Vent filter imparted with oil repellency

A filter and oil-repellent technology, applied in the field of breathable filters, can solve the problem of insufficient prevention of intrusion, and achieve the effect of excellent oil-repellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

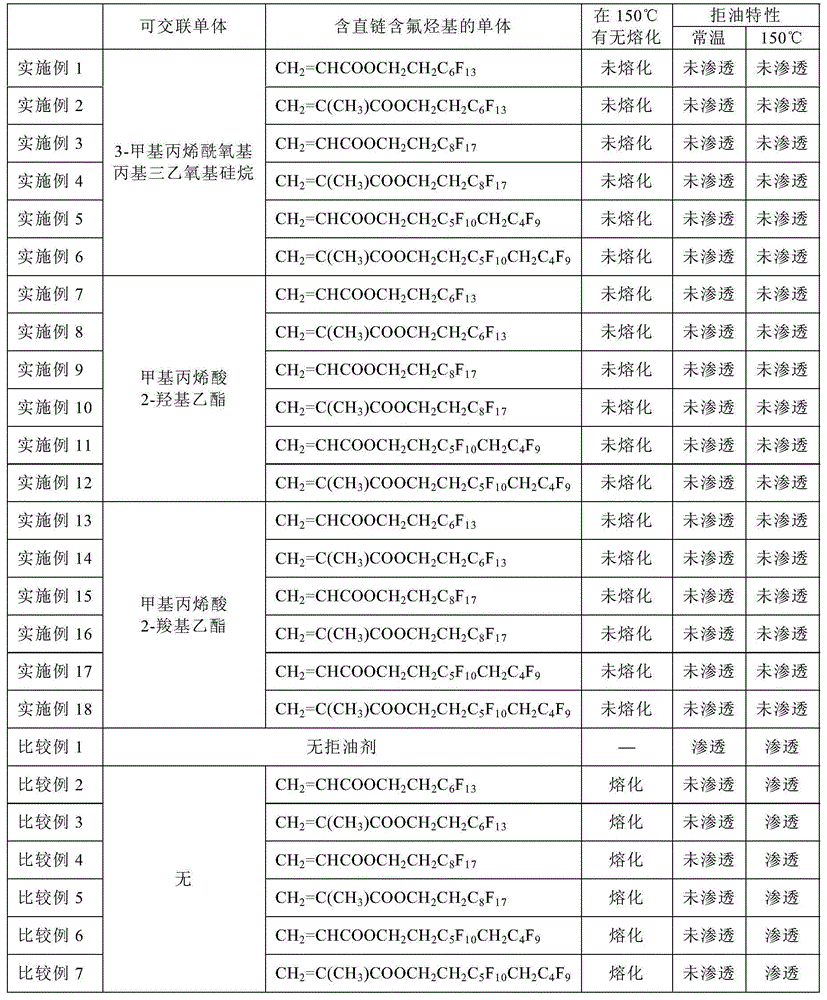

Examples

Embodiment 1

[0053] As the polytetrafluoroethylene porous membrane, a fluorine-containing resin porous film "TEMISH (registered trademark) NTF1131" (thickness: 0.1 mm) manufactured by Nitto Denko Co., Ltd. was used. Diluted with a diluent (“FS Thinner” manufactured by Shin-Etsu Chemical Co., Ltd.) so as to contain 95 mol% of CH 2 =CHCOOCH 2 CH 2 C 6 f 13 As a monomer containing a straight-chain fluorine-containing hydrocarbon group and containing 5 mole % of 3-methacryloxypropyltriethoxysilane as a mixture of crosslinkable monomers is 3.0% by weight, Al chelate cross The oil-repellent treatment liquid was prepared by using a coupling agent ("DF-40" manufactured by Shin-Etsu Chemical Co., Ltd.) at 0.15% by weight. This oil-repellent treatment liquid was kept at 20° C., and NTF1131 was immersed in this oil-repellent treatment liquid for about 3 seconds while being fixed to a 20 cm square frame so as not to shrink. It was then left at 100°C for about 1 hour, thereby drying the solvent an...

Embodiment 2

[0055] Use the general formula CH 2 =C(CH 3 ) COOCH 2 CH 2 C 6 f 13 A gas-permeable filter was obtained in the same manner as in Example 1 except that the straight-chain fluorinated hydrocarbon group-containing monomer was used.

Embodiment 3

[0057] Use the general formula CH 2 =CHCOOCH 2 CH 2 C 8 f 17 A gas-permeable filter was obtained in the same manner as in Example 1 except that the straight-chain fluorinated hydrocarbon group-containing monomer was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com