Design method and production process of double-layer quick-drying three-proofing fabric

A technology of production process and design method, applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of smearing and difficulty in washing clothes, and achieve the effect of improving thermal insulation performance, superior thermal insulation function and improving thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] 1. Product design and fabric specification

[0044] 1.1 Product Design

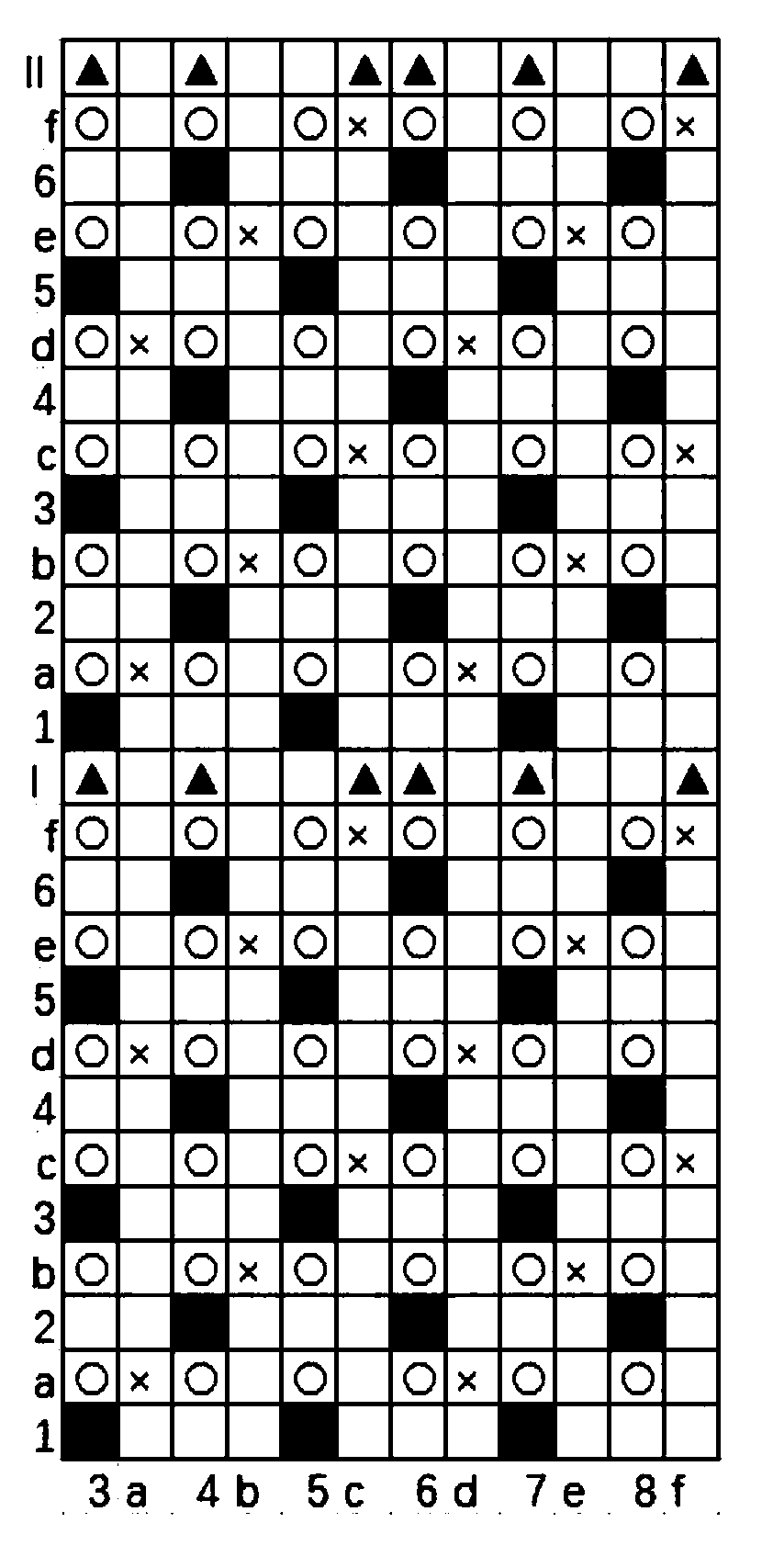

[0045] (1) The fabric is a double-layer fabric, and the warp yarn arrangement ratio is surface layer: inner layer = 1:1; surface weft: inner weft = 1:1.

[0046](2) The design of the inner layer of the fabric: the fabric is a double-layer fabric, and the inner layer of the fabric is the close-fitting side, which requires excellent comfort. Weave design: the weave structure of the inner layer fabric adopts twill weave, which has less interweaving times and is softer than plain weave fabric; in order to reduce the number of hedging during weaving, weft twill weave is used; the warp yarn is single yarn Z twist Yarn, in order to ensure the twill texture and clarity, choose 1 / 2 right twill. Selection of inner fabric raw materials: The inner fabric needs to have better comfort. The commonly used raw materials for the inner fabric are cotton fibers and viscose fibers, which have high moisture regain, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com