Fluorine-containing copolymer having excellent washing resistance and soil release agent

A technology of copolymer and detergent, which is applied in the direction of textiles and papermaking, chemical instruments and methods, and liquid-repellent fibers, etc., can solve the problems of oil repellency, anti-fouling and low durability of stain-removing washing, etc. Achieve outstanding effect, excellent detergency, and excellent washing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0202] Hereinafter, the present invention will be described in detail with reference to Examples, Comparative Examples, and Test Examples. However, these descriptions do not limit the invention.

[0203] Hereinafter, unless otherwise specified, parts or % represent parts by weight or % by weight.

[0204] The test was carried out as follows.

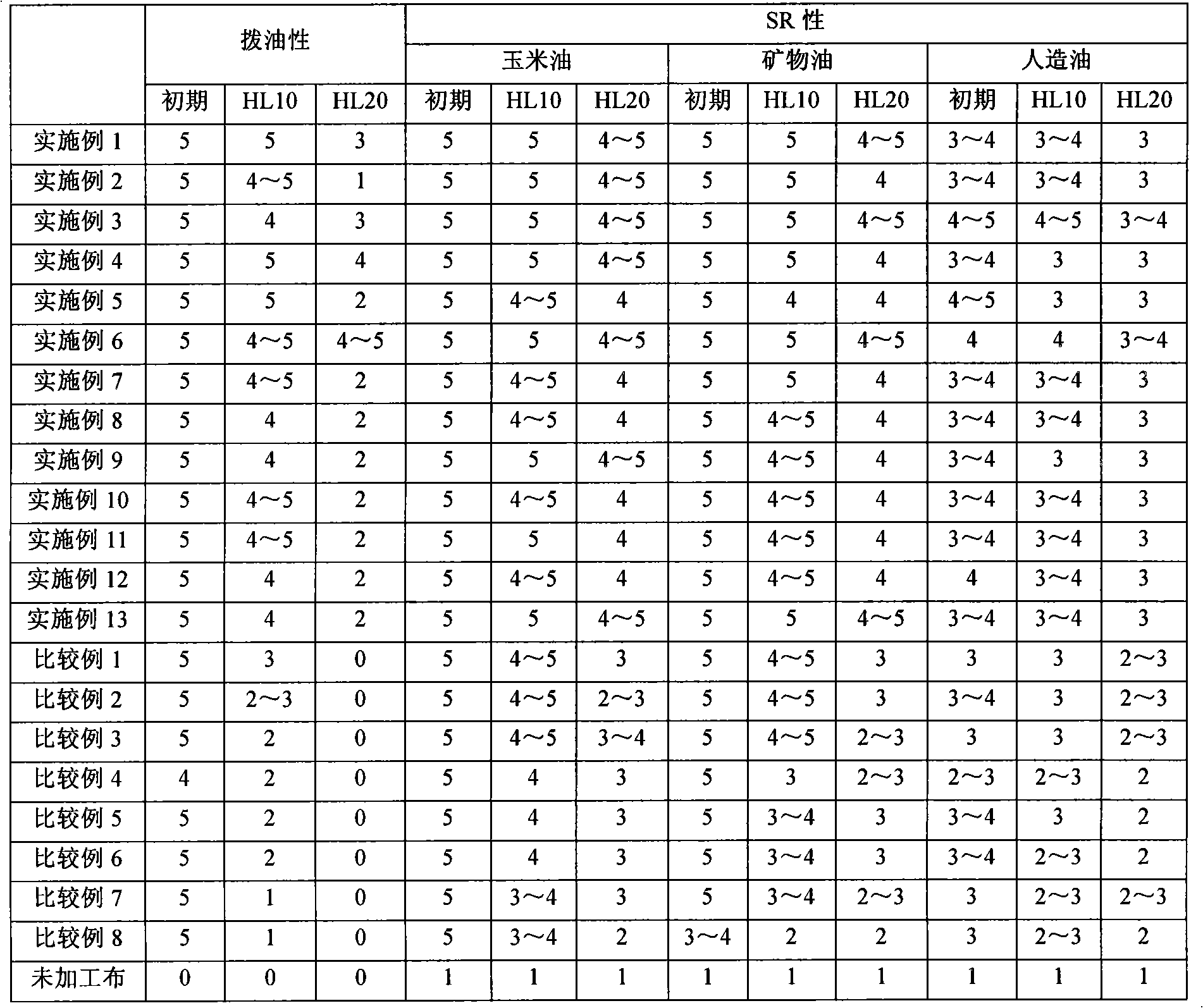

[0205] Decontamination test

[0206] The decontamination test is based on the American AATCC Stain Release Management Performance Test Method. The test soils used corn oil, mineral oil or artificial oil. The artificial oil was prepared by adding 100 ml of Daphne Mechanic Oil (manufactured by Idemitsu Kosan) to 1 g of diamond paste consisting of 16.7% of carbon black, 20.8% of tallow extremely hardened oil, and 62.5% of liquid paraffin.

[0207]On the blotting paper laid out in the horizontal direction, a test cloth with a side length of 20 cm was spread out, and 5 drops (about 0.2 cc) of artificial oil as stains were dropped on the t...

Synthetic example 1

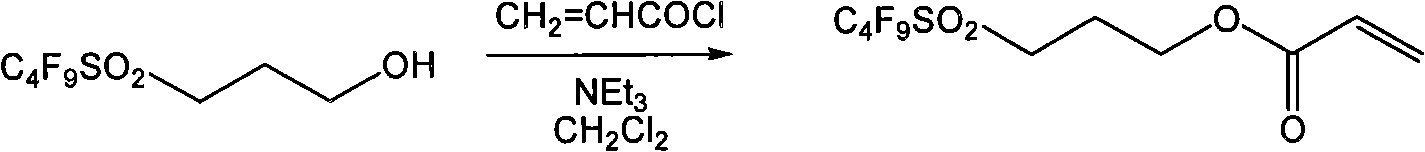

[0214] Synthesis example 1 (9FSO2PA monomer)

[0215] Synthesis of 3-(perfluorobutylsulfonyl)propyl acrylate

[0216]

[0217] Under the condition that a calcium chloride tube is installed, 54.4g (159mmol) of 3-(perfluorobutylsulfonyl) propanol, 33ml (238mmol) of triethylamine, 4-tert-butylcatechol (0.14g), A solution of 520 ml of dichloromethane was cooled to 0°C, and 15.5 ml (191 mmol) of acryloyl chloride was slowly added dropwise over 40 minutes. After stirring at room temperature for 1 hour, the mixture was washed with 600 ml of 15% citric acid water and saturated brine, dried over anhydrous magnesium sulfate, filtered, and concentrated under reduced pressure to obtain a crude acrylate. The residue was purified by silica gel column chromatography (n-hexane:ethyl acetate=6:1), and the concentrated clear liquid was vacuum-dried to obtain 3-(perfluorobutylsulfonyl)propyl acrylate 60.0g. The yield was 95.3%.

[0218] 1 H NMR (CDCl 3 , internal standard TMSδppm): 6.45...

Embodiment 1

[0222] In a 100ml four-necked flask, 14g of 2-(perfluorohexyl)ethyl acrylate (13FA), 4.4g of polyethylene glycol monoacrylate (EO 10mol) (AE-400), 2-hydroxyethyl acrylate 0.6 g of ester (HEA), 0.4 g of dimethylaminoethyl methacrylate (DMAEM), 0.6 g of (acetoacetoxyethyl) methacrylate (AAEM) and 30 g of isopropanol were blown with nitrogen for 60 minutes. After raising internal temperature to 75-80 degreeC, 0.12g of azobisisobutyronitrile was added, and it was made to react for 8 hours. The molecular weight of the obtained polymerization solution was directly measured by gel permeation chromatography, and it was confirmed that the peak derived from the monomer almost disappeared and the peak derived from the copolymer appeared. In addition, the weight average molecular weight of a copolymer was 16000 (polystyrene conversion). Finally, 0.153 g of acetic acid was added for neutralization, and diluted with water to obtain a 20% solution of the fluorinated copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com