Fluorine-containing block copolymer and preparation method and application thereof

A technology of block copolymers and copolymers, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of insufficient oil repellency, low decontamination and solubility of antifouling processing agents, etc., and achieve good decontamination , Excellent oil repellency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In a 500ml four-necked flask, 100g of methoxypolyethylene glycol (EO10mol) monomethacrylate, 100g of dipropylene glycol monomethyl ether, 0.5g of ethyl α-bromoacetate, N,N,N', N,'N''-pentamethyldiethylenetriamine 1.0g, cuprous bromide 0.8g, nitrogen replacement, the oxygen content dropped to below 100ppm, the temperature was raised to 80°C, and after 6 hours of reaction, passed The conversion rate detected by gas chromatography was greater than 98%, and then 10g of hydroxyethyl methacrylate and 10g of N,N-dimethylaminoethyl methacrylate were injected into the system. After 3 hours of reaction, the conversion rate was detected by gas chromatography to be greater than 98%. , and then inject 100g of perfluorohexylethyl methacrylate (6FMA) into the system. After 20 hours of reaction, the conversion rate was detected by gas chromatography to be greater than 99%. Air was introduced, the temperature was lowered, and the reaction was terminated. The product was passed through an...

Embodiment 2~6

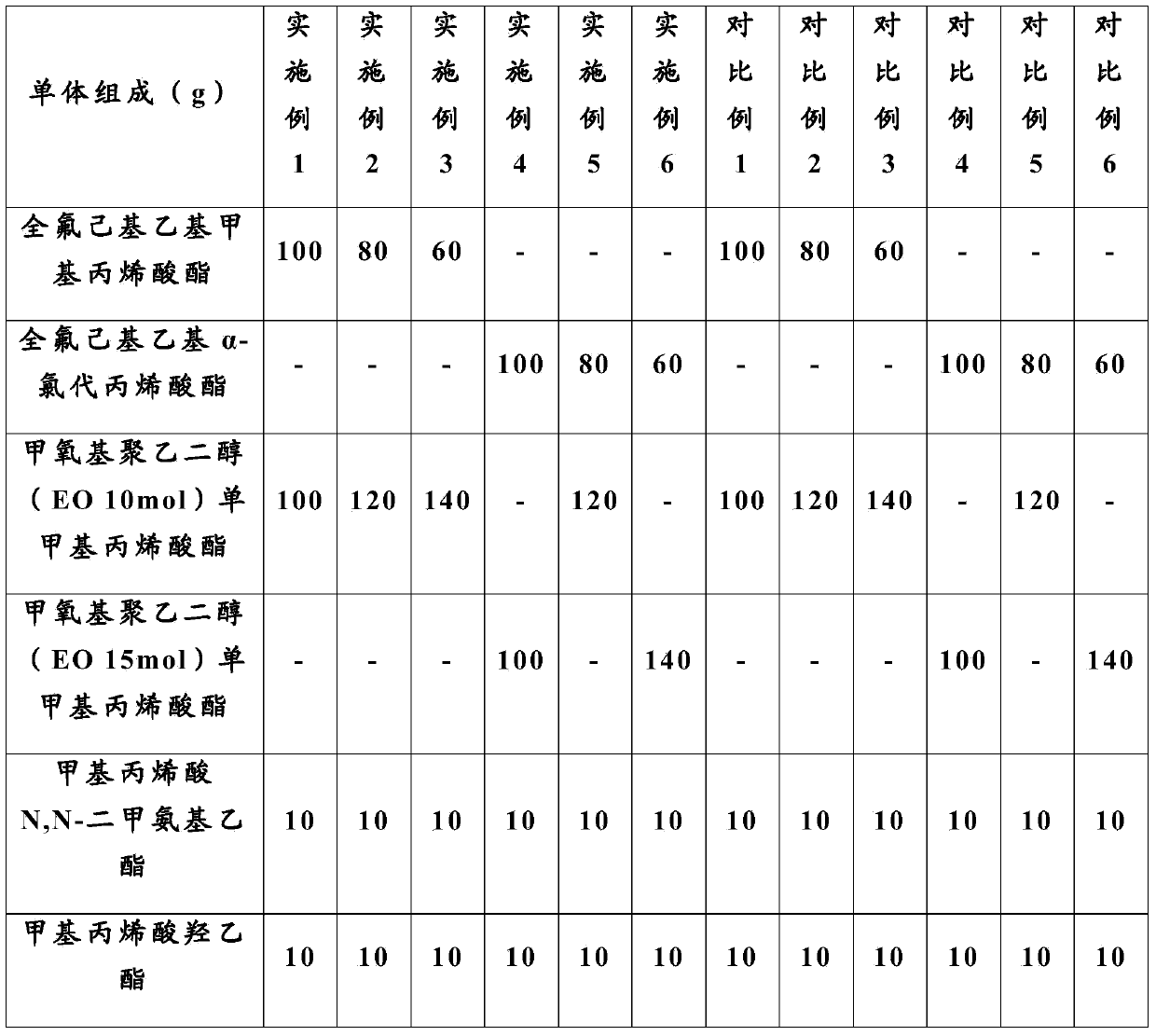

[0045] According to the monomer composition and proportion shown in the table, the same steps as in Example 1 were repeated to finally obtain a solution with a solid content of 20%, and the composition of the copolymer is shown in Table 3.

[0046] table 3

[0047]

Embodiment 2~6 and comparative example 1~6

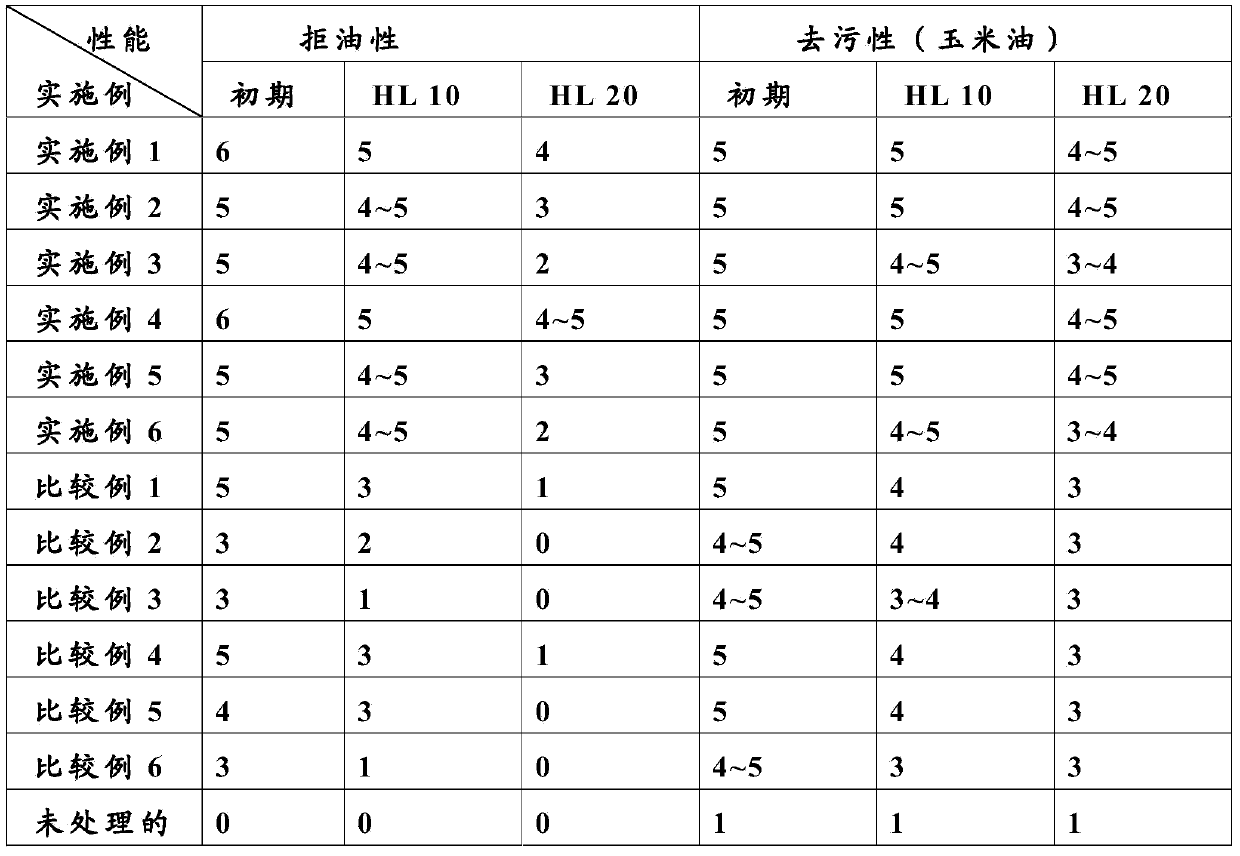

[0060] The fluorine-containing block copolymer solutions were respectively replaced with the substances obtained in Examples 2-6 and Comparative Examples 1-6. In addition, the treatment liquid was prepared according to the same steps as in Test Example 1, cloth treatment was carried out, and the removal rate was measured. Stain and oil repellency. The results are shown in Table 4.

[0061] Table 4

[0062]

[0063]

[0064] Note: Numbers A to B in the table indicate the performance between A and B; HL10 and HL20 indicate after washing 10 times and 20 times respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com