Patents

Literature

67results about How to "Excellent oil repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

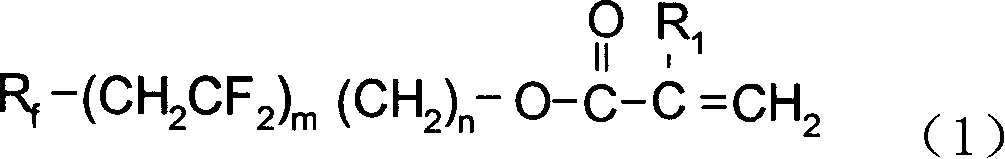

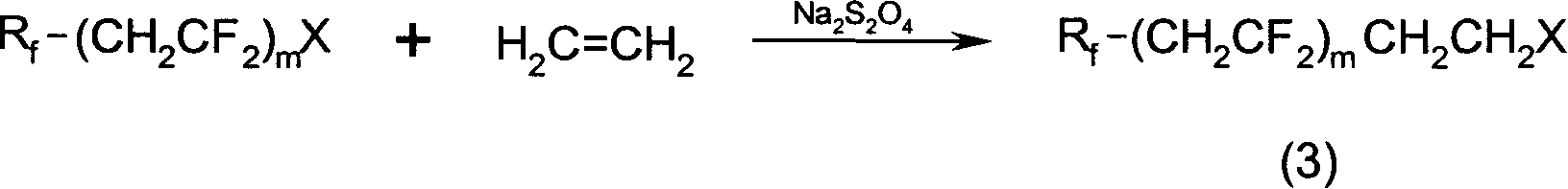

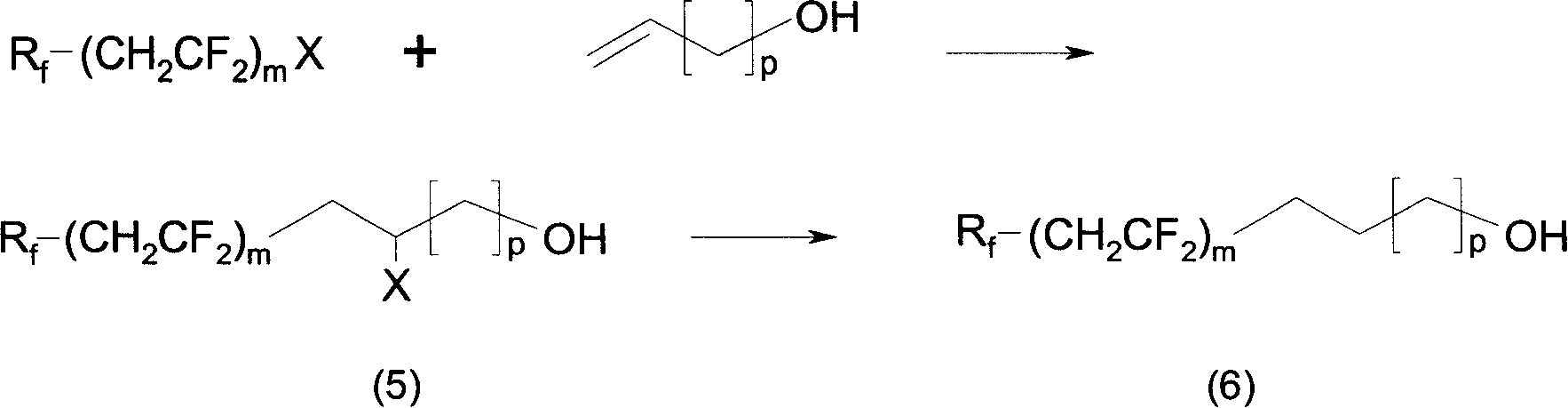

Fluorine-containing carbon chain acrylate, preparation method and application for copolymer thereof

InactiveCN1927894AExcellent water repellencyExcellent oil repellencyLiquid surface applicatorsFibre treatmentAlcoholCarbon chain

The present invention discloses the preparation process and application of fluorocarbon chain-containing acrylate and its copolymer. The preparation process of the fluorocarbon chain-containing acrylate includes the steps of: 1. synthesizing Rf(CH2CF2)mix; 2. synthesizing fluoric alcohol Rf-(CH2CF2)m(CH2)nOH; and 3. synthesizing fluorocarbon chain-containing acrylate. The present invention is used in surface water-repellent and oil-repellent treatment of fabric, metal, paper, glass, plastic, rubber, ceramic, etc. The present invention is one kind of high performance green water-repellent and oil-repellent agent with excellent water-repellent, oil-repellent and antifouling functions and degradability.

Owner:DONGHUA UNIV

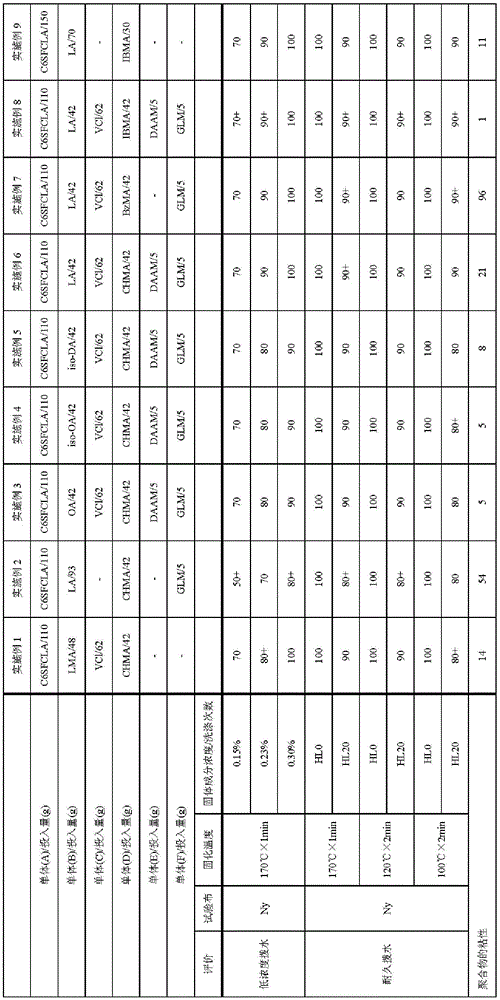

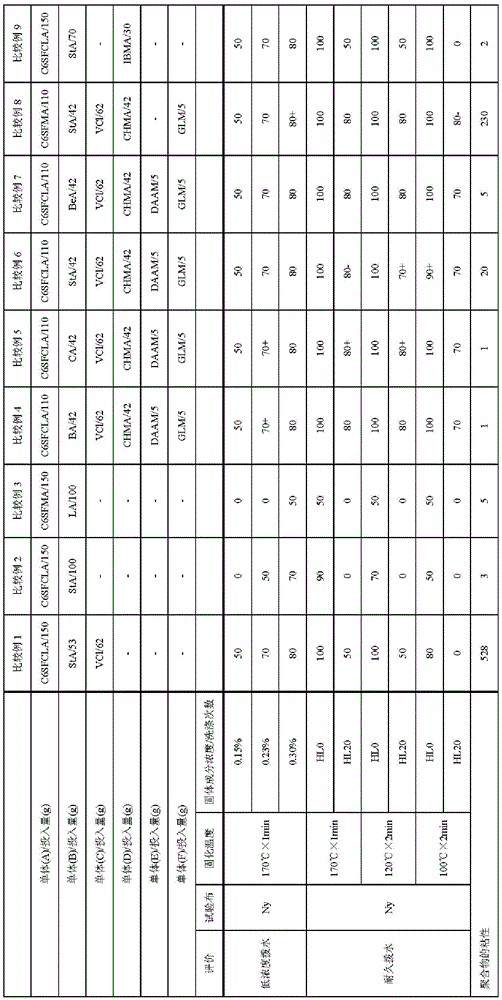

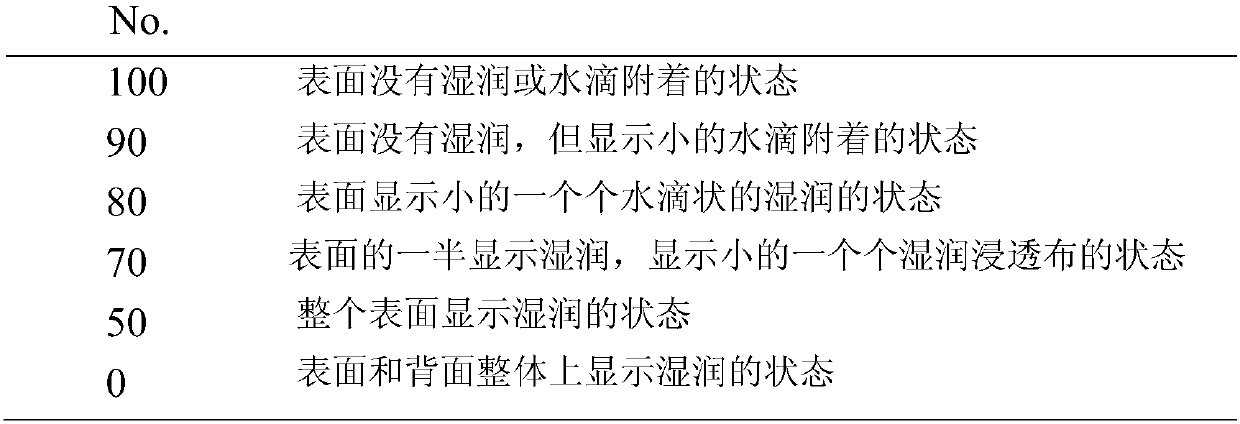

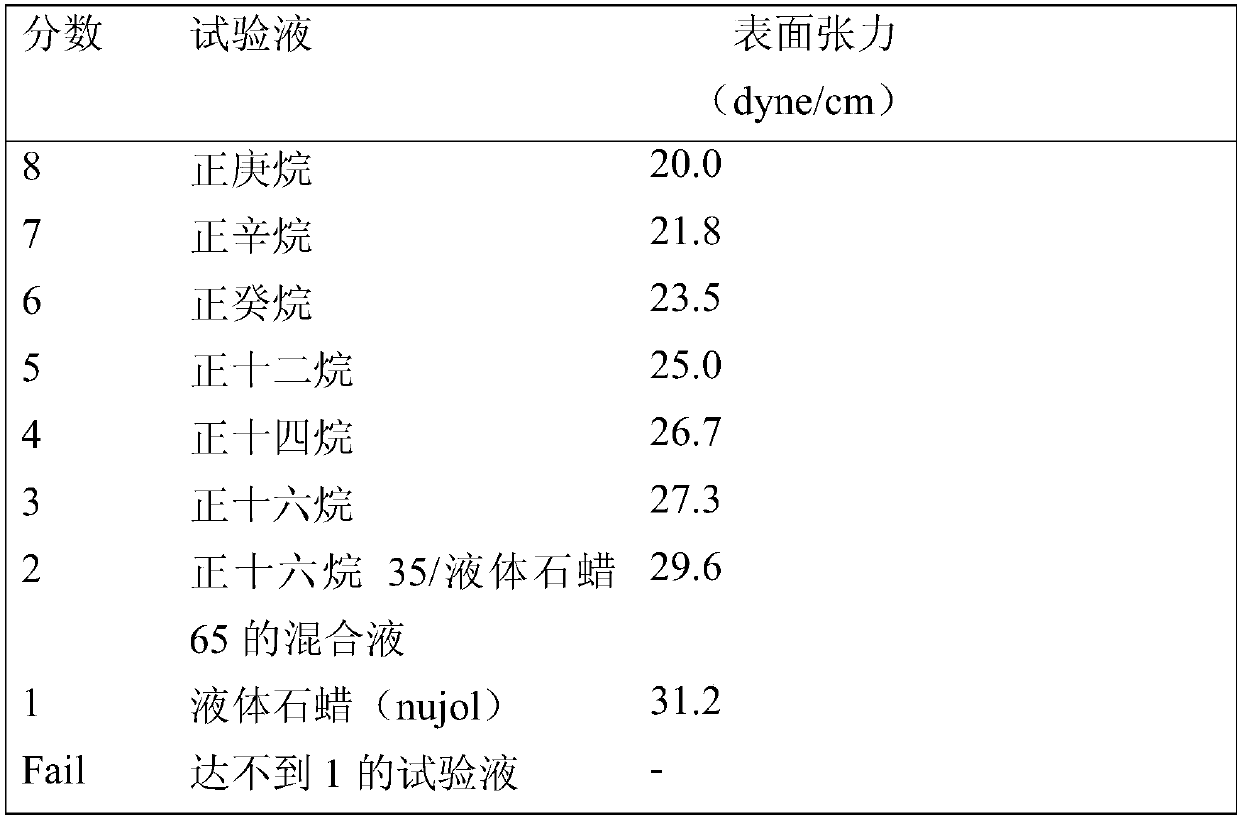

Water-repellent/oil-repellent composition

ActiveUS7820745B2Improve water resistanceExcellent oil-repellencyOther chemical processesLiquid repellent fibresPolymer scienceActive agent

Disclosed is an aqueous water-repellent / oil-repellent composition containing the following components (A), (B) and (C). Fluorine-containing copolymer (A): a copolymer containing a polymerizable monomer (a1) having a perfluoroalkyl group with 1-6 carbon atoms or a perfluoroalkenyl group wherein the amount of (a1) is not less than 20% by weight relative to the copolymer. Surfactant (B): a surfactant essentially containing a sorbitan ester or an alkylene oxide addition product thereof. Aqueous medium (C): a medium substantially containing water only or water and a water-soluble organic solvent.

Owner:DAIKIN IND LTD

Fluorooxyalkylene group-containing polymer composition, a surface treatment agent comprising the same and an article treated with the agent

ActiveUS20110098402A1Increase surface lubricityImprove adhesionPolyether coatingsEmulsion paintsWear resistanceStain

An object of the present invention is to provide a fluorooxyalkylene group-containing polymer composition, which yields a coating having excellent adhesior to a substrate, good water- and oil-repellency, a low dynamic friction coefficient, good releasing property, good abrasion resistance and good stain resistance, and to provide a surface treatment agent comprising the same. The present inventors have found that a composition comprising a fluorooxyalkylene group-containing polymer having a fluorinated group and a hydrolyzable group at each terminal and a fluorooxyalkylene group-containing polymer having hydrolyzable groups at both terminals can form a coating which has excellent water- and oil-repellency, a low dynamic friction coefficient, good releasing property, good abrasion resistance, and good stain resistance.

Owner:SHIN ETSU CHEM IND CO LTD

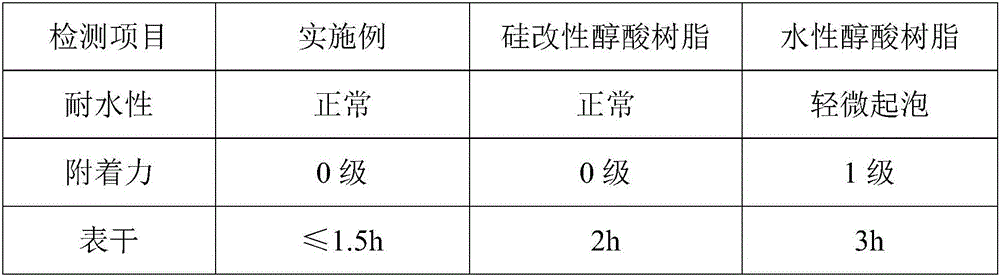

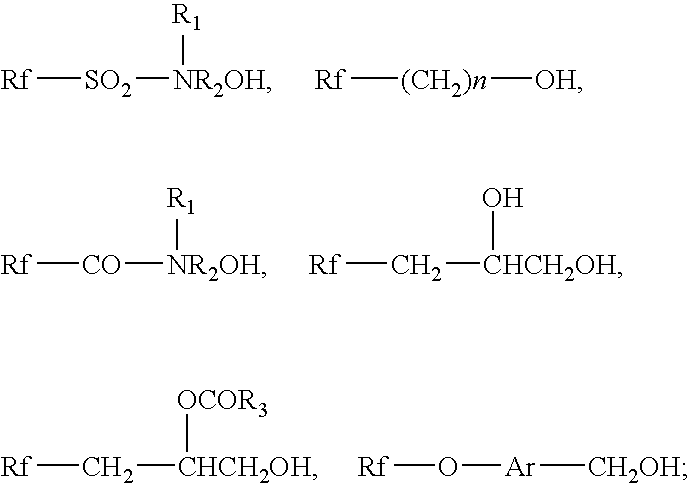

Fluorine-silicon modified waterborne alkyd resin and preparing method thereof

ActiveCN106117449AWith shielding protectionImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesAcid anhydride formationStain

The invention relates to a fluorine-silicon modified waterborne alkyd resin and a preparing method thereof. The fluorine-silicon modified waterborne alkyd resin is prepared from vegetable oil fatty acid, organic acid anhydride, polyol, fluorinated allyl monomers, isocyanate, hydroxyl-terminated organic silicon, acrylic monomers and deionized water. Single-component waterborne paint, double-component waterborne paint and room-temperature curing paint can be blended with the fluorine-silicon modified waterborne alkyd resin prepared through the method. The prepared fluorine-silicon modified waterborne alkyd resin has the performance such as high adhesion, stain resistance, high hardness, water resistance, durability, hydrophobicity and self-cleaning performance, and can be widely applied to waterborne wood paint, waterborne industrial paint, waterborne anti-fouling paint, waterborne corrosion resistance paint, waterborne special engineering paint such as radar dome materials, wind power generation, nuclear power and vessel paint and the like.

Owner:湖南大禹防水建材科技有限公司

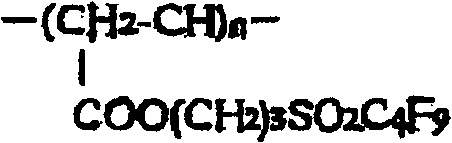

Photo-curing-based water and oil repellent finishing method for fabric

InactiveCN103526552AImprove water repellencyImprove the effect of oil repellent finishingFibre typesOrganic chemistryFluorine containing

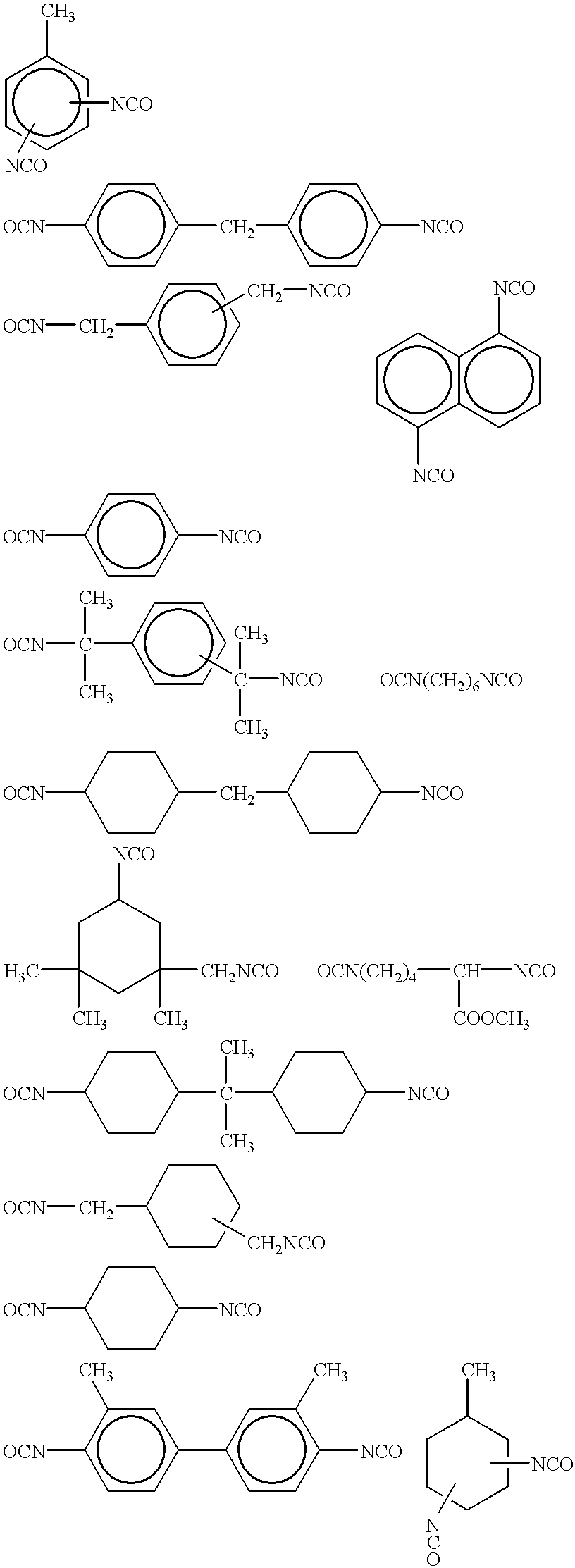

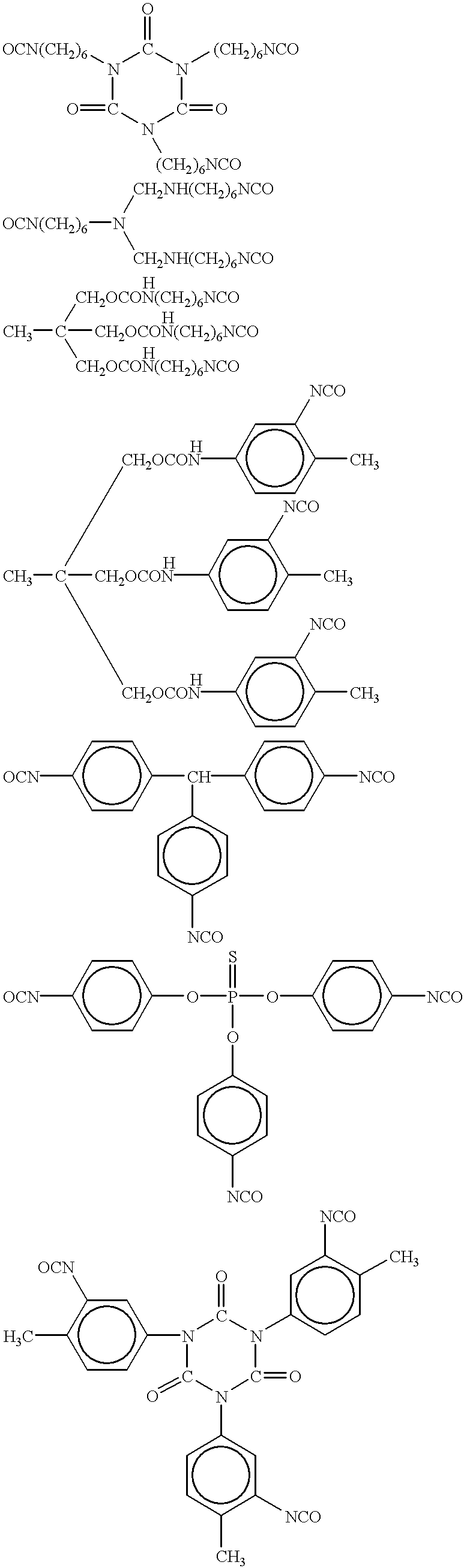

The invention discloses a photo-curing-based water and oil repellent finishing method for a fabric, belonging to the technical field of fabric finishing, and aiming to overcome the shortcomings of high baking temperature, high production energy consumption and low processing efficiency in conventional after-finishing and achieve the water and oil repellent functional finishing of the fabric under a photo-curing condition. A process specifically comprises the following steps of (1) synthesizing a fluorine-containing urethane acrylate prepolymer, namely carrying out reaction on isocyanate and hydroxyethyl acrylate and carrying out reaction on a reaction product and a fluorine-containing polyether type diol long chain to obtain the prepolymer, or carrying out reaction on isocyanate and fluorine-containing polyether type diol and then adding the hydroxyethyl acrylate into a system; and (2) preparing a photo-curable resin system from the prepolymer, a reactive diluent, a photoinitiator, a solvent and the like, coating and rolling-compacting the photo-curable resin system on the surface of the fabric, and irradiating the fabric for a certain time by using ultraviolet light to finish curing of a resin with water and oil repellent effects on the surface of the fabric. According to the method, the water and oil repellent performance of the finished fabric is improved, and the strength of the fabric is slightly weakened; compared with a conventional thermal-baking-based chemical finishing method, the photo-curing-based water and oil repellent finishing method for the fabric has the advantages that the process flow is short, the energy consumption is low and the efficiency is high.

Owner:JIANGNAN UNIV

Preparation method for non-woven fabric for protective garment

InactiveCN109023923AExcellent water repellencyExcellent oil repellencyBiochemical fibre treatmentUltrasonic/sonic fibre treatmentChemistryGlycol methacrylate

The invention discloses a preparation method for a non-woven fabric for a protective garment. The preparation method comprises: cleaning and drying a polypropylene composite non-woven fabric, carryingout plasma treatment, placing the non-woven fabric in air to obtain a material A, uniformly mixing 10-hydroxy-cyclohexyl-phenyl ketone, a fluorine-containing acrylic resin, octadecyl methacrylate, glycidyl acrylate, borneol acrylate, fatty alcohol polyoxyethylene ether, ethylene glycol dimethacrylate and water to obtain a material B, adding the material A into the material B, carrying out ultraviolet light irradiation for a grafting reaction, carrying out washing and drying to obtain a material C, uniformly mixing p-aminobenzotrifluoride, n-octylamine, alkylaminoglucitol, 4-amino-1, 2, 4-triazole and dioxane, adding the material C into the mixture, carrying out a reaction process, carrying out washing and drying to obtain a material D, adding graphene oxide into water, adjusting pH to greater than 7, carrying out ultrasonic treatment, adding glucose into the reaction product for a reaction, mixing the product, hydroxylamine hydrochloride, allicin, a zinc complex, lentinan and a silk fibroin, adding the material D into the mixture, and carrying out padding and drying.

Owner:HEFEI JIENUO MEDICAL PROD CO LTD

Solvent-based fluorinated water and oil repellent and process for producing the same

InactiveUS20050178996A1Easy to waterExcellent oil repellencyPhysical treatmentLiquid repellent fibresPolymer scienceCross linker

This invention discloses a solvent-based fluorinated water and oil repellent and process for producing the same. Said fluorinated water and oil repellent comprises 20˜50% (w / w) blocked polyfluorourethane compound and 50˜80% (w / w) solvent; its reaction agents include fluoroalcohol compound, diisocyanate or polymeric isocyanate compound, cross-linking agent, blocking agent, and solvent. The process for synthesizing the blocked polyfluorourethane is by bulk polymerization.

Owner:JINEX CORP

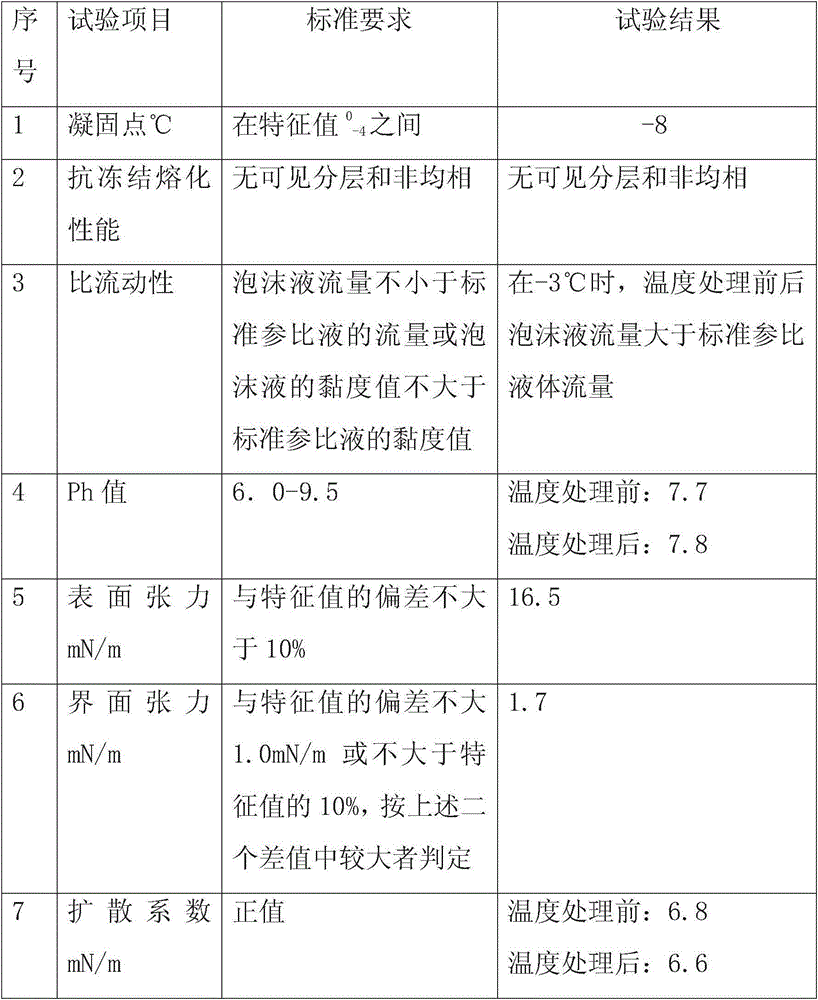

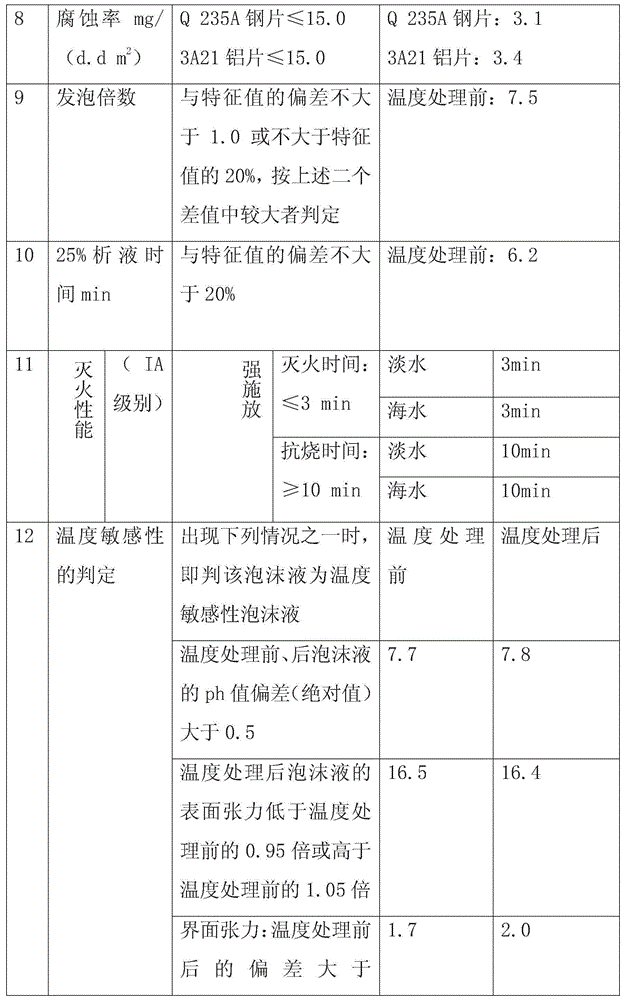

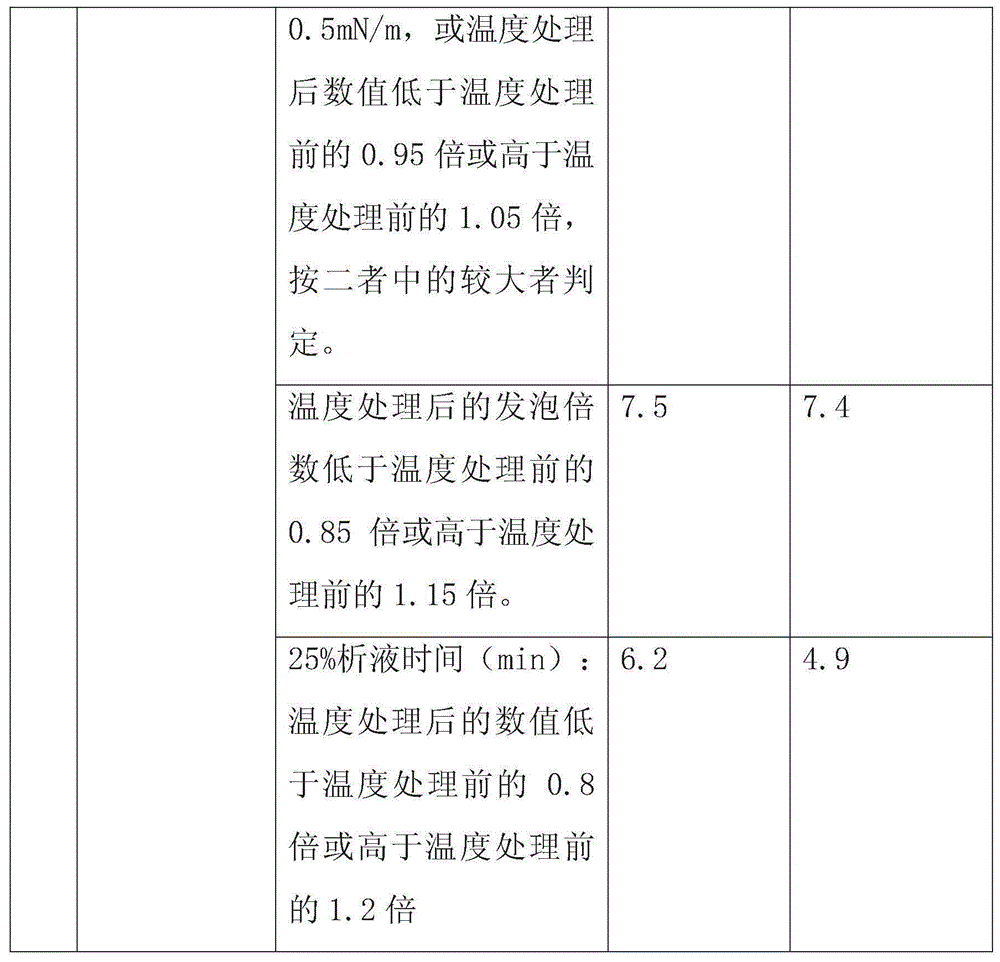

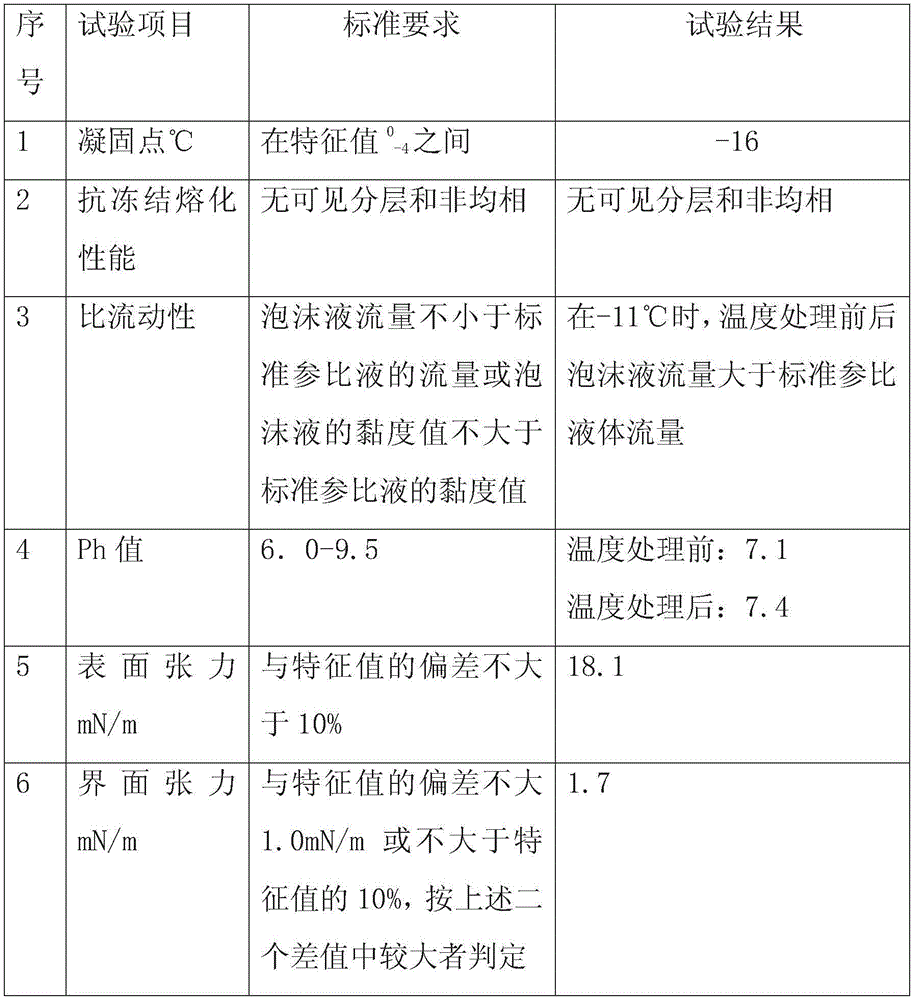

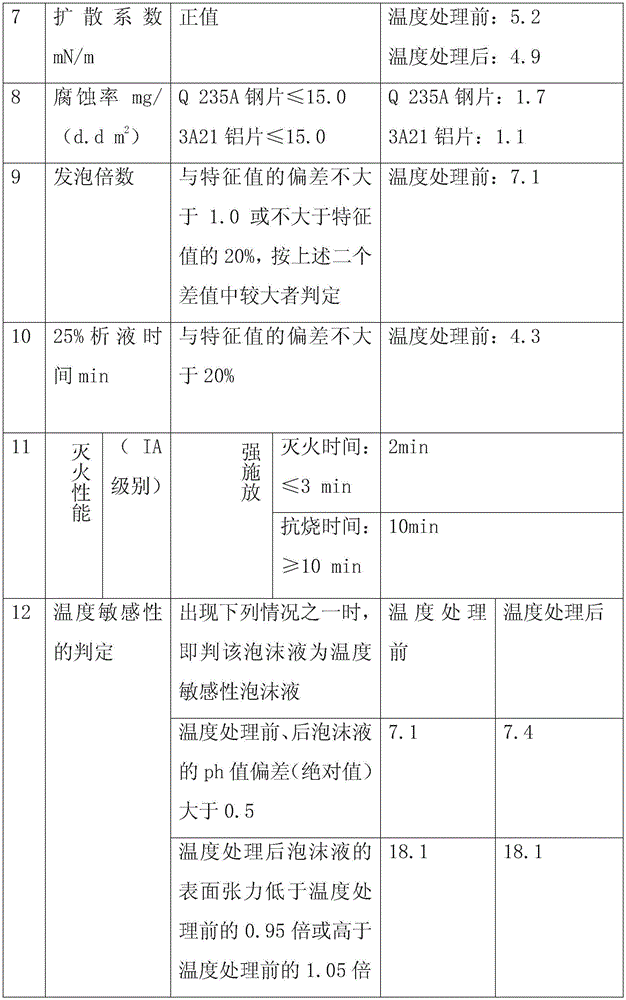

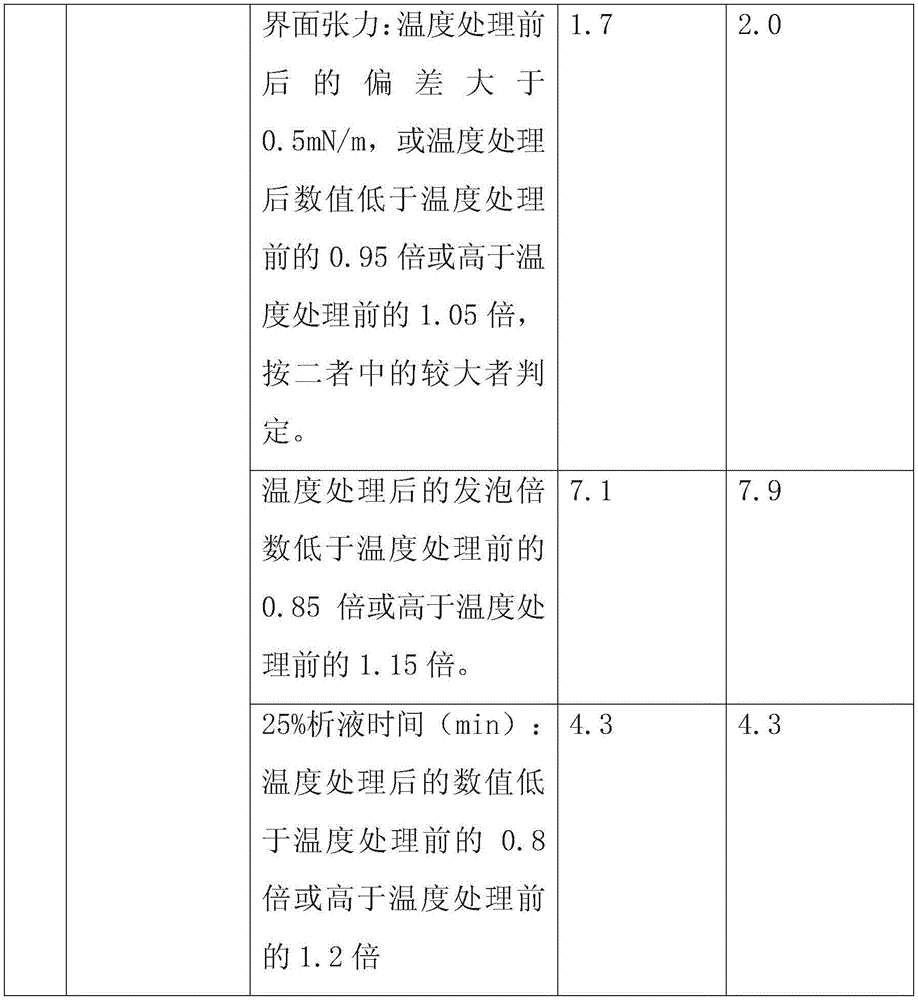

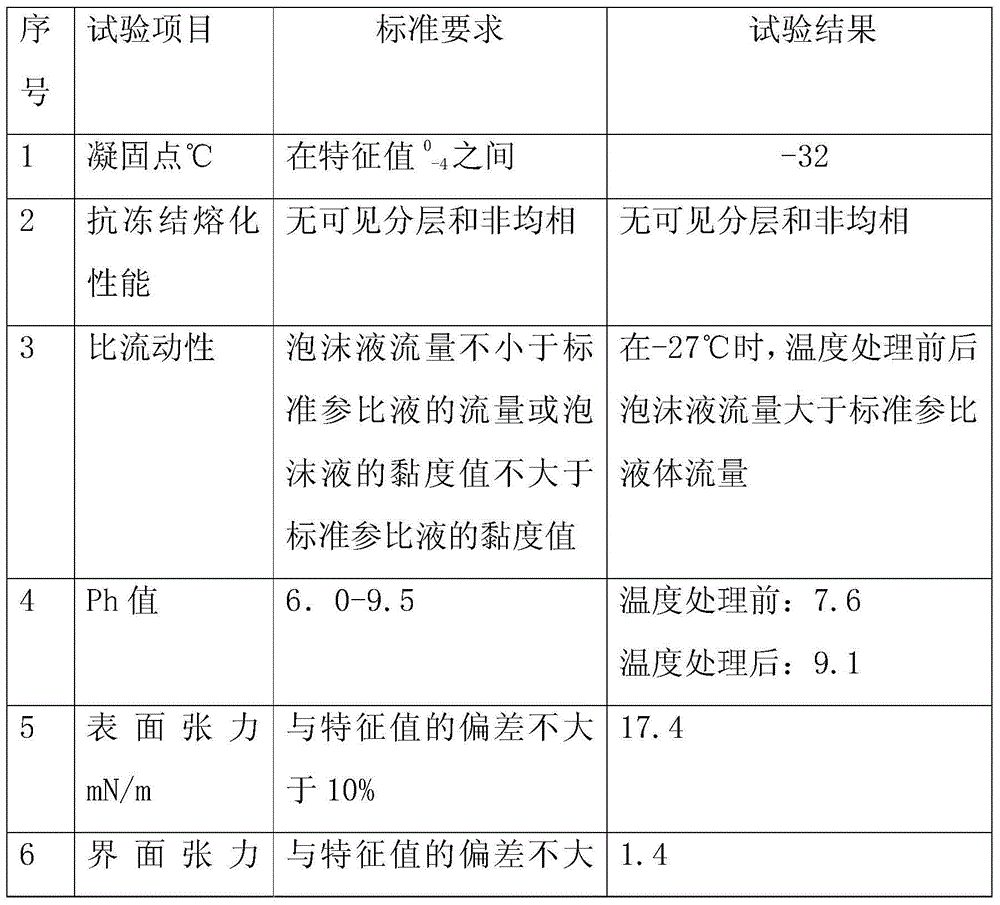

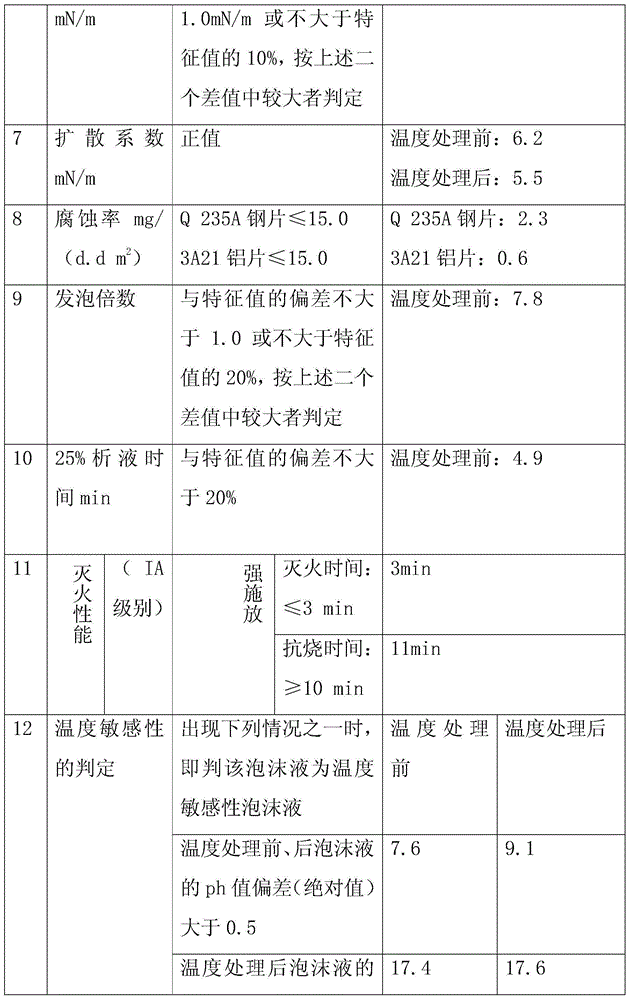

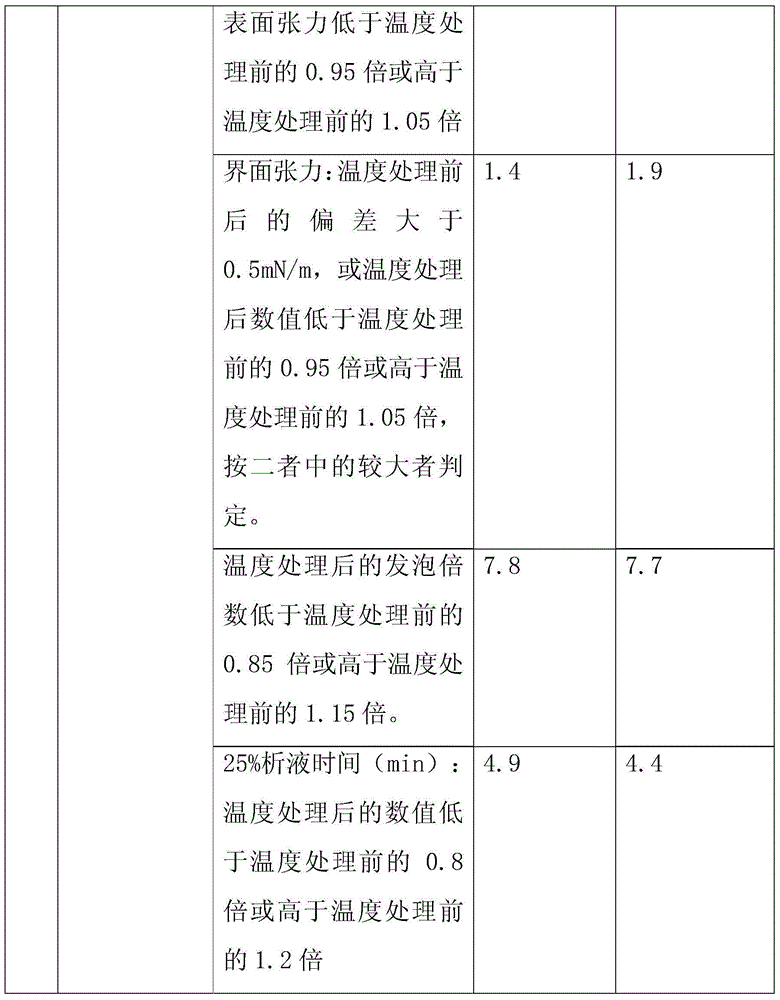

Foam extinguishing agent

The invention discloses a foam extinguishing agent. The foam extinguishing agent is composed of, by mass, 1-3% of perfluorinated betaine, 3-8% of fluorinated alkyl betaine, 1-5% of urea, 5-15% of Sodium alpha olefin sulfonate, 10-15% of lauryl sodium sulfate, 10-16% of alkyl polyglucoside (1412) and the balance water. The invention further discloses application of the foam extinguishing agent. The thickness and the stability of films generated by the foam extinguishing agent are high, the extinguishing speed is high, and the extinguishing effect is good.

Owner:厦门安港消防科技有限公司

Detergent with

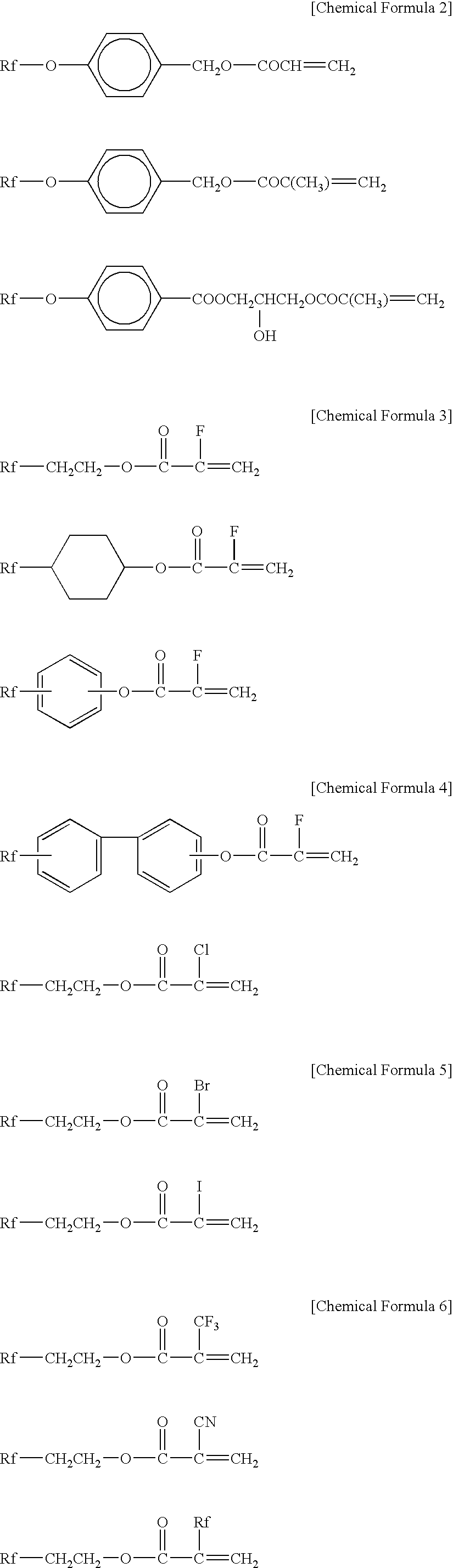

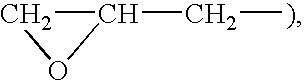

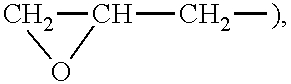

InactiveCN101289525AHigh washing durabilityExcellent oil repellencyOrganic detergent compounding agentsOrganic chemistryArylOligomer

The invention relates to a fluorine-containing copolymer, which takes: (A) repeating units derived from a fluorine-containing macromonomer of the general formula: CH2=C(-X)-COO-(Y)1-Z-MmMn-H (I) and (B) repeating units derived from poly alkylene glycol (meth) acrylic ester as necessary ingredients, in the formula (I), X is hydrogen atom or methyl, Y is -CH2CH(OH)CH2- or R<1>-NHCO-; l is 0 or 1; Z is -L1-L2-S-(wherein L1 is direct bonding, -O-, -COO- or -NH-, L2 is alkylidene group or aryl, S represents sulphur atom); MmMn is a fluorine-containing oligomer composed by m units derived from fluorine-containing monomers (M) and n units derived from fluorine-non-containing monomers (M). The fluorine-containing copolymer provides durability for maintenance of washing, and has the decontaminant with excellent oil removing property, antifouling property and decontamination property.

Owner:DAIKIN IND LTD

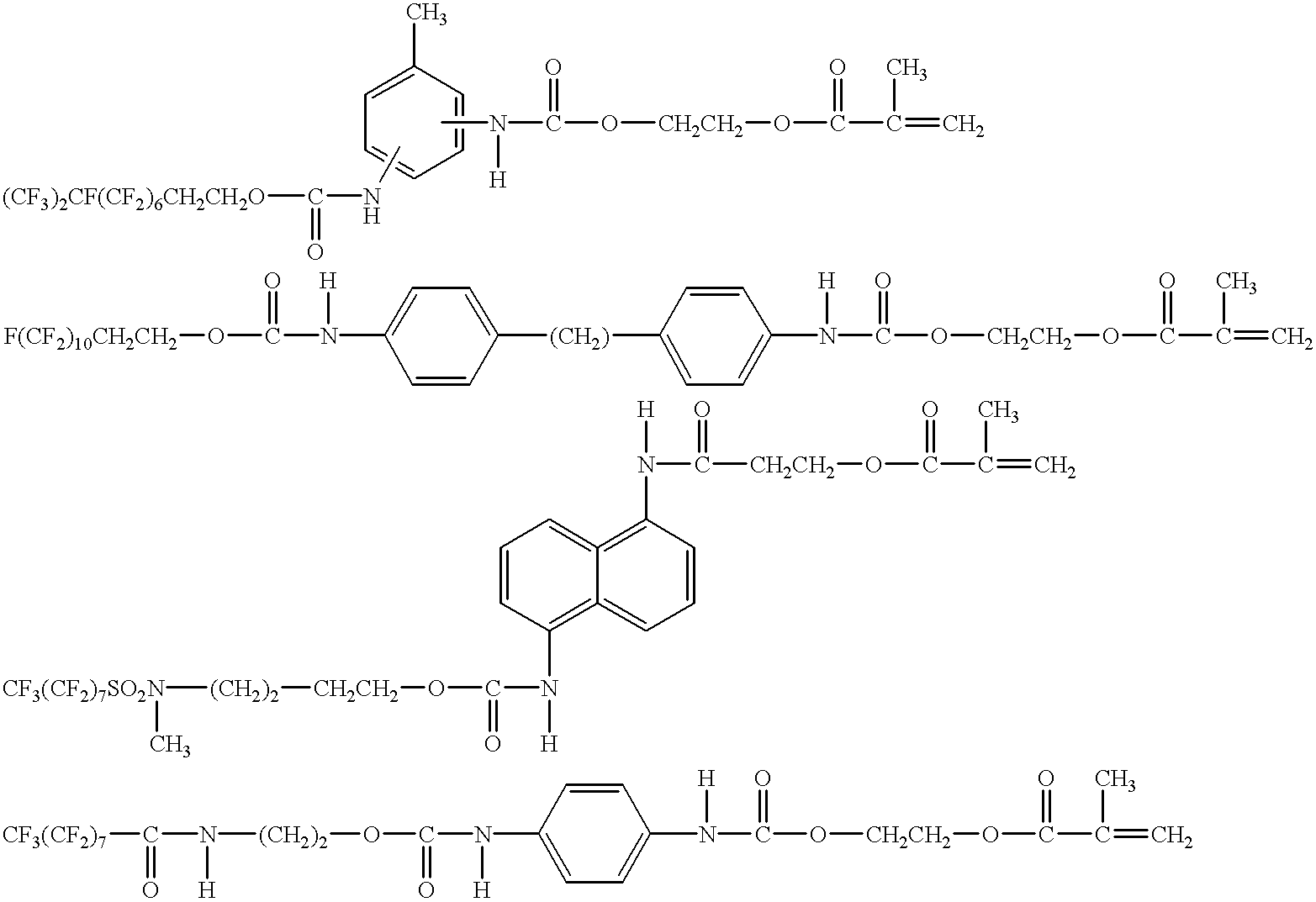

Copolymer and stainproofing agent containing the same

InactiveUS6284853B1Easy to waterExcellent oil-repellencyFibre treatmentSynthetic resin layered productsActive componentCopolymer

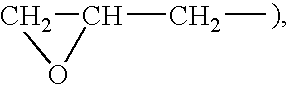

The present invention provides a copolymer whose durability on cleaning is improved while maintaining good water- and oil-repellency. Disclosed is a copolymer having:(i) a fluoroalkyl group,(ii) a urethane or urea linkage, and(iii) a functional group selected from the group consisting of a carboxyl group, a carboxylic anhydride group, an epoxy group, a phosphoric group, an alkoxysilane group, a imine group, a sulfonic group, an amino group, an isocyanate group and a chlorine atom, and a stainproof agent containing the copolymer as an active component.

Owner:DAIKIN IND LTD

Foam extinguishing agent

The invention discloses a foam extinguishing agent, which is prepared from the following components in percentage by mass: 1.5%-3.5% of perfluor glycine betaine, 2%-5% of fluorinated alkyl betaine, 3%-5% of urea, 5%-15% of alpha-sodium olefinsulfonate, 10%-15% of lauryl sodium sulfate, 10%-16% of alkyl glycoside (1412), 10%-20% of ethylene glycol, 0.1%-0.3% of xanthan gum and the balance of water. The invention further discloses an application of the foam extinguishing agent. A film generated by the foam extinguishing agent is relatively high in thickness and stability, high in fire extinguishing speed and relatively good in fire extinguishing effect.

Owner:厦门安港消防科技有限公司

Fluorine-containing copolymer having excellent washing resistance and soil release agent

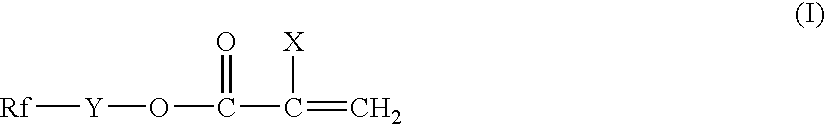

ActiveCN101595142AExcellent oil repellencyImprove antifouling performanceOther chemical processesLiquid repellent fibresFiberHydrogen atom

Disclosed is a soil release agent composition essentially containing a fluorine-containing copolymer, which is essentially composed of (a) a fluorine-containing monomer having a fluoroalkyl group, (b) a polyalkyleneglycol(meth)acrylate, (c) a monomer having an acetoacetyl group and (d) a monomer having a cation-donating group, and a crosslinking agent. This soil release agent composition imparts a base material such as a fiber fabric with excellent oil repellency, antifouling property and soil releasing property, while maintaining washing resistance of the base material. The monomer (a) is preferably represented by the following formula: CH2=C(-X)-C(=O)-Y-Z-Rf (1). In the formula, X represents a hydrogen atom, a linear or branched alkyl group having 1-21 carbon atoms, a fluorine atom, a chlorine atom or the like; Y represents -O- or -NH-; Z represents an aliphatic group having 1-10 carbon atoms, an aromatic group having 6-18 carbon atoms, an alicyclic group or the like; and Rf represents a linear or branched fluoroalkyl group having 1-21 carbon atoms.

Owner:DAIKIN IND LTD

Water-repellent oil-repellent antifouling agent having good solubility in solvent

InactiveUS20100227173A1Improve solubilityEasy to waterOther chemical processesFibre treatmentSolubilitySolvent

Disclosed is a water-repellent oil-repellent antifouling agent containing a fluorine-containing polymer for a treatment for providing water repellency, oil repellency and antifouling property. The fluorine-containing polymer has a repeating unit (A) derived from a fluorine-containing acrylate monomer, and a repeating unit (B) derived from at least one non-fluorine acrylate monomer selected from the group consisting of a monomer (B1) having a cyclic hydrocarbon group and a monomer (B2) having a short chain hydrocarbon group. This water-repellent oil-repellent antifouling agent has good solubility in solvents, and exhibits excellent effects on various bases, especially on masonries.

Owner:DAIKIN IND LTD

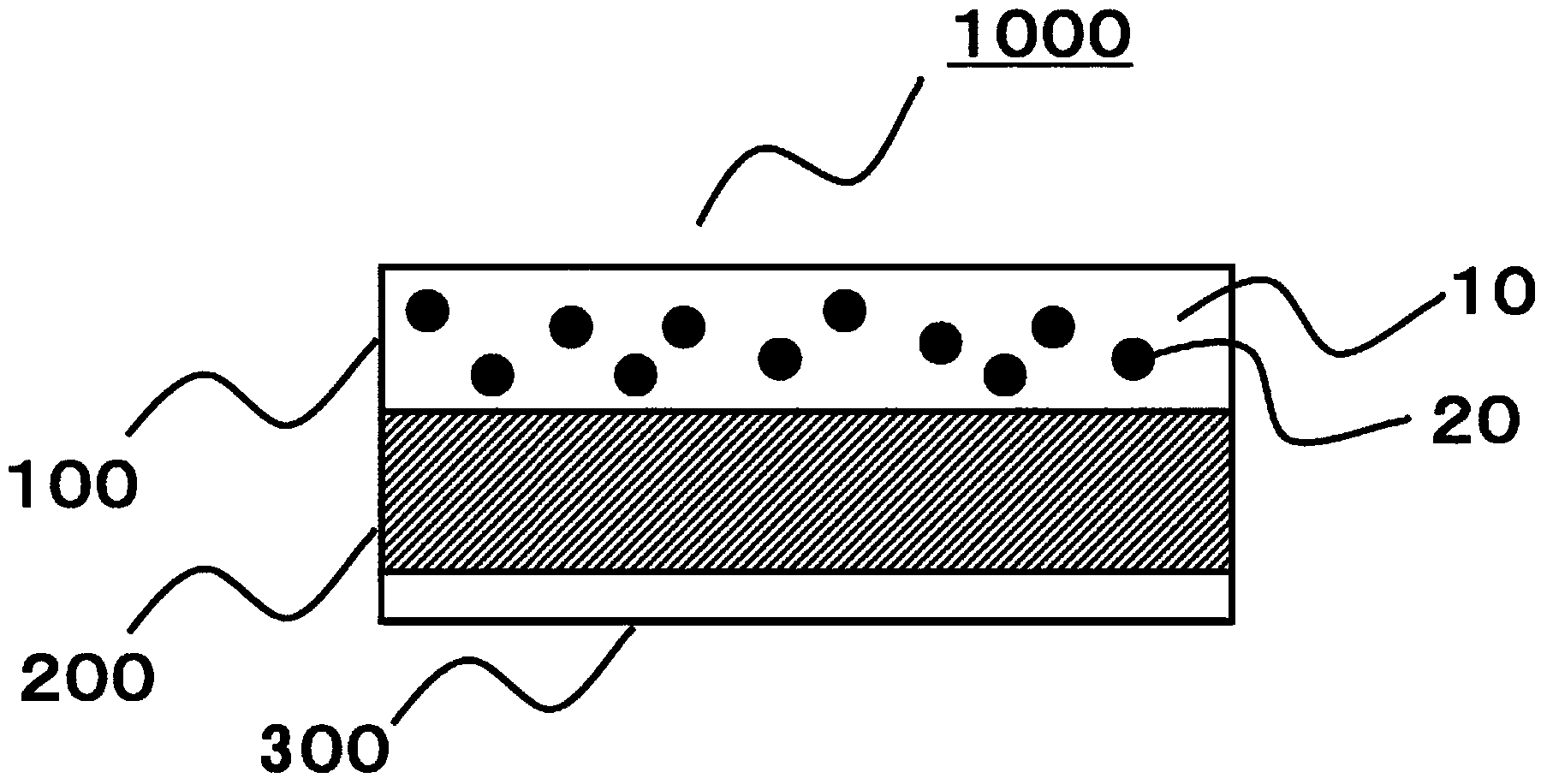

Shatterproofing member with hardenable pressure-sensitive adhesive layer

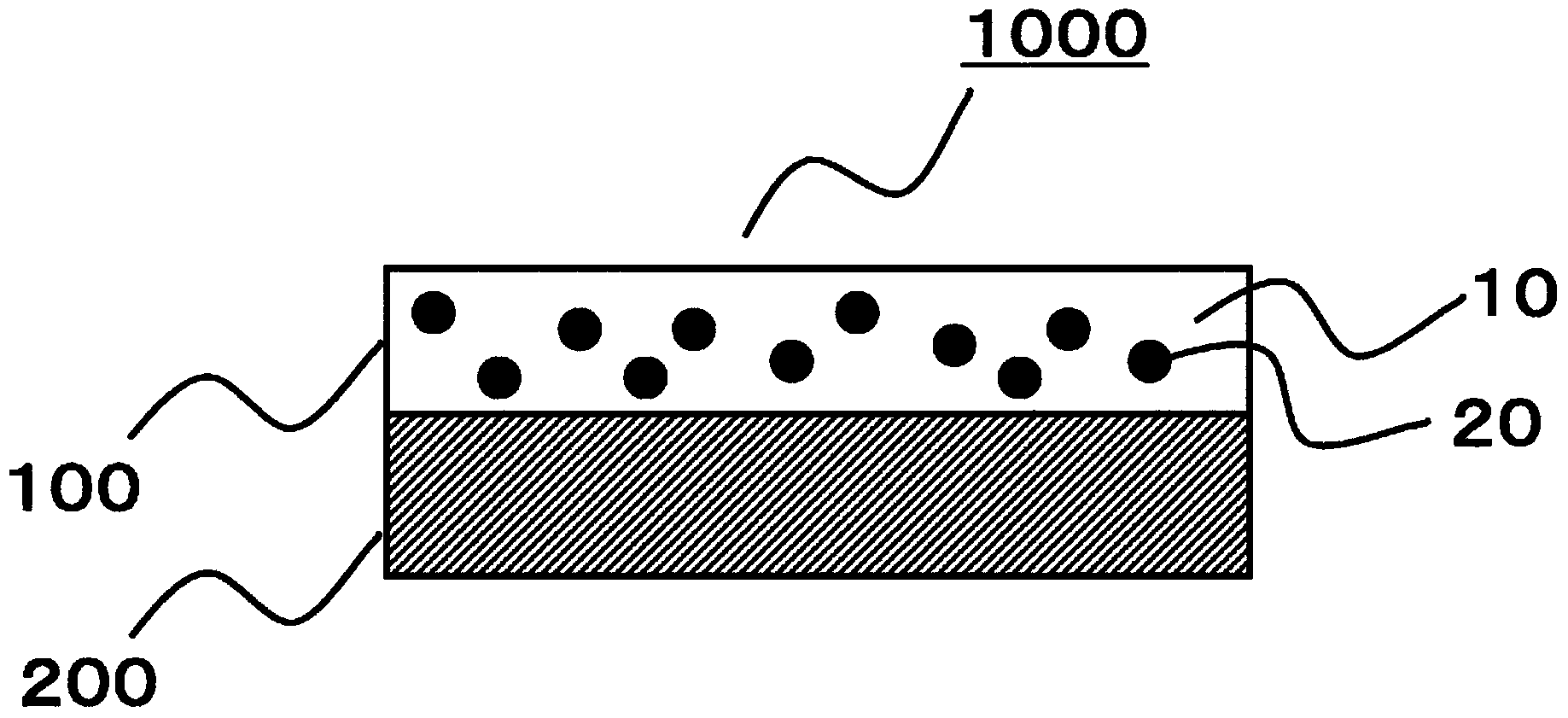

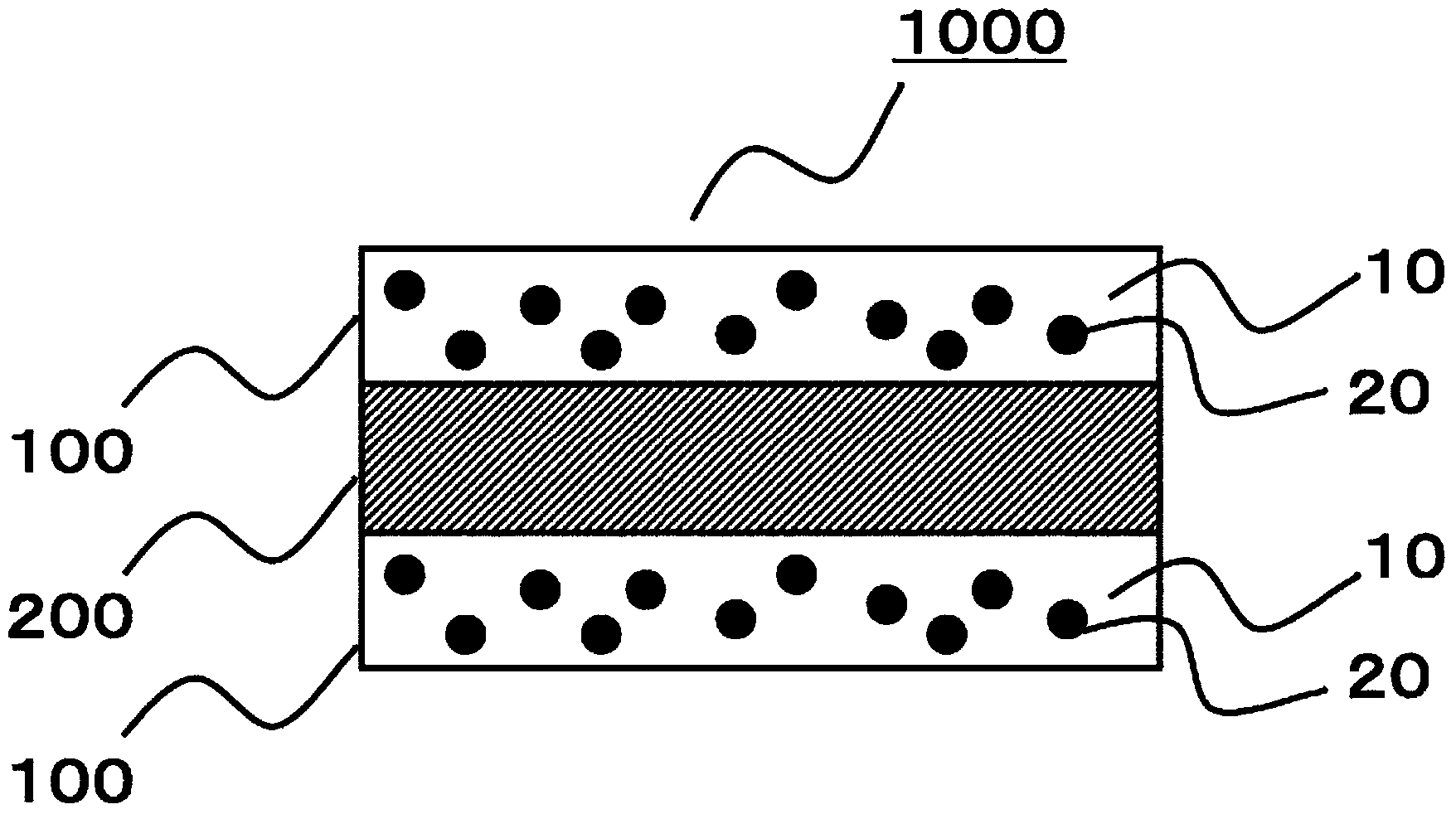

InactiveCN103547645AImprove flame retardant performanceEasy to processNon-macromolecular adhesive additivesSynthetic resin layered productsCombustionEngineering

Provided is a shatterproofing member including a pressure-sensitive adhesive layer convertible into an adhesive layer, which allows adherends to be instantly fixed to each other, allows the adherends to be reattached to each other, is excellent in processability such as being able to be cut into a sheet shape, is not peeled from the adherends even when exposed to a high-temperature atmosphere such as one in a fire, and can express shatterproof property when attached to an adherend that is broken by combustion such as glass even if exposed to combustion during a fire or the like. The shatterproofing member including a pressure-sensitive adhesive layer convertible into an adhesive layer includes: a pressure-sensitive adhesive layer convertible into an adhesive layer; and a flame-resistant material, in which the pressure-sensitive adhesive layer convertible into an adhesive layer has pressure-sensitive adhesive property before being sintered, and has adhesive property after being sintered.

Owner:NITTO DENKO CORP

Foam extinguishing agent

The invention discloses a foam extinguishing agent. The foam extinguishing agent is composed of the following components in percentage by mass: 0.5-2.5 percent of perfluoro betaine, 1.7-2.3 percent of fluoroalkyl betaine, 3.2-5.9 percent of urea, 5.1-15.5 percent of modified succinate, 10-15 percent of n-octyl alcohol ether sulfonate, 10-16 percent of alkyl glycoside (0810), 10-20 percent of ethylene glycol, 0.25-0.45 percent of xanthan gum and the balance of water. The invention further discloses application of the foam extinguishing agent. A film generated by the foam extinguishing agent is larger in thickness and higher in stability, the fire extinguishing speed is high, and the fire extinguishing effect is better.

Owner:厦门安港消防科技有限公司

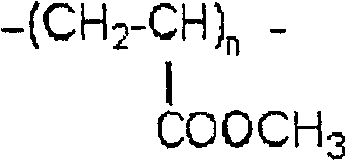

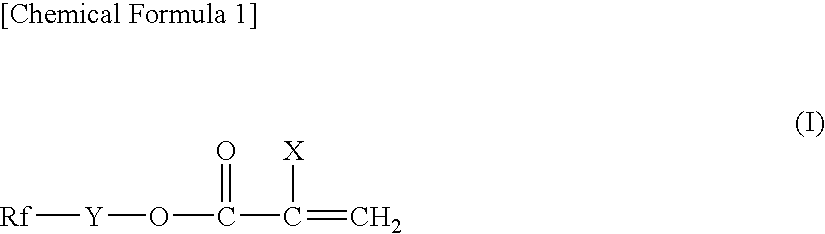

Masonry-treating agent

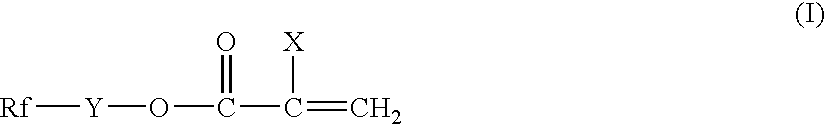

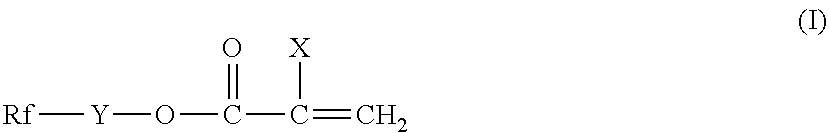

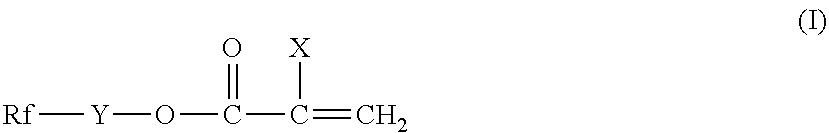

InactiveUS20070066780A1Excellent water and oil repellencyExcellent soil resistanceMonomerFluoropolymer

A fluoropolymer for masonry treatment produced from (A) a fluoromonomer which has been substituted in the α-position by a X group and is represented by the formula (I): and (B) a monomer having a functional group reactive with active hydrogen. It imparts excellent water- and oil-repellency and unsusceptibility to fouling to masonries.

Owner:DAIKIN IND LTD

Fluorine-containing polymer and treatment agent

InactiveCN105658689AImprove stabilityImprove processing stabilityStain/soil resistant fibresAntifouling/underwater paintsMeth-Soil properties

Disclosed is a fluorine-containing polymer comprising: (a) a repeat unit in which the alpha-position is an acrylate ester monomer substituted with a monovalent organic group or a halogen atom and which is derived from a fluorine-containing monomer having a fluoroalkyl group; (b) a repeat unit which is an alkyl acrylate having a C6-13 alkyl group and is derived from a non-fluorine monomer; and (c) a repeat unit derived from a non-fluorine (meth)acrylate monomer having a cyclic hydrocarbon group. A surface treatment agent which imparts a base material with excellent water repellency, oil repellency, anti-soiling properties, and soil release properties can be obtained.

Owner:DAIKIN IND LTD

Fluoropolymer and surface treatment agent composition

ActiveCN108017745AExcellent water repellencyExcellent oil repellencyOther chemical processesLiquid repellent fibresFiberFluoropolymer

The present invention provides a fluoropolymer capable of giving excellent washing durability and water and oil repellency to fibers. The fluoropolymer has a repeating unit derived from a fluorine-containing monomer (a) containing a first fluorine-containing monomer (a1) and a second fluorine-containing monomer (a2), and the first fluorine-containing monomer (a1) is represented by CH2=C(-X1)-C(=O)-Y1-Z1-Rf1, wherein X1 is a halogen atom, Y1 is-O-or-NH-, Z1 is a valence bond or a divalent organic group, Rf1 is a fluoroalkyl group having 1 to 20 carbon atoms, the second fluorine-containing monomer (a2) is represented by CH2=C(-X2)-C(=O)-Y2-Z2-Rf2, in the formula, X2 is a monovalent organic group or a hydrogen atom, Y2 is-O-or-NH-, Z2 is a valence bond or a divalent organic group, and Rf2 isa fluoroalkyl group having 1 to 20 carbon atoms.

Owner:DAIKIN IND LTD

Aqueous film-forming foam extinguishant with high stability

An aqueous film-forming foam extinguishant with high stability belongs to the technical field of fire service inventory and comprises the following components by mass percent: 1.2-3.0% of a fluorocarbon surfactant, 0.5-1.5% of a fluorine-free surfactant, 1.5-3.5% of perfluorbetaine, 2-5% of fluorinated lauryl betaine, 3-5% of urea, 5-15% of sodium alpha-olefin sulfonate, 10-15% of lauryl sodium sulfate, 10-16% of alkyl glycoside, 10-20% of glycol, 0.1-0.3% of xanthan gum, 0.5-1.0% of a foam stabilizer, 0.8-1.5% of a cosolvent, 0.1-1.2% of a thickener and the balance of water. The aqueous film-forming foam extinguishant with high stability is scientific in component, and compared with a traditional aqueous film-forming foam extinguishant, has favorable hydrophobicity and oleophobic propertyand very low surface tension; a thin film can be formed when generated foam covers a burning oil surface, and the thin film tightly covers the oil surface to play a fire smothering role; the aqueousfilm-forming foam extinguishant with high stability has a strong high temperature resisting function; the formed thin film has extremely high stability; the temperature reduction speed is high; the probability of after-combustion is low; the use is stable; and therefore, the fire extinguishing speed is greatly improved.

Owner:靖江市新东机械零部件制造有限公司

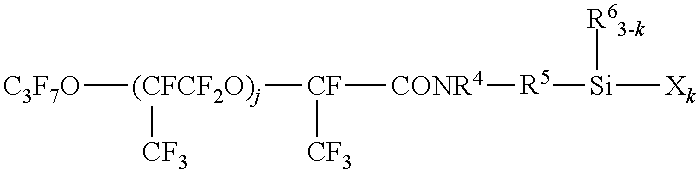

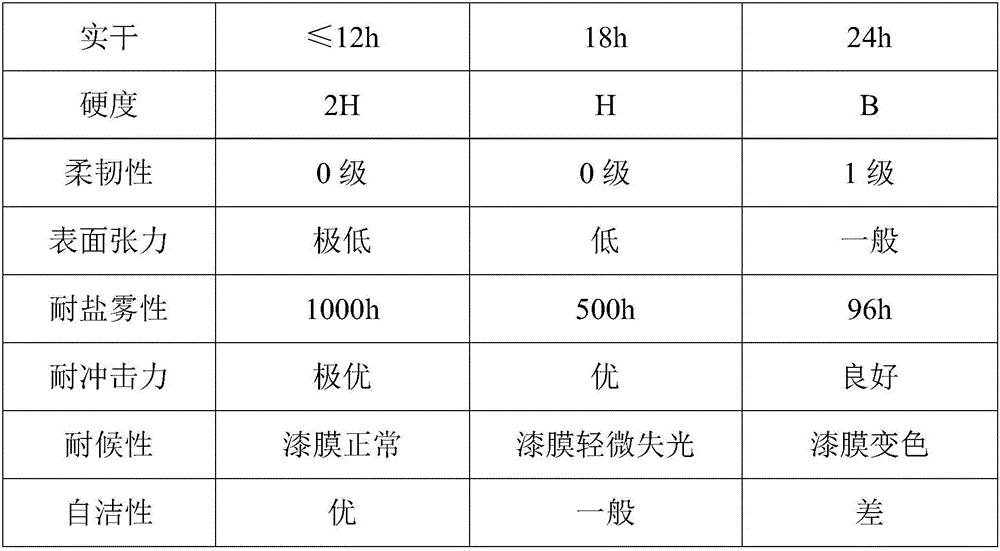

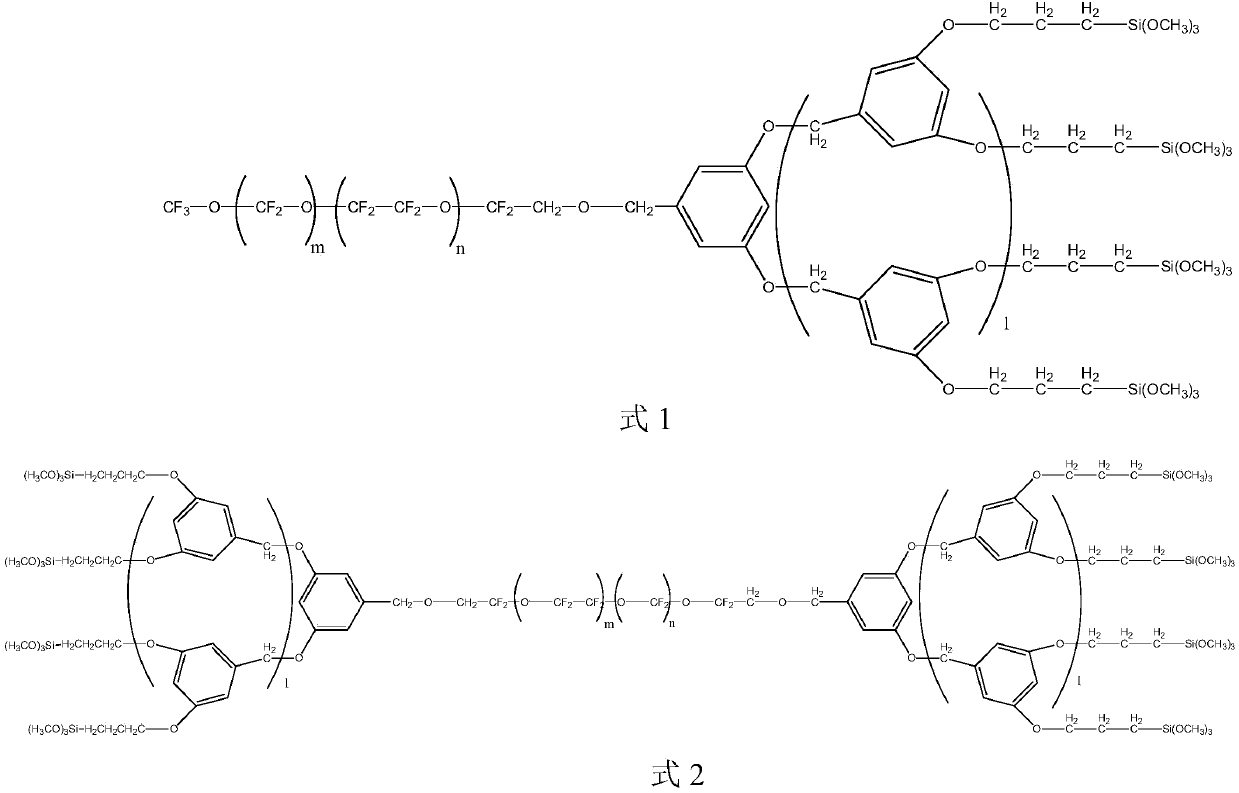

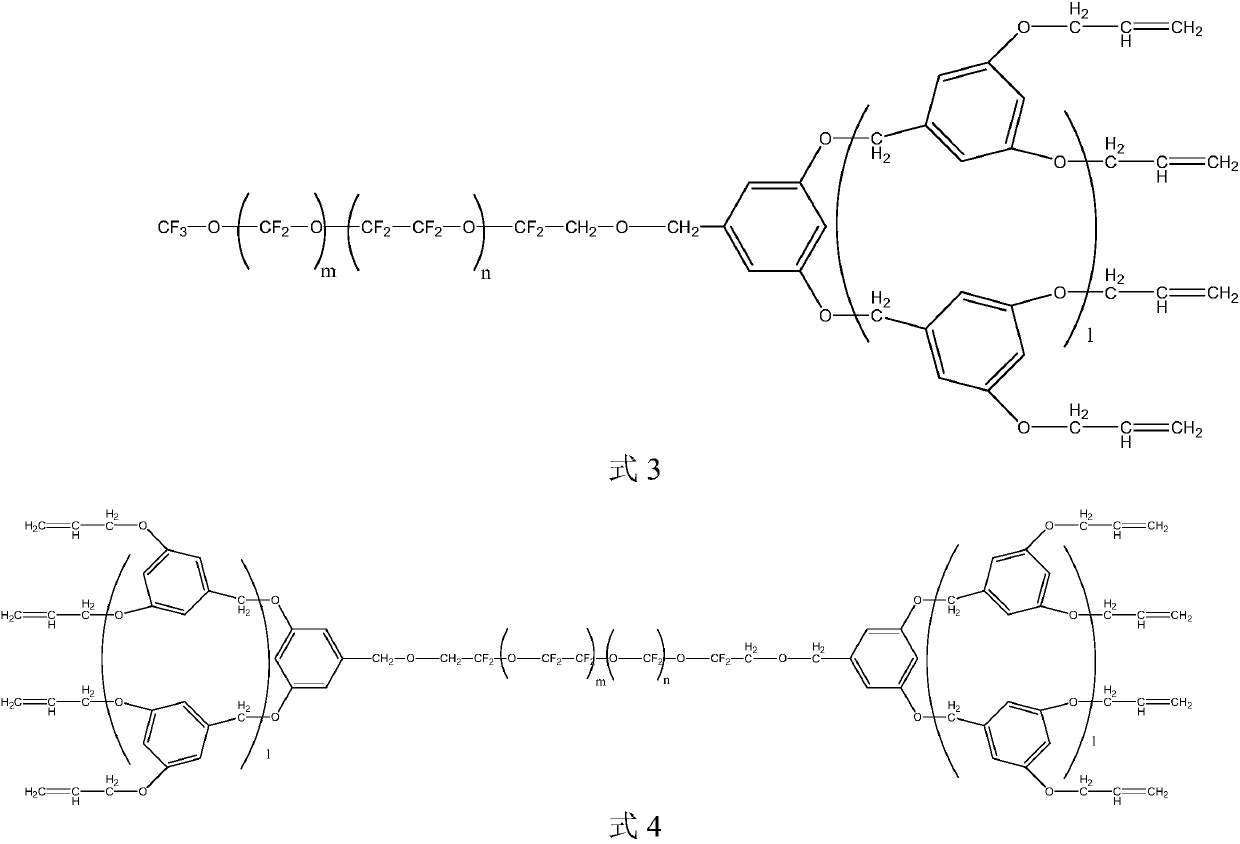

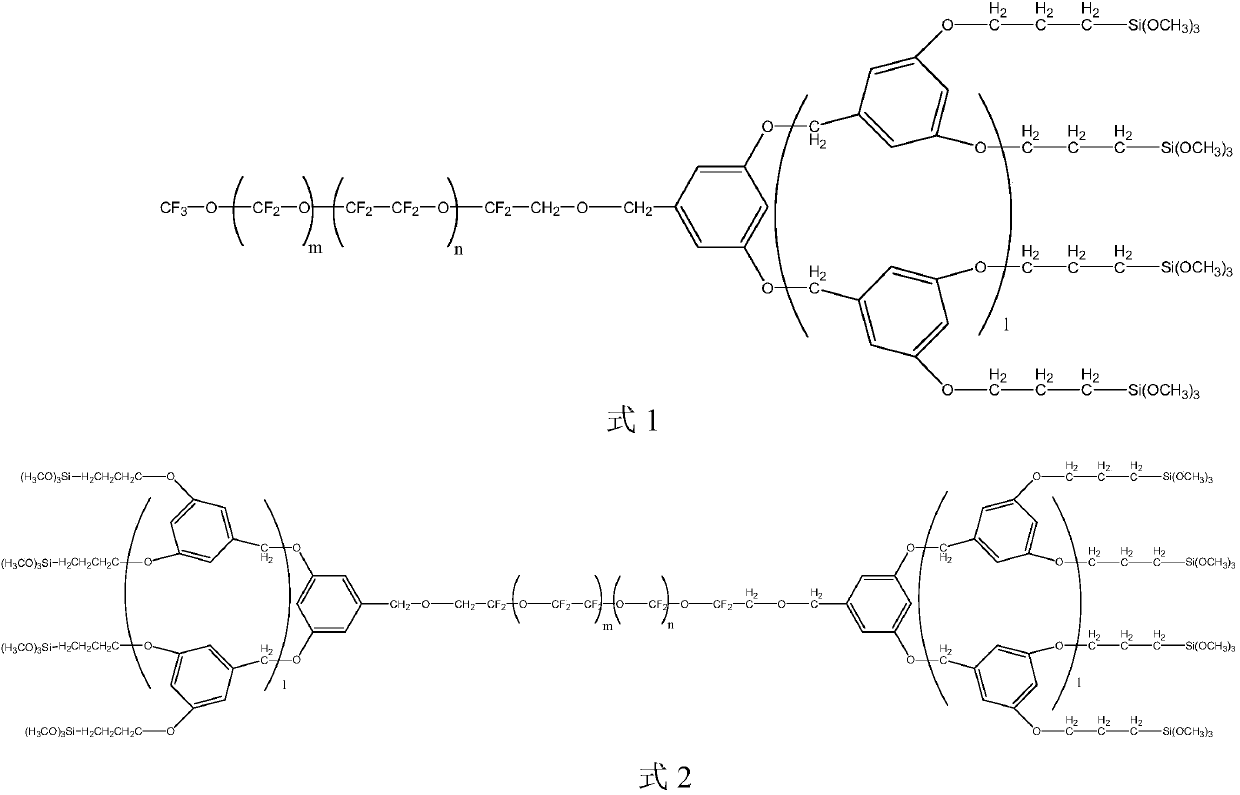

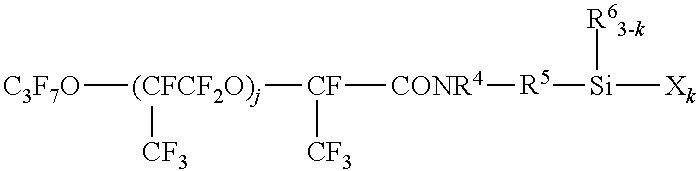

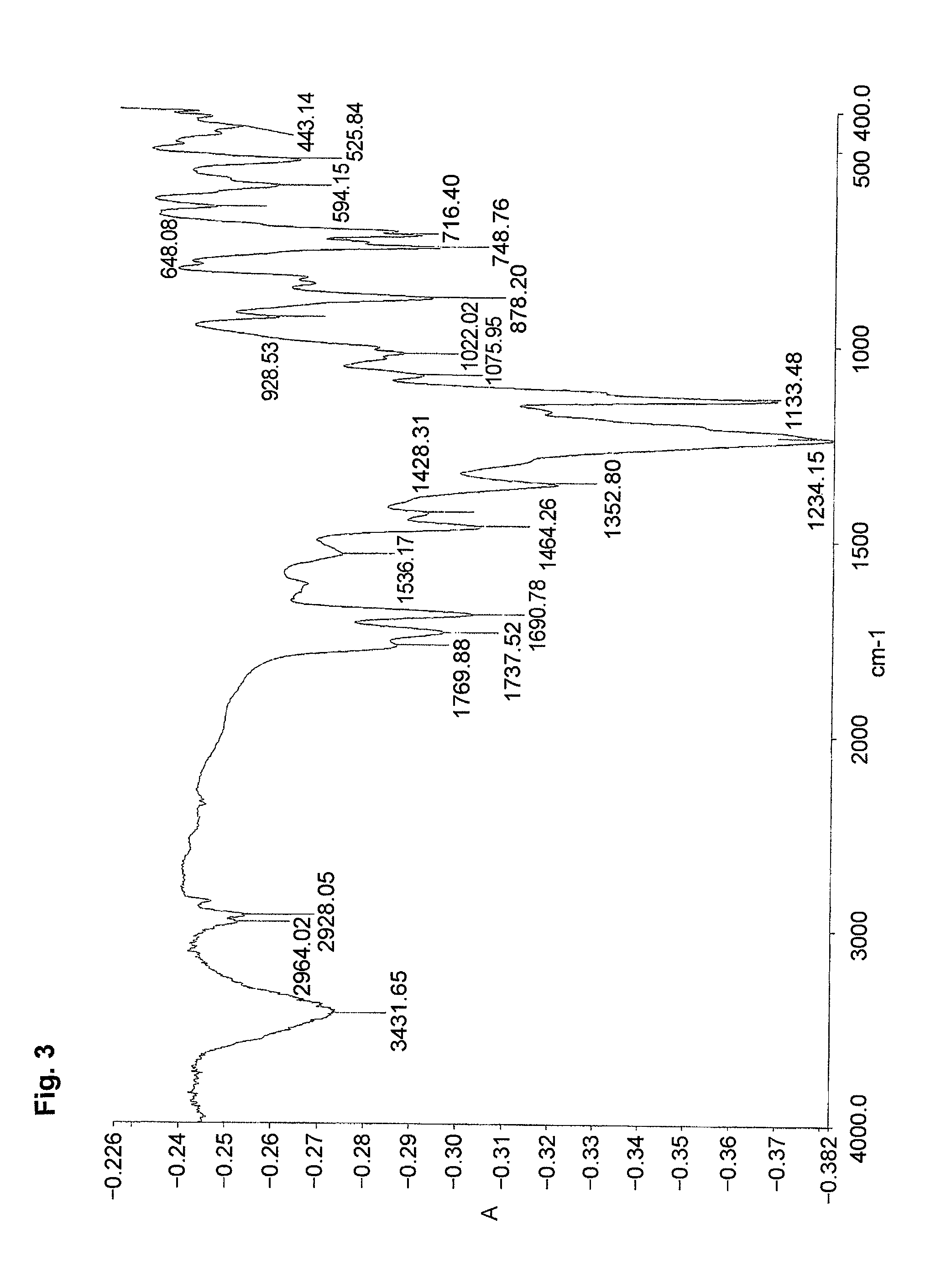

Perfluoropolyether modified dentritic silane derivative, as well as preparation method and application thereof

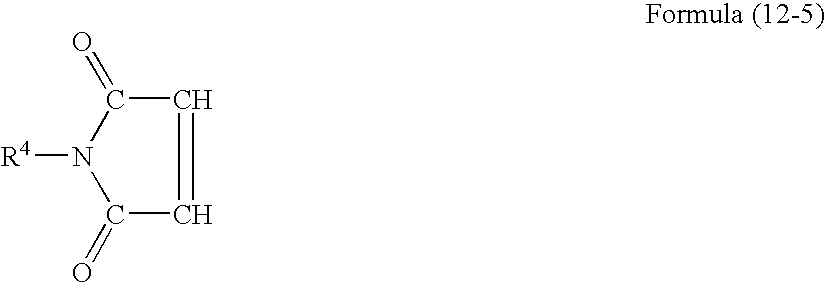

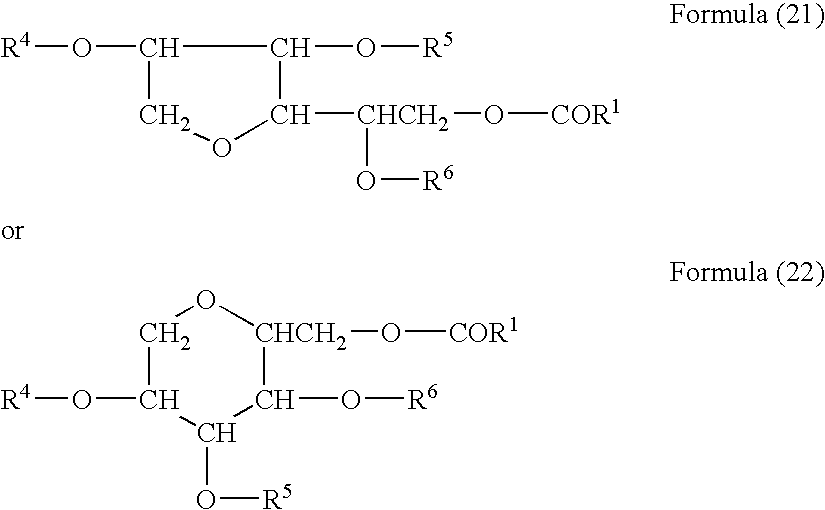

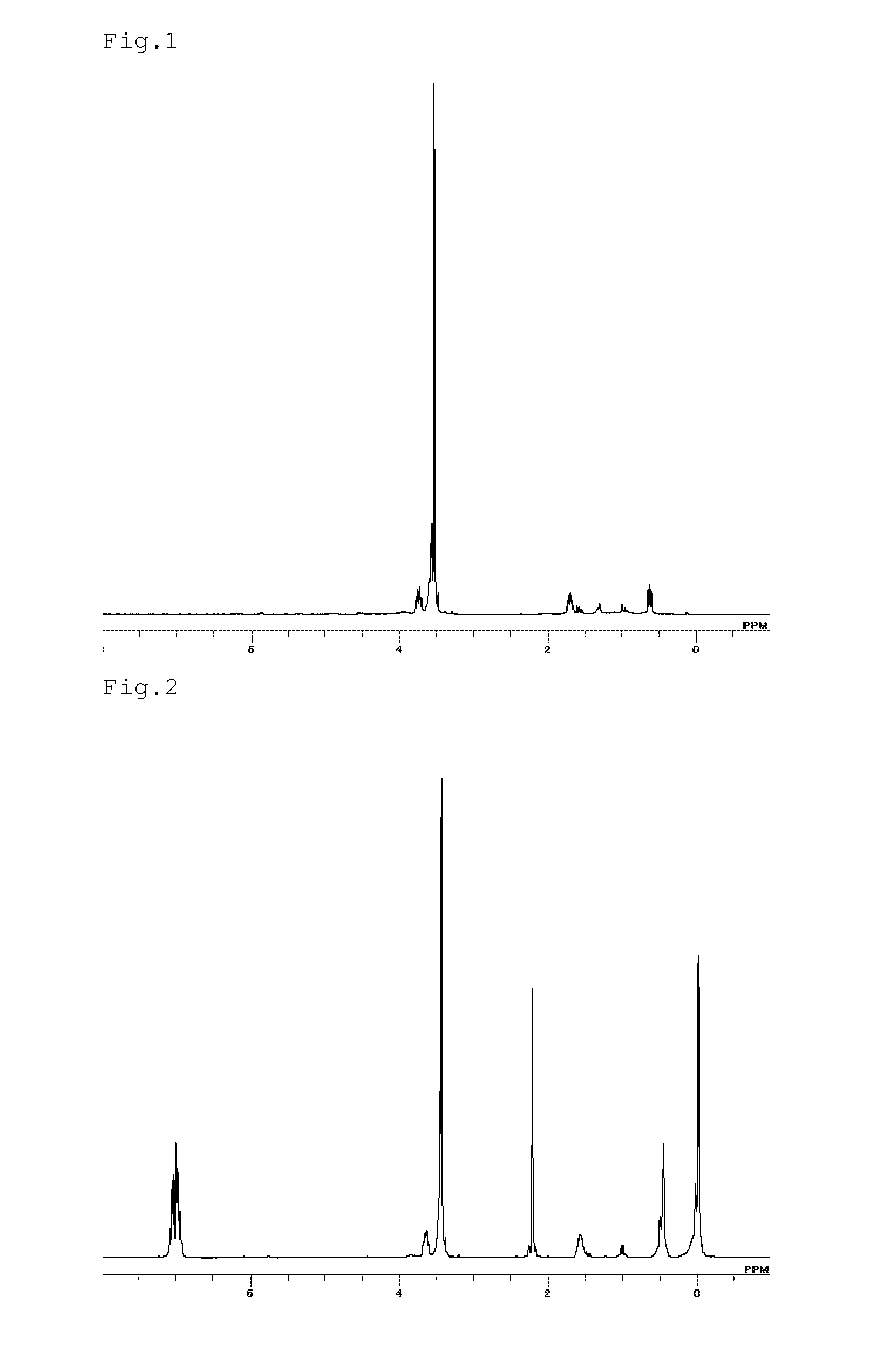

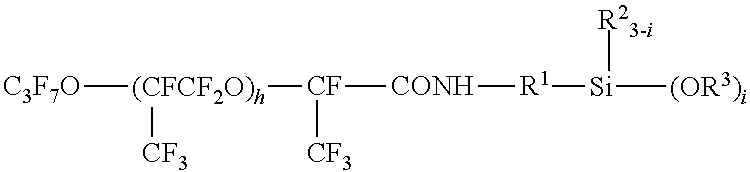

InactiveCN109942806AMild conditionsSimple processAntifouling/underwater paintsPaints with biocidesSilanesPerfluoropolyether

The invention provides a perfluoropolyether modified dentritic silane derivative. The perfluoropolyether modified dentritic polymer has a structural formula as shown in formulae 1 and 2, wherein m andn are respectively selected from integers of 1-40, and sum of m and n is 20-60, and m / n is 0.3-3; l is 0 or 1; and the terminal methoxyl connected with the silicon atom can be replaced by alkoxy having the number of carbon atoms being 2-5.

Owner:SHENZHEN E TOUCH TECH

Fluorooxyalkylene group-containing polymer composition, a surface treatment agent comprising the same and an article treated with the agent

ActiveUS8420763B2Increase surface lubricityImprove adhesionPolyether coatingsOptical elementsWear resistanceStain

An object of the present invention is to provide a fluorooxyalkylene group-containing polymer composition, which yields a coating having excellent adhesior to a substrate, good water- and oil-repellency, a low dynamic friction coefficient, good releasing property, good abrasion resistance and good stain resistance, and to provide a surface treatment agent comprising the same. The present inventors have found that a composition comprising a fluorooxyalkylene group-containing polymer having a fluorinated group and a hydrolyzable group at each terminal and a fluorooxyalkylene group-containing polymer having hydrolyzable groups at both terminals can form a coating which has excellent water- and oil-repellency, a low dynamic friction coefficient, good releasing property, good abrasion resistance, and good stain resistance.

Owner:SHIN ETSU CHEM CO LTD

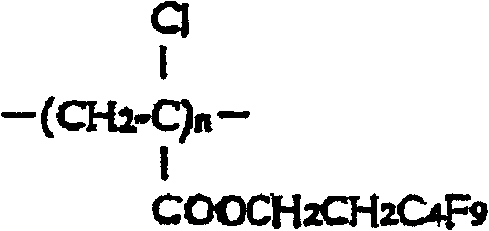

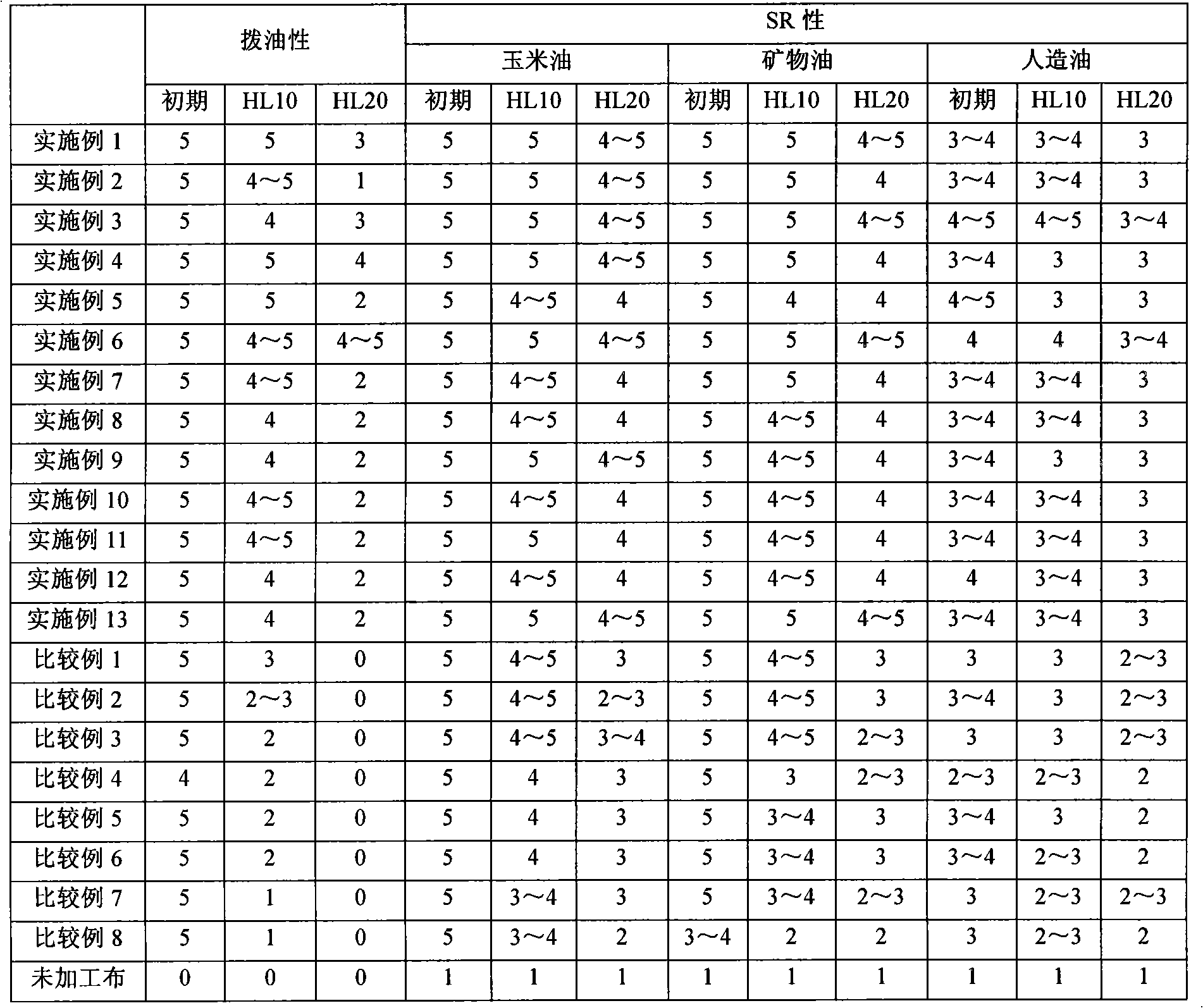

Fluorine-containing block copolymer and preparation method and application thereof

ActiveCN103694429ABoth oil repellencyAntifoulingFibre treatmentSolubilityAtom-transfer radical-polymerization

The invention relates to a fluorine-containing block copolymer and a preparation method and application thereof. The weight-average molecular weight of the polymer is 5,000-100,000, and the polymer is prepared by polymerizing 15-65wt% of monomer A, 10-80wt% of monomer B, 0.5-15wt% of monomer C and 0.5-10wt% of monomer D in an atom transfer radical polymerization (ATRP) way. Compared with the traditional fluorine-containing random copolymer obtained by common free radical polymerization, the fluorine-containing block copolymer with fewer than 8 carbon atom in perfluoroalkyl group and synthesized in an ATRP way integrates the characteristics of oil repellency, antifouling property, decontamination and good solubility when used as an antifouling agent and a decontamination agent; moreover, under the condition of the same dosage of perfluoroalkyl group, better oil repellency can be obtained.

Owner:太仓中化环保化工有限公司

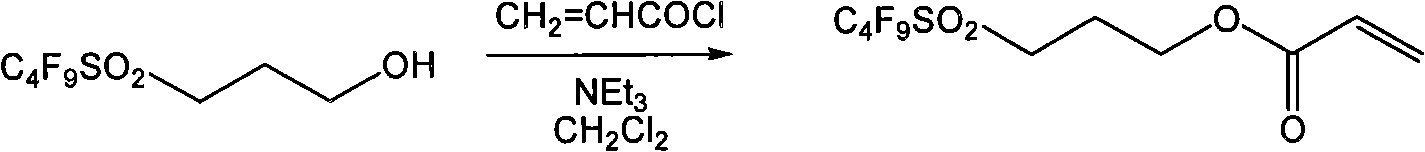

Fluoropolymer having S-sulfate group and water/oil repellent composition containing the polymer

InactiveUS8394887B2Easy to waterExcellent oil-repellencyLayered productsLiquid repellent fibresPolymer scienceEster sulfate

A fluoropolymer comprising: (A) repeating unit derived from an S-sulfate monomer having an —S—SO3— group and carbon to carbon double bond; and (B) repeating unit derived from a fluoromonomer having a fluorine atom and carbon to carbon double bond. This fluoropolymer can be a constituent of water / oil repellent agent having excellent water / oil repelling capability, and is stable in air and permits an arbitrary control of crosslinking.

Owner:DAIKIN IND LTD

Oil-Repellent Coating Material Composition

InactiveUS20120251728A1Good oil-repellencyExcellent oil repellencyOther chemical processesPretreated surfacesHydrogen atomHalogen

An oil-repellent coating material composition containing:(A) an alkoxysilane, represented by the following general formula (1), having a hydrocarbon group to which at least one or more fluorine atoms are bonded;Rf[—X—Y—SiR1a(OR2)3−a]m (1)whereinRf represents an alkyl group, an alkenyl group, or an aromatic hydrocarbon group, the group having at least one fluorine atom and 1 to 20 carbon atoms;X represents an oxygen atom or a divalent organic group containing an oxygen atom;Y represents a spacer group (CH(Z)—)n wherein Z is a substituent selected from a hydrogen atom, a halogen atom, or a hydrocarbon group having 1 to 3 carbon atoms, and n is of 2 to 8;R1 and R2 may be the same or different hydrocarbon group(s) having 1 to 10 carbon atoms;m is 1 or 2; anda is 0, 1, or 2); and(B) a condensation catalyst.

Owner:WACKER CHEM GMBH

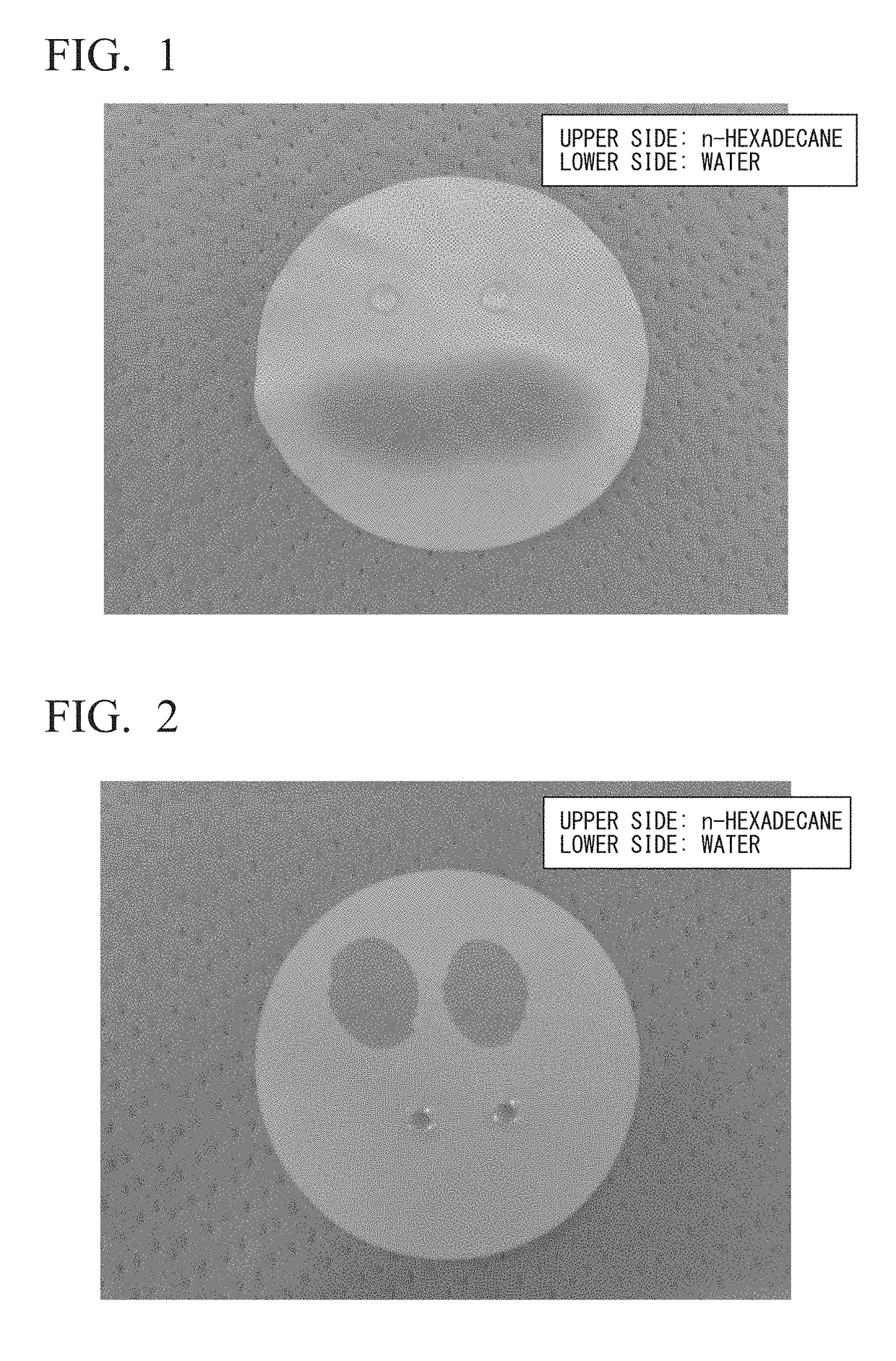

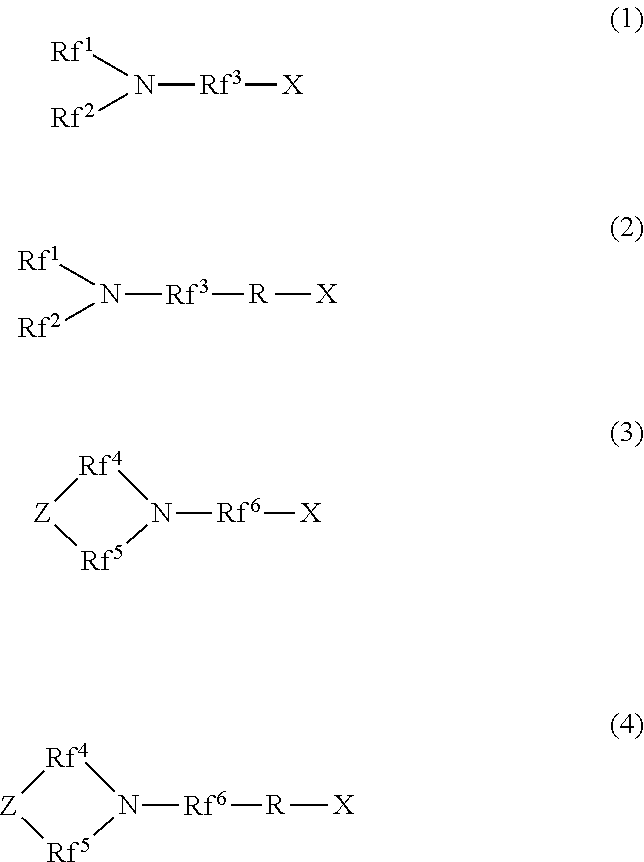

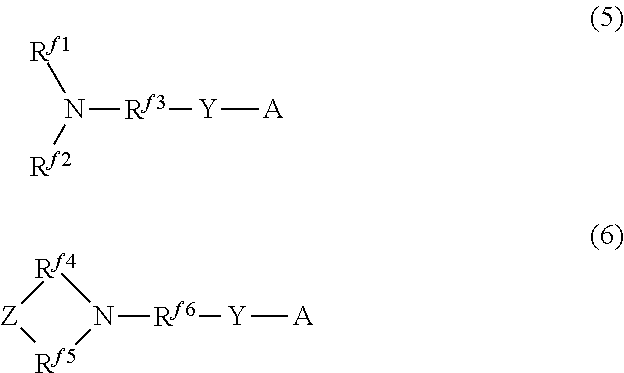

Hydrophilic oil repellent and production method of same, surface coating material, coating film, resin composition, oil-water separation filter material, and porous body

InactiveUS20170210912A1Improve hydrophilicityWell formedFatty/oily/floating substances removal devicesAntifouling/underwater paintsNitrogenOil water

The hydrophilic oil repellent includes one or more types of nitrogen-containing fluorine-based compounds. The nitrogen-containing fluorine-based compound includes any one hydrophilicity imparting group selected from the group consisting of anion type hydrophilicity imparting groups, cation type hydrophilicity imparting groups, and amphoteric type hydrophilicity imparting groups in the molecule.

Owner:MITSUBISHI MATERIALS CORP +1

Vent filter imparted with oil repellency

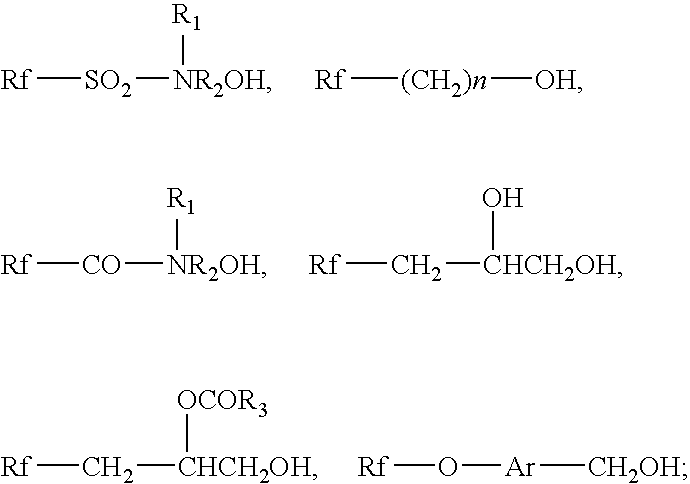

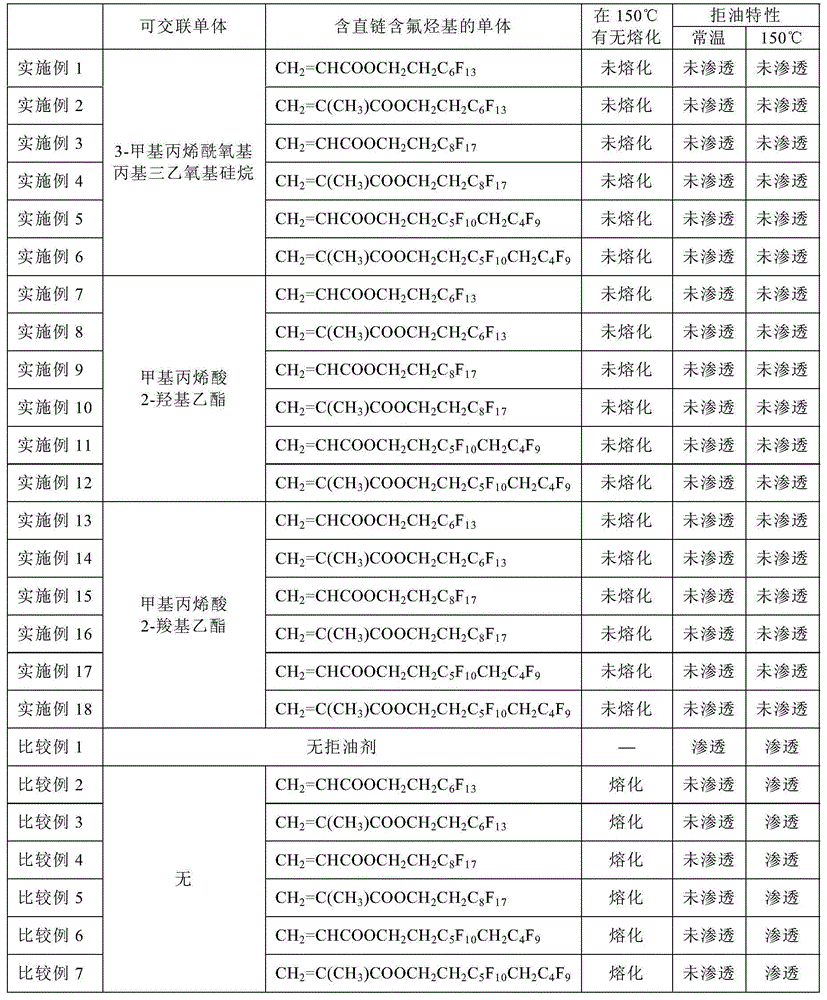

InactiveCN104602797AExcellent oil repellencyMembranesSemi-permeable membranesAlkoxy groupHydroxy group

A vent filter according to the present invention has a surface coated with an oil-repellent agent. The oil-repellent agent comprises a copolymer of a monomer containing a linear fluorinated hydrocarbon group and a crosslinkable monomer. The crosslinkable monomer comprises at least one monomer selected from a monomer containing an alkoxy group, a monomer containing a hydroxy group and a monomer containing a carboxyl group.

Owner:NITTO DENKO CORP

Oil-repellent finishing liquid for woolen sweater and preparation method for oil-repellent finishing liquid

The invention discloses oil-repellent finishing liquid for a woolen sweater and a preparation method for the oil-repellent finishing liquid. The oil-repellent finishing liquid for the woolen sweater consists of the following components in parts by weight: 6 to 8 parts of polyethylene glycol monomethyl ether, 3 to 5 parts of an emulsifier OP-13, 2 to 5 parts of polypropylene glycol, 6 to 10 parts of sodium polyacrylate, 14 to 17 parts of ethanol and 185 to 200 parts of water. The finishing liquid is prepared by the steps of heating, stirring, sealed storage and the like. The prepared finishing liquid has a good oil-repellent effect.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Masonry-treating agent

InactiveUS20110086971A1Excellent oil-repellencyEasy to waterFibre treatmentPretreated surfacesHydrogenFluoropolymer

A fluoropolymer for masonry treatment produced from (A) a fluoromonomer which has been substituted in the α-position by a X group and is represented by the formula (I):and (B) a monomer having a functional group reactive with active hydrogen. It imparts excellent water- and oil-repellency and unsusceptibility to fouling to masonries.

Owner:DAIKIN IND LTD

Surface treatment agent

ActiveUS20190077984A1Easy to waterExcellent oil-repellencyOther chemical processesLiquid repellent fibresWater basedLiquid medium

Provided is a surface treatment agent which does not use fluorine-containing monomers, particularly fluoroalkyl group-containing monomers. The surface treatment agent is a water-based emulsion which includes: a copolymer (1) which includes a first polymer formed from first monomers, and a second polymer formed from second monomers, wherein the second polymer is polymerized in the presence of the first polymer, the first monomers include a long-chain acrylate ester monomer (a) represented by the formula CH2═CA11-C(═O)—O-A12 (in the formula, A11 represents hydrogen, a monovalent organic group, or a halogen, and A12 represents a C18-30 straight-chain or branched hydrocarbon group), the first monomers do not include a halogenated olefin monomer (b), and the second monomers include the halogenated olefin monomer (b); a surfactant (2) including a nonionic surfactant; and a liquid medium (3) including water.

Owner:DAIKIN IND LTD

Dacron textile easy to decontaminate

The invention discloses dacron textile easy to decontaminate. A water sucking oil repellent resin film is covered on the surface of single fibres of the textile. Residual quantity of perfluor octanoic acid ammonium compound in the water sucking oil repellent resin film is more than 0 and less than or equals to 0.05mu g / g. Residual quantity of perfluor octane sulfonic acid compound is greater than 0 or less than or equals to 0.05mu g / g. Sweat can be absorbed when a person wears clothes made from the dacron textile easy to decontaminate. Oily dirt is prevented from permeating to the inner portion of the fibre. The dirt is removed simply under the condition of the combined effect of a dewatering component and a hydrophilic component. The decontamination ability is good when the dacron textile easy to decontaminate is washed while a detergent is not added at the same time.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com