Method for manufacturing warm-keeping warp lace fabric

A lace and fabric technology, applied in warp knitting, rayon manufacturing, hollow filament manufacturing, etc., can solve the problems of poor pilling resistance and wear resistance, achieve good dispersion performance and storage, and avoid settlement problems. , Conducive to transportation and weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

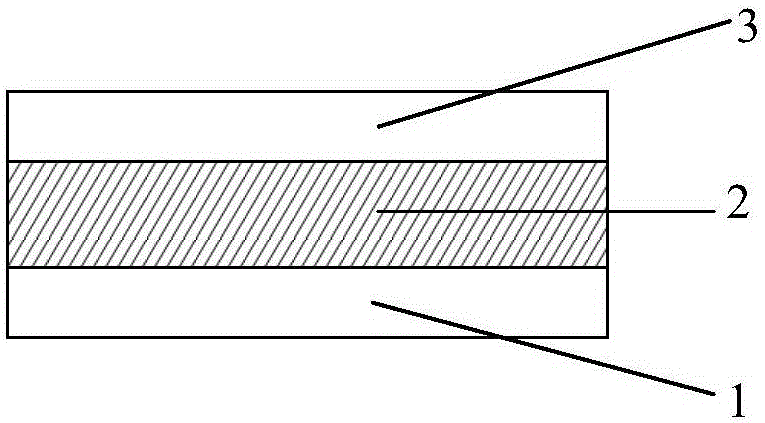

[0067] Please see attached figure 1 , a warm warp knitted lace fabric is divided into surface layer 3, heat preservation layer 2 and hollow fiber bottom, 1 three-layer structure; the raw material of the surface layer is conventional polyester fiber, the raw material of the heat preservation layer is heat preservation fiber, and the bottom layer of the hollow fiber The raw material is hollow polyester fiber with a hollowness of 30%.

[0068] The thickness of the surface layer is 300 microns.

[0069] The thickness of the thermal insulation layer is 500 microns.

[0070] The thickness of the hollow fiber bottom layer is 500 microns.

[0071] Using thermal fiber, hollow polyester fiber and conventional polyester fiber as raw materials, through the three-dimensional warp knitting lace process, through the warp knitting interweaving of thermal fiber and conventional polyester fiber, the surface layer is connected with the thermal layer, and at the same time through the thermal fi...

Embodiment 2

[0087] Please see attached figure 1 , a warm warp knitted lace fabric is divided into surface layer 3, heat preservation layer 2 and hollow fiber bottom, 1 three-layer structure; the raw material of the surface layer is conventional polyester fiber, the raw material of the heat preservation layer is heat preservation fiber, and the bottom layer of the hollow fiber The raw material is hollow polyester fiber with a hollowness of 30%.

[0088] The thickness of the surface layer is 400 microns.

[0089] The thickness of the thermal insulation layer is 700 microns.

[0090] The thickness of the hollow fiber bottom layer is 550 microns.

[0091] Using thermal fiber, hollow polyester fiber and conventional polyester fiber as raw materials, through the three-dimensional warp knitting lace process, through the warp knitting interweaving of thermal fiber and conventional polyester fiber, the surface layer is connected with the thermal layer, and at the same time through the thermal fi...

Embodiment 3

[0107] Please see attached figure 1 , a warm warp knitted lace fabric is divided into surface layer 3, heat preservation layer 2 and hollow fiber bottom, 1 three-layer structure; the raw material of the surface layer is conventional polyester fiber, the raw material of the heat preservation layer is heat preservation fiber, and the bottom layer of the hollow fiber The raw material is hollow polyester fiber with a hollowness of 30%.

[0108] The thickness of the surface layer is 500 microns.

[0109] The thickness of the thermal insulation layer is 800 microns.

[0110] The thickness of the hollow fiber bottom layer is 600 microns.

[0111] Using thermal fiber, hollow polyester fiber and conventional polyester fiber as raw materials, through the three-dimensional warp knitting lace process, through the warp knitting interweaving of thermal fiber and conventional polyester fiber, the surface layer is connected with the thermal layer, and at the same time through the thermal fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com