Manufacturing method of machine washable western-style clothes and western-style clothes surface fabric

A suit and surface layer technology, applied in the direction of chemical instruments and methods, clothing, clothing, etc., can solve the problems of not easy to clean the dust of suits, troublesome washing of suits, and laborious cleaning, etc., and achieve good heat preservation function and antistatic effect, excellent waterproof, The effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiment of the invention discloses a machine-washable suit, which is relatively easy to clean and has good air permeability.

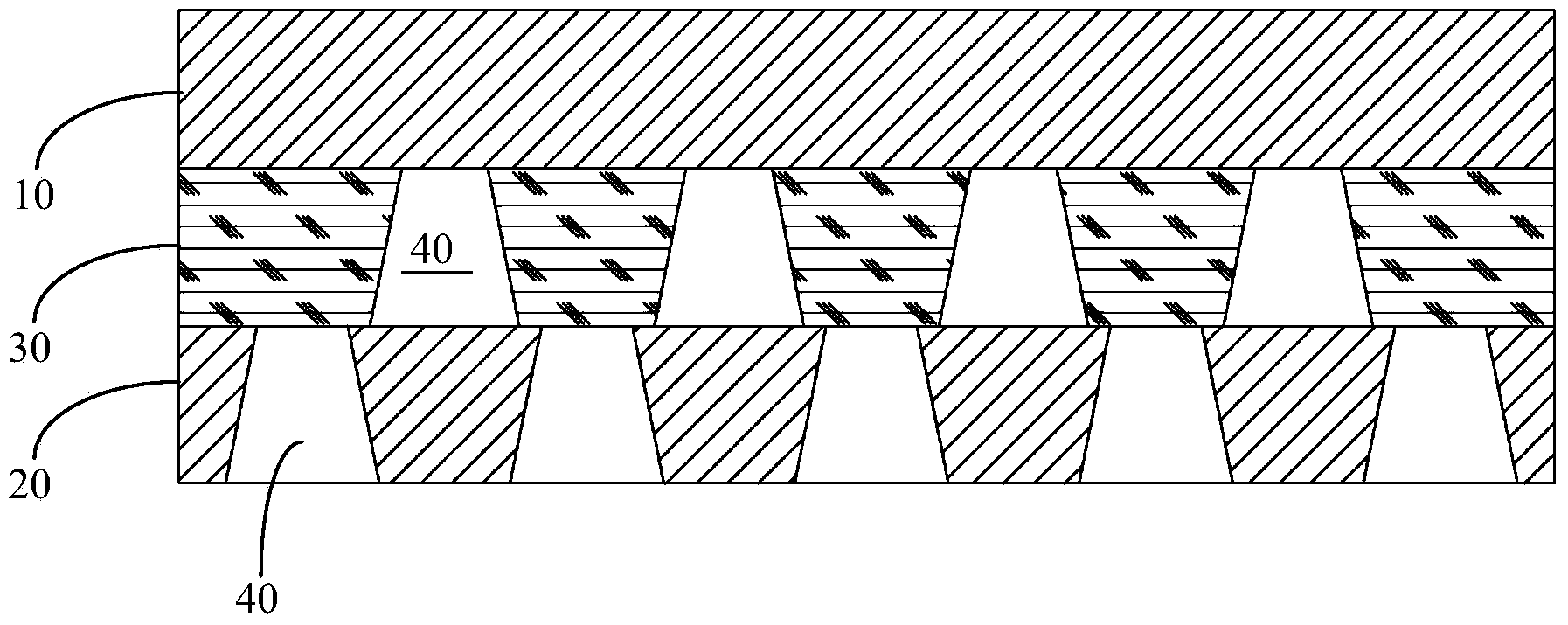

[0020] The technical solution adopted by the present invention to solve the technical problem is: a machine washable suit, which includes a surface layer, a middle layer and an inner layer, the middle layer is used to connect the surface layer and the inner layer, and the middle layer is woven from the middle layer yarn, The inner layer is woven from the inner layer yarn, and several holes are opened on the inner layer and the middle layer, and the fabric of the outer layer includes Australian wool with a weight ratio of 40%-60%, 20-30% wool Thermolite hollow fiber, 20-30% aramid fiber and 0.5-1% aramid-based conductive fiber.

[0021] Preferably, the positions of the holes on the inner layer and the middle layer are staggered; the holes are tapered from the inside to the outside; the distance between the holes is kept constant and evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com