Fluorine-containing polymer and treatment agent

A technology of polymers and surface treatment agents, which is applied in fiber treatment, textiles and papermaking, and liquid-repellent fibers, etc. It can solve the problems of insufficient water and oil repellency, insufficient durability of water and oil repellency, and substrate contamination. etc. to achieve excellent durability, excellent water repellency, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

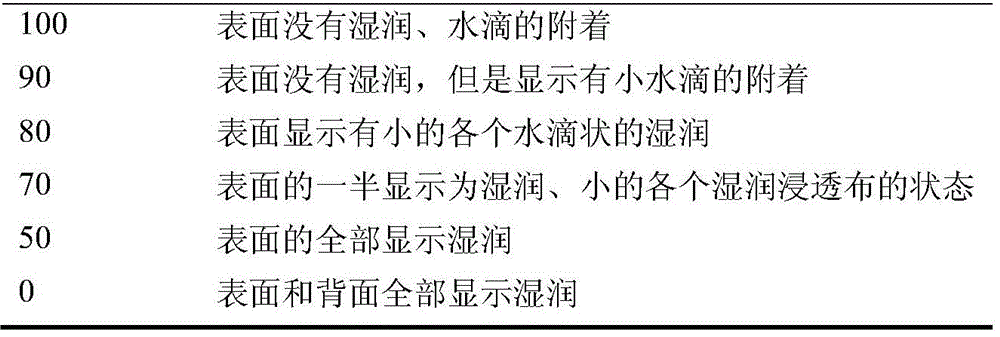

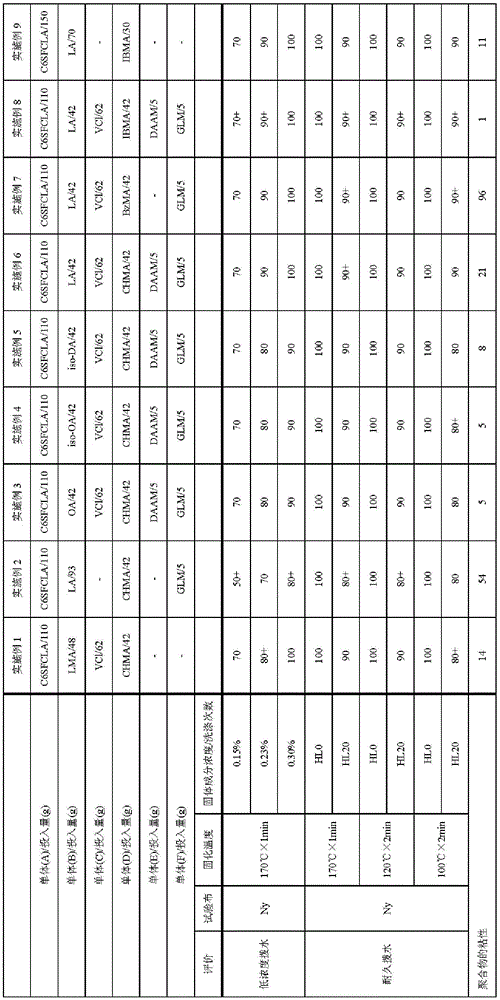

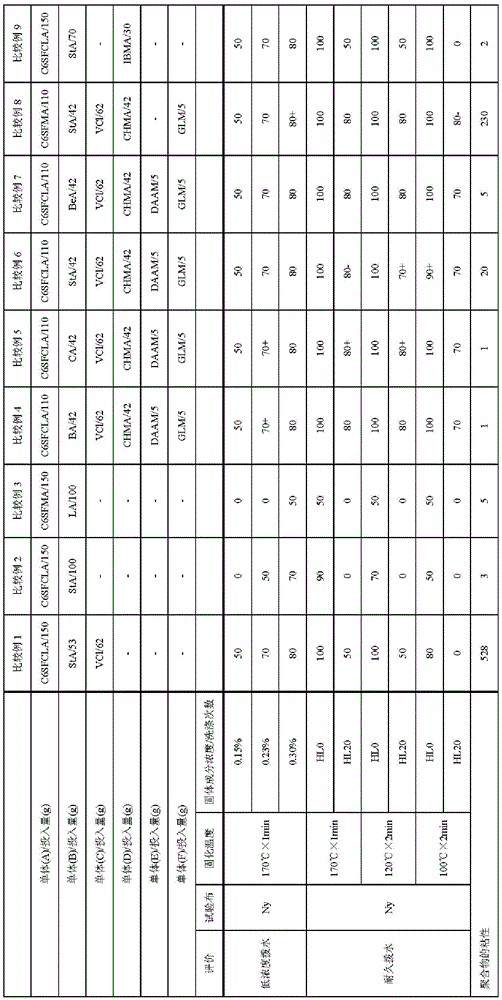

[0185] Add monomer A:C to 1L autoclave 6 f 13 CH 2 CH 2 OCOC(Cl)=CH 2 (C6SFCLA) 110g, monomer B: lauryl methacrylate (LMA) 48g, monomer D: cyclohexyl methacrylate (CHMA) 42g, pure water 446g, tripropylene glycol 76g, polyoxyethylene dodecyl 10.2 g of alkyl ether, 2.47 g of polyoxyethylene octadecyl ether, and 7.6 g of polyoxyethylene isotridecyl ether were emulsified and dispersed using a high-pressure homogenizer after heating at 60°C. After emulsification, 2.5 g of dodecyl mercaptan and 62 g of monomer C: vinyl chloride (VCl) were charged under pressure. Furthermore, 1.6 g of 2,2- azobis(2-amidinopropane) dihydrochloride was added, and it was made to react at 70 degreeC for 3 hours, and the aqueous dispersion liquid of a polymer was obtained. The water repellency (water and oil repellency) and viscosity of the aqueous dispersion liquid whose solid content concentration was adjusted to 30 weight% with pure water were evaluated. The results are shown in Table 2.

Embodiment 2

[0187]Use lauryl acrylate (LA) as monomer B, omit monomer C: vinyl chloride (VCl), add monomer F: glycerol monomethacrylate (GLM), in addition, with embodiment 1 In the same manner, an aqueous dispersion of the polymer was obtained (refer to Table 2 for the input amount of each component). The water repellency and viscosity of the aqueous dispersion whose solid content concentration was adjusted to 30% by weight with pure water were evaluated. The results are shown in Table 2.

Embodiment 3

[0189] Use octyl acrylate (OA) as monomer B, add monomer E: diacetone acrylamide (DAAM) and monomer F: glycerol monomethacrylate (GLM), in addition, operate in the same way as in Example 1, An aqueous dispersion of the polymer was obtained (see Table 2 for the input amount of each component). The water repellency and viscosity of the aqueous dispersion whose solid content concentration was adjusted to 30% by weight with pure water were evaluated. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com