Fluorine-silicon modified waterborne alkyd resin and preparing method thereof

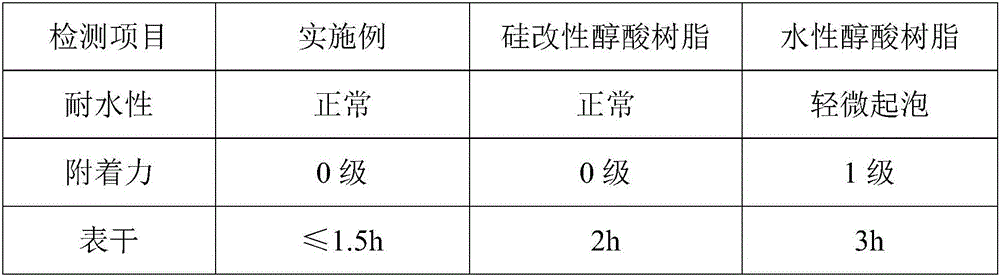

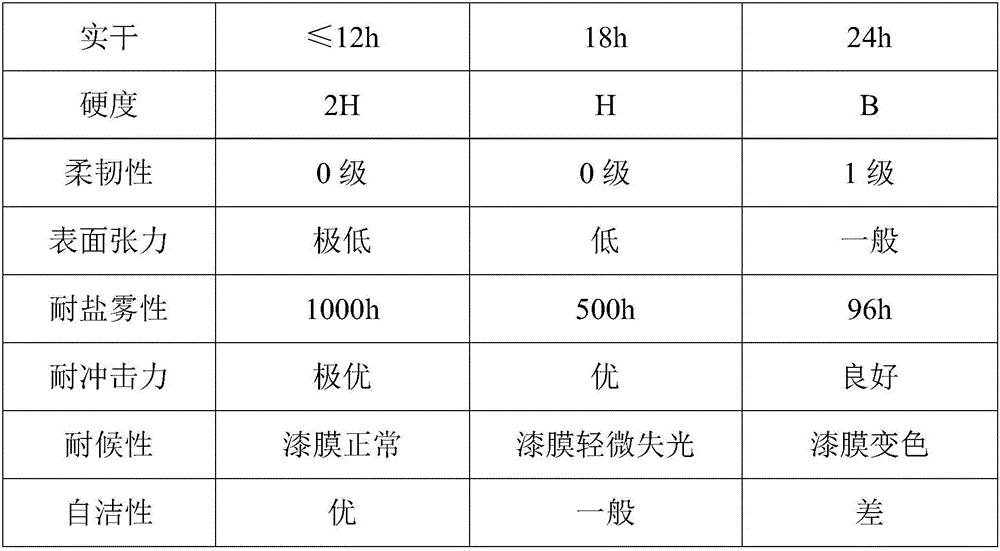

A water-based alkyd resin, fluorosilicon modification technology, used in antifouling/underwater coatings, coatings, anti-corrosion coatings, etc., can solve the problems of aging resistance, poor self-cleaning function, and no high temperature resistance. Achieve the effect of low VOC content, reduced physical and chemical properties, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of fluorosilicon modified water-based alkyd resin, its preparation process is as follows:

[0027] a. Put 4.0 parts of hydroxyl-terminated organosilicon into a four-port reactor equipped with a thermometer, condenser and stirrer and raise the temperature to 82-85°C, then add 6.0 parts of toluene diisocyanate dropwise at a constant speed, and finish the dropping within 1 hour. Continue to react for 2h to obtain active intermediate A, which is ready for use;

[0028] b. In a reactor equipped with a stirring and dripping device, add 8.0 parts of acrylic monomers, 6.0 parts of fluoroolefin monomers and 0.07 parts of catalyst azobisisobutyronitrile according to the recipe requirements, and stir evenly to obtain a monomer mixture B, for use;

[0029] c. In a four-port reactor equipped with a thermometer, condenser, water separator, and agitator, according to the weight percentage of the formula, add 6.0 parts of vegetable oil fatty acid, 3.0 parts of phthalic anhydrid...

Embodiment 2

[0032] A kind of fluorosilicon modified water-based alkyd resin, its preparation process is as follows:

[0033] a. Put 4.5 parts of hydroxyl-terminated organosilicon into a four-port reactor equipped with a thermometer, condenser, and stirrer and raise the temperature to 83-87°C, then add 7.0 parts of isophorone diisocyanate dropwise at a constant speed, within 1 hour After dropping, continue to react for 2h to obtain active intermediate A, which is ready for use;

[0034] b. In the reactor with stirring and dripping device, add 6.0 parts of acrylic monomer, 6.5 parts of fluoroolefin monomer and 0.07 part of catalyst azobisisobutyronitrile according to the recipe requirements, and stir to obtain a monomer mixture B, for use;

[0035] c. In the four-port reactor equipped with a thermometer, condenser, water separator, and agitator, according to the weight percentage of the formula, add 6.0 parts of vegetable oil fatty acid, 3.5 parts of phthalic anhydride, 6.5 parts of trimet...

Embodiment 3

[0038] A kind of fluorosilicon modified water-based alkyd resin, its preparation process is as follows:

[0039] a. Put 3.5 parts of hydroxyl-terminated silicone into a four-port reactor equipped with a thermometer, condenser and stirrer and raise the temperature to 83-87°C, then add 7.0 parts of isophorone diisocyanate dropwise at a constant speed, within 1 hour After dropping, continue to react for 2h to obtain active intermediate A, which is ready for use;

[0040] b. In a reactor equipped with a stirring and dripping device, add 8.5 parts of acrylic monomers, 7.0 parts of fluoroolefin monomers and 0.07 parts of catalyst azobisisobutyronitrile according to the recipe requirements, and stir to obtain a monomer mixture B, for use;

[0041] c. In the four-port reactor equipped with a thermometer, condenser, water separator, and agitator, according to the weight percentage of the formula, add 8.0 parts of vegetable oil fatty acid, 3.2 parts of phthalic anhydride, 6.4 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com