Warm-keeping fabric taking polyurethane aerogel as interlayer material and preparation method of warm-keeping fabric

An interlayer material and aerogel technology, applied in the field of thermal fabrics, can solve the problems of difficulty in meeting the requirements of clothing materials, insufficient softness, etc., and achieve good thermal insulation function, good thermal insulation effect, and the effect of improving softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A kind of thermal insulation fabric with polyurethane airgel as interlayer material, its method preparation comprises the steps:

[0059] (1) Add 0.75mol of pentaerythritol into a three-necked flask, and vacuumize at 90-92°C for 1.5h to remove moisture;

[0060](2) Add 300mL dimethyl sulfoxide as a solvent, control the temperature to 70°C, add 0.075mol toluene diisocyanate and 0.015mol dibutyltin dilaurate to react, and the reaction time is 1.5h;

[0061] (3) After the reaction is completed, add 3mL silicone softener (model: SI-R101, Laiyang Shengbang Silicone Technology Co., Ltd.), and stir well;

[0062] (4) Put it in the mold and let it stand for 18 hours to make it into a wet gel. The size of the mold is: 100cm×50cm×5cm (length×width×thick); put the wet gel into a large amount of deionized water for replacement for 3 days, 24h for deionized water;

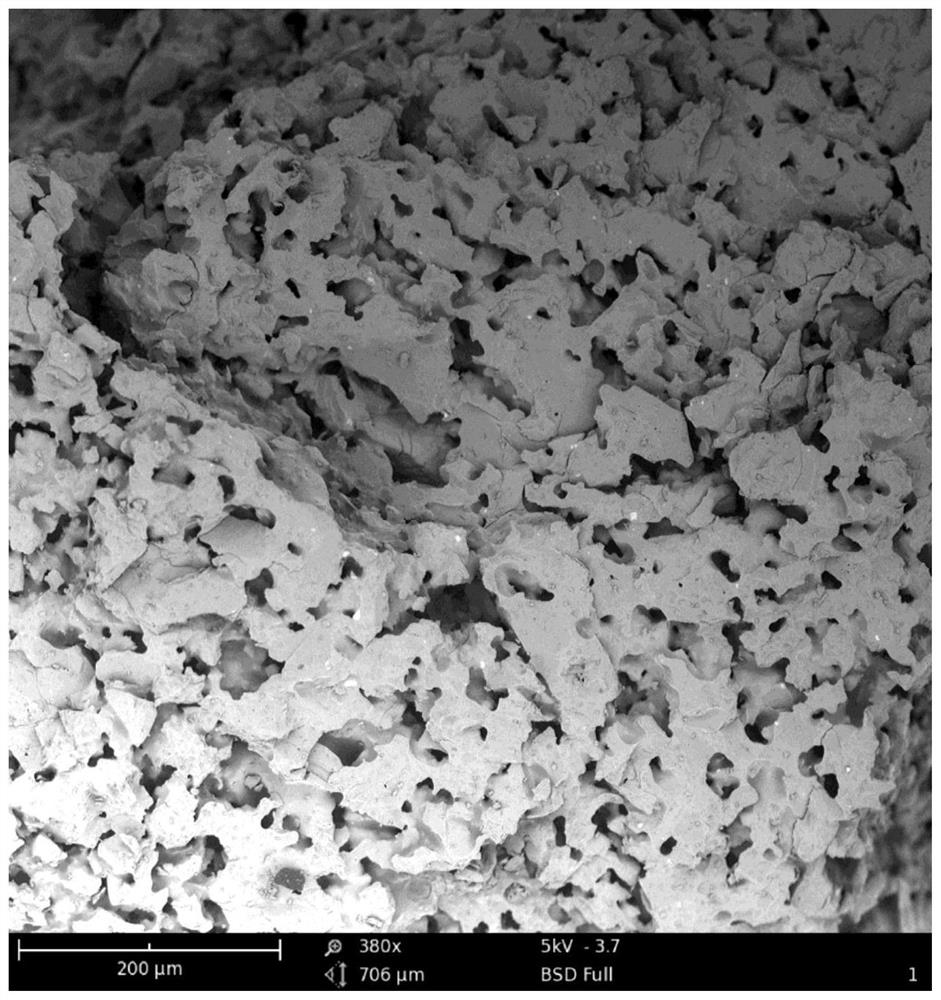

[0063] (5) via CO 2 Supercritical drying makes thin-layer soft polyurethane airgel a, and the electron microscope p...

Embodiment 2

[0066] A kind of thermal insulation fabric with polyurethane airgel as interlayer material, its method preparation comprises the steps:

[0067] (1) Add 0.5mol of pentaerythritol into a three-necked flask, and vacuumize at 90-92°C for 1.5h to remove moisture;

[0068] (2) Add 250 mL of dimethyl sulfoxide as a solvent, control the temperature at 60 ° C, add 0.05 mol of toluene diisocyanate and 0.01 mol of dibutyltin dilaurate to react, and the reaction time is 1.5 h;

[0069] (3) After the reaction is completed, add 5mL silicone softener (model: SI-R101, Laiyang Shengbang Silicone Technology Co., Ltd.), and stir evenly;

[0070] (4) Put it in a mold and let it stand for 12 hours to make it into a wet gel. The size of the mold is: 100cm×50cm×5cm (length×width×thick); put the wet gel into a large amount of deionized water for replacement for 4 days. 24h for deionized water;

[0071] (5) via CO 2 Supercritical drying to prepare a thin layer of soft polyurethane airgel b;

[00...

Embodiment 3

[0074] A kind of thermal insulation fabric with polyurethane airgel as interlayer material, its method preparation comprises the steps:

[0075] (1) Add 1.0mol of pentaerythritol into a three-necked flask, and vacuumize at 90-92°C for 1.5h to remove moisture;

[0076] (2) Add 350mL dimethyl sulfoxide as a solvent, control the temperature at 80°C, add 0.1mol toluene diisocyanate and 0.02mol dibutyltin dilaurate to react, and the reaction time is 2h;

[0077] (3) After the reaction is completed, add 7mL silicone softener (model: SI-R101, Laiyang Shengbang Silicone Technology Co., Ltd.), and stir evenly;

[0078] (4) Put it into a mold and let it stand for 24 hours to make it into a wet gel. The size of the mold is: 100cm×50cm×5cm (length×width×thick); put the wet gel into a large amount of deionized water for replacement for 4 days, 24h for deionized water;

[0079] (5) via CO 2 Supercritical drying to prepare a thin layer of soft polyurethane airgel c;

[0080] (6) Put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com