Rubber sealing element with good anti-aging performance

A rubber seal, anti-aging technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems that affect the service life of seals, harsh use environments, and reduce the life of rubber seals, so as to reduce activity and improve mechanics Properties, effects of improving tensile strength and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

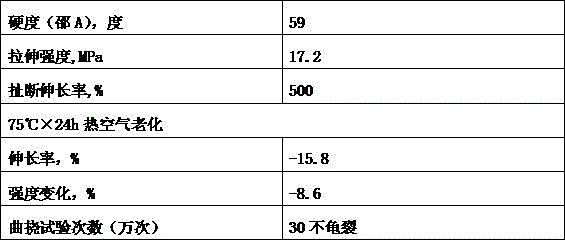

Examples

Embodiment 1

[0018] A rubber seal with good aging resistance, made of the following components in parts by weight: rubber base material 120, silicone oil 3, filler 30, crosslinking agent 1.2, lubricant 0.1, vulcanizing agent 2.5, plasticizer 0.2 , carbon black 1, functional additive 1.4;

[0019] The preparation method of the functional auxiliary agent is as follows: dissolving 0.12 mol of pyrogallol in isoamyl alcohol, adding 0.12 mol of sodium hydroxide and heating and stirring under the protection of nitrogen, when the temperature rises to the point where sodium hydroxide reacts with pyrogallol to form When the white suspension is present, add 0.04mol dichloroethyl ether dropwise within 16min, then stir for 2 hours, cool to 55°C, then add 0.12mol sodium hydroxide to heat and stir, and then add 0.06mol dichloroethyl ether at the same time ether, stirred for 2 hours, and then filtered to remove the solids to obtain a filtrate, which was evaporated to remove the solvent under reduced press...

Embodiment 2

[0029] A rubber seal with good aging resistance, made of the following components in parts by weight: rubber base material 120, silicone oil 5, filler 50, crosslinking agent 1.5, lubricant 0.3, vulcanizing agent 2.8, plasticizer 0.5 , carbon black 3, functional additive 1.8;

[0030] The preparation method of the functional auxiliary agent is as follows: dissolving 0.12 mol of pyrogallol in isoamyl alcohol, adding 0.12 mol of sodium hydroxide and heating and stirring under the protection of nitrogen, when the temperature rises to the point where sodium hydroxide reacts with pyrogallol to form When the white suspension is present, add 0.04mol dichloroethyl ether dropwise within 16min, then stir for 2 hours, cool to 55°C, then add 0.12mol sodium hydroxide to heat and stir, and then add 0.06mol dichloroethyl ether at the same time ether, stirred for 2 hours, and then filtered to remove the solids to obtain a filtrate, which was evaporated to remove the solvent under reduced press...

Embodiment 3

[0040] A rubber seal with good aging resistance, made of the following components in parts by weight: rubber base material 120, silicone oil 4, filler 40, crosslinking agent 1.3, lubricant 0.2, vulcanizing agent 2.6, plasticizer 0.4 , carbon black 2, functional additive 1.5;

[0041] The preparation method of the functional auxiliary agent is as follows: dissolving 0.12 mol of pyrogallol in isoamyl alcohol, adding 0.12 mol of sodium hydroxide and heating and stirring under the protection of nitrogen, when the temperature rises to the point where sodium hydroxide reacts with pyrogallol to form When the white suspension is present, add 0.04mol dichloroethyl ether dropwise within 16min, then stir for 2 hours, cool to 55°C, then add 0.12mol sodium hydroxide to heat and stir, and then add 0.06mol dichloroethyl ether at the same time ether, stirred for 2 hours, and then filtered to remove the solids to obtain a filtrate, which was evaporated to remove the solvent under reduced press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com