System for grouting pile side sealing and pile tip extrusion grouting of cast-in-place pile and construction method thereof

A technology of grouting system and cast-in-situ pile, which is applied in the direction of sheet pile wall, foundation structure engineering, building, etc., can solve the problems of large discreteness, low reliability of foundation pile bearing capacity, poor controllability of post-grouting technology, etc. Achieve the effects of increasing pile side resistance, increasing single pile bearing capacity, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

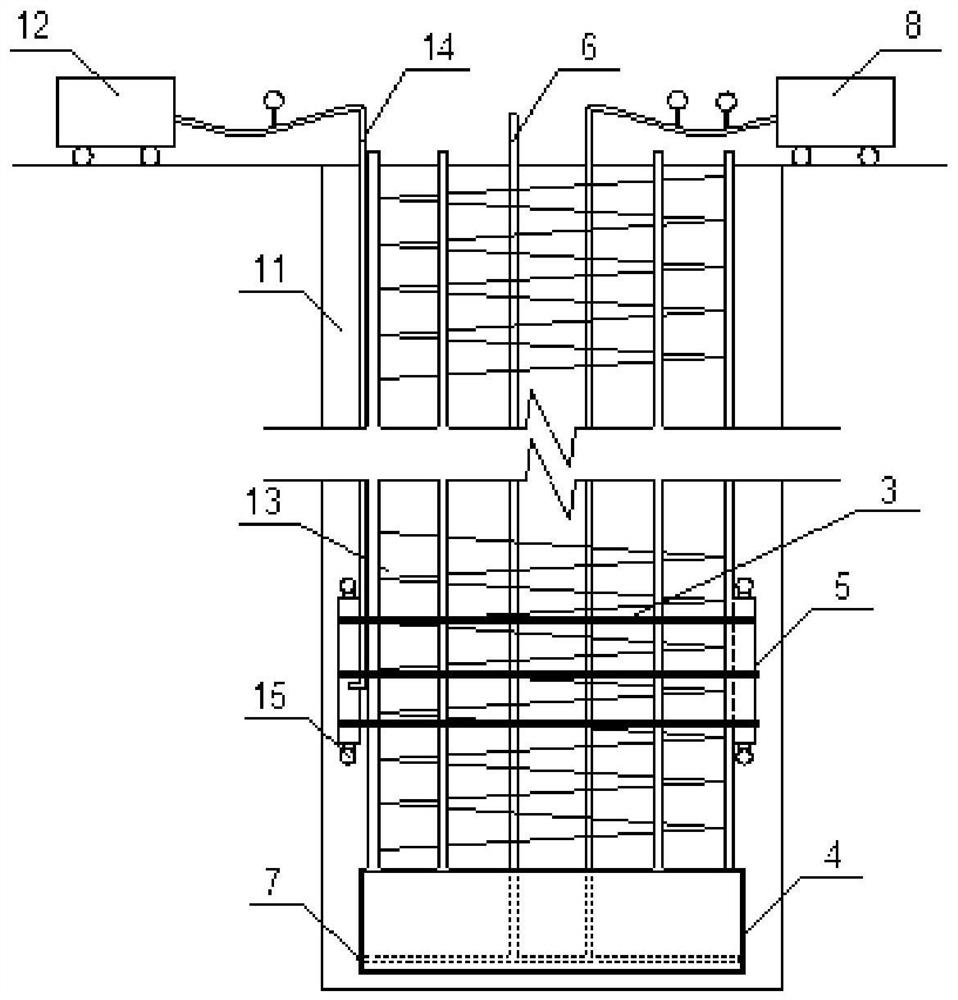

[0051] Below in conjunction with embodiment and attached Figure 1-9 The present invention is further elaborated, and this embodiment is a bored cast-in-place pile, the pile length is 30m, the pile diameter is 600mm, and the outer diameter of the reinforcement cage 13 is 500mm.

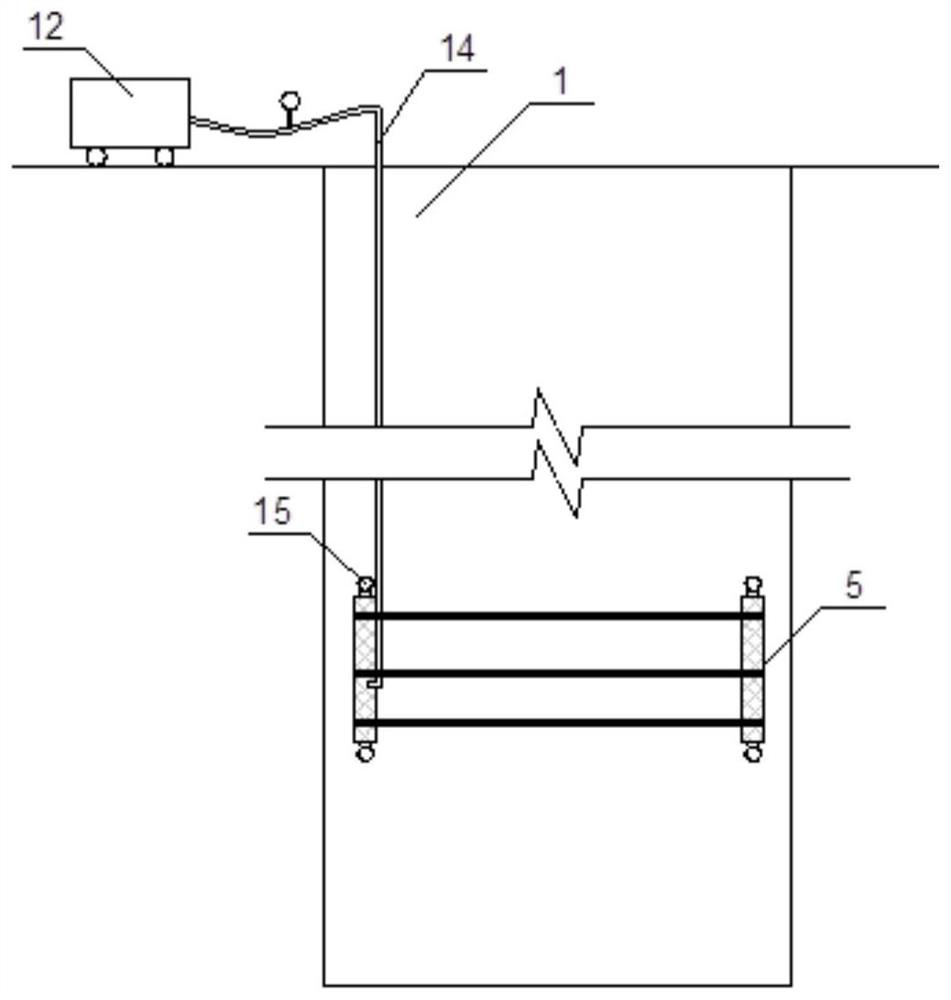

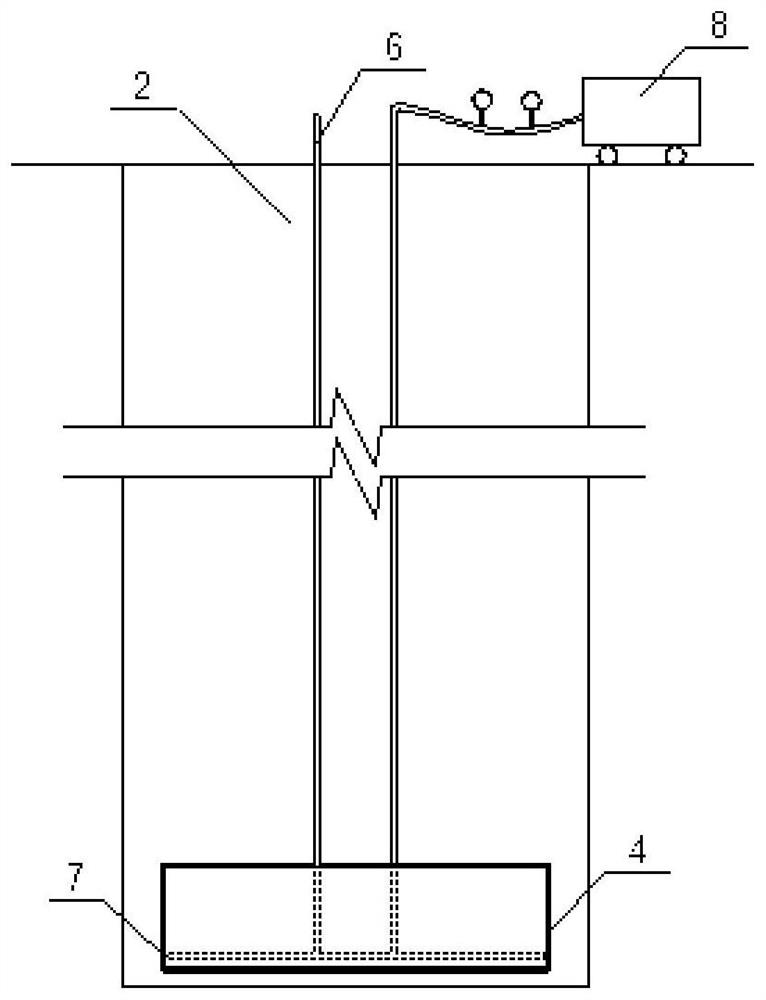

[0052] Using the pile side grouting and pile end extrusion grouting system for cast-in-place piles of the present invention, a grouting bag 5 surrounds and wraps the steel cage 13, and the upper and lower ends of the grouting bag 5 are connected to the steel bar through the fixing buckle 15. The cage 13 is fixed together, the vertical grouting pipe 14 on the pile side is bound together with the reinforcement cage 13, and goes up to the ground to connect with the outlet end of the high-pressure grouting pump 12 on the pile side, and the lower end of the vertical grouting pipe 14 on the pile side The opening communicates with the inner cavity of the grouting bladder 5, and the junction joint is sealed a...

Embodiment 2

[0059] Embodiment 2 is another implementation of the pile side grouting device and pile end extrusion grouting device of the present invention, as attached Figure 6 , Figure 9 and Figure 10 As shown, this embodiment adopts the same foundation pile design parameters as that of Embodiment 1, and this embodiment will not repeatedly describe the components similar to Embodiment 1. The difference between this embodiment and embodiment 1 is that, as attached Figure 6 As shown, the grouting pouch 5 is in the shape of a circular cylinder, and the sewing method is to sew the annular outer layer cloth 9 and the inner layer cloth 10 first, and then sew the upper and lower ends of the outer layer cloth 9 and the inner layer cloth 10 , forming a sealed grouting bag 5 . as attached Figure 9 and Figure 10 As shown, in this embodiment, the pile end extrusion device 4 selects four independent extrusion units 19, which is beneficial to fill the jacking section with grouting at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com