interlayer material and preparation method of warm-keeping fabric

ActiveCN112318974AGood flexibilityGood warmth functionSynthetic resin layered productsLaminationPolyesterFiber

The invention relates to a warm-keeping fabric taking polyurethane aerogel as an interlayer material and a preparation method of the warm-keeping fabric, and the preparation method comprises the following steps: firstly, preparing soft polyurethane aerogel, then putting the soft polyurethane aerogel between two layers of polyester fibers, and carrying out hot press molding on the two layers of polyester fibers and the polyurethane aerogel by adopting a hot press method to prepare the warm-keeping fabric. The warm-keeping fabric with the polyurethane aerogel as the interlayer material has the advantages of being light in weight, good in warm-keeping effect, good in softness and the like, and has good application prospects.

Owner:南京汇科高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com